Patents

Literature

35results about How to "Good air filtration" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

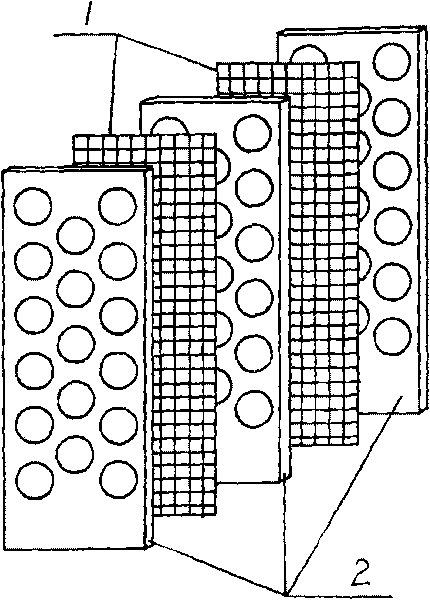

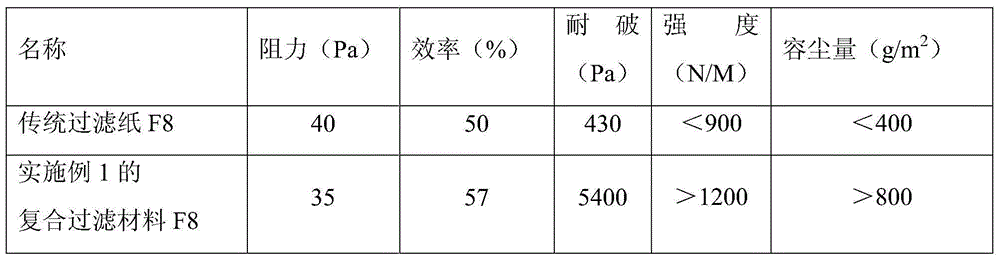

Air filtration glass fiber cotton composite material of series F5-F9 and manufacturing method thereof

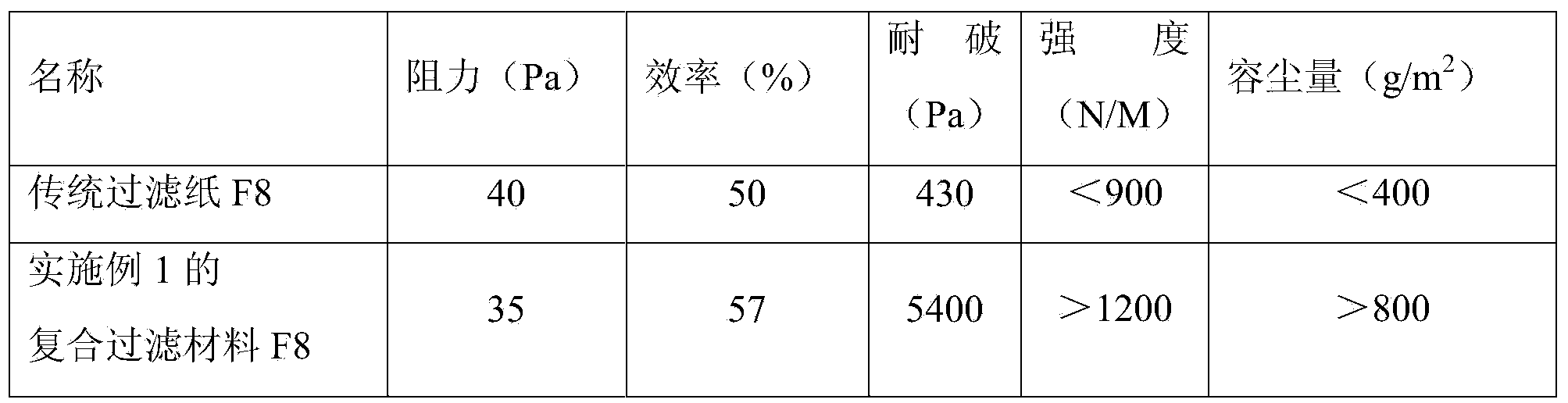

ActiveCN103657258AHigh porosityGood coarse and medium filter effectLaminationLamination apparatusAir filtrationGlass fiber

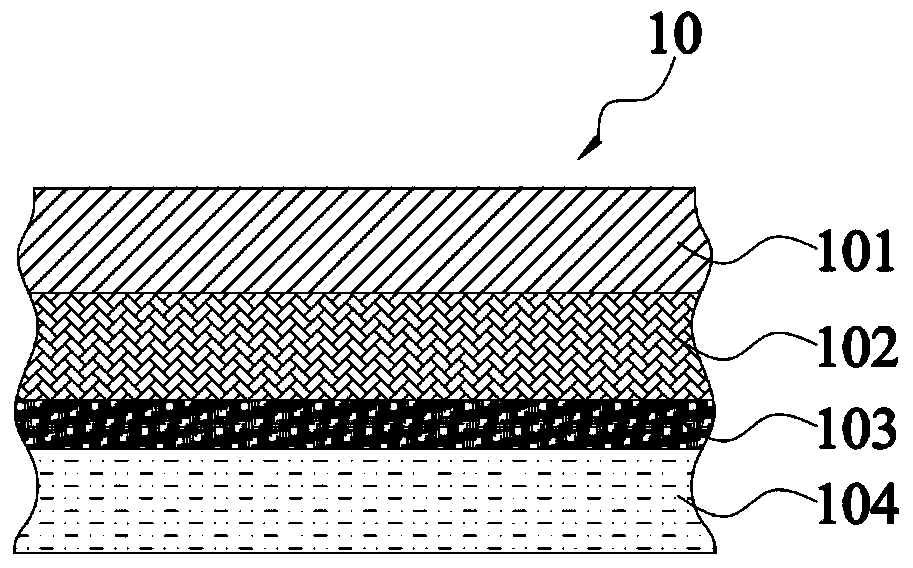

The invention discloses an air filtration glass fiber cotton composite material of series F5-F9. The air filtration glass fiber cotton composite material comprises non-woven cloth and a glass fiber cotton layer combined on the surface of the non-woven cloth through an adhesive material, wherein the non-woven cloth is 0.05-0.1mm thick; the glass fiber cotton layer is 0.25-1.5 mm thick and consists of glass fiber cotton with the diameter of 0.75-1.25 microns; the adhesive material is acrylic resin. A method for preparing the composite material comprises the steps of mixing and smelting proper amount of zinc oxide, borax, white sand, potash feldspar powder, pure alkaline, calcite, potassium carbonate and barium carbonate, performing primary fiber forming and then dragging the fibers through high-temperature and high-speed air flow to obtain the glass fiber cotton; dispersing the glass fiber cotton on the surface of the non-woven cloth, spraying glue, and drying to obtain the product. The air filtration glass fiber cotton composite material disclosed by the invention is high in intensity and high in filtration performance and has wide application prospects; due to the preparation method, the performance of the air filtration glass fiber cotton composite material can be further guaranteed.

Owner:CHONGQING ZAISHENG TECH CORP

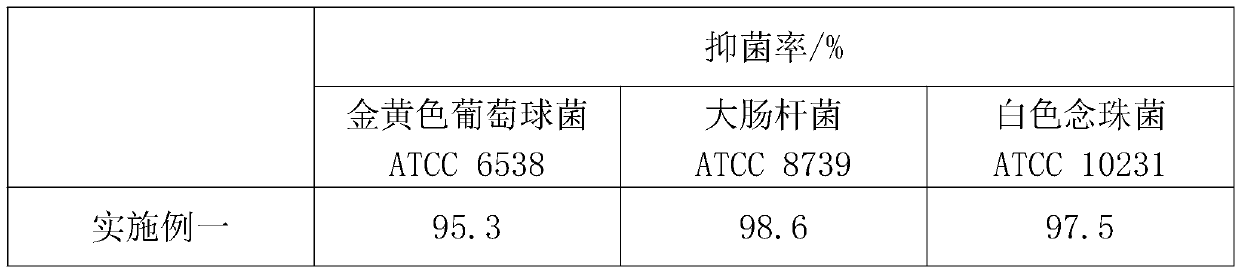

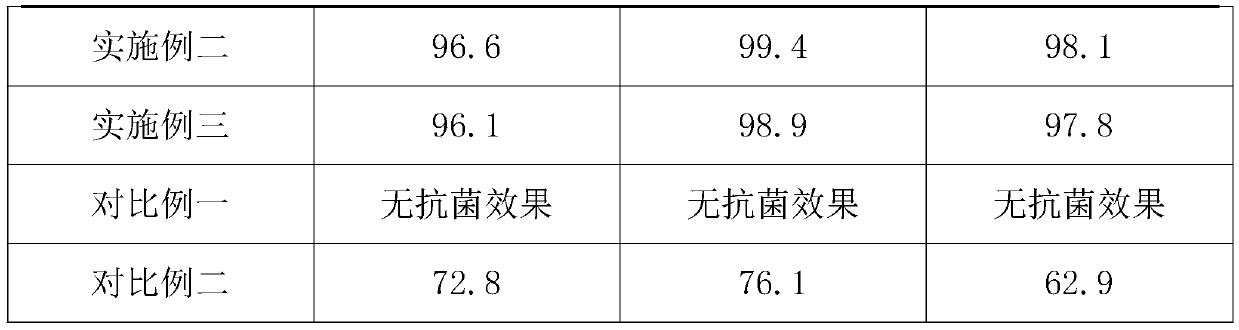

Preparation method for antibacterial melt-blown non-woven fabric

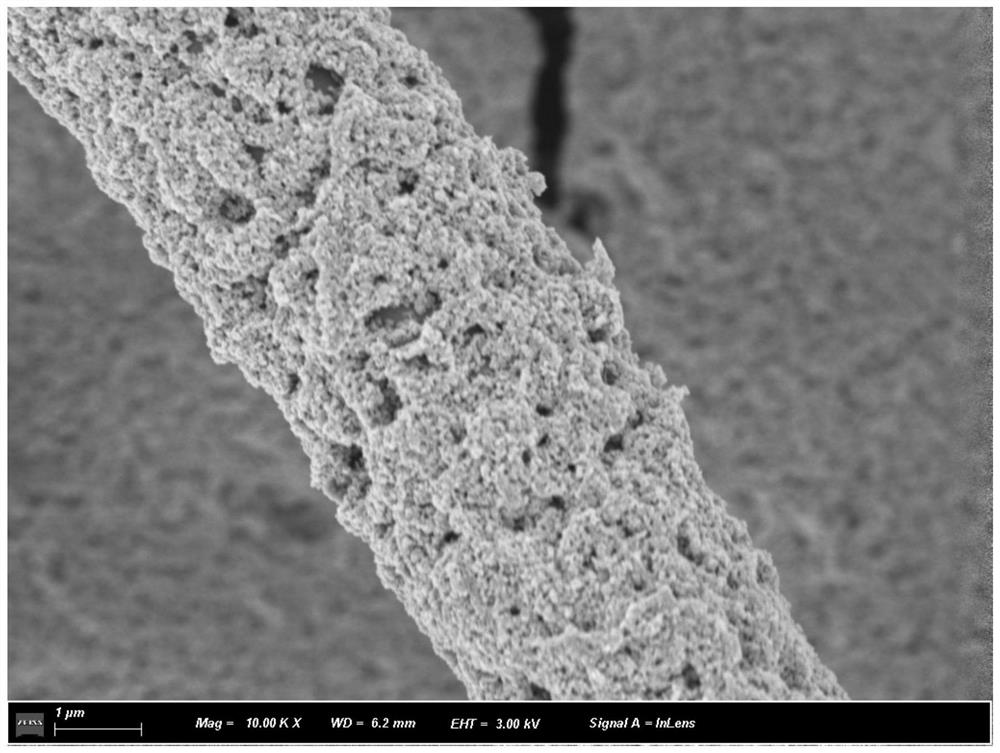

ActiveCN111424428AMany gapsFluffy structurePhysical treatmentBiochemical fibre treatmentPolymer scienceMethacrylate methyl

The invention relates to the technical field of non-woven fabrics, and provides a preparation method for an antibacterial melt-blown non-woven fabric. The preparation method comprises the following steps of (1) carrying out oxygen plasma treatment on a polypropylene non-woven fabric, and carrying out graft modification on the polypropylene non-woven fabric to prepare a modified polypropylene non-woven fabric; (2) polymerizing an amino-terminated hyperbranched polymer with propylene diamine and methyl methacrylate as raw materials, and preparing a modified hyperbranched polymer through polycondensation of carboxymethyl chitosan and the amino-terminated hyperbranched polymer; and (3) adding a copper chloride solution into a modified hyperbranched polymer aqueous solution, dropwise adding a sodium borohydride solution under nitrogen protection and ice bath conditions, carrying out impregnation treatment on the modified polypropylene non-woven fabric in the modified hyperbranched polymer aqueous solution after the reaction is finished, and drying to obtain the antibacterial melt-blown non-woven fabric. The preparation method solves a problem that the melt-blown non-woven fabric in theprior art only has an efficient filtering effect and does not have antibacterial property.

Owner:FUJIAN HENGAN HLDG CO LTD +2

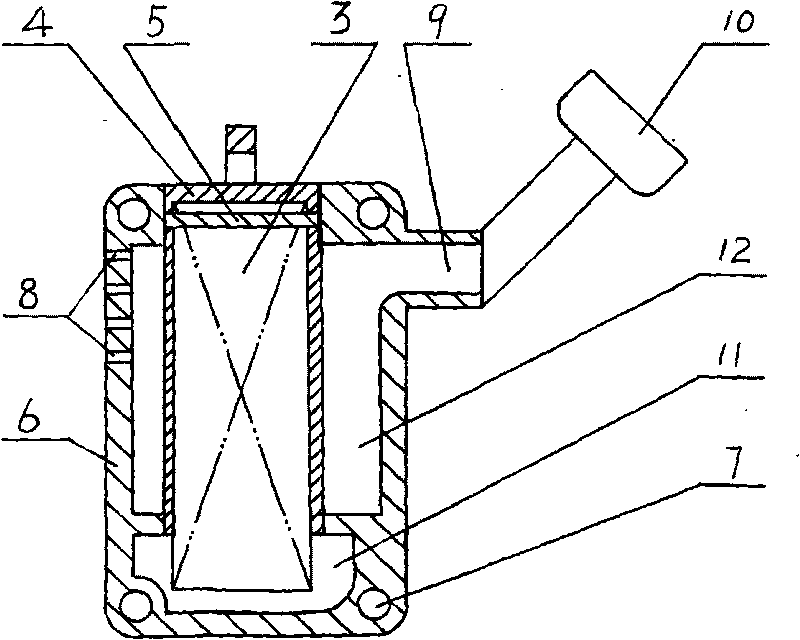

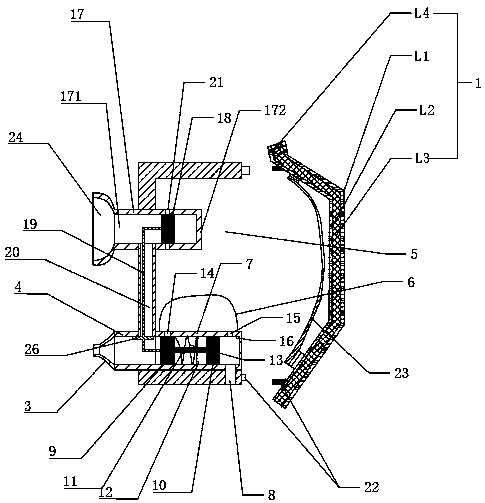

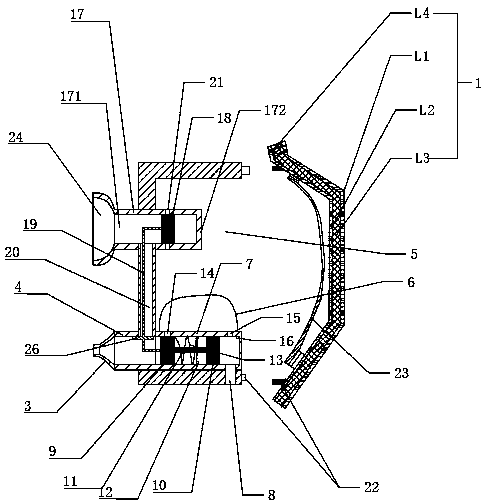

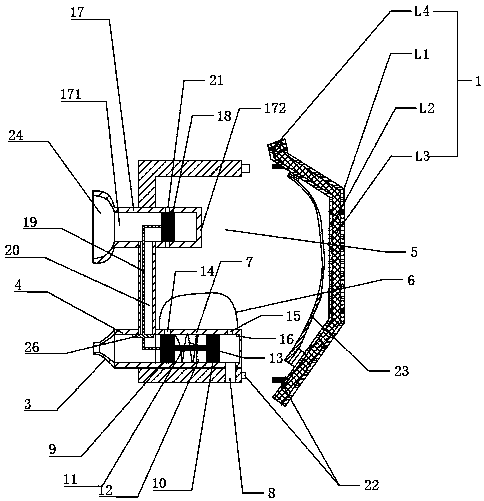

Air filter for breathing and filter element thereof

InactiveCN101700426AProtect healthMaintain healthBreathing filtersRespiratory apparatusInlet channelFire control

The invention relates to an air filter for breathing and a filter element thereof, belonging to the field of health protection. By adopting the bionic principle simulating the nasal cavity of human body, the filter element is formed by stacking a filtering layer and a liquid absorbing layer at intervals, and is positioned between an air inlet channel and an air outlet channel which are arranged inside a shell of a filtering component; and the liquid absorbing layer of the filter element extends into filtrate inside a liquid storage cavity, and the air outlet channel of the filtering component is connected with a breathing mask. The air filter has good filtering effect and convenient use, is suitable for staff working in the environment of dust, smoke and waste gas, and can be taken as fire control preparation article for standby application.

