Multi-station mechanized switching mechanism for bolting construction and bolt construction device

A bolt support and switching mechanism technology, which is applied in mining equipment, bolt installation, earthwork drilling and mining, etc., can solve the problems of heavy workload, low overall efficiency, and many manual operations, and achieve large benefits and low construction costs. The effect of reducing and the overall structure design is reasonable

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

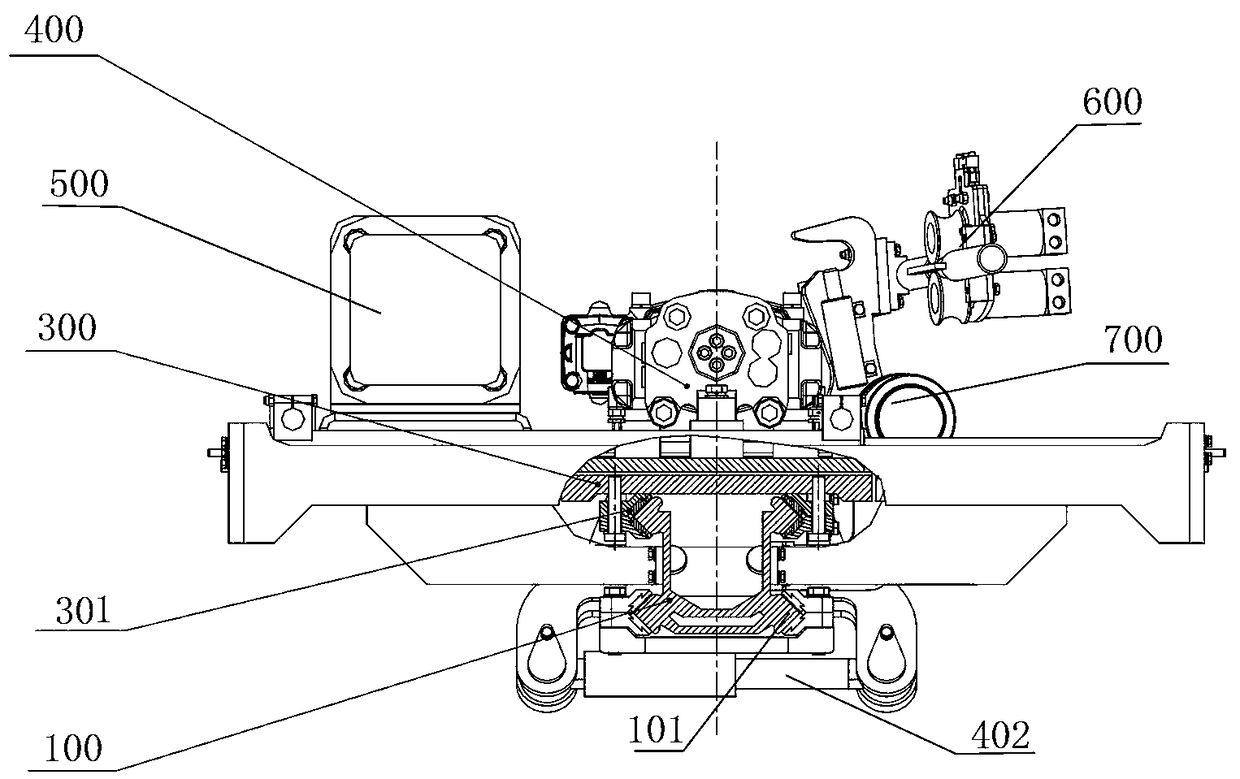

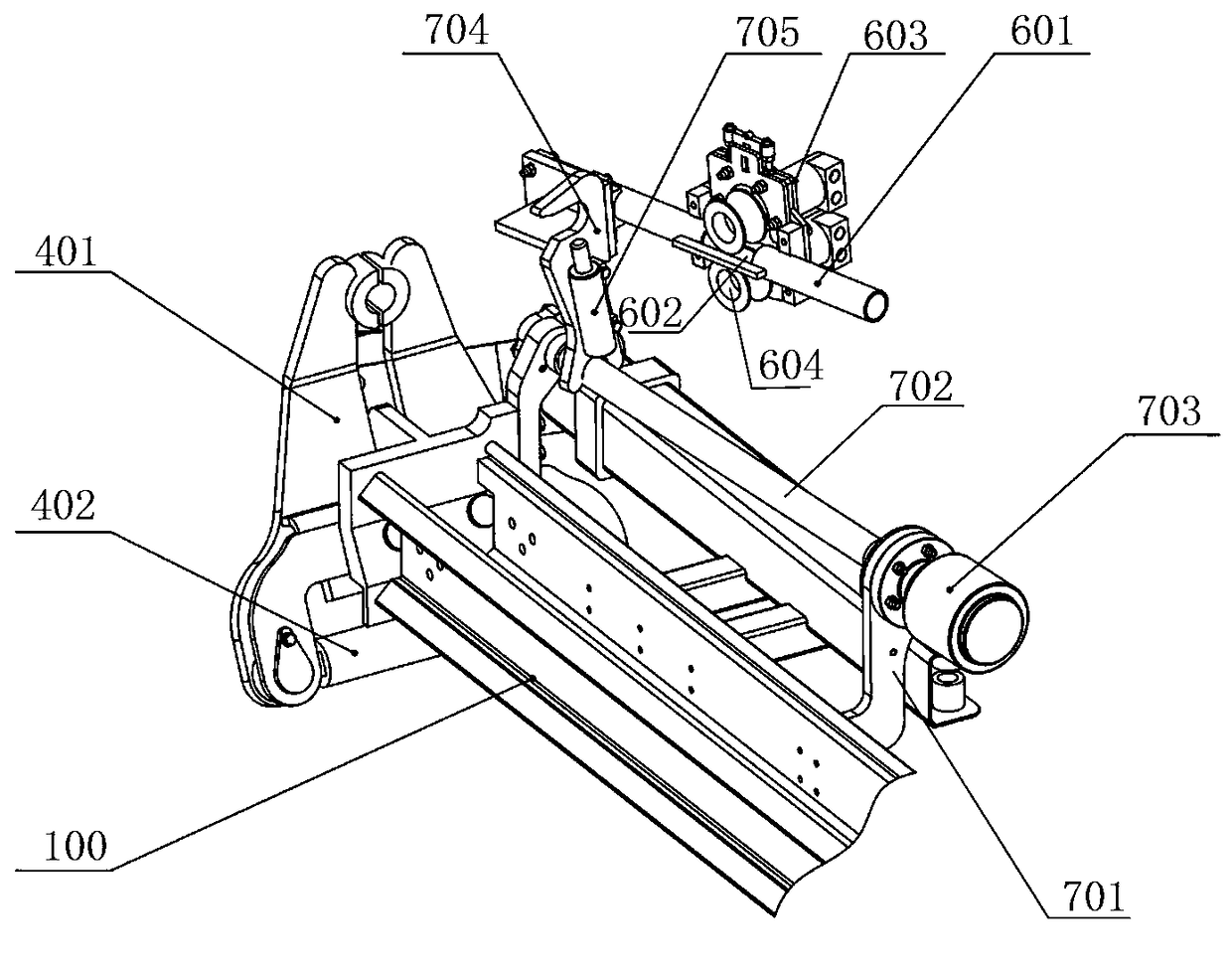

[0039] The second embodiment is: due to the requirements of the process or the lateral movement of the three, the lateral width of the fixed frame is too large, resulting in poor structural design stability and complicated process operations. Therefore, a further design is carried out, that is, the bolt support mechanism includes a rock drill Assembly 400, bolter head assembly 500 and grouting assembly 600, the grouting assembly 600 is arranged on the rock drill assembly 400, or on the bolter head assembly 500, or on the working end side of the push beam 100, From the perspective of convenient process operation, this embodiment is preferably as follows: the grouting assembly 600 is arranged on the working end side of the push beam 100, and this structure will also be described in detail below; when the grouting assembly 600 and the push beam 100 A swing assembly 700 is arranged therebetween, and the swing assembly 700 drives the grouting pipe of the grouting assembly 600 to cha...

Embodiment 3

[0042] Embodiment 3: This embodiment further discloses the structure of the fixing frame. Specifically, the fixing frame includes a left bracket 202, a right bracket 203, and a front fixing bracket 204 and a rear end arranged at both ends of the left bracket and the right bracket. Fixed frame 205, movable frame 300 is arranged between left support 202 and right support 203, is provided with corresponding transverse slideway between left support 202, right support 203 and movable frame 300, thus, can make bolt support The mechanism slides in the transverse slideway, that is, the determination of the positions of the three stations is realized through the left bracket 202, the right bracket 203 and the movable frame 300. This embodiment is used to meet the second embodiment and when the bolt support mechanism includes a rock drill Assembly 400, bolt head assembly 500 and grouting assembly 600 when two of them are in the situation, is a further deepening of the above-mentioned emb...

