Spiral self-drilling steel pile capable of being reinforced through diameter increasing, and construction method of spiral self-drilling steel pile

A construction method and self-drilling technology, which is applied in construction, sheet pile walls, and foundation structure engineering, etc., can solve the problem of limited diameter increase of helical blades, large slenderness ratio of helical self-drilling steel piles, and bending deformation of blades To achieve the effects of increased bending stiffness, improved corrosion resistance, and high lateral load-bearing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

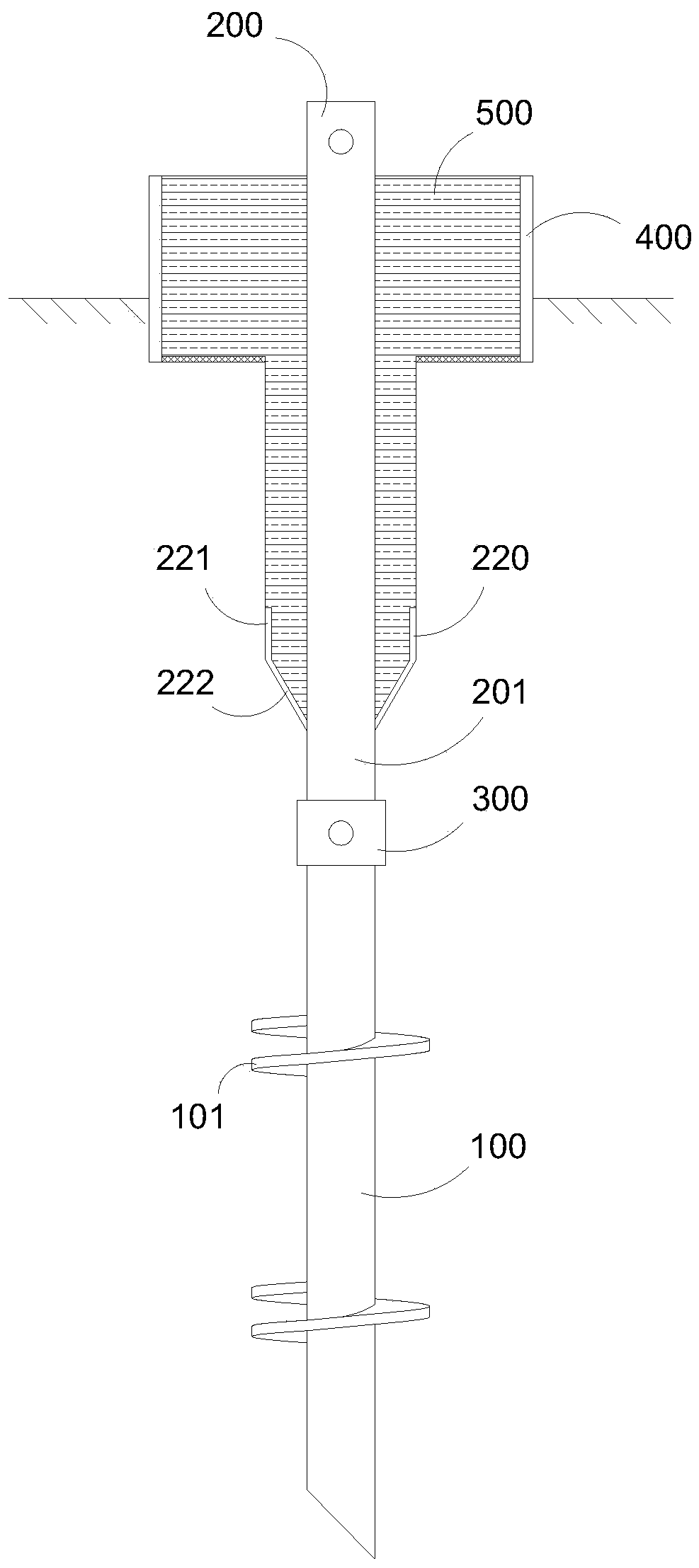

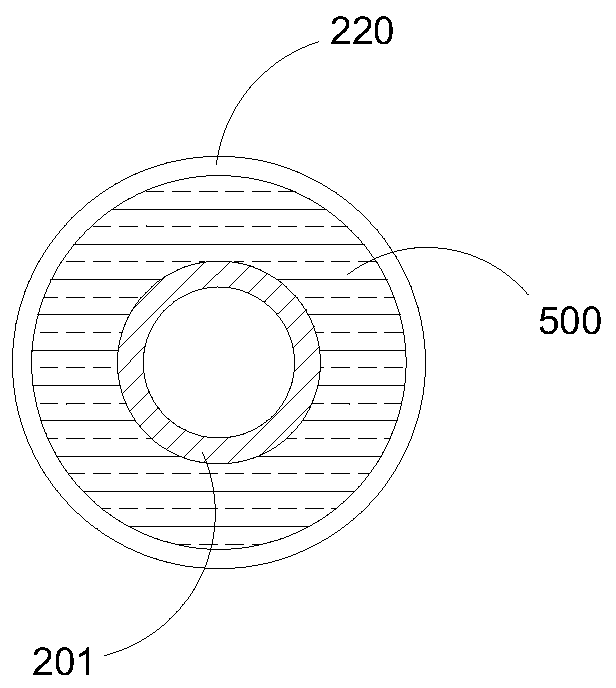

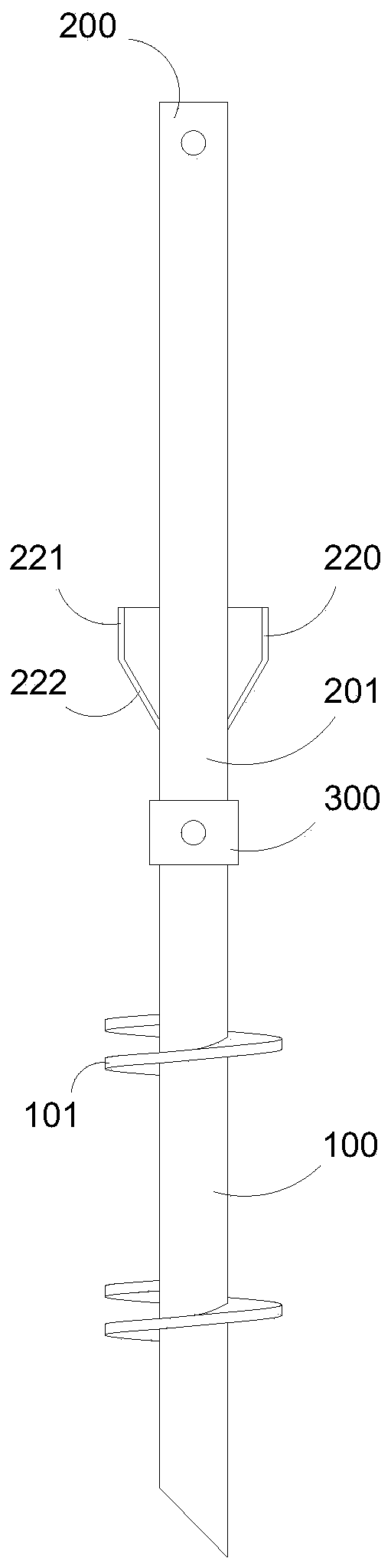

[0054] Embodiment 2: Different from Embodiment 1, the above-mentioned extension rod 200 includes two extension sections 201, and each extension section 201 is provided with a diameter-expanding guide plate 220, which is used for weak soil layers and easy side walls to collapse. According to the situation of the hole, when grouting according to the specific situation, the expansion guide plate 220 of a section of the extension section 201 will be continuously grouted when it enters the soil layer. At the same time, the grouting in the soil layer is uninterrupted, so that the connecting part of the reinforcing body 500 between the diameter-expanding guide plate 220 located below and the diameter-expanded guide plate 220 located above is uninterrupted and continuous.

[0055] A sleeve 300 is fitted at the connection between the extension sections 201 , and the sleeve 300 is connected with the two extension sections 201 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com