Owner:张涛

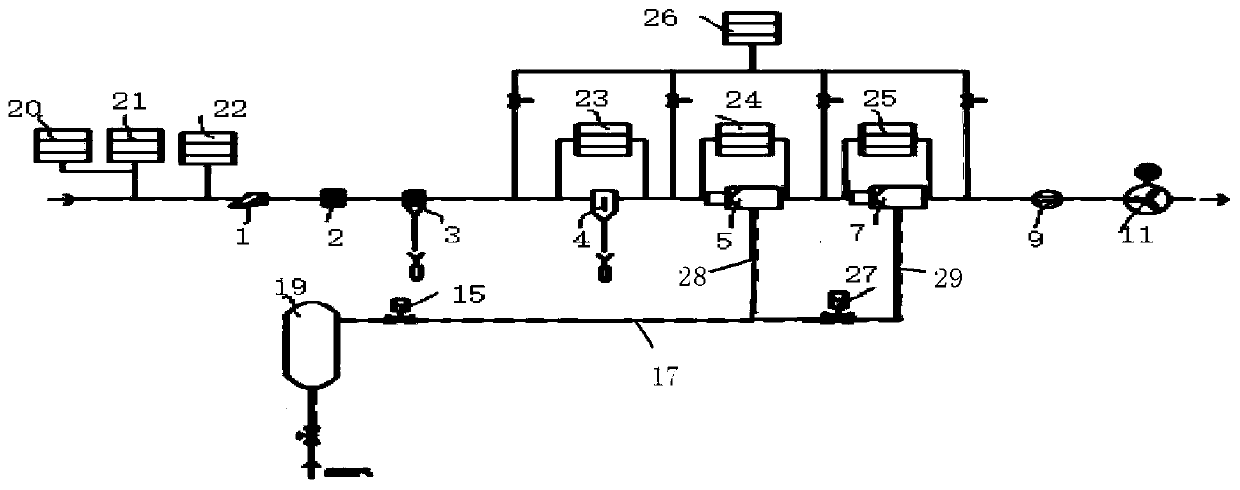

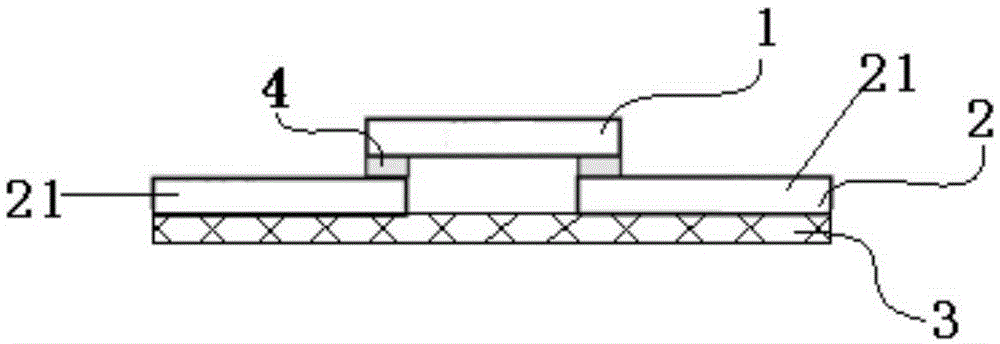

Filter element testing system

PendingCN110987758AAcquisition automatic controlAutomatic control processingPermeability/surface area analysisControl systemDisplay device

The invention provides a filter element testing system. The filter element testing system comprises a test channel, a filter element mounting assembly, a blowback system and a monitoring control system, wherein the filter element mounting assembly is arranged in the test channel, the filter element mounting assembly comprises a first mounting part, a second mounting part and a third mounting partwhich are sequentially arranged in an airflow direction, and the first mounting part, the second mounting part and the third mounting part are respectively used for detachably mounting a filter element; the blowback system comprises a blowback air source, a blowback pipeline and a blowback control valve arranged on the blowback pipeline and used for controlling on-off of the blowback pipeline, oneend of the blowback pipeline is connected with the blowback air source, and the other end of the blowback pipeline extends to the second mounting part and the third mounting part; and the monitoringcontrol system comprises a controller, a display, an air inlet parameter acquisition unit and a filtering parameter acquisition unit. By configuring a plurality of filter elements of different models,the filter element testing system can perform filtering tests on air quality of different regions, and can select gas turbines suitable for different regions through comparison to perform system filter element configuration, so as to select reasonable and better filter element models.

Owner:SHANGHAI ELECTRIC GAS TURBINE CO LTD

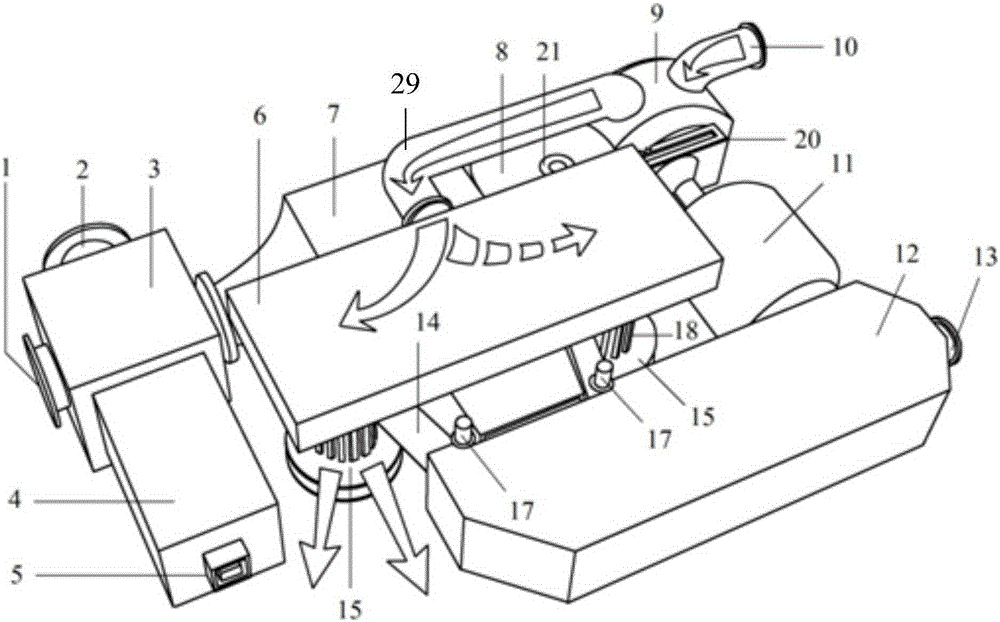

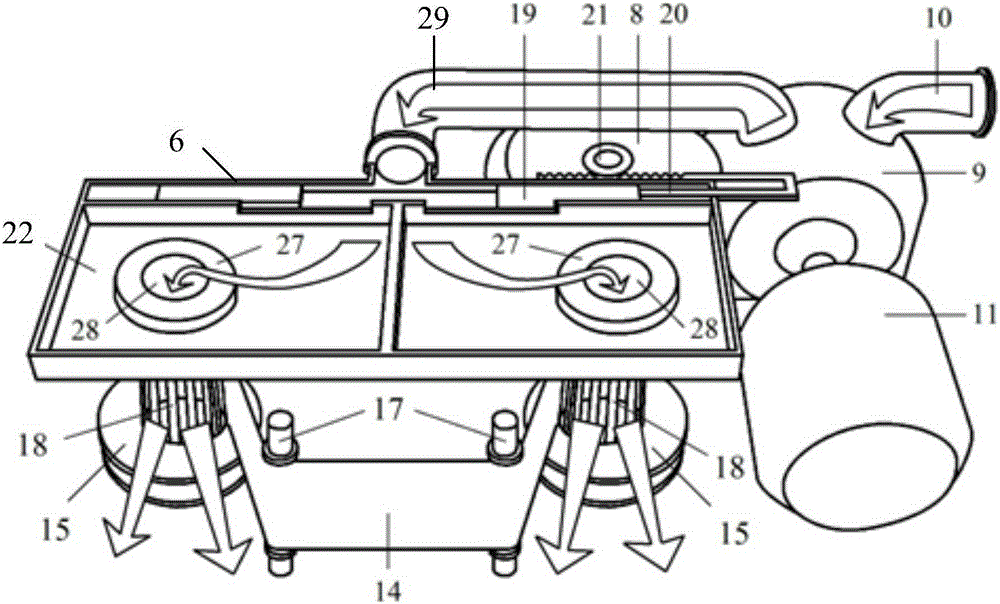

Air filtering device with self-cleaning function

InactiveCN105344174AGood air filtrationKeep cleanGas treatmentDispersed particle filtrationEngineeringFilter strip

The invention discloses an air filtering device with a self-cleaning function. The provided air filtering device comprises an air cleaning device and a filtering strip cleaning device. The air cleaning device comprises a dirty air inlet, an air compressor, an air input pipe, an air mixer and left and right filters. The filtering strip cleaning device comprises a clean air inlet, an air sterilizer, a fan and a dust box. The air compressor blows dirty air from the dirty air inlet into the air input pipe. The air mixer shunts the dirty air to the left and right filters for filtering and purifying. When the air compressor detects that the air pressure in the air compressor is larger than the preset air pressure, the fan blows clean air from the clean air inlet to the air sterilizer for sterilization, the clean air after sterilization blows the air filtering strip in the dust box through strong force and self-cleaning of the filters is carried out. The air filtering device can carry out self cleaning of filters, and achieves an effect of keeping the filters clean without replacing of the filters.

Owner:ANYCHECK INFORMATION TECH

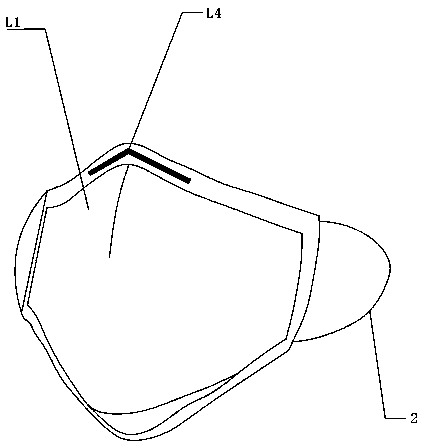

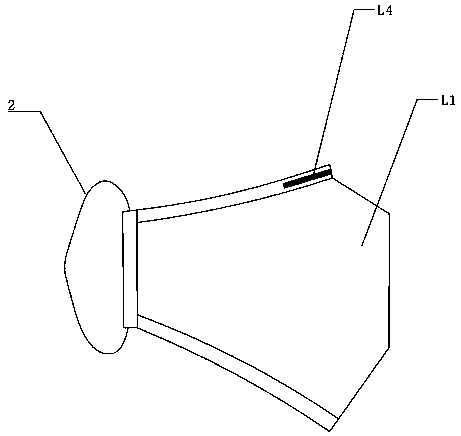

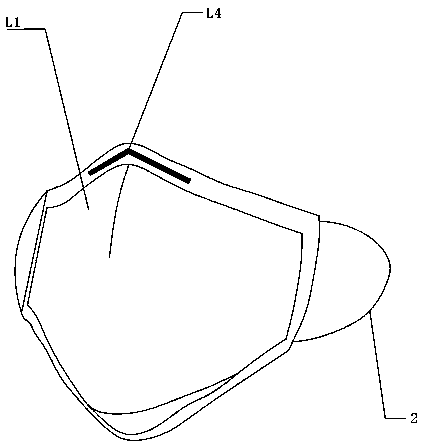

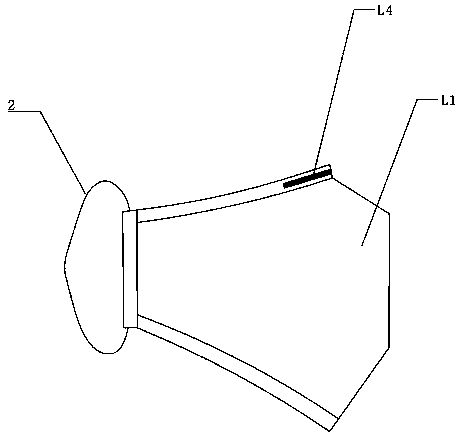

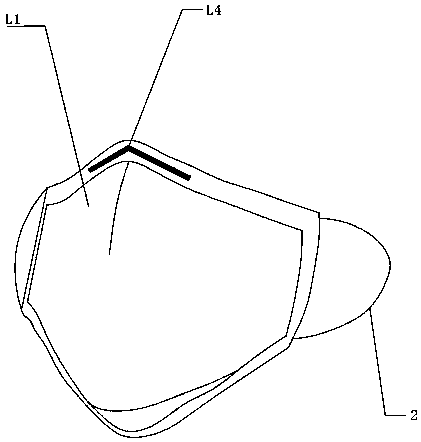

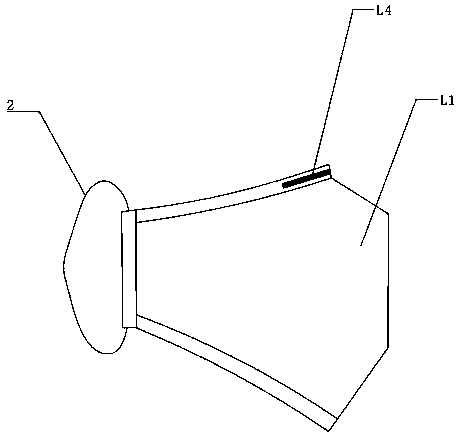

Face mask capable of preventing fogging of glasses

ActiveCN107788596AEasy to carryPlay a filtering effectFire rescueRespiratory apparatusRespiratorInhalation

The invention discloses a face mask capable of preventing fogging of glasses. According to the technical scheme, the face mask is characterized in that by forming an independent inhaled air and exhaled air flowing channel, and the exhaled air flows out along the designed channel and cannot flow to the upper portion of the nose, so that fogging of the glasses is avoided. In order to solve the problem that the inhalation resistance is increased due to the design of the independent flowing channel, a special respiration assisting device is arranged, the respiration assisting device comprises a chamber, an elastic air bag is arranged in the chamber and connected with an exhalation pipe, the chamber is connected with an inhalation pipe, the exhalation pipe is connected with an exhalation pipe control device, and accordingly, when exhalation is conducted through the exhalation pipe, because the air bag becomes large, the air in the chamber can be discharged into the inhalation pipe for inhalation of people. When one time of exhalation is completed, the exhalation pipe control device discharges the air in the air bag, because the air bag becomes small, the outside air enters the chamber due to air pressure difference, so that the aim of assisting the respiration is achieved. By means of the face mask, fogging of the glasses can be avoided to the greatest extent, and the respiration assisting function is achieved.

