Repeatedly utilized grass grid sand fixing method

A sand-fixing method and a grass-checking technology, applied in soil protection, climate change adaptation, construction, etc., can solve problems such as unreusable, and achieve the effects of easy updating and maintenance at any time, simple method, and convenient construction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

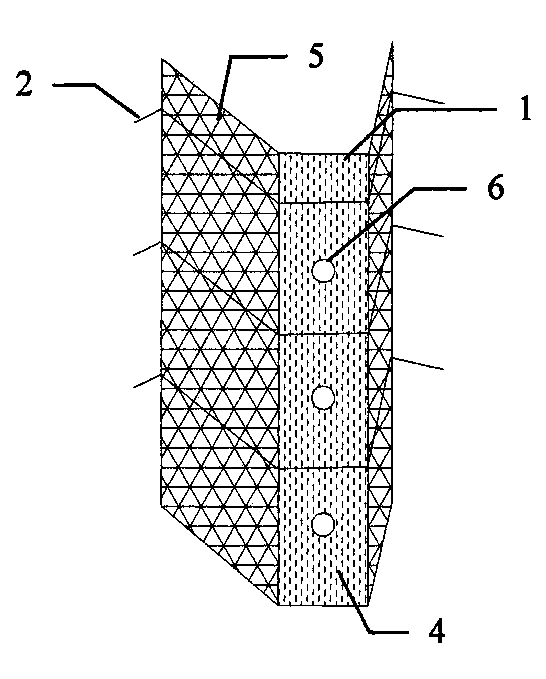

[0025] U-shaped fixer: U-shaped fixer 1 is made of a base plate 4 and two side plates 5, jacks 6 are set every 30 cm on the center of base plate 4, and U-shaped fixer 1 is 3 cm wide;

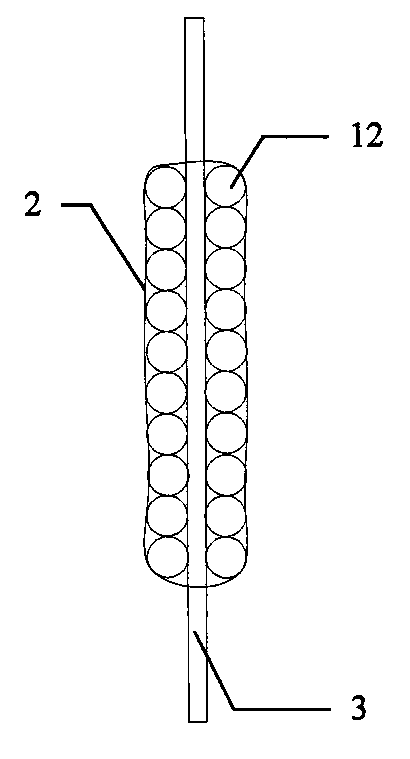

[0026] Plant straw binding: Insert the fixing braze 3 into the socket 6 on the bottom plate 4 of the U-shaped holder 1, spread the binding wire 2 on the bottom plate 4 and the side plate 5, and place a section of binding wire 2 every 10cm with a diameter of 1mm iron wire;

[0027] Put the plant straw 12 flatly in the gap between the side plate 5 and the fixed braze 3, fill the plant straw 12 with a thickness of 1 cm and a height of 5 cm, and then tighten the two ends of the iron wires of the binding wire 2 one by one to form a whole plant straw handle ;

