Temperature-sensitive glucan-based hydrogel and preparation method thereof

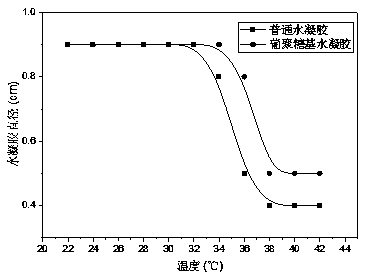

A temperature-sensitive hydrogel and dextran technology, which is used in medical science, bandages, etc., can solve the problems of low porosity, poor mechanical properties, and poor air permeability of ordinary hydrogels, and achieve controllable drugs. Release, high mechanical properties, good biocompatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

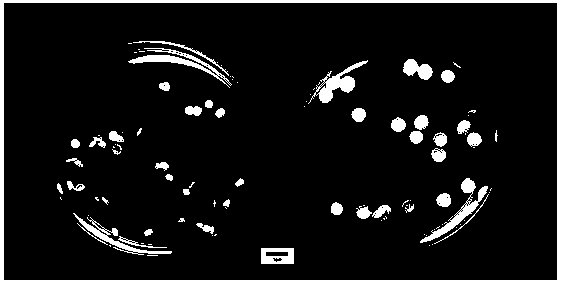

[0037] Example 1 Preparation of porous thermosensitive dextran-based hydrogel

[0038] (1) Prepare an aqueous ammonium persulfate solution with a mass fraction of 5%, and then use 4.5ml of deionized water to prepare a solution containing 6.6% N-isopropylacrylamide and 0.33% N,N-methyleneacrylamide mixture. After the resulting mixed solution was mixed on a rotary oscillator, 135 μL of the configured ammonium persulfate aqueous solution was quickly added and quickly mixed on a rotary oscillator. The volume ratio of the added ammonium persulfate solution to the mixed solution was 3:100 .

[0039] (2) Add tetramethylethylenediamine to the solution obtained in step (1), and the volume ratio of tetraethylenediamine to the solution obtained in step (1) is 2:100. The obtained solution was quickly mixed on a rotary oscillator, quickly poured into a mold, and left to stand for 30 minutes to obtain a temperature-sensitive hydrogel.

[0040] (3) Take the formed hydrogel out of the mold...

Embodiment 2

[0042] Example 2 Preparation of porous thermosensitive dextran-based hydrogel

[0043] (1) Prepare an aqueous solution of ammonium persulfate with a mass fraction of 5%, and use 4.5ml of deionized water to prepare a mass fraction of 6.6% N-isopropylacrylamide, 0.33% N,N-methyleneacrylamide and 1 % NaHCO 3 mixed solution. After the resulting mixed solution was mixed on a rotary oscillator, 135 μL of the configured ammonium persulfate aqueous solution was quickly added and quickly mixed on a rotary oscillator. The volume ratio of the added ammonium persulfate solution to the mixed solution was 3:100 .

[0044] (2) Add tetramethylethylenediamine to the solution obtained in step (1), and the volume ratio of tetraethylenediamine to the solution obtained in step (1) is 2:100. The obtained solution was quickly mixed on a rotary oscillator, quickly poured into a mold, and left to stand for 30 minutes to obtain a temperature-sensitive hydrogel.

[0045] (3) Take the formed hydrogel...

Embodiment 3

[0047]Example 3 Preparation of porous thermosensitive dextran-based hydrogel

[0048] (1) Use 0.1ml of deionized water to prepare a potassium persulfate solution with a mass fraction of 3%, and use 10ml of deionized water to prepare a mixture containing 5% of carbityl acrylate and 0.1% of N-methylolacrylamide solution. After the resulting mixed solution was mixed on a rotary oscillator, the configured potassium persulfate solution was quickly added and quickly mixed on a rotary oscillator.

[0049] (2) Add tetramethylethylenediamine to the solution obtained in step (1), and the volume ratio of tetraethylenediamine to the solution obtained in step (1) is 0.8:100. The obtained solution was quickly mixed on a rotary oscillator, then quickly poured into a mold, and left to stand for 10 minutes to obtain a temperature-sensitive hydrogel.

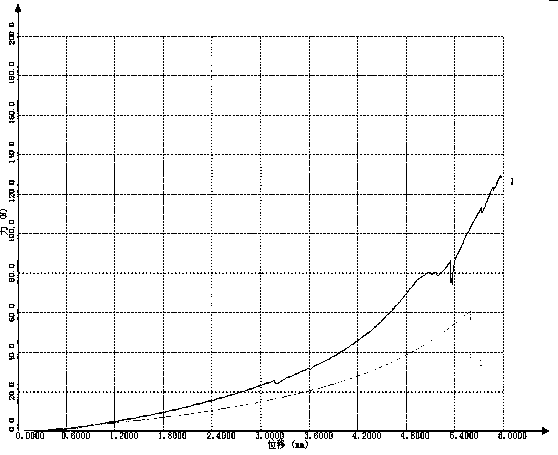

[0050] (3) Take the formed hydrogel out of the mold, put it into a mixed solution containing 0.2%wt tannic acid, 1%wt dextran and 0.3%wt cipro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com