Filter element material for automobile activated carbon air conditioner

A technology of activated carbon and air conditioning, applied in filtration and separation, membrane filters, vehicle parts, etc., can solve the problems of short service life, difficult to remove industrial waste gas, large air resistance, etc., and achieve anti-bacteria, good air filtration effect, economical low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

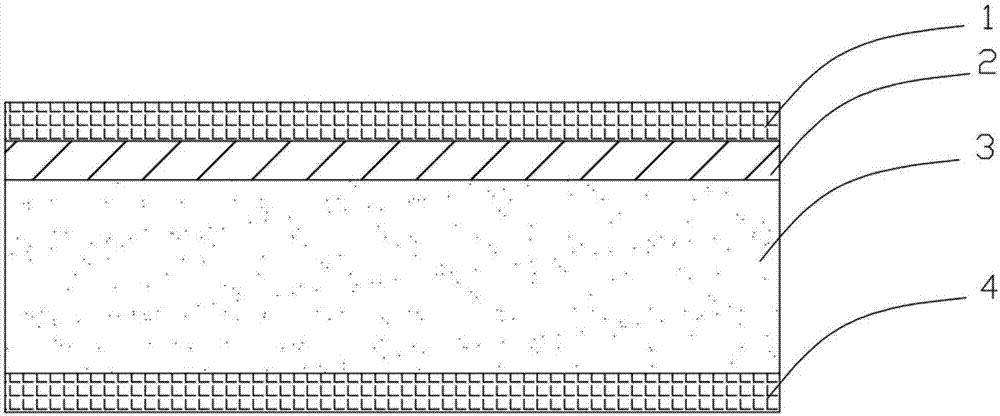

[0020] An automobile activated carbon air-conditioning filter element core material, including a first protective net 1, a dust removal net 2, a filter cotton 3 and a second protective net 4 from top to bottom, wherein: the first protective net 1 and the second protective net 4 are Nylon material fabric, its edges are stitched together, the fabric tissue surface aperture of the first protective net 1 is 400-500 microns, and the wire diameter is 70-80 microns, the first protective net 1 has fixed and fixed parts for the dust removal net 2 and the filter cotton 3 It has a protective effect and has a preliminary filtering effect on large suspended particles in the air; the dust removal net 2 is a polyurethane fiber fabric, the fabric structure of the polyurethane fiber fabric is plain weave, and the warp density of the filter screen is 27.82-28.46 pieces / centimeters, the weft density is 27.6-29.1 strands / cm, the pore diameter is 301-311 microns, the wire diameter is 51-57 microns...

Embodiment 2

[0030] The automobile air conditioner filter core material that embodiment 1 is made is packed in the air conditioner filter, and the pleat density is 1.6 / cm, and the pleat height is 3.7cm, and it is installed in a Ford Focus 1.6 automatic transmission vehicle, The air volume of the air conditioner was adjusted to the maximum, and the maximum wind speed at the air outlet in front of the driver's seat was measured to be 4.2m / s. Using the Hanwang Haze Meter M1 smart air detector, the measured PM2.5 value outside the car is 127.6; close all windows and turn on the air conditioner, and after 15 minutes, the PM2.5 value inside the car stabilizes between 55.1-55.6;

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com