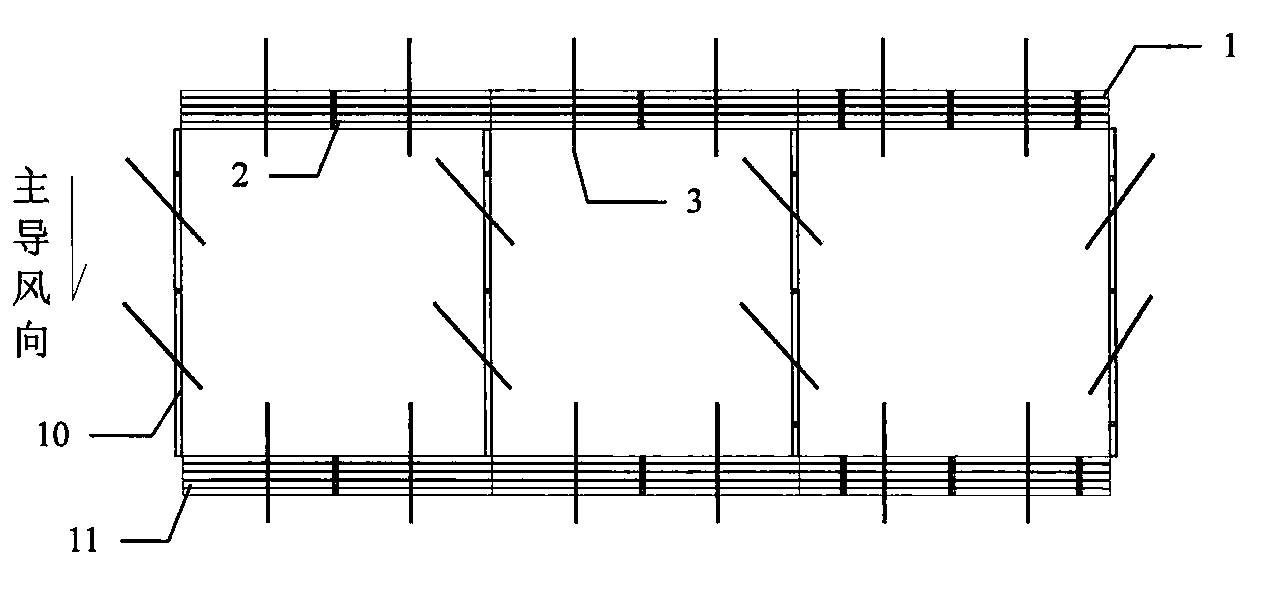

[0028] Cutting the finished whole plant straw handles into short handles 10 with a length of 1m and long handles 11 with a length of 2m, and then transporting the cut plant straw handles to the sand prevention project site;

[0029] Rake prod...

Embodiment 2

[0033] U-shaped fixer: U-shaped fixer 1 is made of a base plate 4 and two side plates 5, jacks 6 are set every 30 cm on the center of base plate 4, and U-shaped fixer 1 is 5 cm wide;

[0034] Plant straw binding: Insert the fixing braze 3 into the socket 6 on the bottom plate 4 of the U-shaped holder 1, spread the binding wire 2 on the bottom plate 4 and the side plate 5, and place a section of binding wire 2 every 15cm to resist aging nylon rope;

[0035] Put the plant straw 12 flatly in the gap between the side plate 5 and the fixed braze 3, the plant straw filling layer is 3 cm thick and 10 cm high, and then tighten the two ends of the binding wire 2 one by one to form a whole plant straw handle;

[0036] Cutting the prepared plant straw handles into short handles 10 with a length of 1m and long handles 11 with a length of 3m, and then transporting the cut plant straw handles to the sand control project site;

[0037] Rake production: fix the handle 7 on the top of the sup...

Embodiment 3

[0041] U-shaped fixer: U-shaped fixer 1 is made of a base plate 4 and two side plates 5, jacks 6 are set every 40cm on the center of base plate 4, and U-shaped fixer 1 is 10cm wide;

[0042] Plant straw binding: Insert the fixing braze 3 into the jack 6 on the bottom plate 4 of the U-shaped holder 1, spread the binding wire 2 on the bottom plate 4 and the side plate 5, and place a section of binding wire 2 every 20cm with a diameter of 2mm the iron wire;

[0043] Put the plant straw 12 flatly in the gap between the side plate 5 and the fixed braze 3, the plant straw filling layer is 5 cm thick and 20 cm high, and then tighten the two ends of the binding wire 2 one by one to form a whole plant straw handle;

[0044] The prepared plant straws are cut into short handles 10 with a length of 1m and long handles 11 with a length of 4m, and then the cut plant straws are transported to the sand control project site;

[0045] Rake production: fix the handle 7 on the top of the support...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com