High-power light-emitting diode (LED) street lamp

A technology of LED street lamps and LED light boards, which is applied in damage prevention measures of lighting devices, cooling/heating devices of lighting devices, outdoor lighting, etc., and can solve the problem of unsatisfactory heat dissipation effect of lamps with heat dissipation structure and affect the heat dissipation effect of heat pipe radiators , can not solve the problems of heat conduction of LED lamp beads, so as to achieve the effect of simplifying the structure, improving the heat dissipation efficiency and reducing the light decay

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

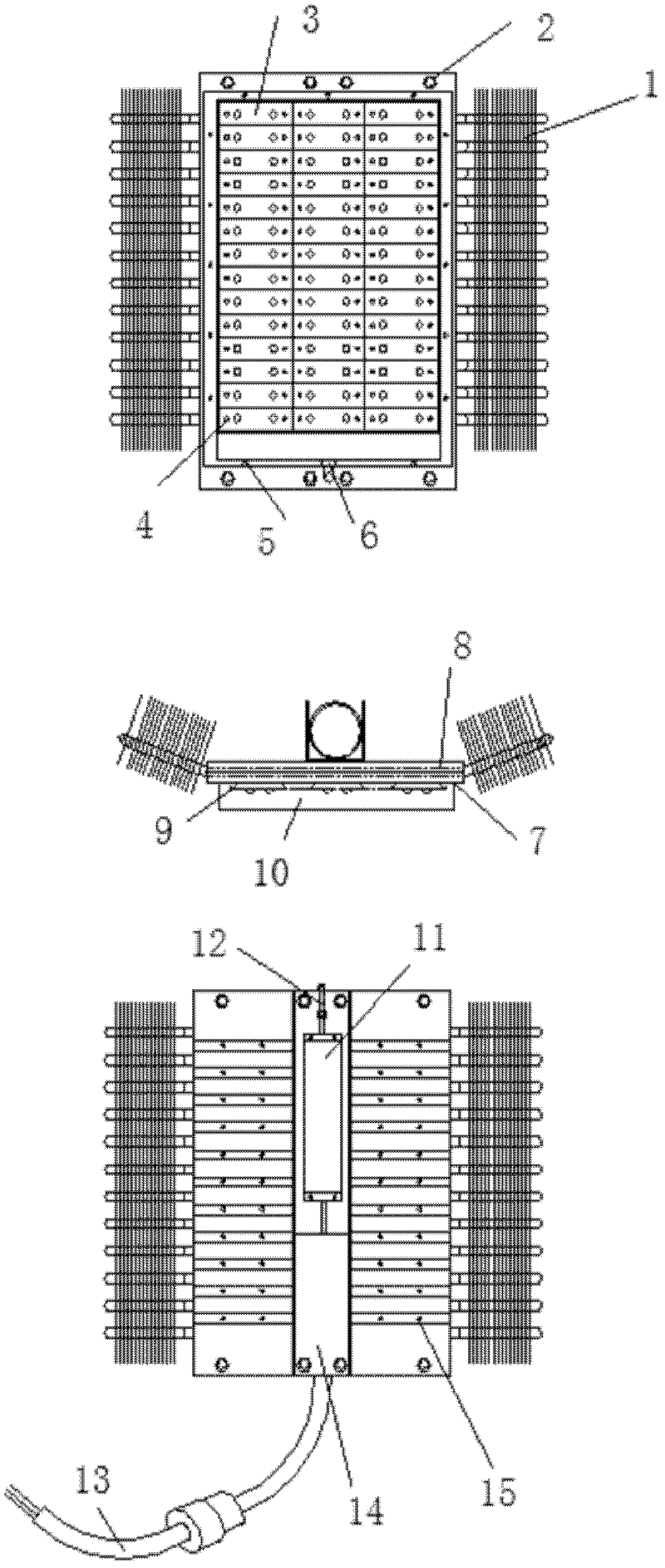

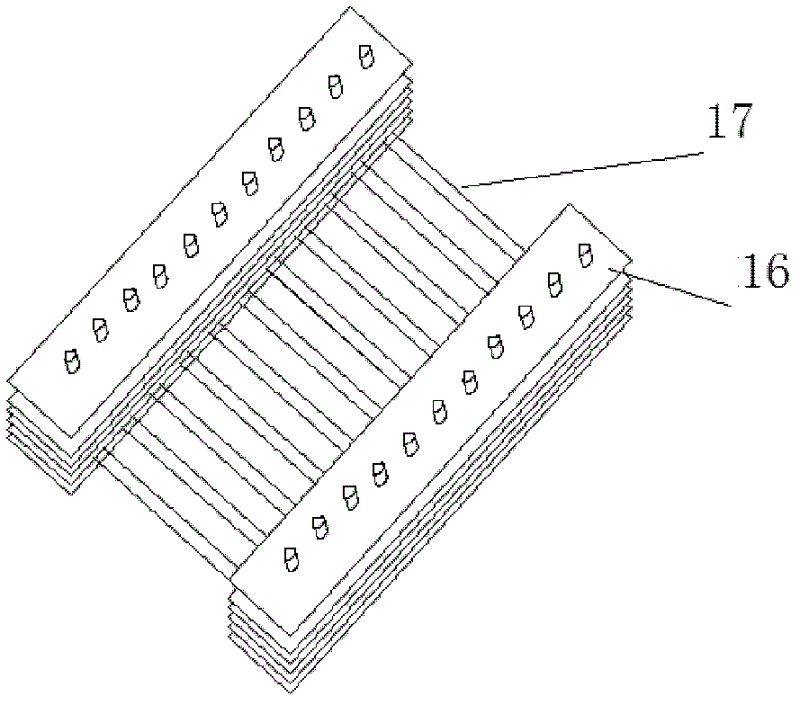

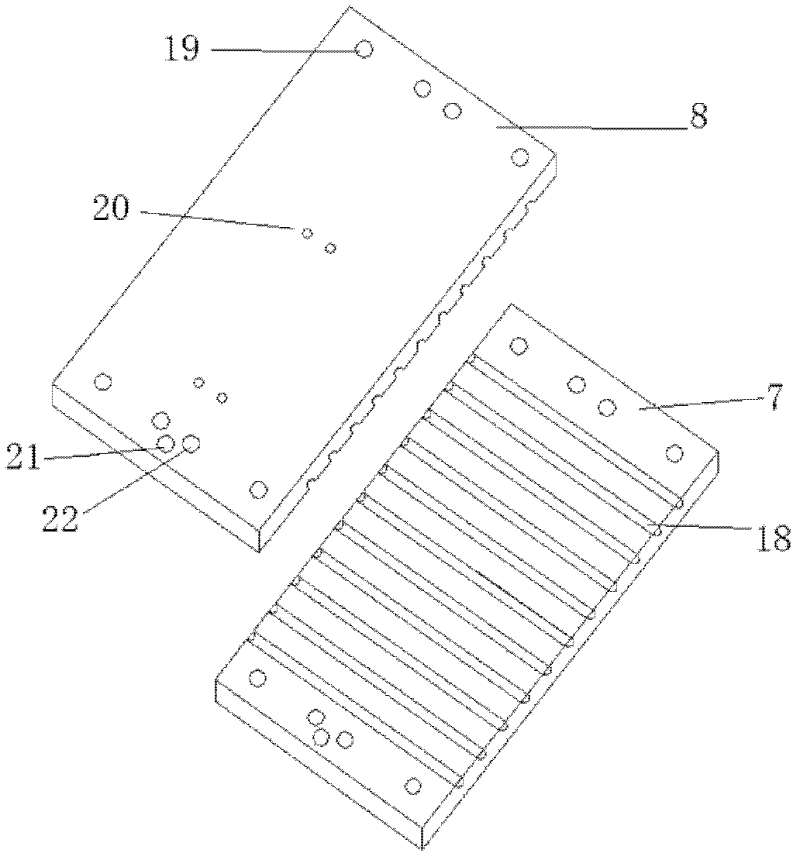

[0037] Figure 1-7 As a specific embodiment of the present invention, the present invention will be further described below in conjunction with the accompanying drawings.

[0038] Apply heat-conducting silicone grease evenly in the semicircular arc of the bottom plate 7 and the pressure plate 8 and the heat-conducting pipe section in contact with the bottom plate 7 and the pressure plate 8, and press-fit the heat pipe radiator 1 between the bottom plate 7 and the pressure plate 8 with M5 self-tapping screws 15, Fix the bottom plate 7 and the pressure plate 8 with the fixing bolt 2 and install the light pole fixing frame 14 on the pressure plate 8, fix the power supply 11 on the power supply installation position on the pressure plate 8 at the opening of the bottom surface of the light pole fixing frame 14, and install the LED light board The surface of the base plate 7 of 9 and the aluminum metal surface of the LED light plate 9 are evenly coated with heat-conducting silicone ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com