Owner:海门市创豪工业设计有限公司

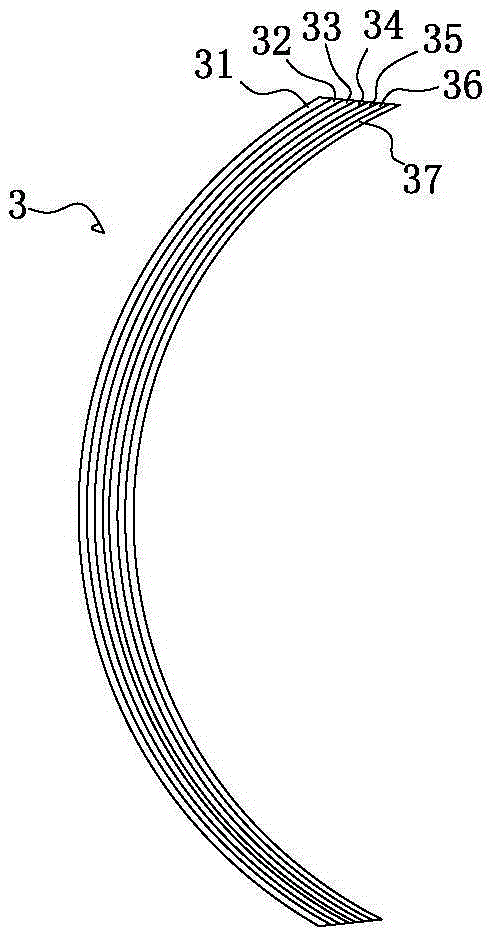

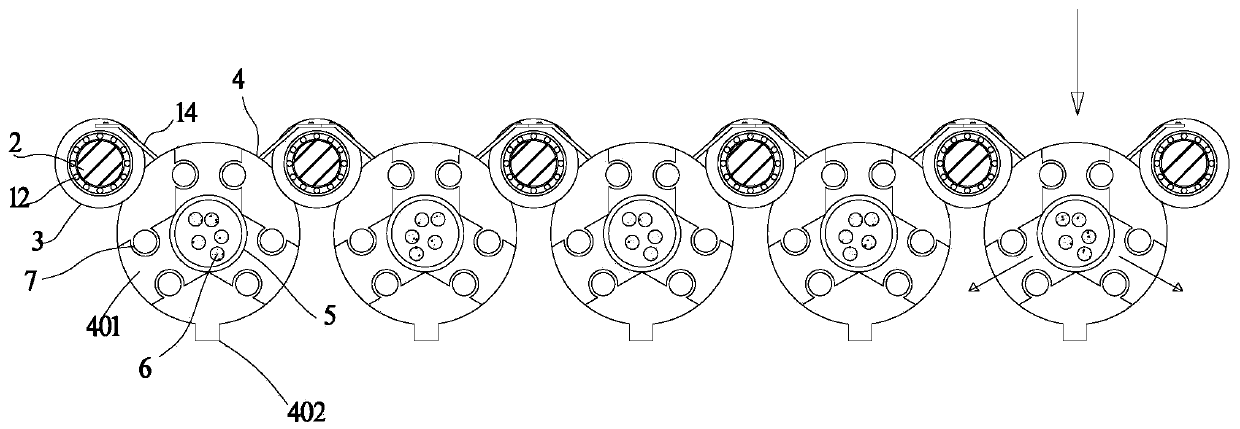

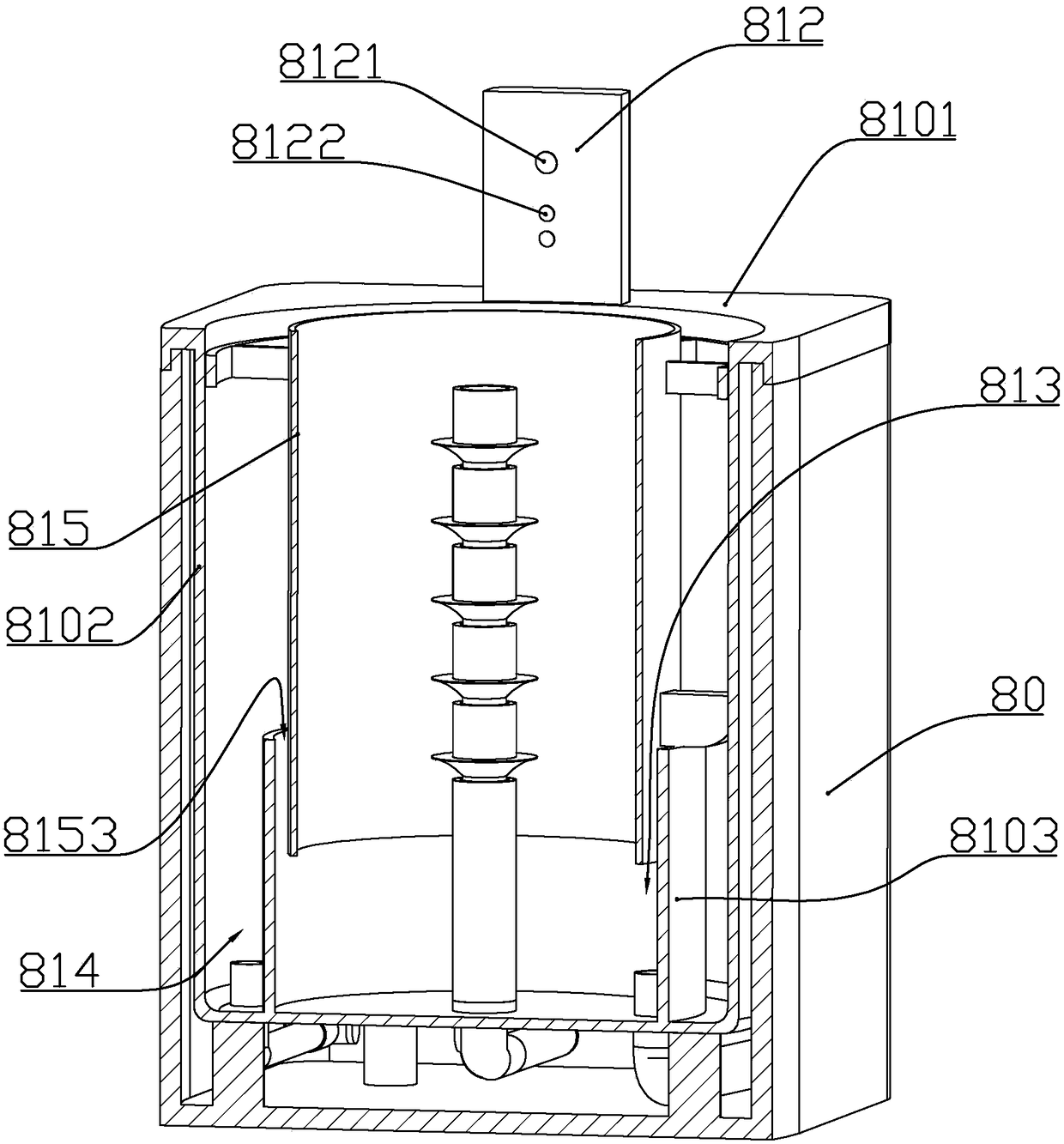

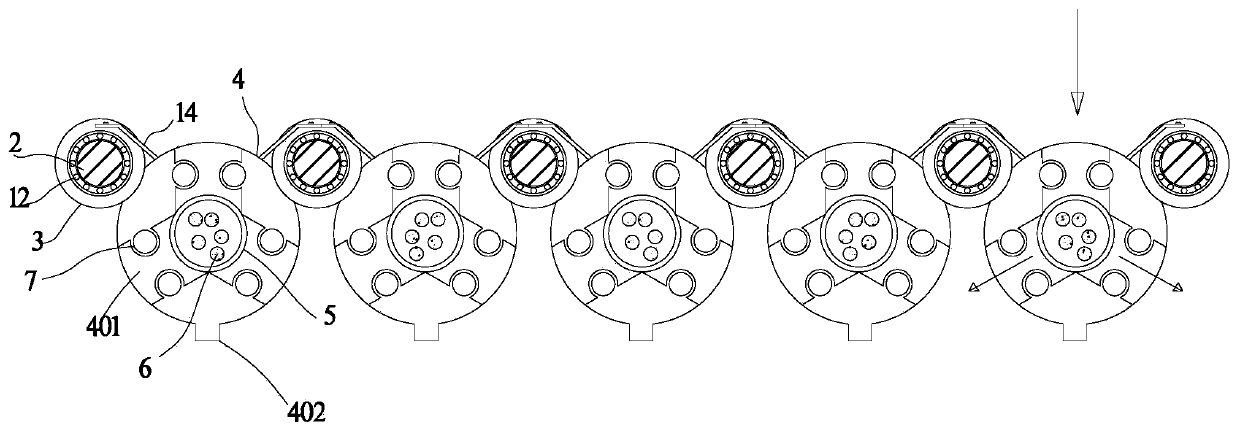

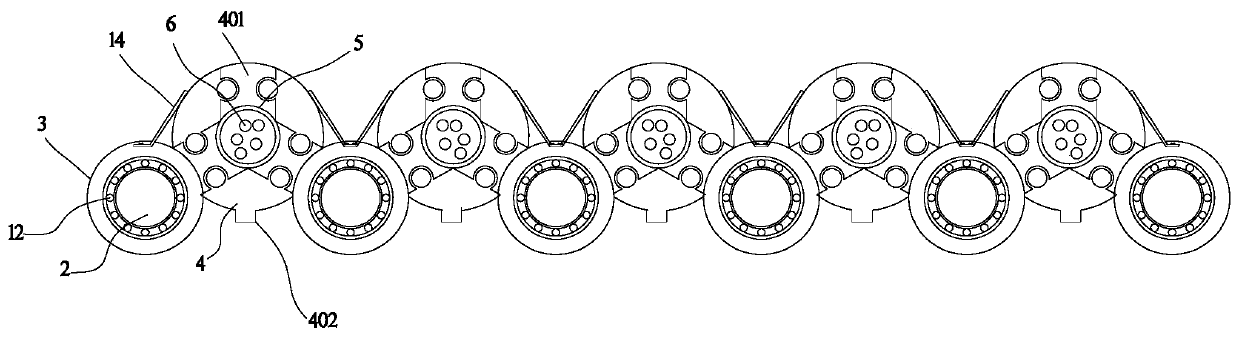

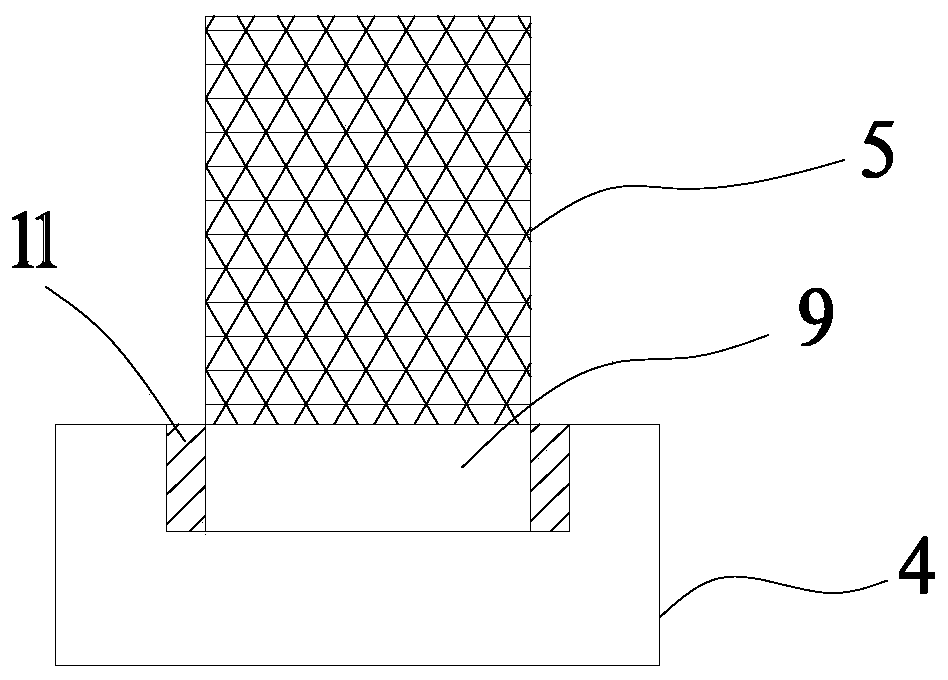

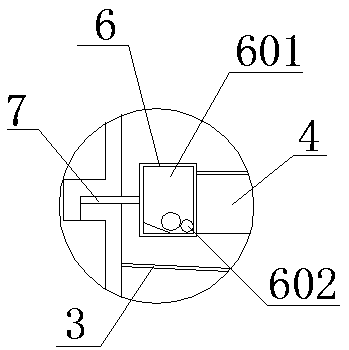

Rotary water curtain forming mechanism

InactiveCN105910206ASimple structureEasy to assembleLighting and heating apparatusUsing liquid separation agentWater dischargeWater flow

The invention discloses a rotary water curtain forming mechanism. The rotary water curtain forming mechanism comprises a first water spraying pipe and a plurality of water curtain generators which are installed at the upper end of the first water spraying pipe and connected in series in the longitudinal direction. When the rotary water curtain forming mechanism works, water flows into the first water spraying pipe, flows into lower pipe portions of the water curtain generators in sequence, and flows out of an upper portion of each water curtain generator to enter the next adjacent water curtain generator. Part of the water is sprayed out from an annular water discharging seam when flowing to the next water curtain generator, the sprayed water can flow onto an inwardly concave inverted-cone-shaped water curtain forming wall along the outer wall of each lower pipe portion, and a small part of water is sprayed out of flow guide spouts along flow guide grooves to form water curtains with wrinkles. In addition, when water passes through middle pipe portions, a small part of water is sprayed out of water spraying nozzles to drive the water curtain generators to rotate clockwise, and thus the multiple layers of rotary water curtains with the wrinkles are formed between the upper edge of a flow guide barrel and an annular air inlet channel.

