Small sealant filling photovoltaic junction box

A volt junction box and glue-filling technology, which is applied in the field of small-scale glue-filled photovoltaic junction boxes, can solve the problems of wasting power resources, increasing the thickness and volume of photovoltaic junction boxes, and difficulty in achieving heat dissipation, so as to increase the internal space and heat dissipation Improved performance and large heat dissipation area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

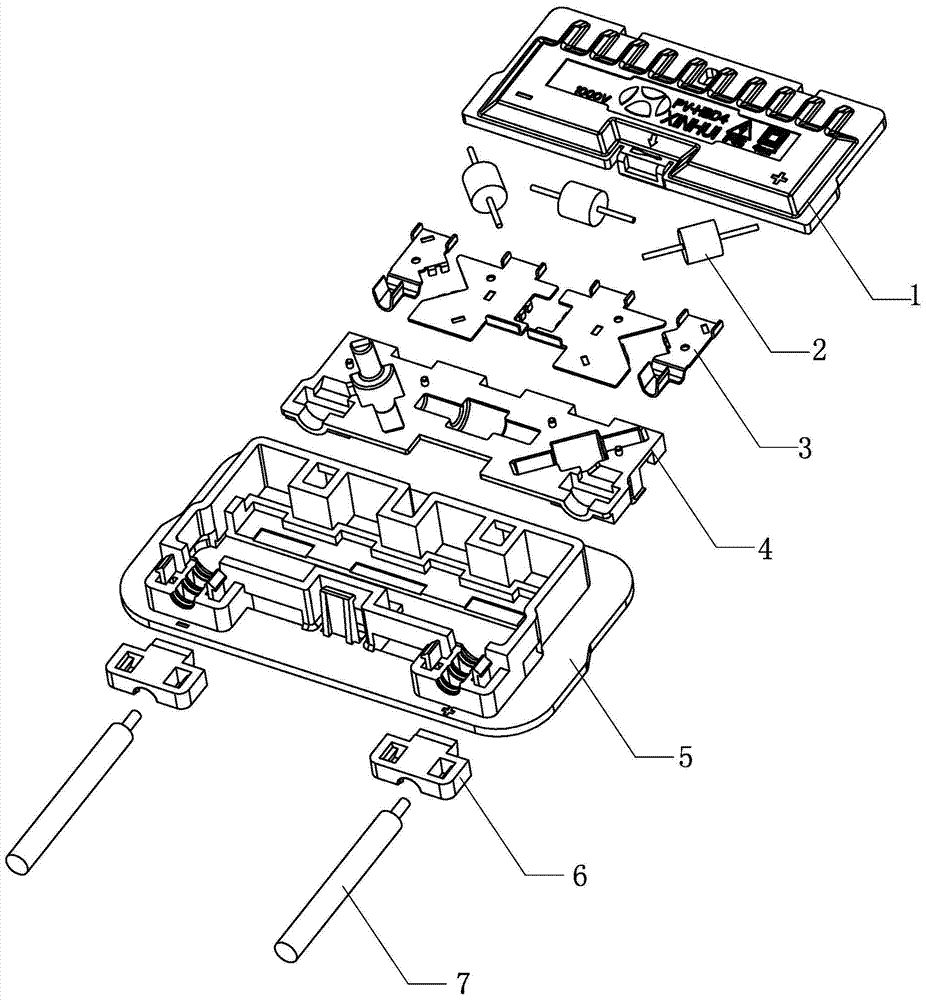

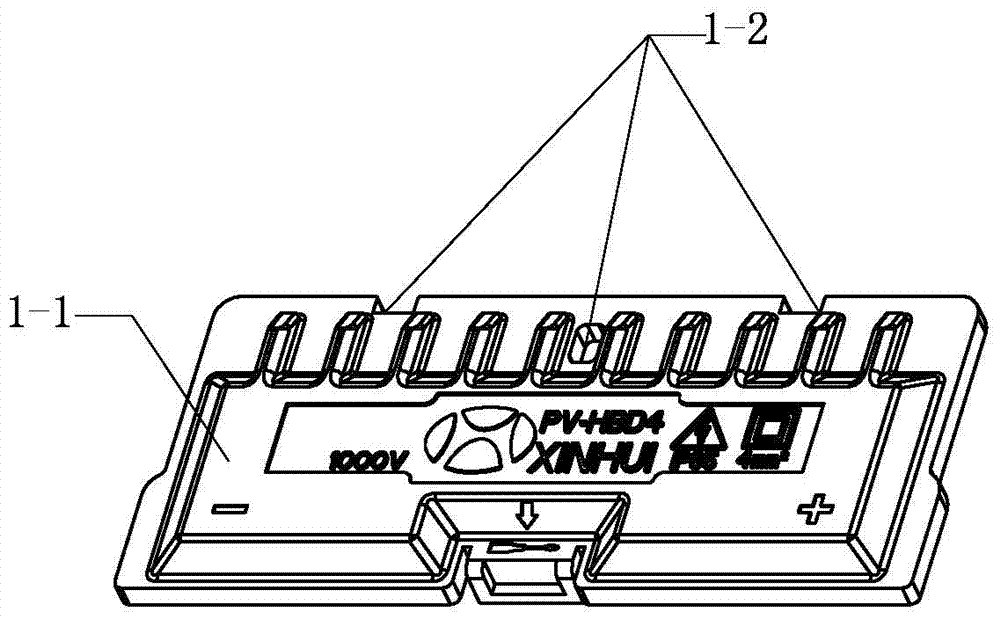

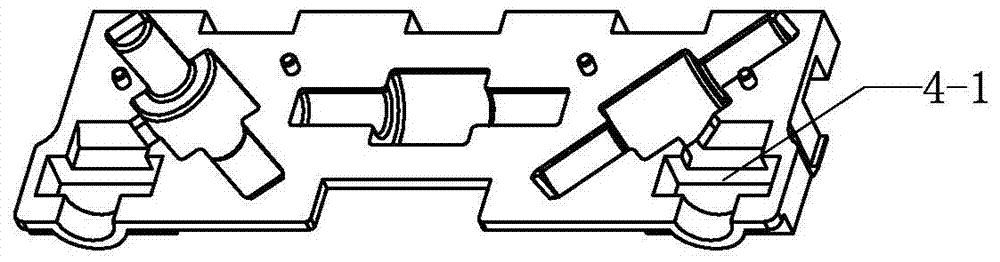

[0019] Such as figure 1 As shown, the present invention includes a base 5 and an upper cover 1 that cover each other. A bottom plate 4 is installed in the base 5 , and multiple terminals 3 and multiple diodes 2 of different shapes are installed on the bottom plate 4 . See Figure 5 , the installation method is to install diodes 2 between adjacent terminals 3. Such as figure 1 As shown, two crimping buckles 6 are installed in the base 5 , and two photovoltaic cables 7 pass through the crimping buckles 6 and are welded to the terminals 3 .

[0020] Such as Figure 5 As shown, the two pins of the diode 2 are soldered to two adjacent terminals 3 , the terminals 3 are installed on the bottom plate 4 , and the bottom plate 4 is installed on the base 5 .

[0021] Since the present invention is a glue-filling type, the space above the bottom pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com