Corrosion solution for TiW films and corrosion method thereof

A technology of corrosion solution and film layer, which is applied in the direction of coating, metal material coating process, ion implantation plating, etc., can solve the problems affecting the corrosion effect of TiW film layer, affecting the production yield and production efficiency of multilayer film products, etc. , to achieve the effect of guaranteeing corrosion effect, facilitating production operation and improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

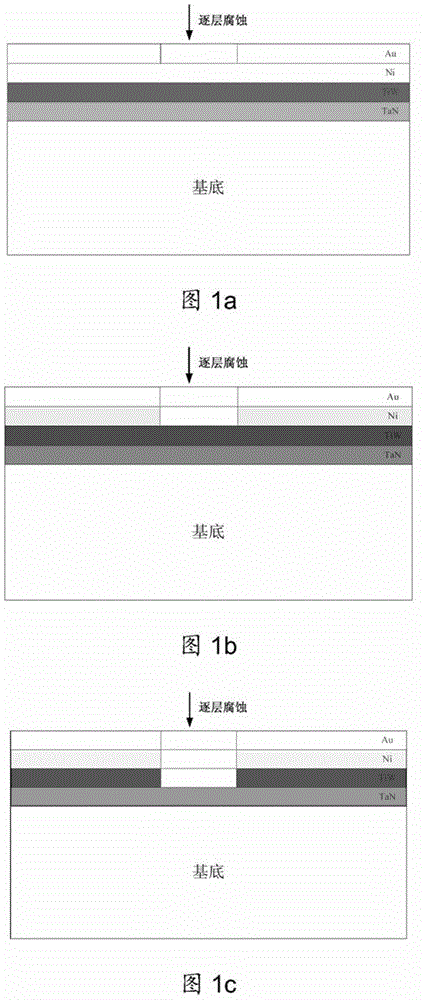

[0053]Using the continuous sputtering film forming method, TaN, TiW, Ni, Au are formed in sequence to form a multi-layer film (TaN)-TiW-Ni-Au film system, and then the film-forming substrate is evenly distributed on the film-forming substrate by mask photolithography. Glue, exposure, and development, etch the Au layer and Ni layer in sequence according to the conventional process, then corrode the TiW layer, and finally corrode the TaN layer according to the conventional process, and then obtain the required circuit pattern, such as figure 1 Shown is the corrosion process diagram of the present invention for the TaN-TiW-Ni-Au multilayer film structure.

[0054] The TiW film layer is obtained by magnetron sputtering, the target material is a TiW alloy target material, wherein 10% Ti and 90% W are uniformly mixed, and the film thickness is 500 angstroms.

[0055] The volume ratio of hydrogen peroxide, ammonia water and phosphoric acid is: hydrogen peroxide: ammonia water: phosph...

Embodiment 2

[0060] Using the continuous sputtering film forming method, TaN, TiW, Ni, Au are formed in sequence to form a multi-layer film (TaN)-TiW-Ni-Au film system, and then the film-forming substrate is evenly distributed on the film-forming substrate by mask photolithography. Glue, exposure, and development, etch the Au layer and Ni layer in sequence according to the conventional process, then corrode the TiW layer, and finally corrode the TaN layer according to the conventional process, and then obtain the required circuit pattern, such as figure 1 Shown is the corrosion process diagram of the present invention for the TaN-TiW-Ni-Au multilayer film structure.

[0061] The TiW film layer is obtained by magnetron sputtering method, the target material is TiW alloy target material, wherein 10% Ti and 90% W (mass percentage content) are uniformly mixed, and the film layer thickness is 500 angstroms.

[0062] The volume ratio of hydrogen peroxide, ammonia water and phosphoric acid is: hy...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com