Ink box

An ink cartridge and box body technology, which is applied in printing and other directions, can solve the problems of disconnection, air bubbles, ink waste, etc., and achieve the effects of high ink utilization rate, convenient use, and simple and feasible process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

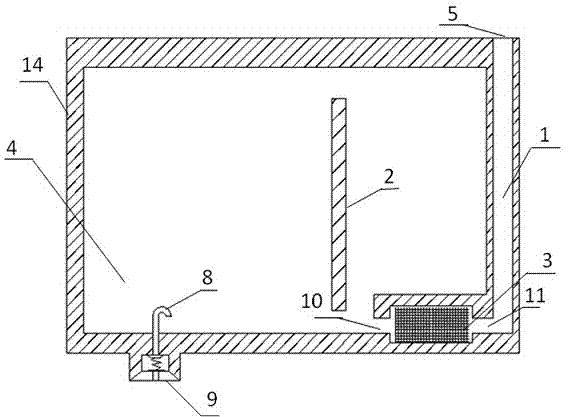

[0035] Such as figure 1 A kind of ink cartridge shown, comprises ink cartridge case body 14, ink storage chamber 4, sponge tank 3, ink filling pipeline 1, ink outlet pipeline 8, air inlet 5, ink outlet 9; Described ink storage chamber 4 is located in the middle of the ink cartridge body 14; the air inlet 5 is connected with the ink filling pipeline 1 and is located at the top of the ink cartridge; the ink outlet 9 is connected with the ink outlet pipeline 8; the sponge groove 3 is located The bottom of the ink storage chamber 4, the sponge tank 4 is a closed structure with a first air hole 10 and a second air hole 11 respectively at both ends, and a sponge is arranged inside, and the sponge tank 3 communicates with the storage tank 3 through the first air hole 10. The ink chamber 4 is connected to each other, and is connected to the ink filling pipeline 1 through the second air hole 11 .

[0036] As a further improvement of the present invention, a partition 2 is arranged in ...

Embodiment 2

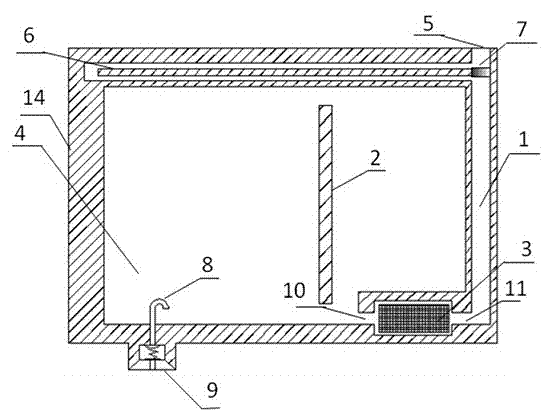

[0044] A kind of ink cartridge as shown in Figure 2, comprises ink cartridge case body 14, ink storage cavity 4, sponge tank 3, ink filling pipeline 1, ink outlet pipeline 8, air inlet 5, ink outlet 9; The ink chamber 4 is located at 14 in the ink cartridge body; the air inlet 5 is connected with the ink filling pipeline 1 and is located at the top of the ink cartridge; the ink outlet 9 is connected with the ink outlet pipeline 8; the sponge groove 3 is located at the bottom of the ink storage chamber 4. The sponge tank 4 is a closed structure with a first air hole 10 and a second air hole 11 at both ends, and a sponge is arranged inside. The sponge tank 3 passes through the first air hole 10 It is connected with the ink storage chamber 4 and connected with the ink filling pipeline 1 through the second air hole 11 .

[0045] As a further improvement of the present invention, a partition 2 is arranged in the ink storage chamber 4 .

[0046] As a further improvement of the pres...

Embodiment 3

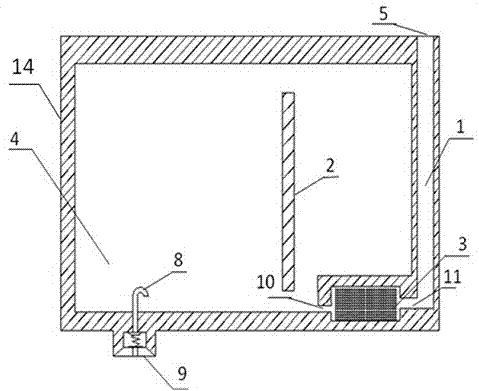

[0055] like image 3 A kind of ink cartridge shown, comprises ink cartridge case body 14, ink storage chamber 4, sponge tank 3, ink filling pipeline 1, ink outlet pipeline 8, air inlet 5, ink outlet 9; Described ink storage chamber 4 is located in the middle of the ink cartridge body 14; the air inlet 5 is connected with the ink filling pipeline 1 and is located at the top of the ink cartridge; the ink outlet 9 is connected with the ink outlet pipeline 8; the sponge groove 3 is located The bottom of the ink storage chamber 4, the sponge tank 4 is a closed structure with a first air hole 10 and a second air hole 11 respectively at both ends, and a sponge is arranged inside, and the sponge tank 3 communicates with the storage tank 3 through the first air hole 10. The ink chamber 4 is connected to each other, and is connected to the ink filling pipeline 1 through the second air hole 11 .

[0056] As a further improvement of the present invention, a partition 2 is arranged in the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com