Owner:SHANDONG LUOXIANG AUTOMOBILE MFG CO LTD

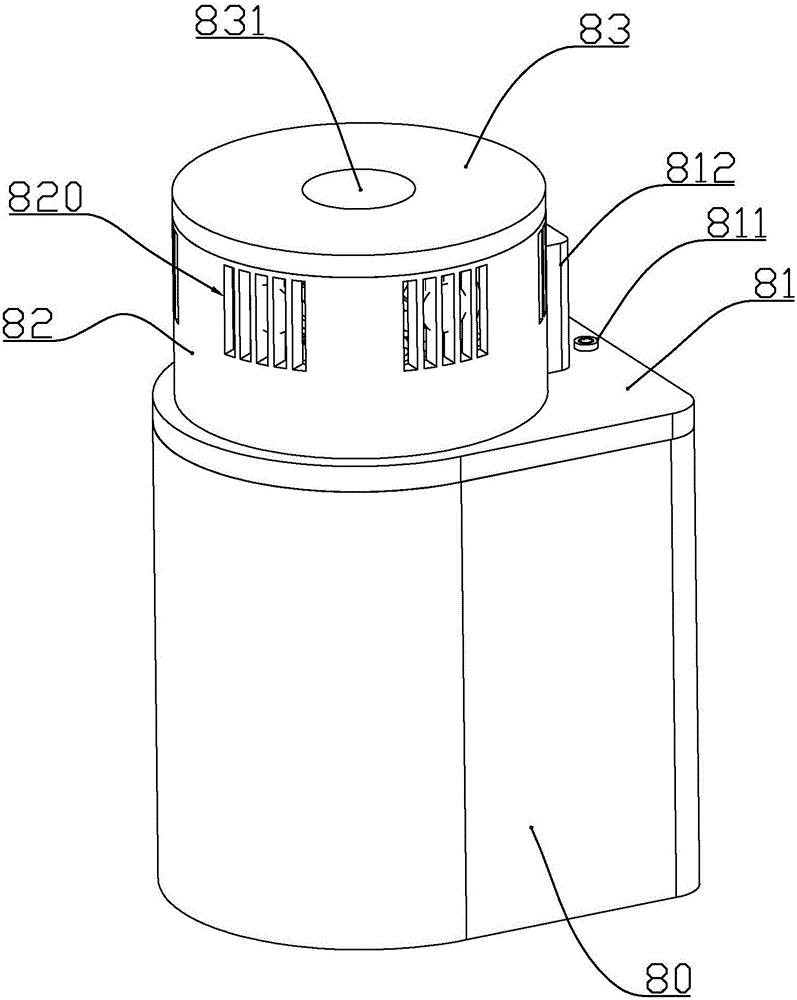

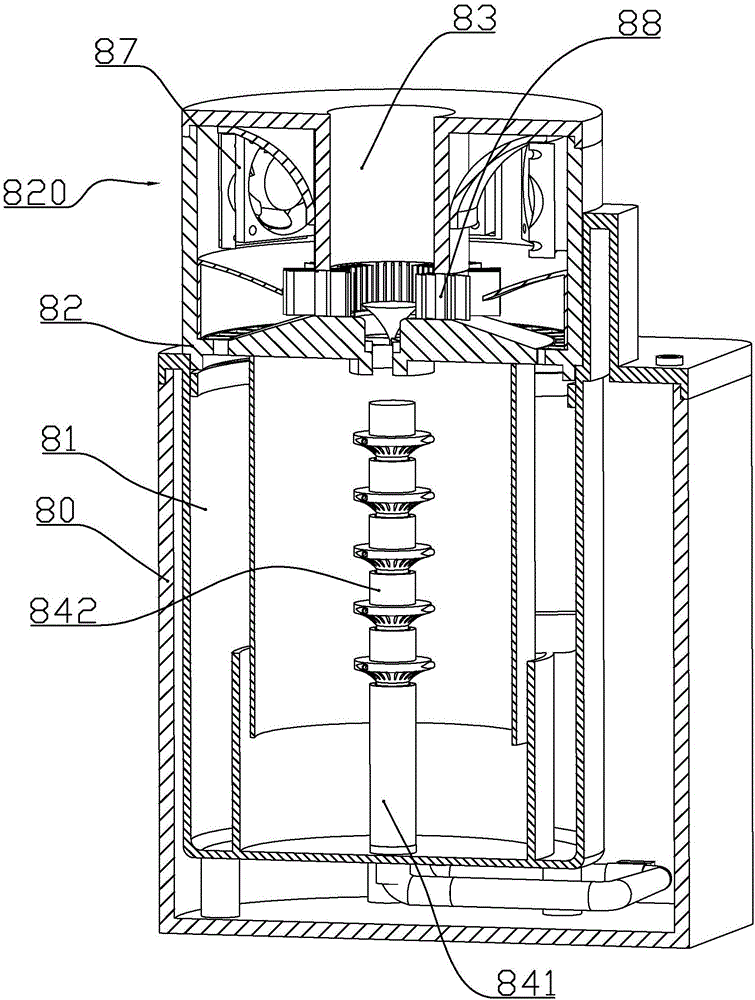

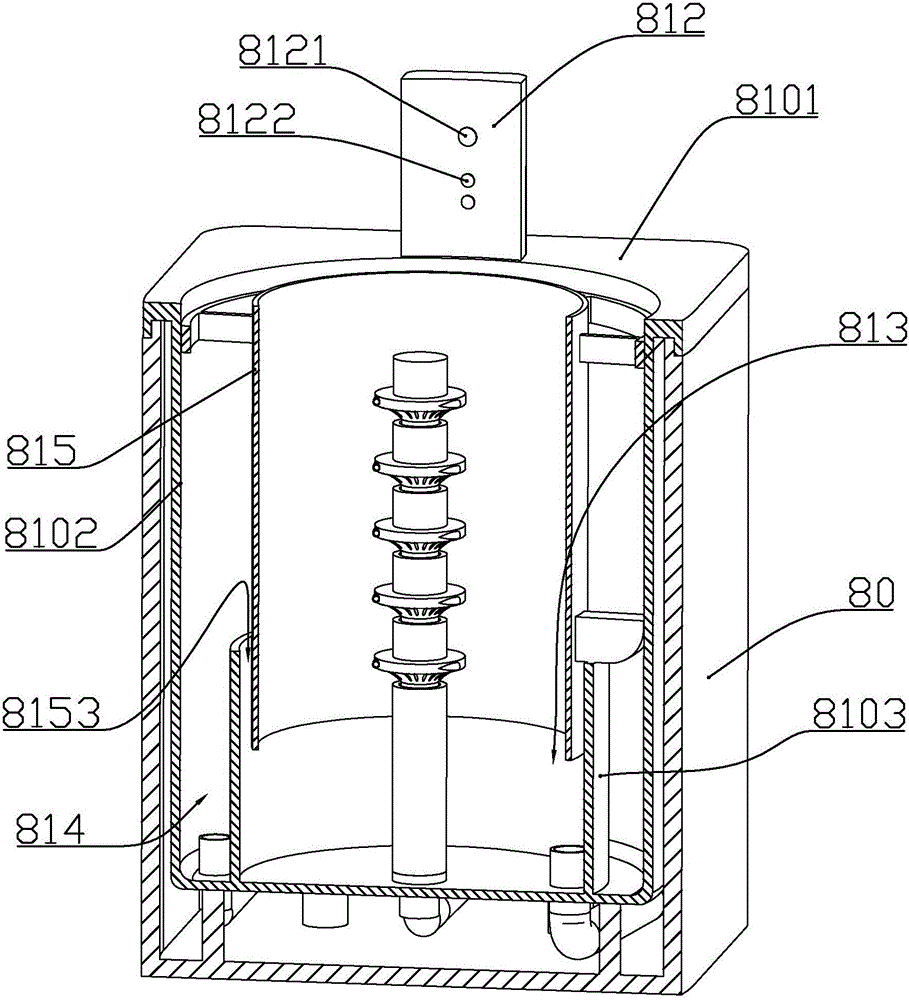

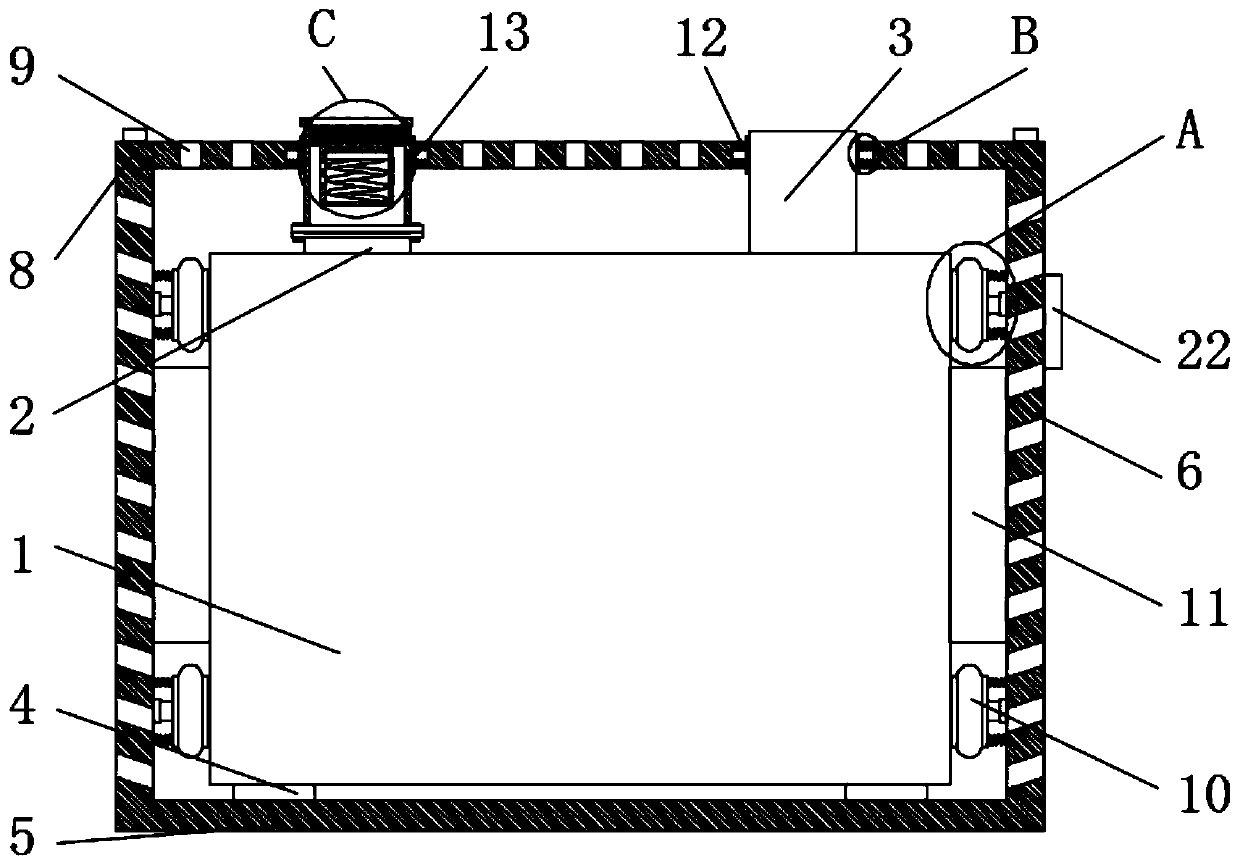

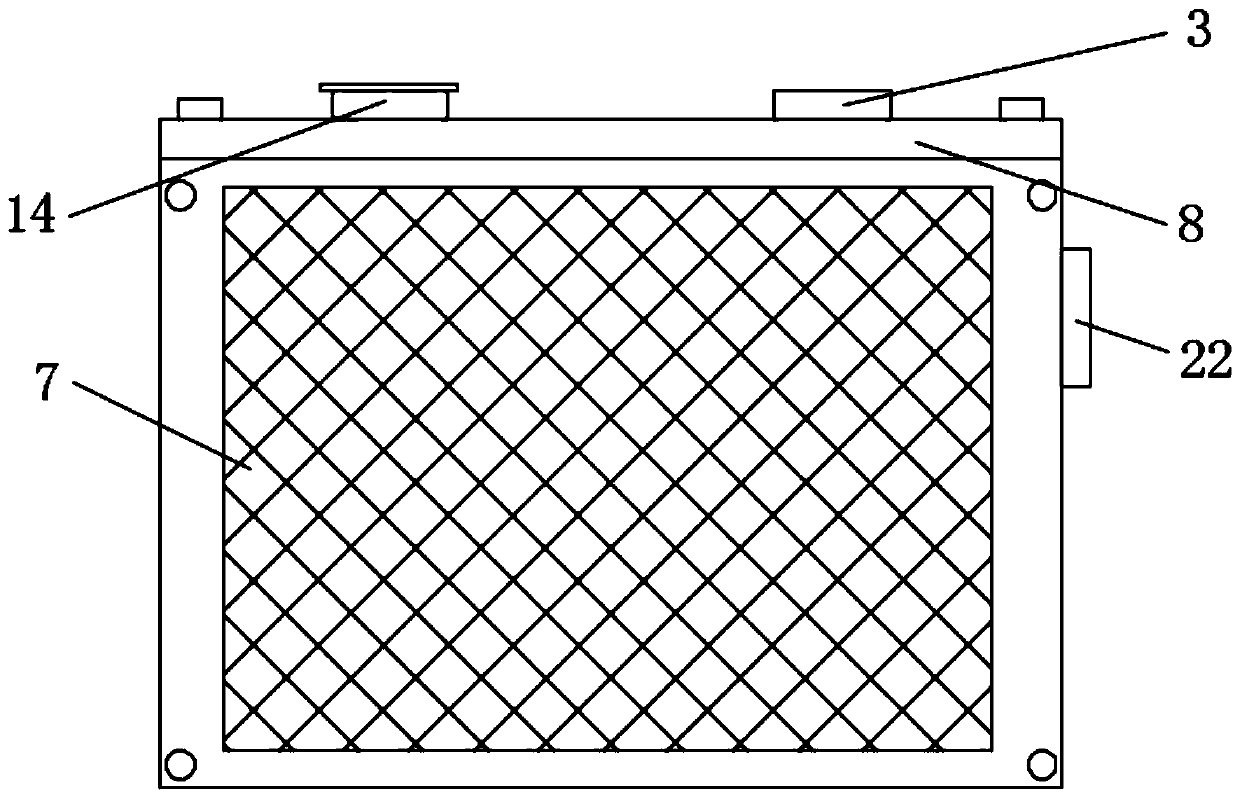

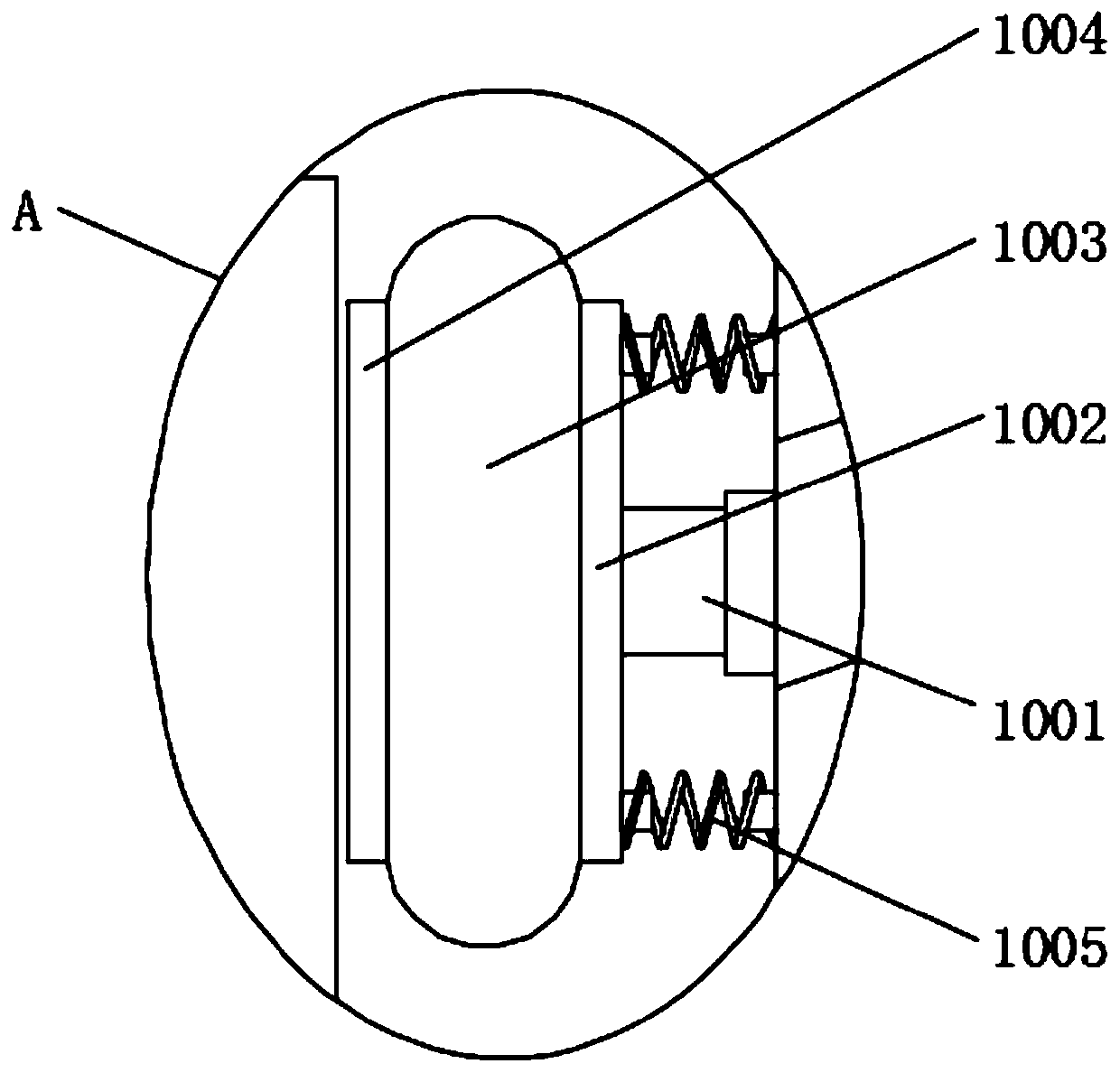

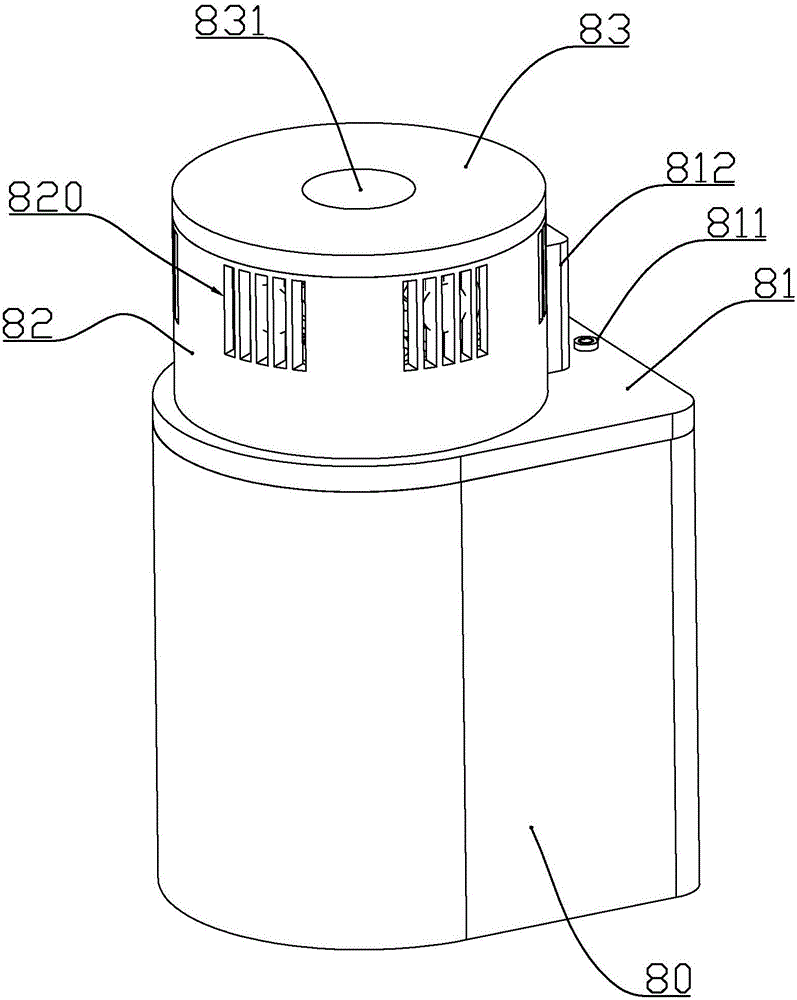

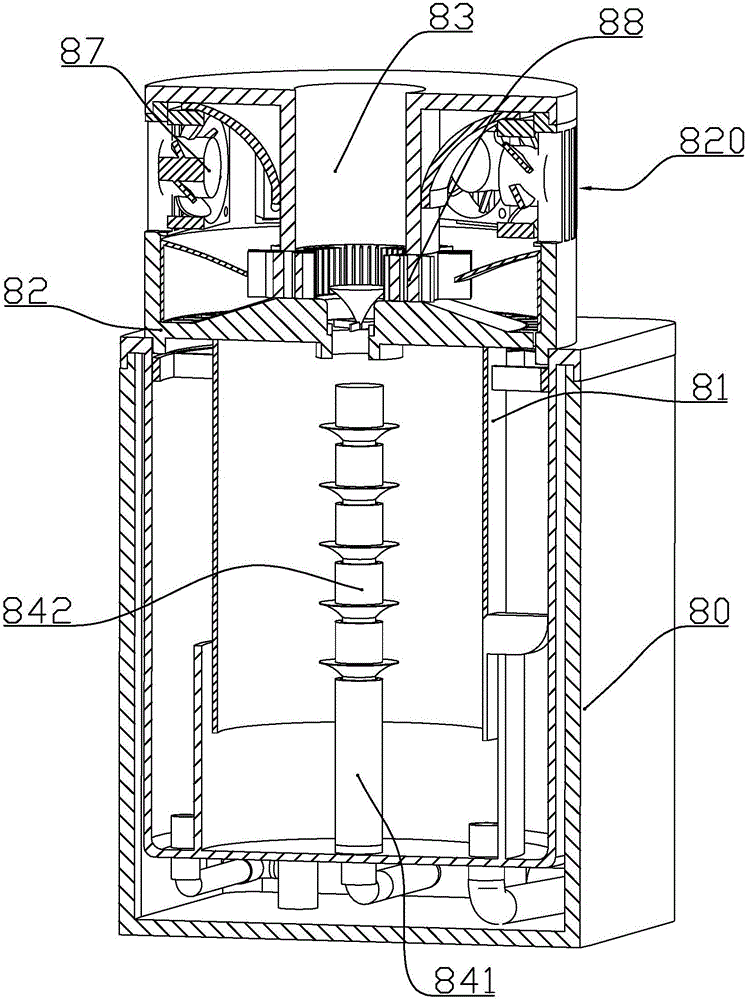

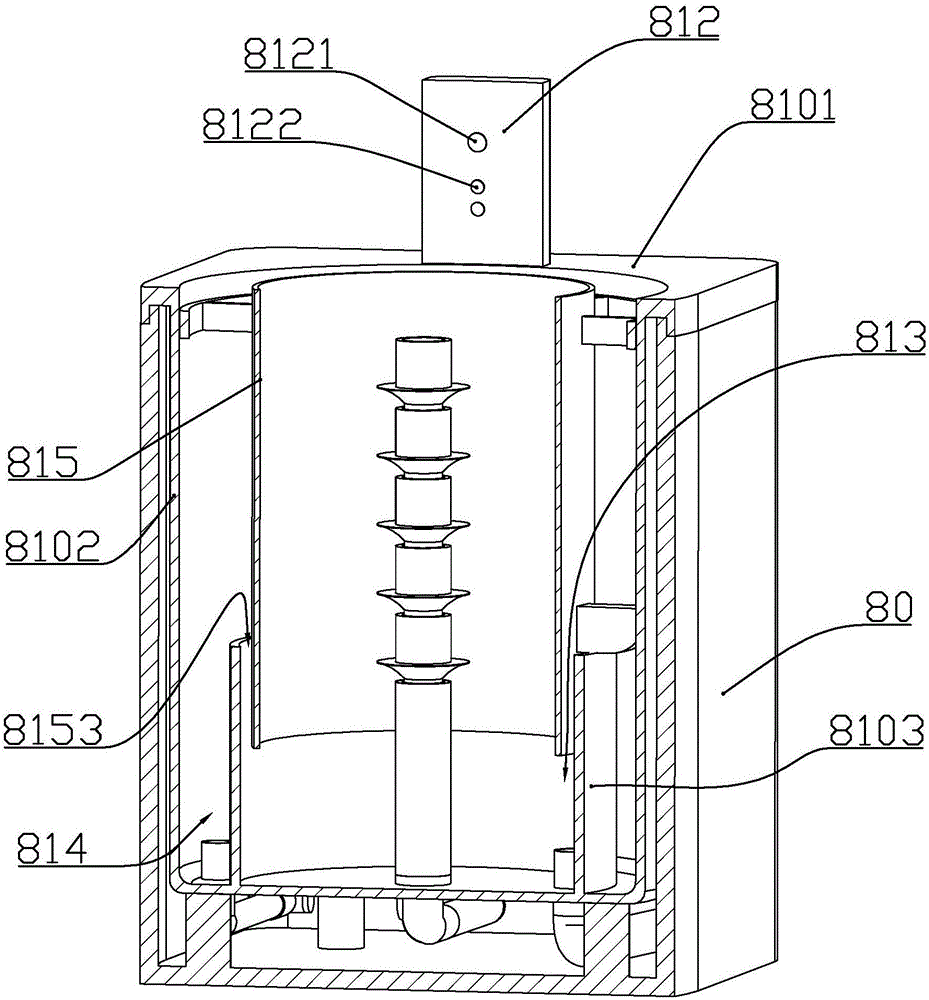

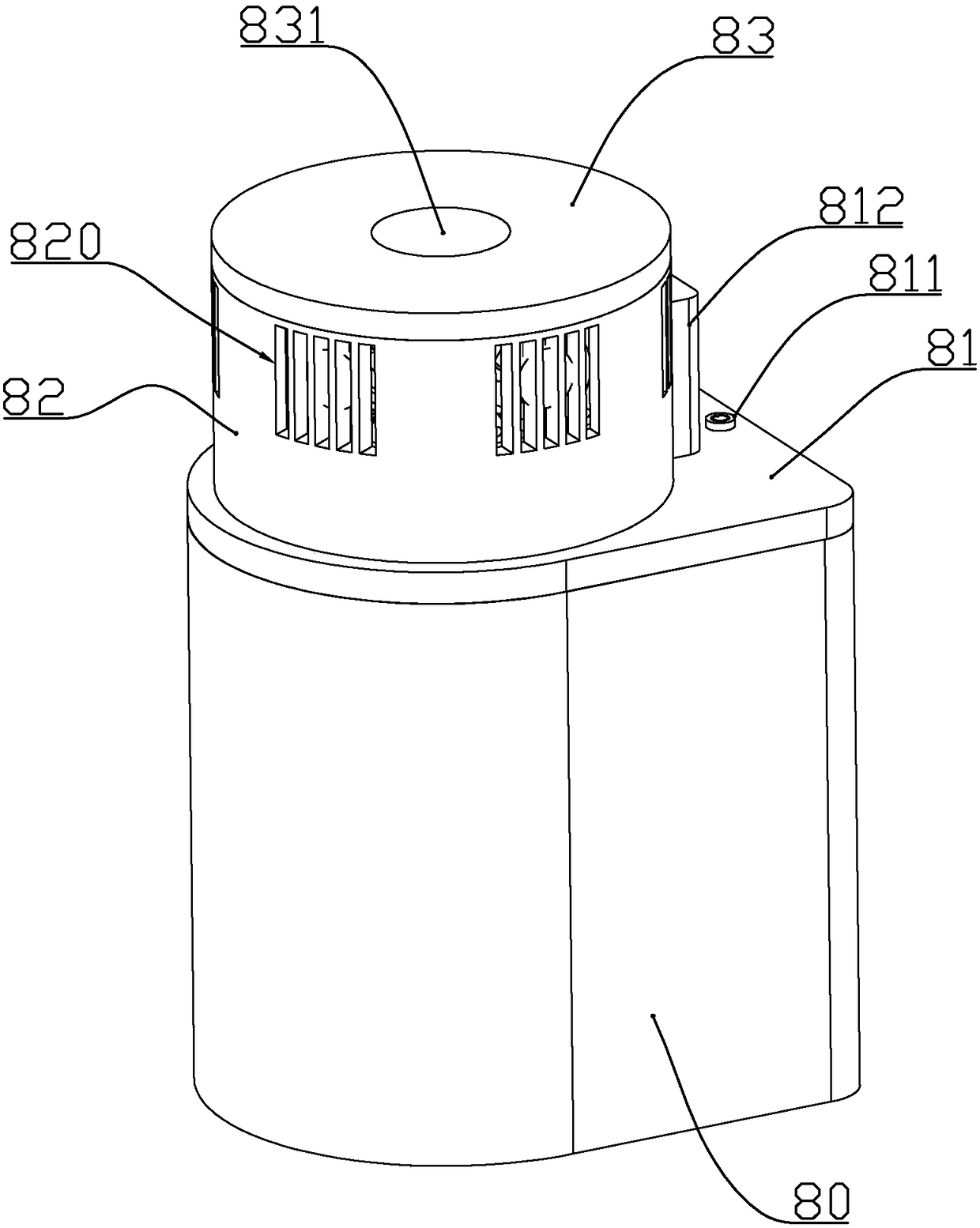

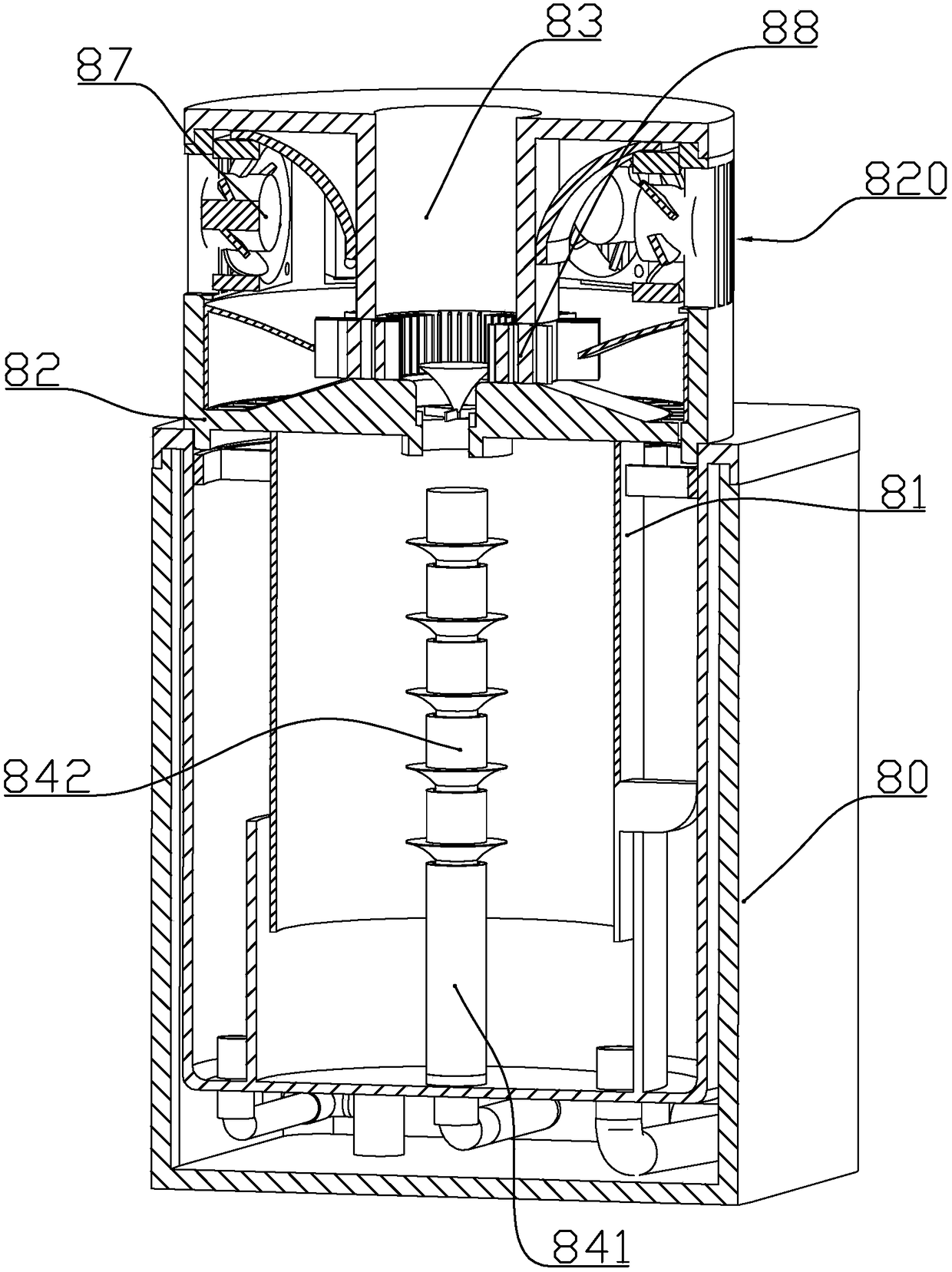

Special cooling dryer for vacuum nitrogen-filled insecticidal sterilization disinfection equipment

PendingCN110465165AProtection lifeAvoid enteringDispersed particle filtrationAir filtrationAir filter

The invention discloses a special cooling dryer for vacuum nitrogen-filled insecticidal sterilization disinfection equipment. According to the special cooling dryer, the main structure of the specialcooling dryer comprises a cooling dryer body, an air filtering mechanism and a heat dissipation mechanism; compressed air is filtered by the air filtering mechanism to prevent the impurities in the air from entering the cooling dryer body so as to improve the cooling drying efficiency; the heat dissipation mechanism performs vibration reducing and heat dissipation on the cooling dryer body, wherein the cooling dryer body is clamped and fixed by a border through a vibration reducing mechanism, and a vibration reducing airbag, a first spring and a rubber rod are retractable structures, such thatthe vibration generated during the working of the cooling dryer body can be absorbed, and the cooling dryer body can be effectively protected; through a first venting hole and heat dissipation fans on the left side, the right side and the rear side, the cooling dryer body is subjected to multi-angle ventilation and heat dissipation, such that the heat of the cooling dryer body can be rapidly dissipated, and the service life of the cooling dryer body can be effectively protected; and through the threaded connection between a threaded filtering main shell body and an installing column, the installing column and an air filtering membrane can be conveniently removed and replaced.

Owner:SHANGHAI HUIHAI VACUUM MASCH EQUIP CO LTD

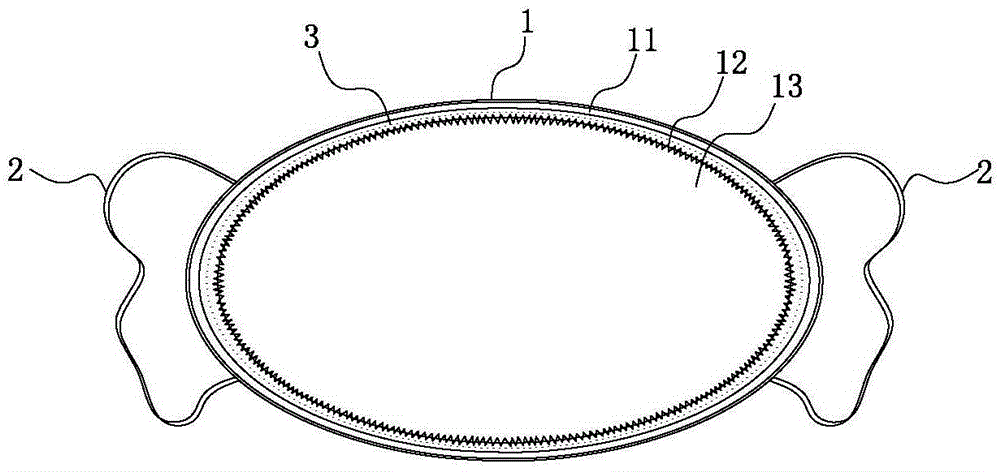

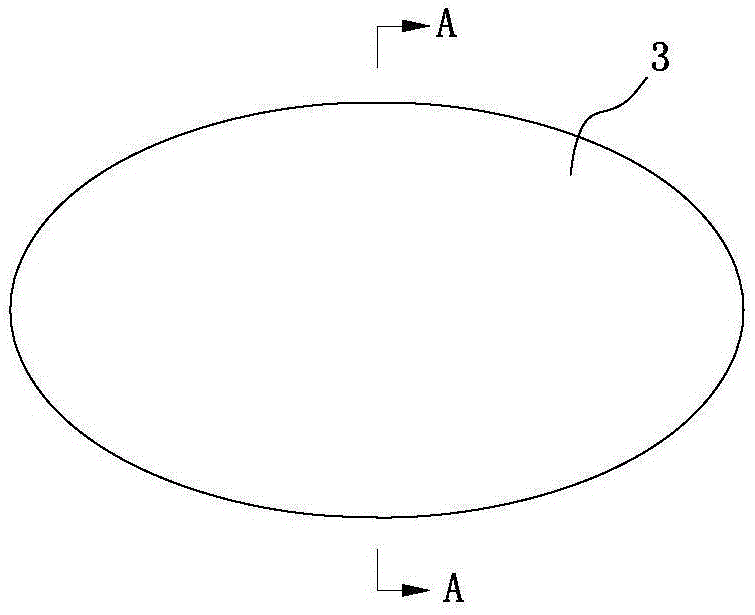

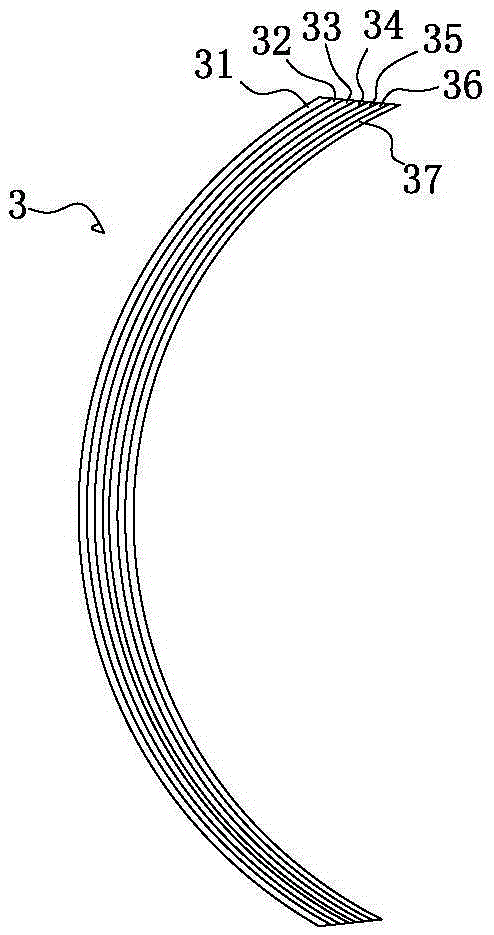

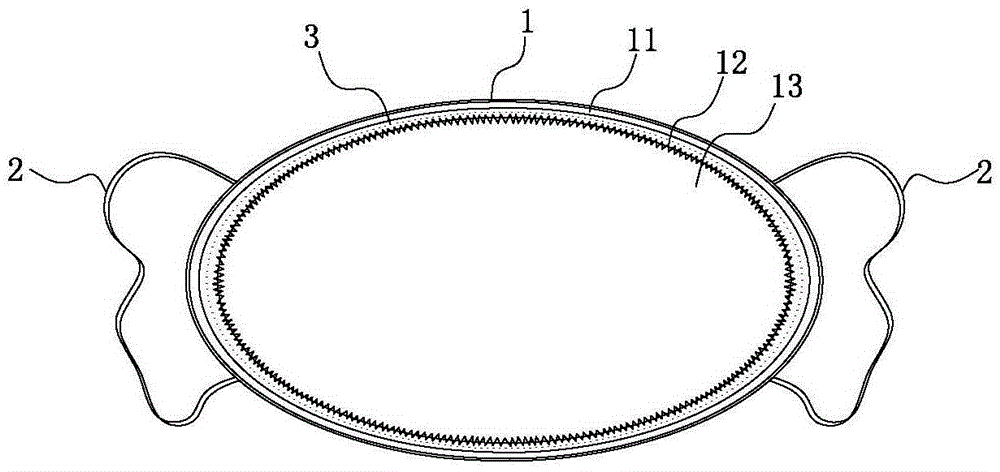

Filtering mask

The invention discloses a filtering mask. The filtering mask comprises a mask body and ear hangers, wherein a soft washer is fixed to the edge of the mask body, and a first filter and a second filter are arranged on the inner side and the outer side of the mask body respectively; the first filter comprises a first non-woven fabric layer, a first PM2.5 filter screen layer, a first silver woven mesh layer, a spice layer, a second silver woven mesh layer, a second PM2.5 filter screen layer and a second non-woven fabric layer which are fixed in sequence; a plurality of air holes are formed in the spice layer, and the first silver woven mesh layer and the second silver woven mesh layer are each provided with a plurality of honeycomb holes which correspond to the air holes; the second filter comprises an aerogel plate, a first bamboo fiber fabric and a second bamboo fiber fabric, and the first bamboo fiber fabric and the second bamboo fiber fabric are fixed to the front side and the back side of the aerogel plate respectively; the outer side of the first filter and the outer side of the second filter are both fixed to the mask body through hidden buttons; the first filter and the second filter are each in a bowl shape, so that a bowl-shaped groove is formed in the inner side of the filtering mask; the soft washer is located at the edge of the bowl-shaped groove. The filtering mask is quite easy and convenient to disassemble and assemble and has a very good filtering effect.