Embodiment 4

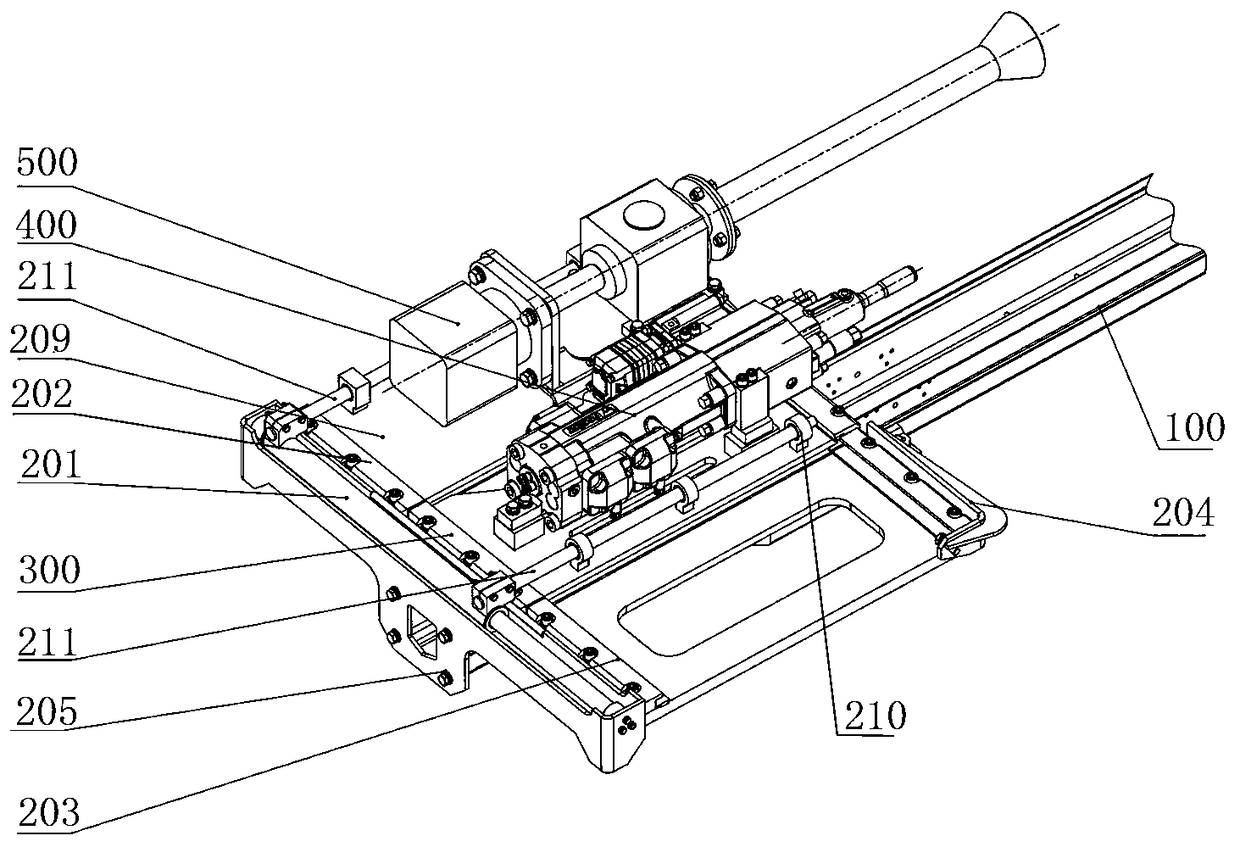

[0043] Embodiment 4: For Embodiment 3, for the structural design of the lateral movement and longitudinal movement of each component of the bolt support mechanism, and optimize the control structure, this embodiment is provided with multiple supporting slides 209 arranged side by side in the horizontal slideway Each component in the bolt support mechanism is matched and supported on the corresponding support slide plate 209; a guide sleeve 210 is provided on each support slide plate 209, and a drive pin shaft 211 is provided for matching and sliding in the guide sleeve 210, and the second power The assembly 201 is arranged between the drive pin shaft 211 and the fixed frame. Specifically, as shown in the figure, the second power assembly 201 is an oil cylinder, and the drive pin shaft 211 is arranged on the cylinder body of the oil cylinder, and the end of the piston rod of the oil cylinder is arranged On the fixed frame; when it moves, the second power assembly 201 drives the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com