Method and device for further purifying wet desulfurization purified flue gas

A technology for wet desulfurization and flue gas purification, which is applied in chemical instruments and methods, separation methods, and the use of liquid separation agents, etc., can solve problems such as the formation of smog, achieve improved emission standards, significant energy-saving and environmental protection effects, and simple devices Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] A method for further purifying wet desulfurization net flue gas of the present invention comprises the following steps on the basis of the existing wet desulfurization process:

[0029] (1) The clean flue gas enters the water membrane and then purified;

[0030] (2) collecting the re-purification solution produced in step (1);

[0031] (3) Recycle the repurified liquid collected in step (2).

[0032] In the above embodiments, the existing wet desulfurization process includes limestone-gypsum method, ammonia method, double alkali method, magnesium method and so on.

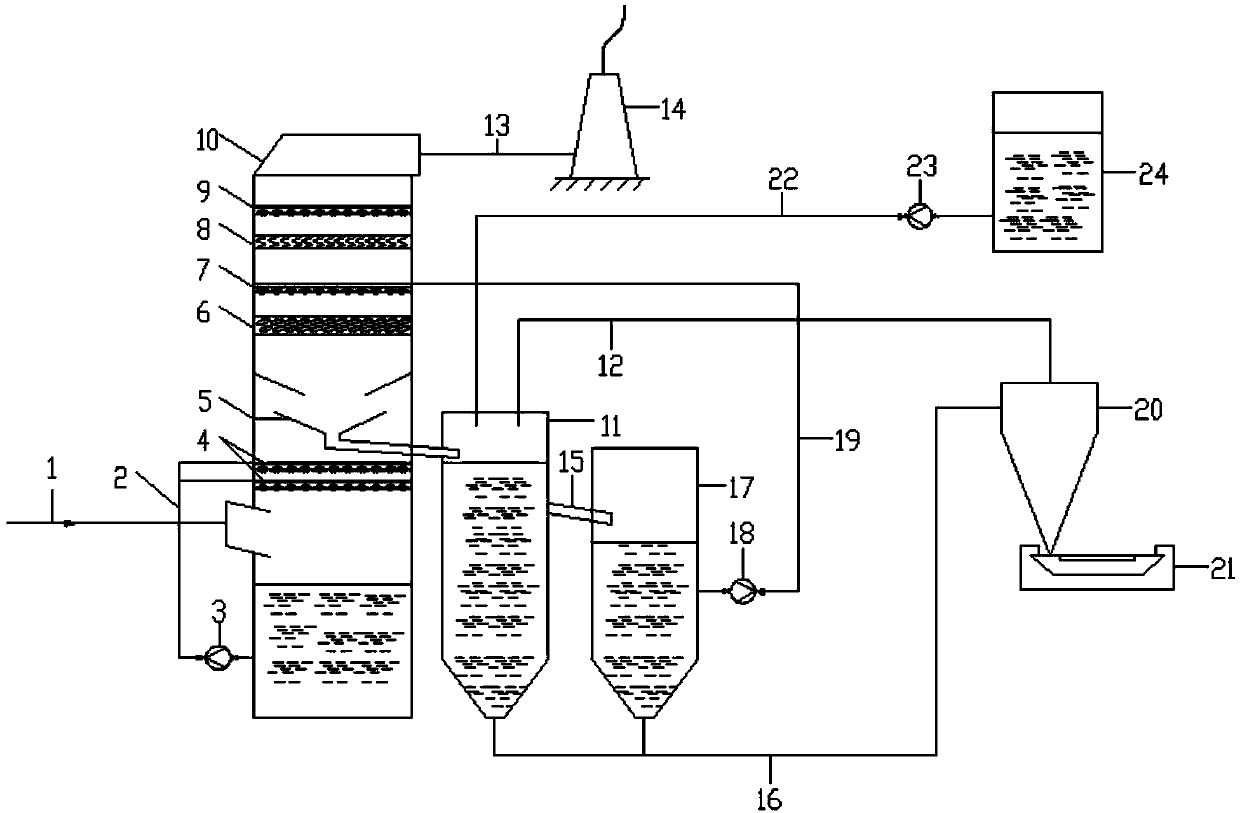

[0033] like figure 1 As shown, the method for further purifying wet desulfurization net flue gas by applying the present invention can be realized by the following device, specifically a device for further purifying wet desulfurization net flue gas of the present invention, including for realizing the existing The wet desulfurization device of the wet desulfurization process, the wet desulfurization devic...

Embodiment 2

[0037] The basic steps of a method for further purifying wet desulfurization net flue gas of the present invention are the same as in Example 1, specifically:

[0038] In the step (1), the clean flue gas is re-purified through the water film in the water film packing layer 6, and the purified clean flue gas goes up through the water film packing spray layer 7 and is discharged. The film filler spray layer 7 sprays the purifier to the water film filler layer 6, and the purifier enters the water film filler spray layer 7 through the water film spray circulation pipeline 19 and the water film spray circulation pump 18 from the liquid collection tank, The cleaning agent in the liquid collection tank is transported through the cleaning agent supply device;

[0039] In the step (2), the repurification liquid generated in the step (1) is collected through the liquid collector 5;

[0040] In the step (3), the repurification liquid collected in the step (2) is recovered and processed ...

Embodiment 3

[0050] The basic steps of a method for further purifying wet desulfurization net flue gas of the present invention are the same as in Embodiment 2, specifically:

[0051] In order to fully save water and other reagents, and to achieve full recycling, the number of the liquid collection tanks is two, and the two liquid collection tanks are respectively the primary liquid collection tank 11 and the secondary liquid collection tank 17;

[0052]In the step (1), the purifying agent supply device delivers the purifying agent to the primary collecting tank 11, and the purifying agent in the upper layer of the primary collecting tank 11 flows into the secondary collecting tank 17 through the overflow pipe 15 Among them, the middle part of the secondary liquid collection tank 17 is provided with a water film spray circulation pipe interface, and the purifying agent enters the water film filler spray layer 7 through the water film spray circulation pipe 19 and the water film spray circul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com