Owner:钟治超

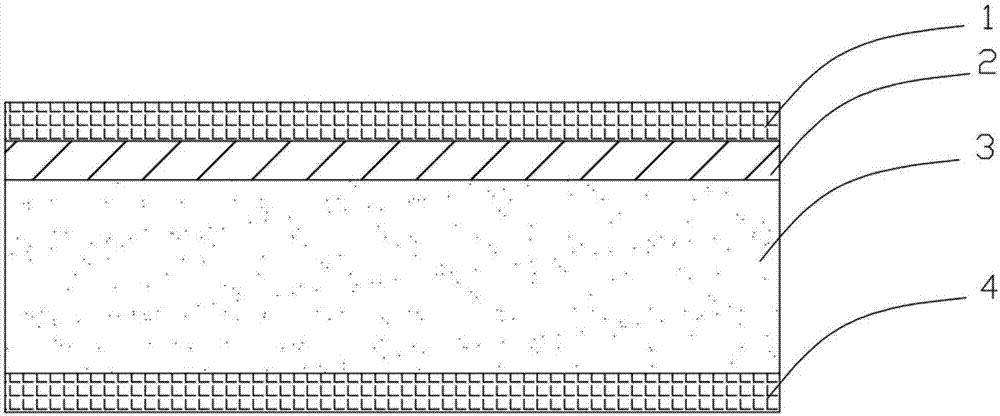

Filter element material for automobile activated carbon air conditioner

InactiveCN107983015ANot easy to breedGood air filtrationGas treatmentAir-treating devicesFiberAir filtration

The invention relates to a filter element material for an automobile activated carbon air conditioner. The filter element material comprises a first protecting net, a dust removal net, filtering cotton and a second protecting net from top to bottom, wherein the dust removal net is a polyurethane fiber fabric, and the surface of the polyurethane fiber fabric is coated with graphene oxide heptanes suspension liquid; the concentration of graphene oxide in the graphene oxide heptanes suspension liquid is 4g / L-8g / L, and the graphene oxide heptane suspension liquid further contains heptane, organicsilicon resin, a polyurethane prepolymer and a curing agent; and the filtering cotton is produced from activated carbon, foamed ceramic particles and graphene processed animal hair. The filter elementmaterial is capable of filtering partial particles with the particle sizes of smaller than 2 microns in air, so that a good air filtration effect is achieved; and meanwhile, the filter element material further has the characteristics that bacteria is unlikely to be bred, and the material can be repeatedly used after being cleaned and is low in economic cost.

Owner:SUZHOU QINGRUI AIR SYST

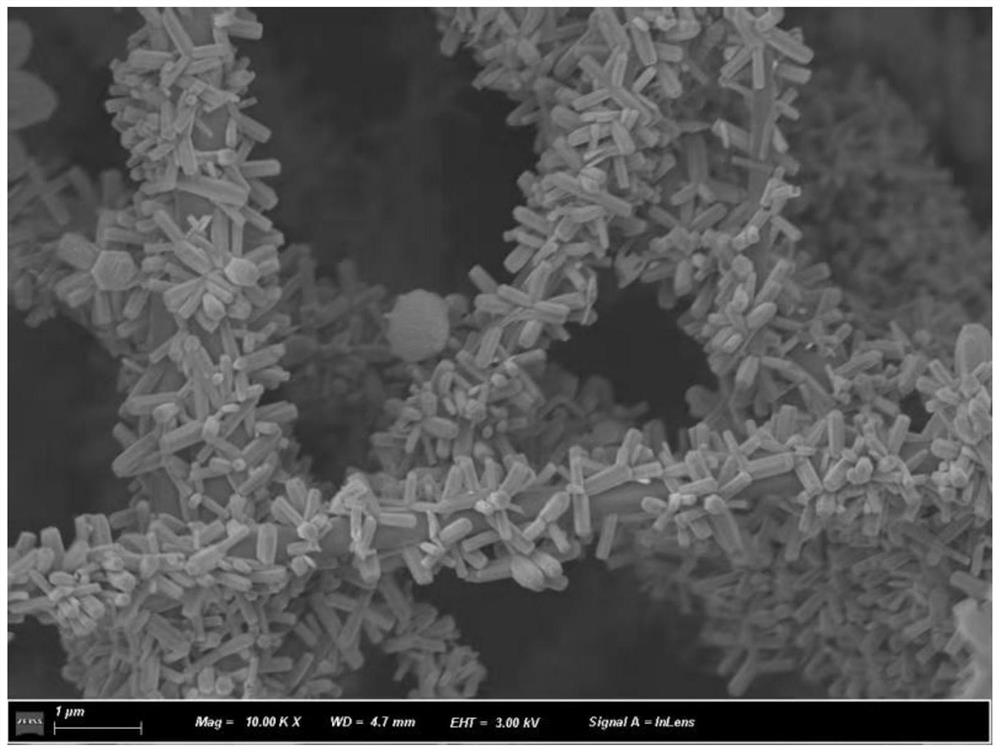

Method for preparing photocatalytic air purification rod-like titanium dioxide particle composite fibrofelt

PendingCN112588284AHigh specific surface areaImprove antibacterial and bactericidal effectBiocidePhysical/chemical process catalystsChemistryMicrofiber

The invention discloses a method for preparing photocatalytic air purification rod-like titanium dioxide particle composite fibrofelt. The method comprises the following steps: preparing a titanium dioxide precursor solution; dispersing the photocatalytic nanoparticles with deionized water, carrying out ultrasonic oscillation to obtain a dispersion liquid, impregnating the fibrofelt in the dispersion liquid for ultrasonic treatment, and performing drying; and putting the fibrofelt into a titanium dioxide precursor solution, and then putting the fibrofelt into a microwave rapid reaction synthesizer for annealing to obtain the composite fibrofelt of which the fiber surface is uniformly coated with the rod-like photocatalytic composite nanoparticles. The titanium dioxide particles in a form of precursor mixed liquid are dispersed and attached to the surfaces of fibers, and photocatalytic particles are uniformly loaded and tightly coated with a special three-dimensional network structure of the composite fibrofelt, so that the specific surface area of original single superfine fibers is increased; and the contact area of the catalyst and bacteria and microorganisms and the number of active sites participating in oxidation-reduction reaction are increased, microbial particles in air are captured more efficiently to achieve rapid photocatalytic response, and photocatalytic antibacterial inactivation is achieved.

