Efficient recovery device for waste automobile components

A technology of automobile components and recycling devices, which is applied in the direction of plastic recycling, mechanical material recycling, recycling technology, etc., can solve problems such as polluting the environment and wasting resources, and achieve high cleanliness, high practicability, and cleanliness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The following is a further detailed description of the high-efficiency recovery device for waste automobile components according to the present invention through specific examples.

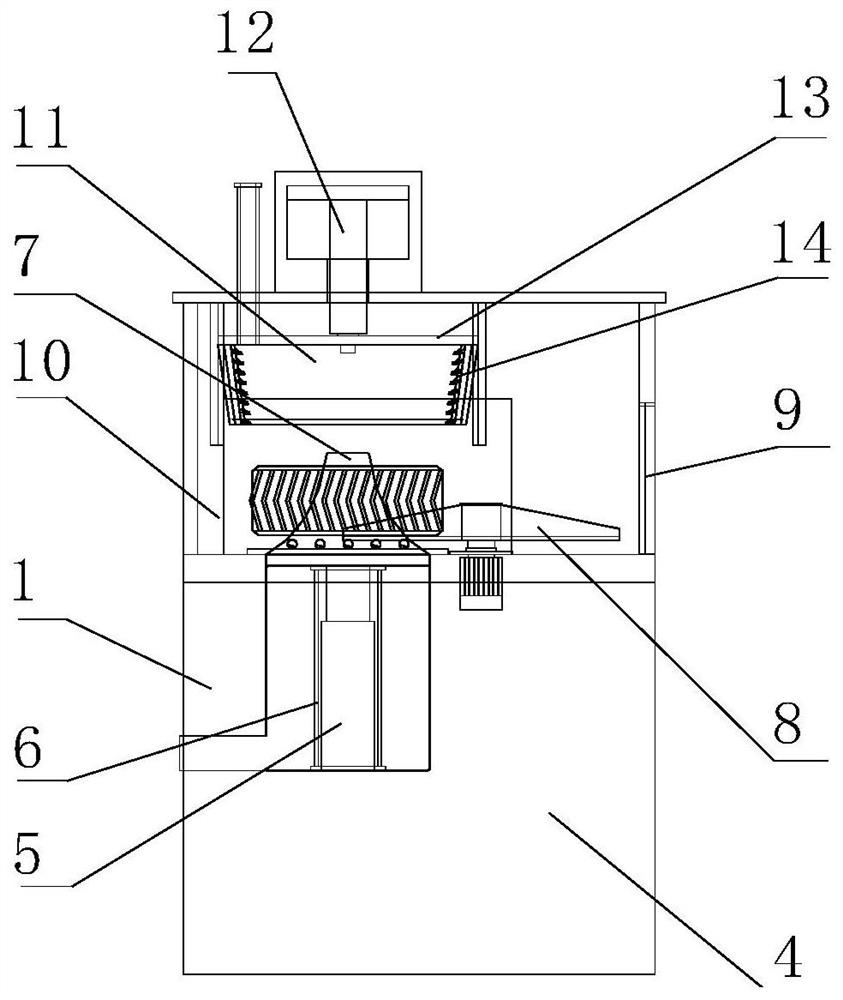

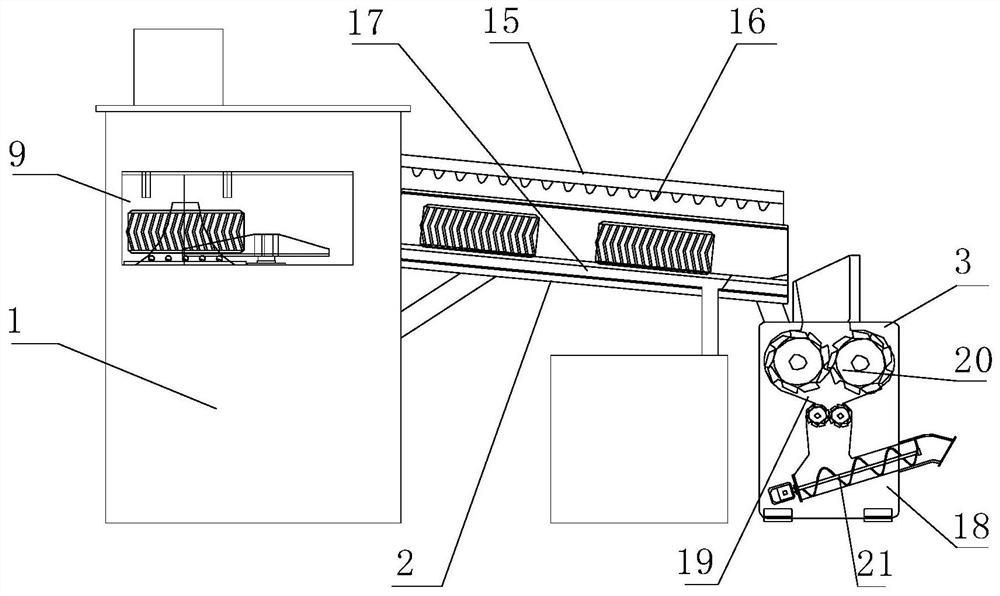

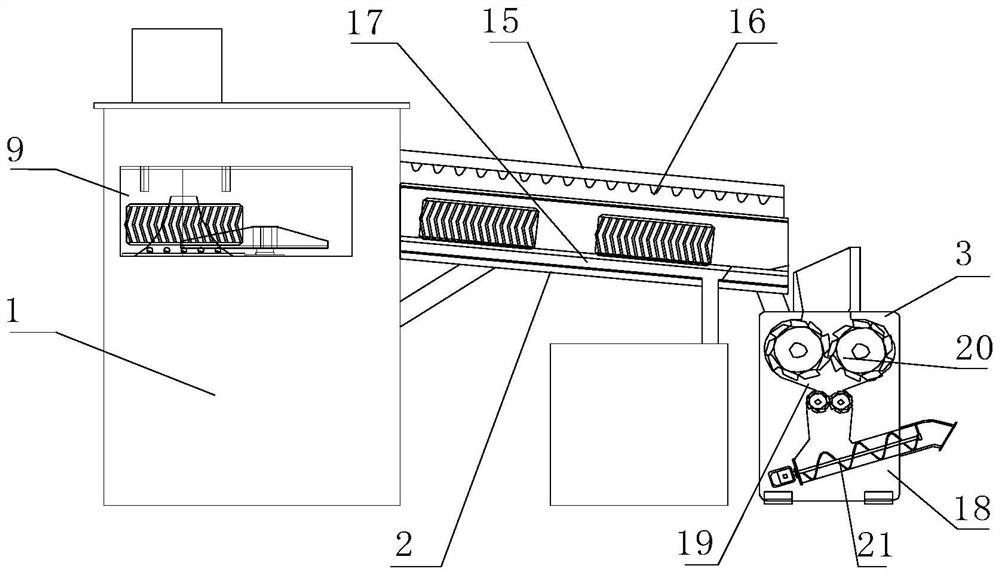

[0019] Such as Figure 1-3 As shown, the present invention provides a technical solution: a high-efficiency recovery device for waste automobile components, including a cleaning device 1, a drying device 2, a crushing device 3, a body A4, an electric lifting rod A5, a waterproof telescopic sleeve 6, and a fixing sleeve 7. Turning plate 8, waterproof curtain 9, discharge port 10, spray assembly 11, electric lifting rod B12, protective shell 13, high-pressure nozzle 14, shell 15, air knife 16, vibration draining belt 17, body B18, crusher 19. The crushing roller 20 and the conveyor 21, the drying device 2 is fixed at the rear output end of the cleaning device 1, the crushing device 3 is fixed at the rear output end of the drying device 2, and the cleaning device 1 includes the body A4 and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com