Observation method of platinum rhodium alloy metallographic structures

A technology of platinum-rhodium alloy and metallographic structure, which is applied in the field of material surface structure observation, can solve the problem of inconspicuous etching effect, achieve the effect of improving corrosion effect, good repeatability, and accelerating corrosion speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

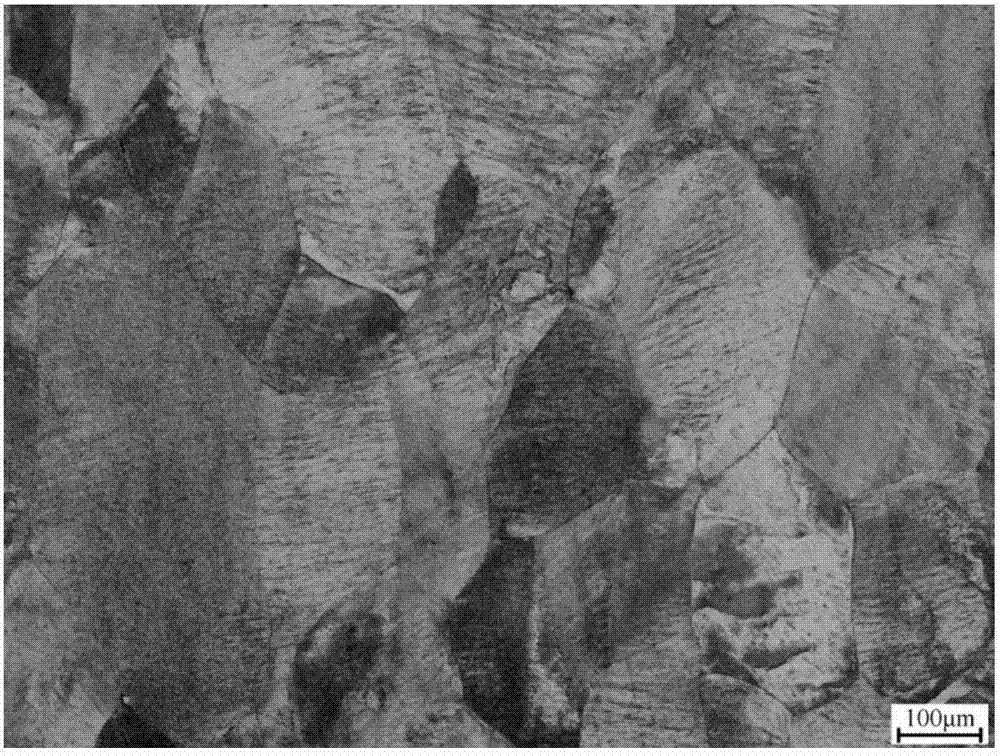

Embodiment 1

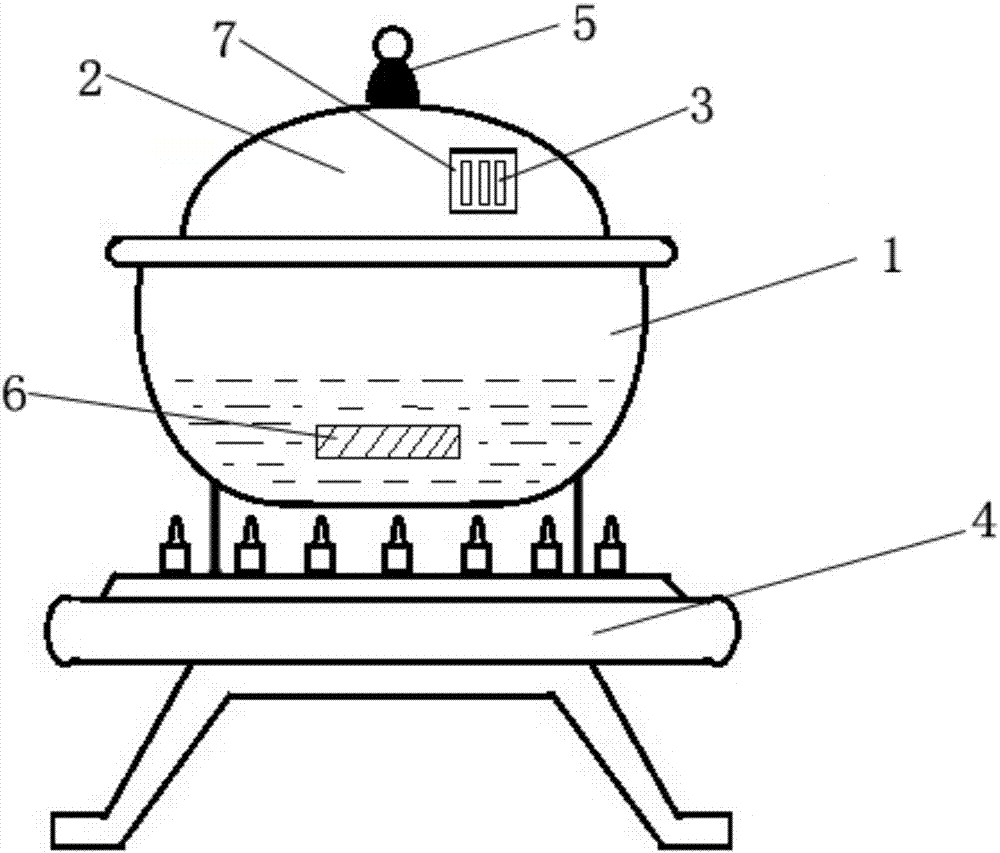

[0033] The observation method of the platinum-rhodium alloy (Pt-10Rh) metallographic structure of the present embodiment comprises the following steps:

[0034]Step 1, the mosaic of platinum-rhodium alloy sample 6: cut platinum-rhodium alloy sample 6 on the Pt-10Rh alloy plate, in order to prevent the loss of platinum-rhodium alloy, adopt shearing machine to sample, the obtained platinum-rhodium alloy sample 6 The size is: length × width × height=10mm × 5.5mm × 3mm, a 10mm × 5.5mm surface of the platinum-rhodium alloy sample 6 is selected as the metallographic observation plane; the weight of the platinum-rhodium alloy sample 6 taken by weighing is 2.74g, then inlaid the alloy platinum-rhodium alloy sample 6 on the Yuzhou XQ-1 metallographic sample inlay machine, the specific process of the inlay is: put the cut platinum-rhodium alloy sample 6 in Yuzhou On the workbench of the XQ-1 metallographic sample mounting machine, and the metallographic observation plane of the platinum...

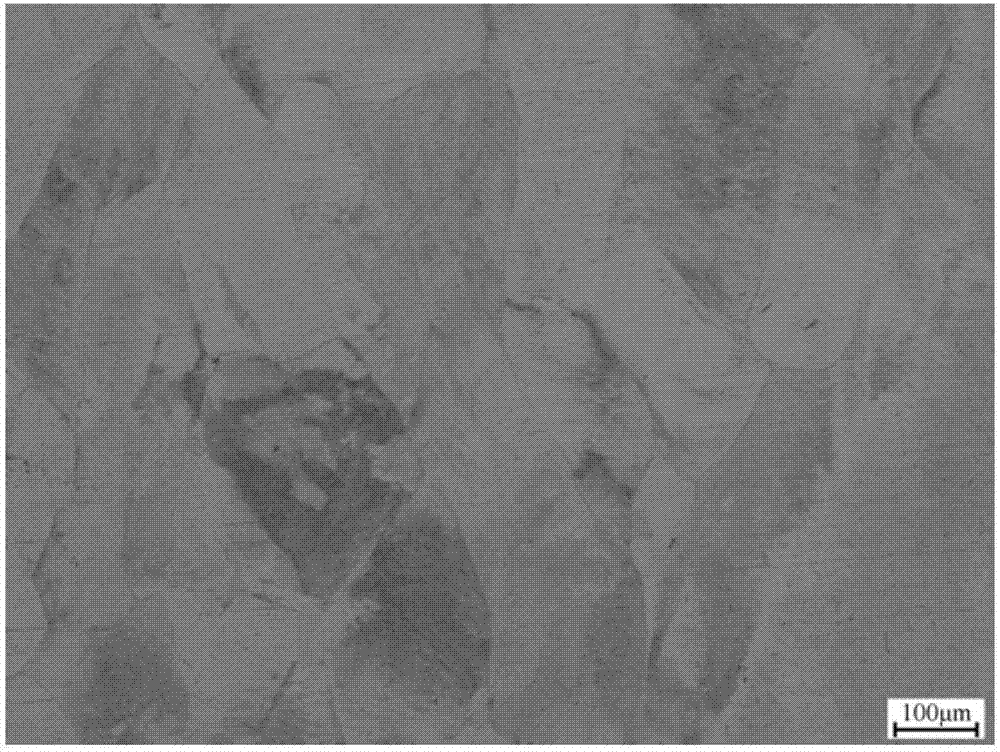

Embodiment 2

[0043] The observation method of the platinum-rhodium alloy (Pt-8Rh) metallographic structure of the present embodiment comprises the following steps:

[0044] Step 1, the mosaic of platinum-rhodium alloy sample 6: cut platinum-rhodium alloy sample 6 on the Pt-8Rh alloy plate, in order to prevent the loss of platinum-rhodium alloy, adopt shearing machine to sample, the obtained platinum-rhodium alloy sample 6 The size is: length × width × height = 6mm × 7mm × 3mm, take a 6mm × 7mm surface of the platinum-rhodium alloy sample 6 as the metallographic observation plane, and the weight of the platinum-rhodium alloy sample 6 taken by weighing is 2.32g , and subsequently inlay the alloy platinum-rhodium alloy sample 6 on the Yuzhou XQ-1 metallographic sample inlay machine. The specific process of the inlay is: place the cut platinum-rhodium alloy sample 6 in the Yuzhou XQ- On the workbench of Type 1 metallographic sample mounting machine, and the metallographic observation plane of ...

Embodiment 3

[0052] The observation method of the platinum-rhodium alloy (Pt-5Rh) metallographic structure of the present embodiment comprises the following steps:

[0053] Step 1, the mosaic of platinum-rhodium alloy sample 6: cut platinum-rhodium alloy sample 6 on the Pt-5Rh alloy plate, in order to prevent the loss of platinum-rhodium alloy, adopt shearing machine to sample, the obtained platinum-rhodium alloy sample 6 The size is: length × width × height = 7mm × 7mm × 2mm, take a 7mm × 7mm surface of the platinum-rhodium alloy sample 6 as the metallographic observation plane, and the weight of the platinum-rhodium alloy sample 6 taken by weighing is 2.17g , and subsequently inlay the alloy platinum-rhodium alloy sample 6 on the Yuzhou XQ-1 metallographic sample inlay machine. The specific process of the inlay is: place the cut platinum-rhodium alloy sample 6 in the Yuzhou XQ- On the workbench of Type 1 metallographic sample mounting machine, and the metallographic observation plane of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com