Owner:重庆纤维研究设计院股份有限公司

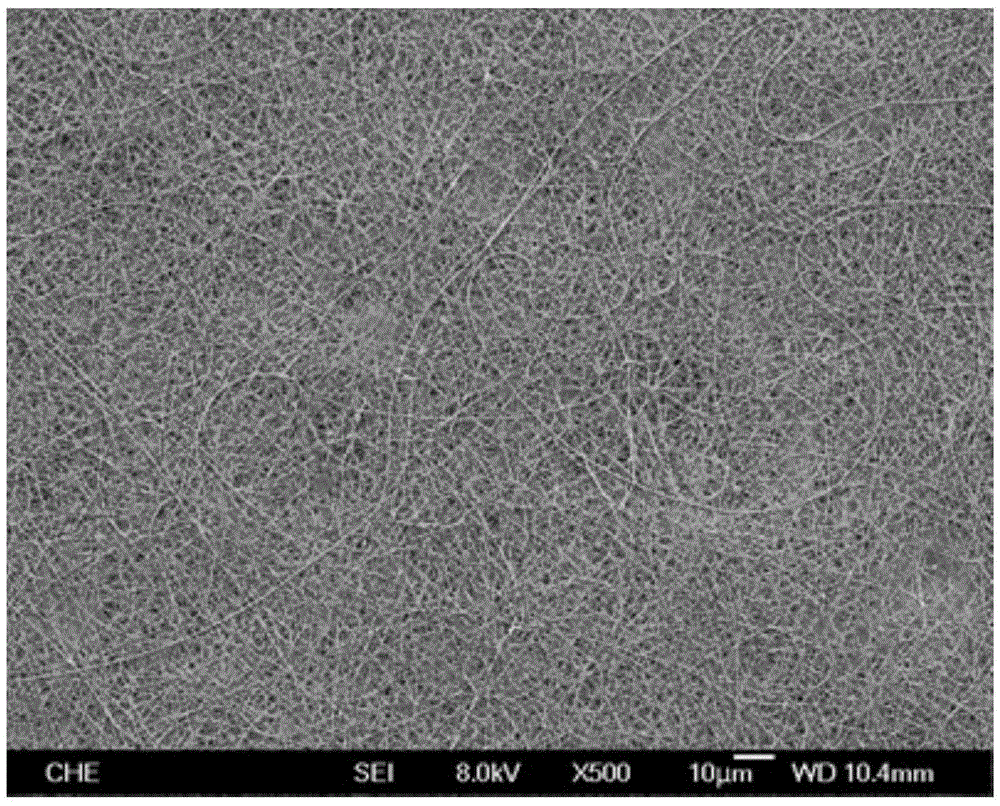

Method for preparing composite nanofibers, prepared composite nanofibers, filtering layer body, and mask with the filtering layer body

InactiveCN105821493AEasy to blockGood air filtrationSynthetic resin layered productsFilament/thread formingAir filtrationFiber

A method for preparing composite nanofibers includes the following steps: providing an electrospinning solution which includes polymethyl methacrylate or its derivatives, chitosan, oligomer adsorbent and a solvent, and the solvent including formic acid; and forming a plurality of nanofibers by performing electrospinning on the electrospinning solution. The invention also provides the nnaofibers with the diameter less than 250nm prepared by the method. The nanofibers prepared by the invention method have thinner diameter, and a mask with a good air filtration effect can be prepared without additionally applying electrostatic treatment to a basic layer or adding active carbon, and the preparation cost is saved.

Owner:粘誉薰

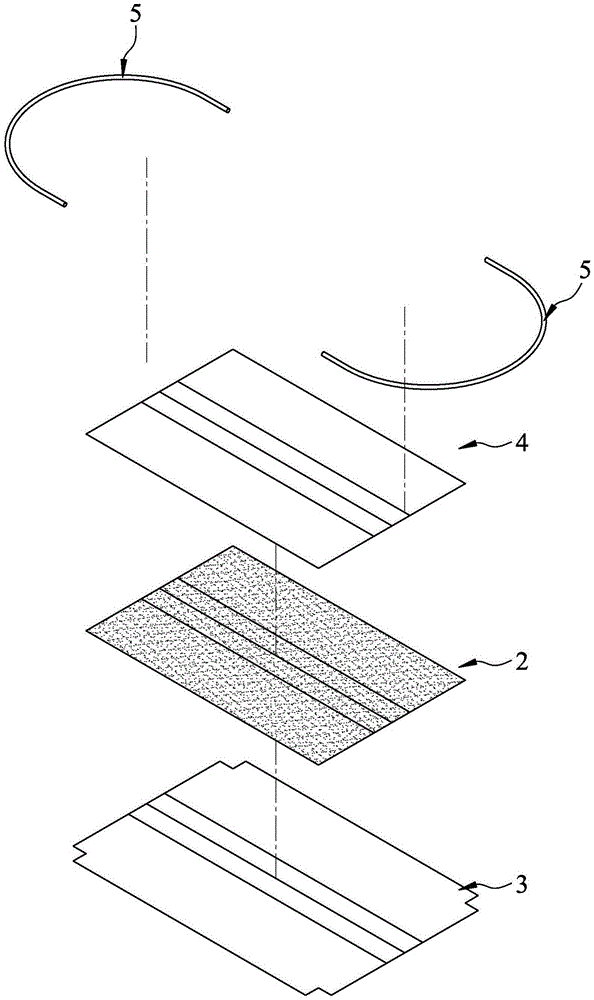

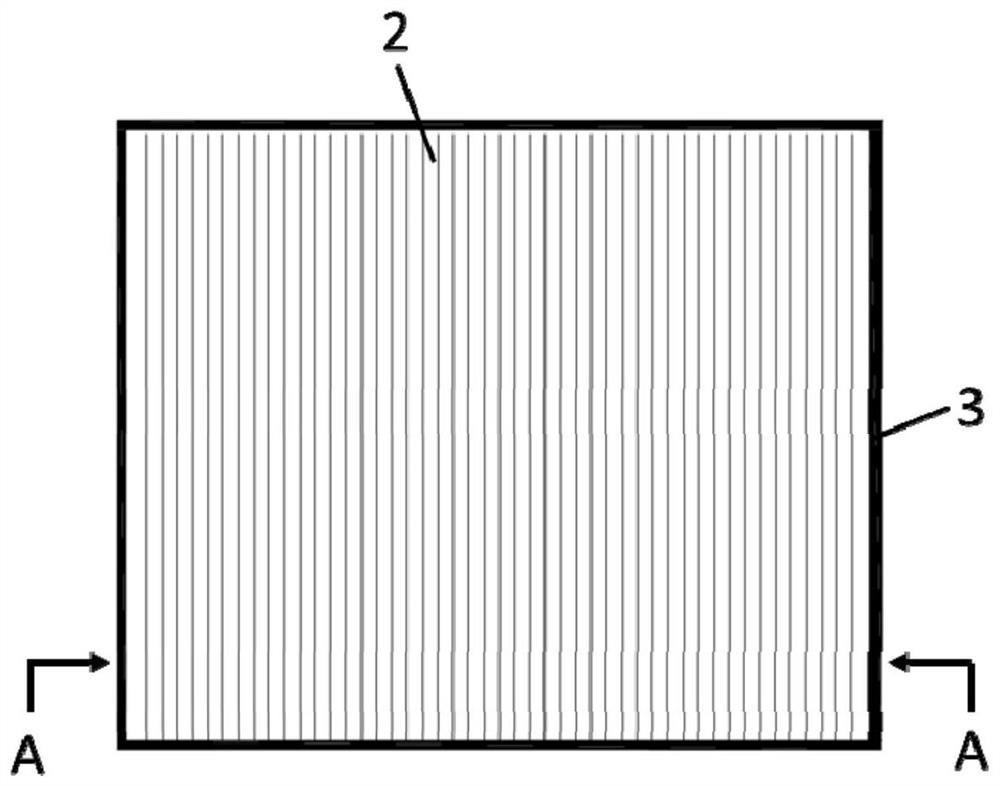

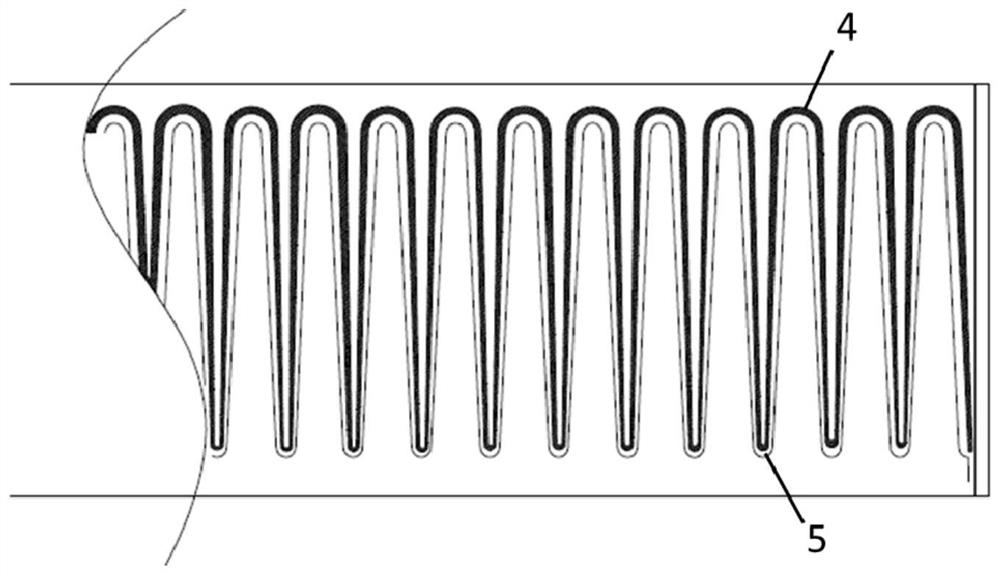

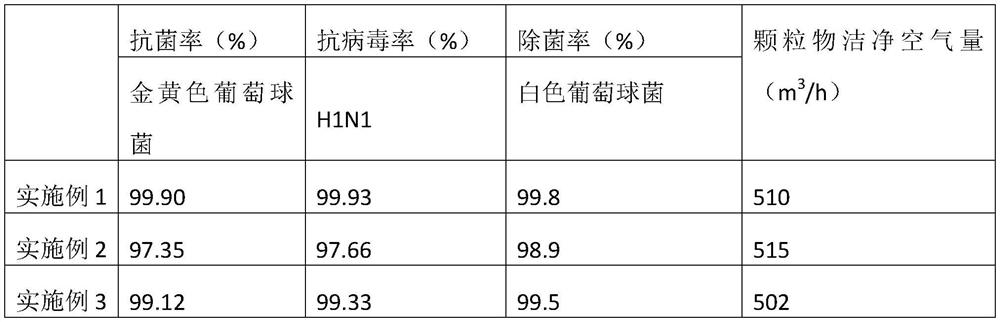

Air conditioner purification filter screen and air conditioner

InactiveCN112439274AImprove filter qualityGrowth inhibitionMechanical apparatusDispersed particle filtrationMicroorganismIndoor air quality

The invention discloses an air conditioner purification filter screen and an air conditioner; the air conditioner purification filter screen comprises a filter main body and a frame for fixing the filter main body, the filter main body is formed by superposing, compounding and pleating an antibacterial and antiviral non-woven fabric and electret melt-blown non-woven fabric, the antibacterial and antiviral non-woven fabric is formed by polymer fibers with the surfaces loaded with silver-loaded copper zeolite. Therefore, the air conditioner purification filter screen has antibacterial and antiviral performance and fine particulate matter filtering performance, the air filtering quality can be remarkably improved; meanwhile, breeding of microorganisms on the filter screen can be effectively avoided, the service life of the filter screen is prolonged, secondary pollution to indoor air is avoided, indoor air quality is destroyed, and human health is affected.

Owner:HISENSE (GUANGDONG) AIR CONDITIONER

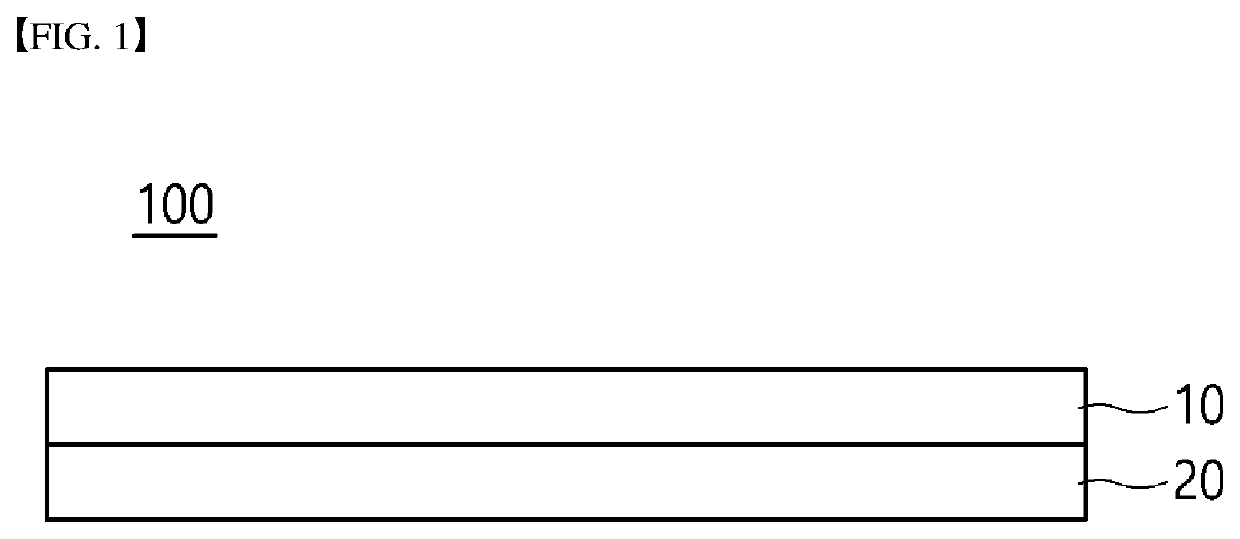

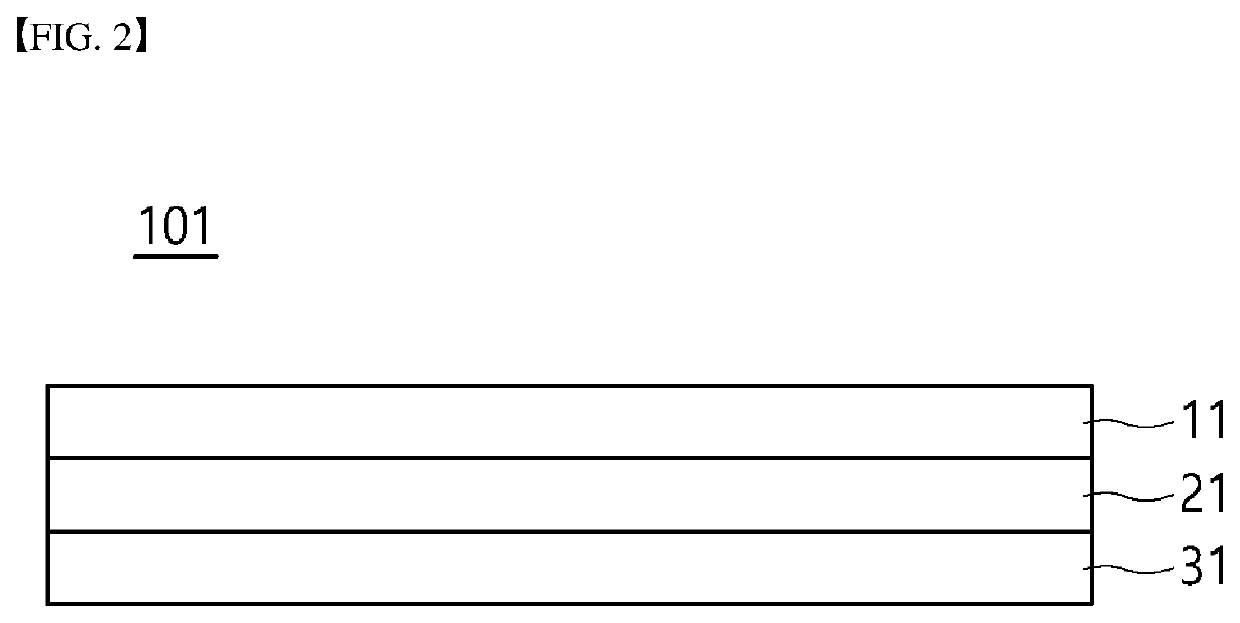

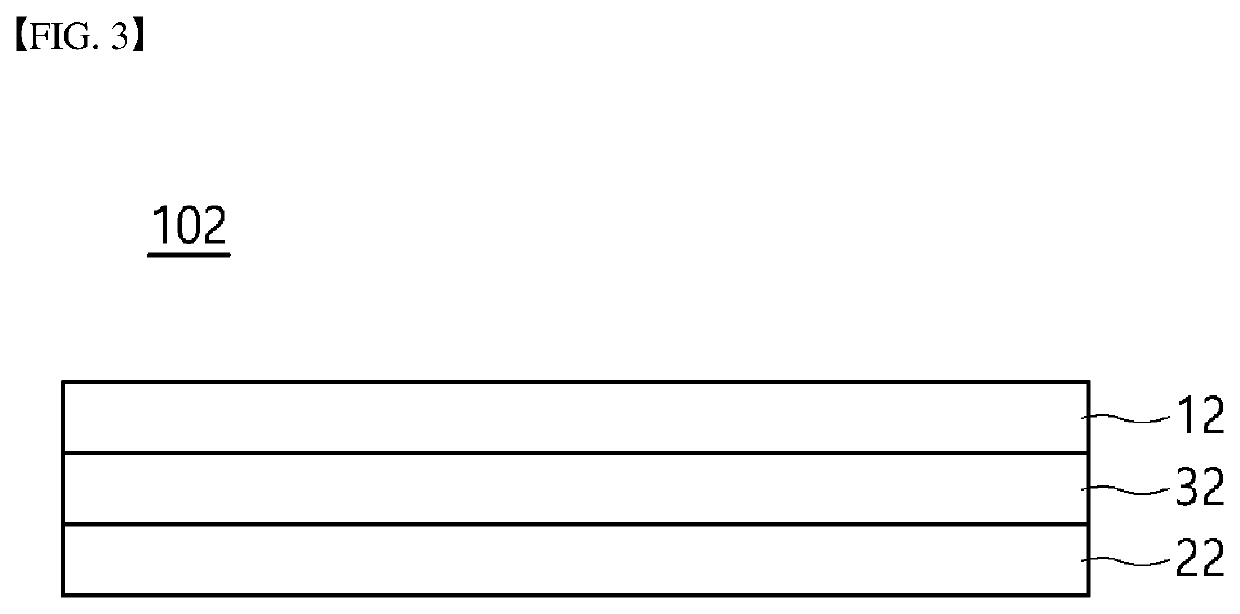

Filter medium and composite filter including same

PendingUS20220347609A1Good air filtrationInhibit deteriorationDispersed particle filtrationBreathing filtersAir filterFilter media

Provided is a filter medium. A filter medium according to an embodiment of the present invention comprises: a first porous support body which has been electrostatically treated; and a nanofiber web which is disposed on one surface of the first support body and formed by accumulating nanofibers. Accordingly, excellent air filtering efficiency is obtained even for fine dust of PM 2.5 or below, and furthermore, deterioration in air filtering efficiency may be prevented or minimized even when usage is extended for a long period of time. Therefore, the filter medium and the composite filter according to an embodiment of the present invention can be widely utilized as media of filters for various air filtering devices.

