Warm-air pipe

A technology of hot air ducts and air ducts, applied in lighting and heating equipment, dryers, drying, etc., can solve the problems of air ducts that cannot quickly disperse gas, weak gas circulation capacity, and uneven products, and achieve guaranteed The consistency and stability of temperature, the effect of reducing wind vortex and stabilizing temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

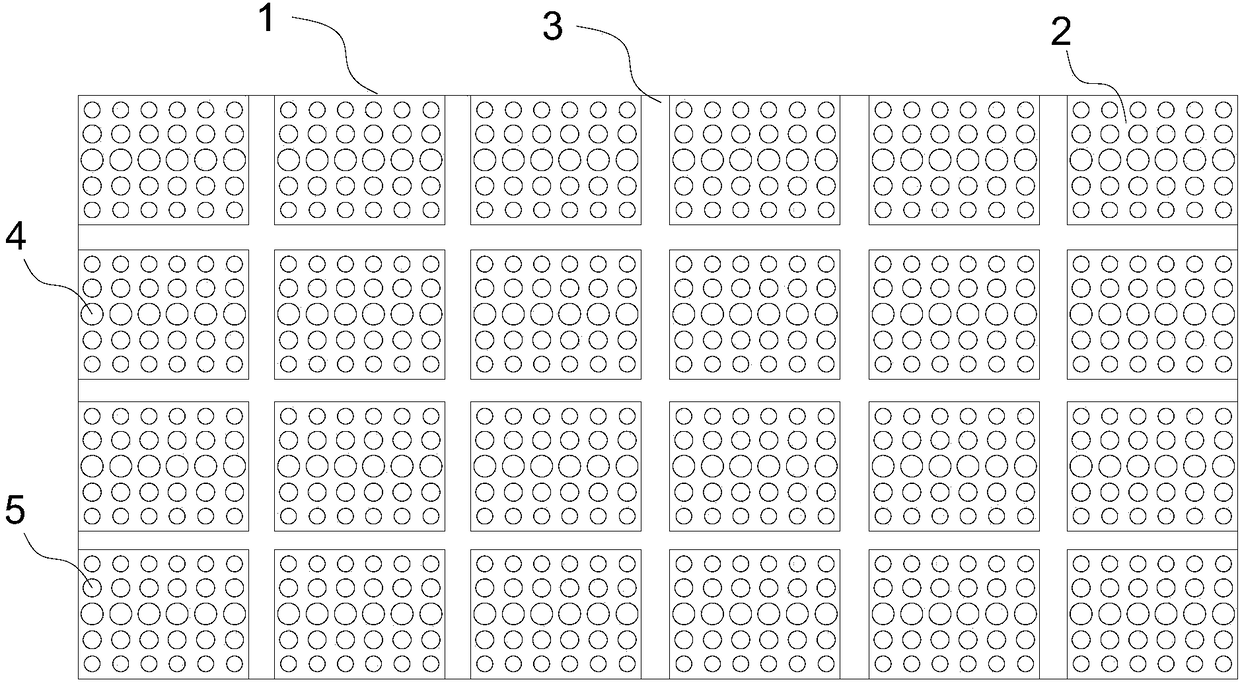

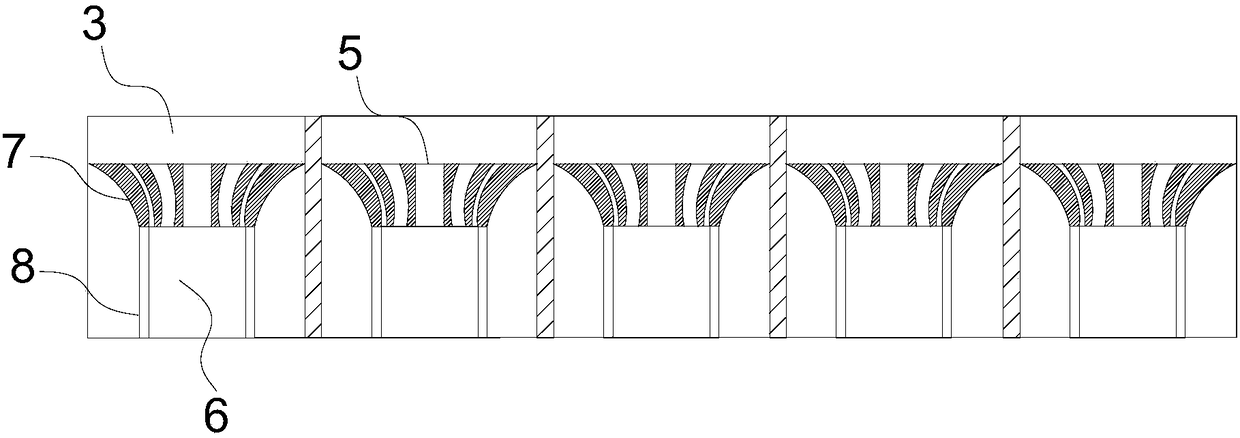

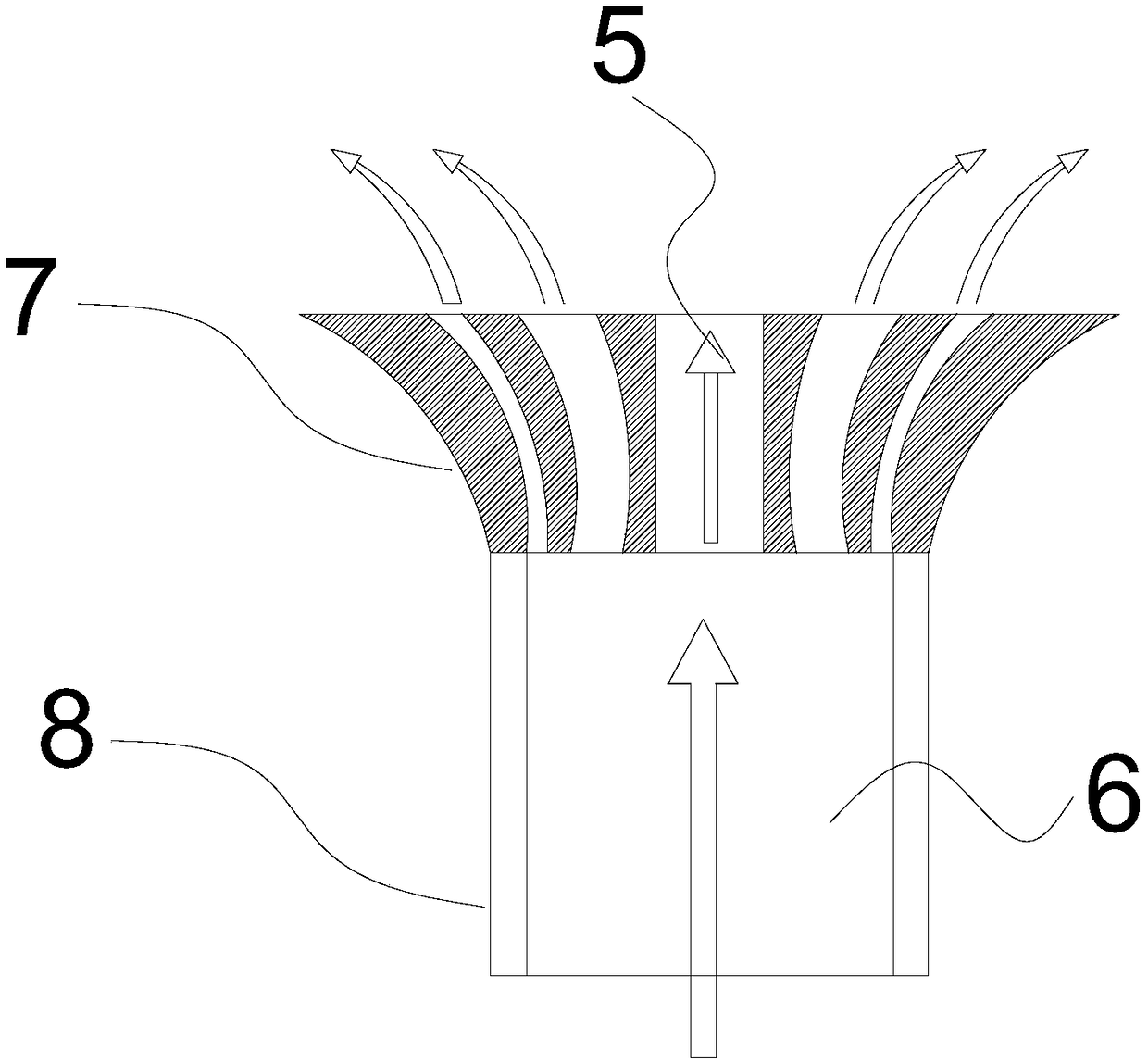

[0030] Please refer to figure 1 , attached figure 2 , the present embodiment provides a hot air duct 1, which is applied to a heat treatment oven, including an air duct 2, the material of the air duct 2 is stainless steel or aluminum, stainless steel will not rust, corrosion resistance, high temperature resistance, long service life; aluminum The air duct 2 is light in weight, easy to disassemble and install, easy to process, does not change color, and is not easy to deform; one end of the air duct 2 is an air inlet 8, and the other end of the air duct 2 is an air outlet 7, and the shape of the air inlet 8 is a rectangle or a cylinder The shape of the air outlet 7 is a trumpet shape with a large outer end surface and a small inner side, which facilitates the outflow of gas and ensures the stability of the air volume and wind pressure. The air inlet 8 of the air duct 2 is provided with a main chamber 6 for gas entry. , the gas enters and flows from the main cavity 6 to the ai...

no. 2 example

[0033] Please refer to image 3 , attached Figure 4 , combined with figure 1 , figure 2, the present embodiment provides a hot air pipe 1, which is applied to a heat treatment oven. The circular centers of the directions are on the same straight line, each row of air chambers 4 is evenly arranged inside the air outlet 7, and the sub-chambers 5 on each row of air chambers 4 are correspondingly distributed on the end faces of the air outlet 7.

[0034] The gas flows from the main chamber 6 of the air inlet 8 to the air outlet 7, and the gas is dispersed into multiple strands at the air outlet 7, and flows out from the sub-chambers 5 at different positions respectively. The air chambers 4 in the air outlet 7 are evenly arranged, and each air exhaust The sub-chambers 5 at the same position of the chamber 4 are equal in size, and the gas discharge of the sub-chambers 5 on the straight line perpendicular to the air chamber 4 is relatively uniform. The diameter of the middle sub...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com