Owner:AMOGREENTECH CO LTD

Gas-phase filter material and filter unit

PendingCN110613978AImprove the capture effectImprove capture capacitySemi-permeable membranesMembranesMicro nanoParticulates

The invention provides a gas-phase filter material and a filter unit, and belongs to the technical field of air filtration. According to the gas-phase filter material, a breathable covering layer, a pre-trapping layer, a main trapping layer and a breathable support layer are sequentially laminated from the upstream side of an air flow; the main trapping layer comprises a porous PLA micro-nano fiber membrane doped with rGO-g-PLLA nano particles. The filter unit comprises the gas-phase filtering material and a frame body. The filter material and the filter unit are simple and feasible to prepare, high in yield and capable of increasing the softness of the surfaces of the micro-particles, so that the micro-particles are easier to swell and modify. The porous PLA micro-nano fiber membrane forthe main trapping layer of the gas-phase filter material is small in fiber diameter, large in specific surface area and large in pore volume; the gas-phase filter material has excellent mechanical properties, antibacterial activity and high-temperature resistance, has strong trapping capability on particulate matters such as PM2.5, reduces the resistance pressure, and also has excellent air filtering performance when the thickness of the main trapping layer is relatively low.

Owner:宋恩

Formula of polyurethane foaming product with good air filtering effect

InactiveCN111957108AModification speed is fastGood air filtrationDispersed particle filtrationCarbon fibresIsocyanatePolymer chemistry

The invention discloses a formula of a polyurethane foaming product with a good air filtering effect. The formula comprises isocyanate, polyether, glycerol, a catalyst, a flame retardant, a modified reinforced fiber net, an auxiliary additive, isopropanol, a binder, palygorskite and sepiolite. Bamboo fibers, carbon fibers and a filter screen pipe are interwoven to form a mixed weaving fiber net structure. A plant leaf and stem extracting solution in the soaking solution enters pores of the mixed woven fibers; air entering the mixed weaving fiber net structure is purified and deodorized; a composite salt solution is used as a cosolvent, so that the plant leaf and stem extracting solution can be accelerated to enter pores of the mixed woven fibers, the modification speed is increased, alkaline metal ions contained in the composite salt solution can play a role in sterilization and disinfection, and the filtering effect is optimized; palygorskite and sepiolite are added into a finished polyurethane foaming product, impurities in air are adsorbed by means of the unique layer chain structure characteristic and the nano scale hole channel microstructure of palygorskite and sepiolite, andthe filtering effect is better.

Owner:宁波耀众模塑科技有限公司

Improved filter gauze mask

InactiveCN105595470AEasy to assemble and disassembleGuaranteed filtering effectGarment special featuresProtective garmentHEPAFiber

The invention discloses an improved filter gauze mask which comprises a gauze mask main body and ear hooks. A soft gasket is fixed at the edge of the gauze mask main body, and the inner side and the outer side of the gauze mask main body are provided with a first filter sheet and a second filter sheet respectively; the first filter sheet comprises a first non-woven fabric layer, a first HEPA filter screen layer, a first silver woven mesh layer, a Chinese herbal medicine layer, a second silver woven mesh layer, a second HEPA filter screen layer and a second non-woven fabric layer which are sequentially fixed, wherein the Chinese herbal medicine layer can prevent a cold and comprises a gauze bag and granular Chinese herbal medicines placed in the gauze bag; the second filter sheet comprises an aerogel plate, first bamboo fiber and second bamboo fiber cloth, wherein the first bamboo fiber and the second bamboo fiber cloth are fixed to the obverse side and the reverse side of the aerogel plate respectively; the outer side of the first filter sheet and the outer side of the second filter sheet are both fixed with the gauze mask main body through hook and loop fasteners, the first filter sheet and the second filter sheet are each shaped like a bowl, a bowl-shaped groove used for being connected with the mouth of a human body in a butt-joint mode is formed in the inner side of the filter gauze mask, and the soft gasket is located at the edge of the bowl-shaped groove. The improved filter gauze mask is very easy and convenient to disassemble and assemble and has the excellent filter effect.

Owner:钟治超

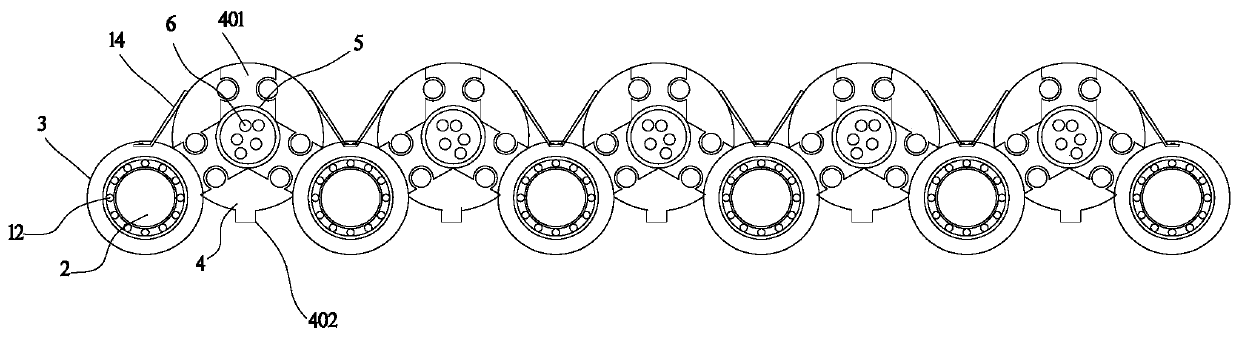

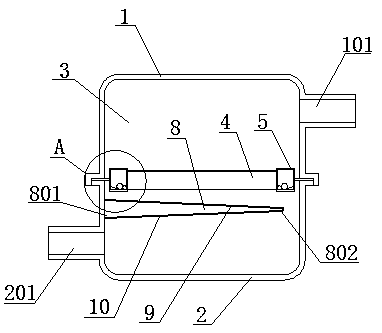

Water curtain forming device

InactiveCN105910203AGood air filtrationSimple structureLighting and heating apparatusUsing liquid separation agentWater flowEnvironmental engineering

The invention discloses a water curtain forming device. The water curtain forming device comprises a first spray pipe and a plurality of water curtain generators which are connected to the upper end of the first spray pipe in series in the longitudinal direction. When the water curtain forming device operates, water flows into the first spray pipe, sequentially flows into the lower pipe portion of each water curtain generator and flows out of the upper pipe portion of the water curtain generator to the next adjacent water curtain generator; and a part of the water is sprayed out of an annular water outlet gap when the water flows to the next water curtain generator, and the sprayed water can flow to an inward-concave inverted-cone-shaped water curtain forming wall along the outer wall surface of the lower pipe portion and is sprayed out through the water curtain forming wall to form a water curtain.

Owner:山东纳赫汽车零部件有限公司

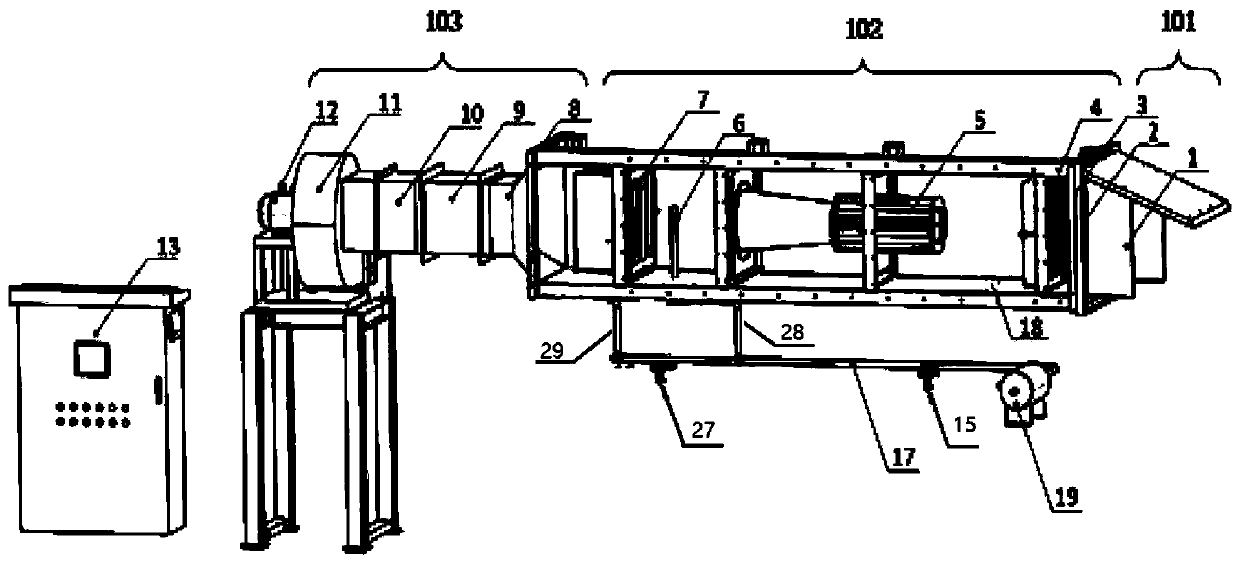

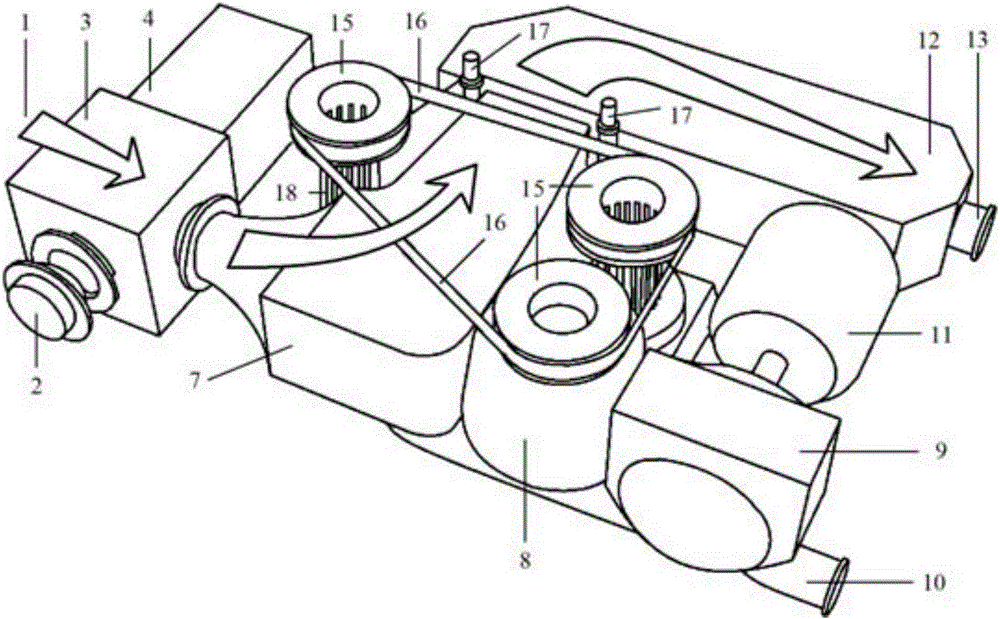

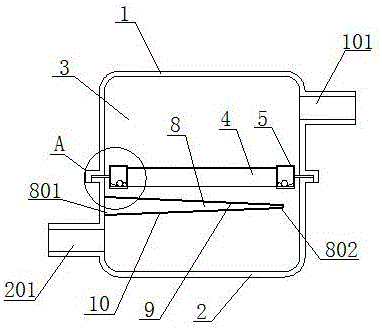

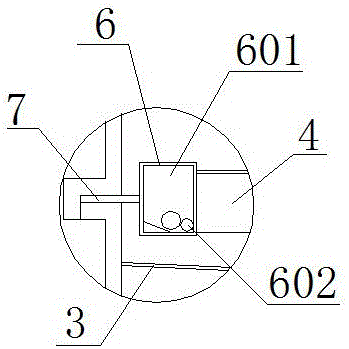

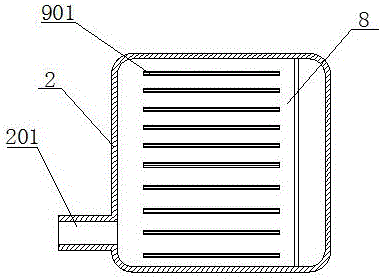

Air filter of engine

ActiveCN106286032ATroubleshoot clogged filter elementsExtend the life cycleCombustion-air/fuel-air treatmentMachines/enginesAir filterImpurity

The invention discloses an air filter of an engine. The air filter comprises an upper casing and a lower casing, wherein a filtering element is arranged in the middle part of a filtering cavity; the periphery of the filtering element is fixedly arranged in the filtering cavity through a fixing device; the fixing device comprises a vibration bin and an elastic skirt; a hollow dust dropping plate is arranged in the filtering cavity and is positioned under the filtering element; one end of the dust dropping plate is fixedly connected with the wall surface of one side of the lower casing to form a support end, and a gap is reserved between the other end of the dust dropping plate and the wall surface of the other side of the lower casing to form a free end of the dust dropping plate. The air filter has the advantages that by designing the vibration bin, dust and impurities adhered onto the filtering element can fall down, and the problem of blockage of the filtering element by the dust is solved; by arranging the dust dropping plate, when the noise is reduced, the dust falling from the filtering element due to vibration can be collected, the use cycle of the filtering element is prolonged, and the filtering element does not need to be frequently replaced; the self-cleaning capacity of the air filter is improved, and the air filter gas good air filtering capacity.

Owner:浙江荣际汽车零部件股份有限公司

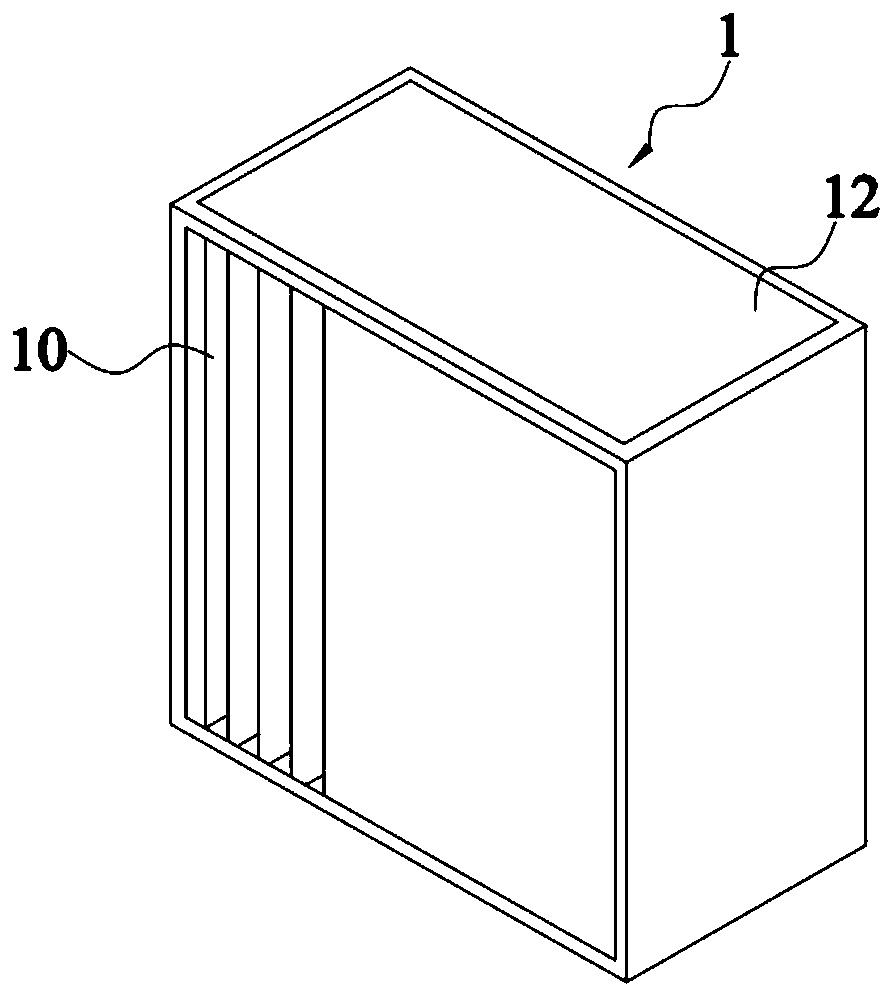

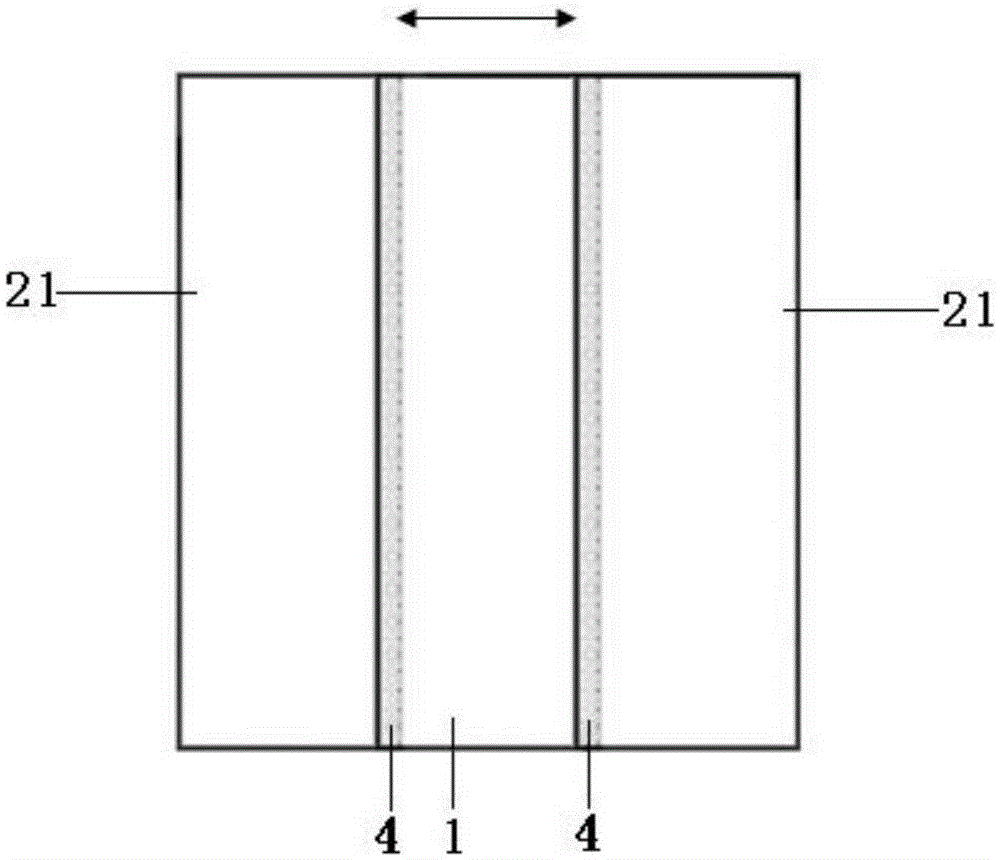

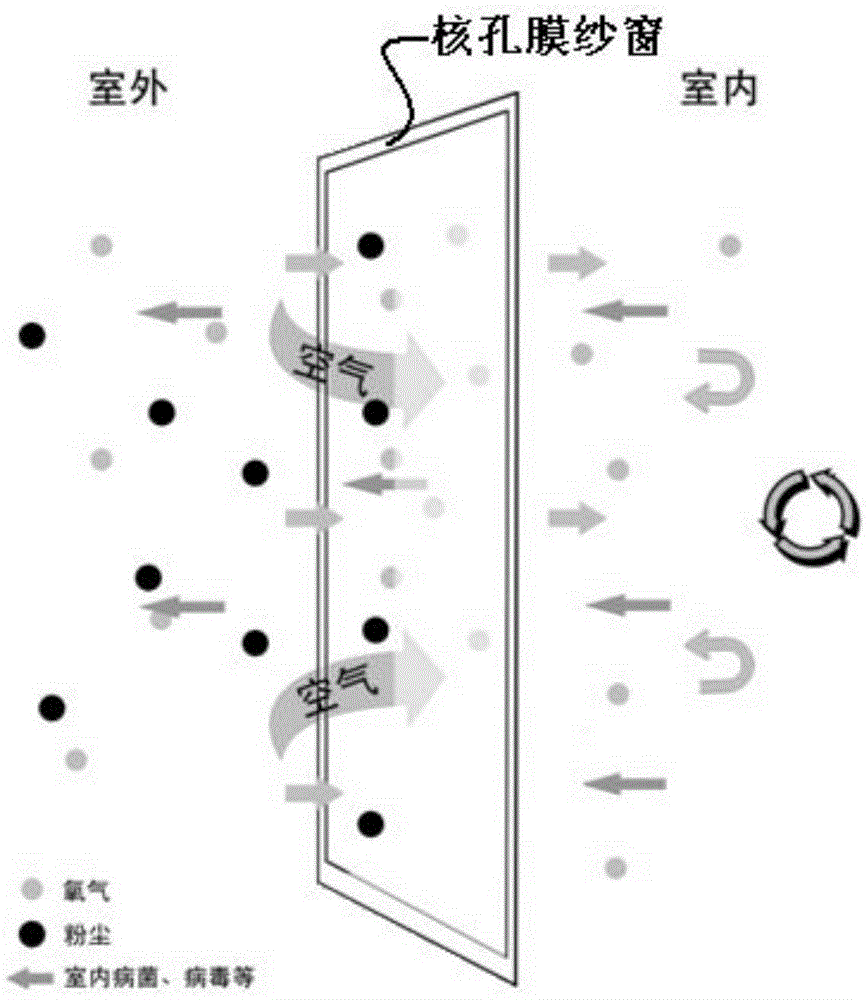

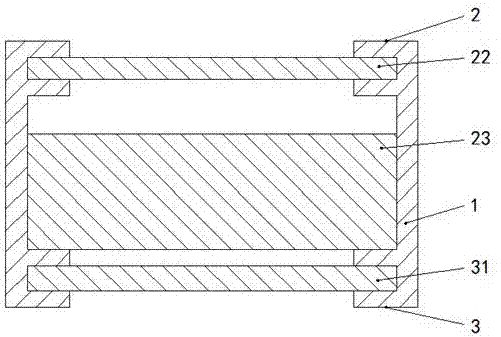

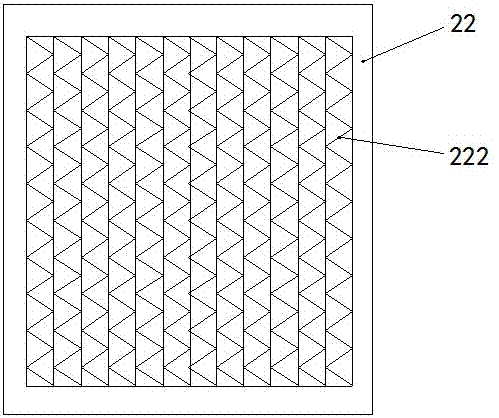

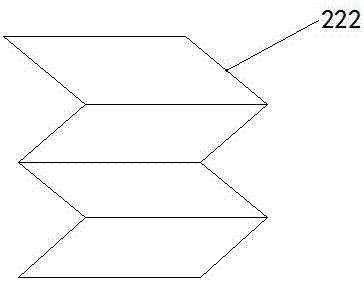

A kind of preparation method of nuclear pore veil, nuclear pore veil window and nuclear pore veil

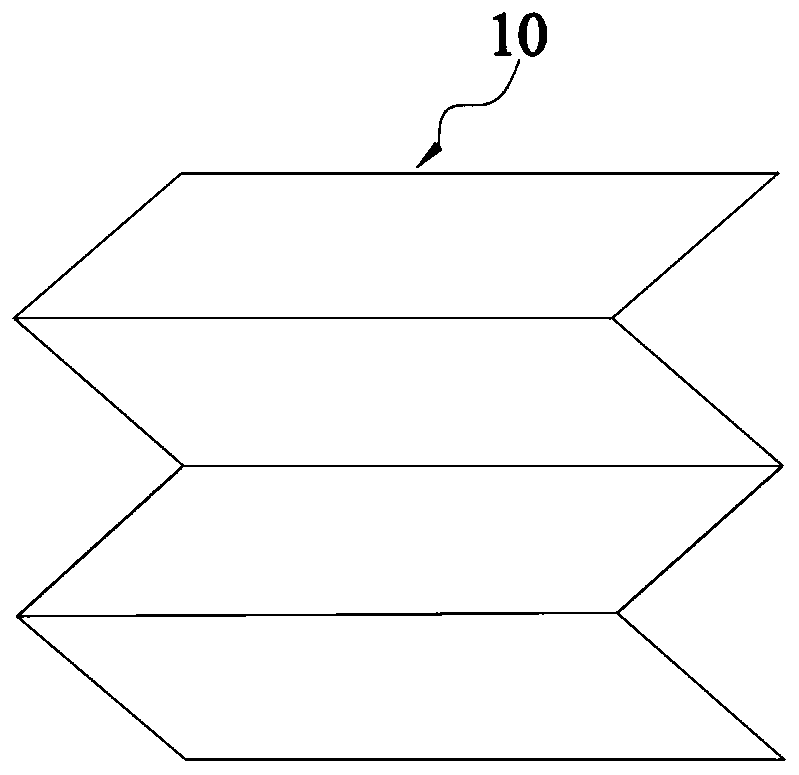

ActiveCN103587172BHigh mechanical strengthExtended service lifeSynthetic resin layered productsInsect protectionAir filtrationYarn

The invention discloses a nuclear track membrane screen, a nuclear track membrane screen window and a preparation method of the nuclear track membrane screen, wherein the nuclear track membrane screen comprises a nuclear track membrane layer, an extension layer for increasing the superficial area of the nuclear track membrane layer, and a supporting layer for supporting the nuclear track membrane layer and the extension layer, wherein the nuclear track membrane layer, the extension layer and the supporting layer are sequentially overlapped. According to the invention, the nuclear track membrane layer, the extension layer and the supporting layer are combined together to obtain the wide nuclear track membrane screen having the advantages of high mechanical strength, long service life and good air filtering effect. The area of the nuclear track membrane screen can be specifically chosen according to the practical requirement. The nuclear track membrane screen can prevent outdoor atmospheric pollutants from entering indoors and meanwhile allows indoor pollutants to flow outdoors during air exchange, so that the concentrations of indoor pollutants are greatly reduced. The nuclear track membrane screen is convenient to use and transport; the industrial application is convenient.

Owner:陈武 +2

Low-cost and environment-friendly type meltblown polypropylene electret air filter material and preparation method thereof

InactiveCN106268039AImprove charge stabilitySmall filter resistanceDispersed particle separationMembrane filtersWaxIon

The invention discloses a low-cost and environment-friendly type meltblown polypropylene electret air filter material. The low-cost and environment-friendly type meltblown polypropylene electret air filter material comprises raw material components in parts by weight as follows: 50-60 parts of polypropylene, 9-16 parts of silicon monoxide, 11-17 parts of powdered activated carbon, 1-4 parts of a 3-aminopropyltriethoxysilane coupling agent, 0.6-1.3 parts of glacial acetic acid, a proper amount of deionized water, 1-2.5 parts of low-density polyethylene wax, 0.5-2 parts of antioxidant 1010, 0.7-1.4 parts of a titanate coupling agent, 2-5 parts of peanut hulls, 3-5 parts of zeolite powder, a proper amount of petroleum ether and a proper amount of absolute ethyl alcohol. Silicon nanowires containing alpha-quartz are prepared and added to a meltblown polypropylene electret material, so that the material has excellent filter efficiency and a bacterial reproduction inhibiting function; the silicon nanowires treated with the silane coupling agent are supported by the activated carbon, the silicon nanowire supporting quantity of the activated carbon is increased, and the adsorption of hazardous substances in the air by the filter material is improved effectively.

Owner:中安丰磊环境科技股份有限公司

Air filtration glass fiber cotton composite material of series F5-F9 and manufacturing method thereof

ActiveCN103657258BIncreased durabilityHigh strengthLaminationLamination apparatusAir filtrationAcrylic resin

The invention discloses an air filtration glass fiber cotton composite material of series F5-F9. The air filtration glass fiber cotton composite material comprises non-woven cloth and a glass fiber cotton layer combined on the surface of the non-woven cloth through an adhesive material, wherein the non-woven cloth is 0.05-0.1mm thick; the glass fiber cotton layer is 0.25-1.5 mm thick and consists of glass fiber cotton with the diameter of 0.75-1.25 microns; the adhesive material is acrylic resin. A method for preparing the composite material comprises the steps of mixing and smelting proper amount of zinc oxide, borax, white sand, potash feldspar powder, pure alkaline, calcite, potassium carbonate and barium carbonate, performing primary fiber forming and then dragging the fibers through high-temperature and high-speed air flow to obtain the glass fiber cotton; dispersing the glass fiber cotton on the surface of the non-woven cloth, spraying glue, and drying to obtain the product. The air filtration glass fiber cotton composite material disclosed by the invention is high in intensity and high in filtration performance and has wide application prospects; due to the preparation method, the performance of the air filtration glass fiber cotton composite material can be further guaranteed.

Owner:CHONGQING ZAISHENG TECH CORP

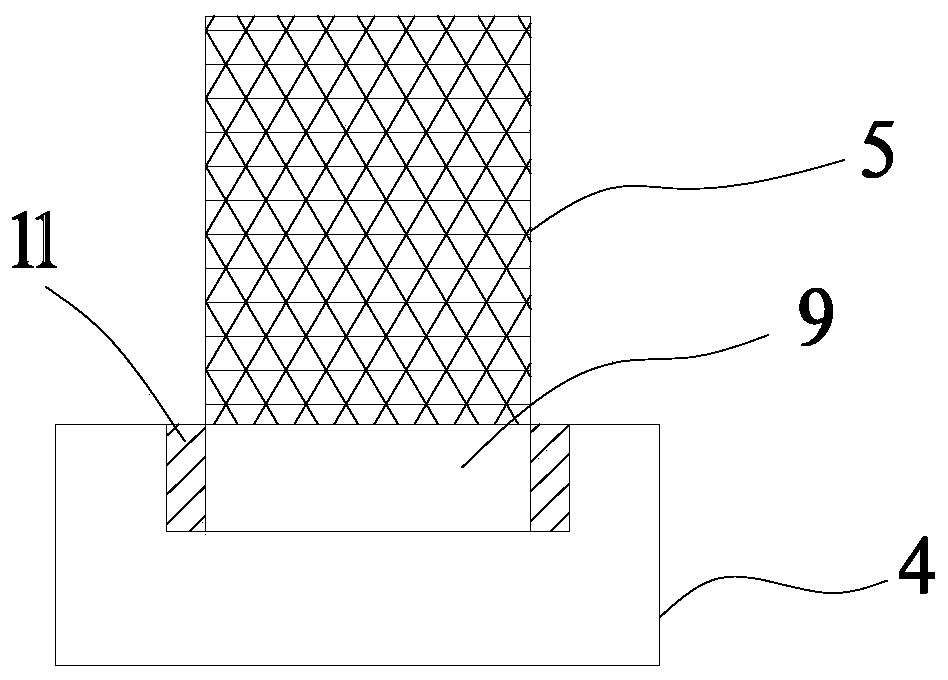

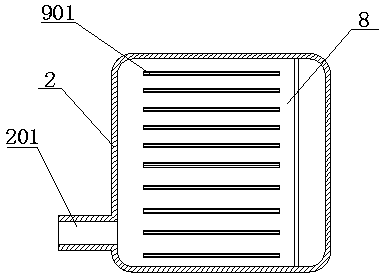

Air filtering window

ActiveCN109930970AEasy to cleanGood air filtrationDispersed particle filtrationVentilation arrangementAgricultural engineeringFilter material

Owner:东阳市君泰建筑工程有限公司

A water curtain forming device

InactiveCN105910203BGood air filtrationSimple structureLighting and heating apparatusUsing liquid separation agentWater flowEngineering

The invention discloses a water curtain forming device. The water curtain forming device comprises a first spray pipe and a plurality of water curtain generators which are connected to the upper end of the first spray pipe in series in the longitudinal direction. When the water curtain forming device operates, water flows into the first spray pipe, sequentially flows into the lower pipe portion of each water curtain generator and flows out of the upper pipe portion of the water curtain generator to the next adjacent water curtain generator; and a part of the water is sprayed out of an annular water outlet gap when the water flows to the next water curtain generator, and the sprayed water can flow to an inward-concave inverted-cone-shaped water curtain forming wall along the outer wall surface of the lower pipe portion and is sprayed out through the water curtain forming wall to form a water curtain.

Owner:山东纳赫汽车零部件有限公司

Mask capable of preventing fog on glasses

The invention discloses a mask capable of preventing fog on glasses. According to the technical scheme, the mask is characterized in that independent inhaling and exhaling flow passages are provided so that exhaled gas flows along the designed pass without flowing above the nose, and fogging of glasses is avoided accordingly; in order to prevent increase in inhalation resistance due to the designof the independent flow passages, a special breath assist is provided which comprises a chamber, an elastic balloon is arranged in the chamber and is connected with an exhaling tube, the chamber is connected with an inhaling tube, the exhaling tube is connected with an exhaling tube control device, the balloon enlarges when exhaling is performed via the exhaling tube, air in the chamber may be discharged into the inhaling tube for a user to breathe, the exhaling tube control device discharges the gas in the balloon after single breathing, external air enters the chamber under the action of pressure difference since the balloon diminishes, and assisted breathing is achieved accordingly. The mask of the invention can prevent fogging of glasses to maximum extent and can assist in breathing.

Owner:南通汇优洁医用材料有限公司

air filter windows

ActiveCN109930970BLess dead endsEasy to cleanDispersed particle filtrationVentilation arrangementAir filtrationAir filter

Owner:东阳市君泰建筑工程有限公司

A kind of preparation method of antibacterial meltblown non-woven fabric

ActiveCN111424428BMany gapsFluffy structurePhysical treatmentBiochemical fibre treatmentPolymer scienceNonwoven fabric

The invention relates to the technical field of non-woven fabrics, and provides a method for preparing an antibacterial melt-blown non-woven fabric, comprising the following steps: (1) performing oxygen plasma treatment on a polypropylene non-woven fabric, and then grafting and modifying it to obtain Modified polypropylene non-woven fabric; (2) using propylene diamine and methyl methacrylate as raw materials, polymerized into an amino-terminated hyperbranched polymer, and then through the polycondensation reaction of carboxymethyl chitosan and amino-terminated hyperbranched polymer The prepared modified hyperbranched polymer; (3) adding the cupric chloride solution to the modified hyperbranched polymer aqueous solution, dripping the sodium borohydride solution under nitrogen protection and ice bath conditions, and adding the modified polymer solution after the reaction. The propylene non-woven fabric is immersed in the modified hyperbranched polymer aqueous solution, and dried to obtain an antibacterial melt-blown non-woven fabric. The present invention solves the problem that the prior art melt-blown non-woven fabric has only high-efficiency filtering effect and no antibacterial property.

Owner:FUJIAN HENGAN HLDG CO LTD +2

Anti-fogging mask for glasses

InactiveCN106820345BEasy to carryPlay a filtering effectFire rescueRespiratory apparatusRespiratorInhalation

The invention discloses a mask with a function of preventing glasses from fogging. The technical scheme of the mask is characterized in that independent inhaling and exhaling flow channels are formed, so that exhaled gas flows out according to the designed channel and cannot flow to the position above the nose, and fogging of the glasses is avoided; in order to solve the problem of increase of inhaling resistance caused by design of the independent flow channels, a special breathing assistant device is arranged and comprises a cavity, an elastic air bag is arranged in the cavity and connected with an exhaling tube, the cavity is connected with an inhaling tube, the exhaling tube is connected with an exhaling tube control device, when a person exhales through the exhaling tube, the air bag expands to enable air in the cavity to be discharged into the inhaling tube for inhalation, when one-time exhalation is finished, the exhaling tube control device discharges gas in the air bag, the air bag shrinks, and outside air enters the cavity under the action of atmospheric pressure difference, so that the purpose of assistance in breathing is achieved. The mask can prevent the glasses from fogging to the greatest extent and has the breathing assistant function.

Owner:潘景英

Air filter for engine

ActiveCN106286032BExtend the life cycleTroubleshoot clogged filter elementsCombustion-air/fuel-air treatmentMachines/enginesAir filterImpurity

Owner:浙江荣际汽车零部件股份有限公司

Dust removing device for air purifier

InactiveCN106994389AGood air filtrationGood sterilization effectHuman health protectionDeodrantsCarbon nanotubeSilver oxide

The invention discloses a dust removing device for an air purifier. The device comprises a shell; the shell is provided with an intake end and an exhaust end; an electrostatic dust removing layer is arranged in the shell; a dust collecting net is arranged at the exhaust end; the dust collecting net is corrugated; folding lines of corrugations are perpendicular to a mounting surface of the dust collecting net; an absorbing material is sprayed to a corrugated surface of the dust collecting net; the absorbing material is prepared by mixing the following raw materials in parts by weight: 5-10 parts of oxidized graphene, 1-3 parts of carbon nanotube, 2-5 parts of titanium dioxide chromium phosphate compound, and 0.1-2 parts of silver oxide; the electrostatic dust removing layer comprises a fixed electric conducting plate and a high-pressure dust removing device; multiple through holes are arranged on the fixed electric conducting plate; electric conducting rods are arranged between adjacent through holes, and are perpendicular to the fixed electric conducting plate; the diameters of the electric conducting rods are gradually reduced; the end parts of the electric conducting rods are needle-shaped; threads are arranged on the electric conducting rods; the high-pressure dust removing device is provided with multiple columnar ventilation channels; the center lines of the columnar ventilation channels are overlapped with the center lines of the electric conducting rods; and the electric conducting rods are positioned in the columnar ventilation channels.

Owner:SOLVE AIR HEFEI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com