Method for preparing composite nanofibers, prepared composite nanofibers, filtering layer body, and mask with the filtering layer body

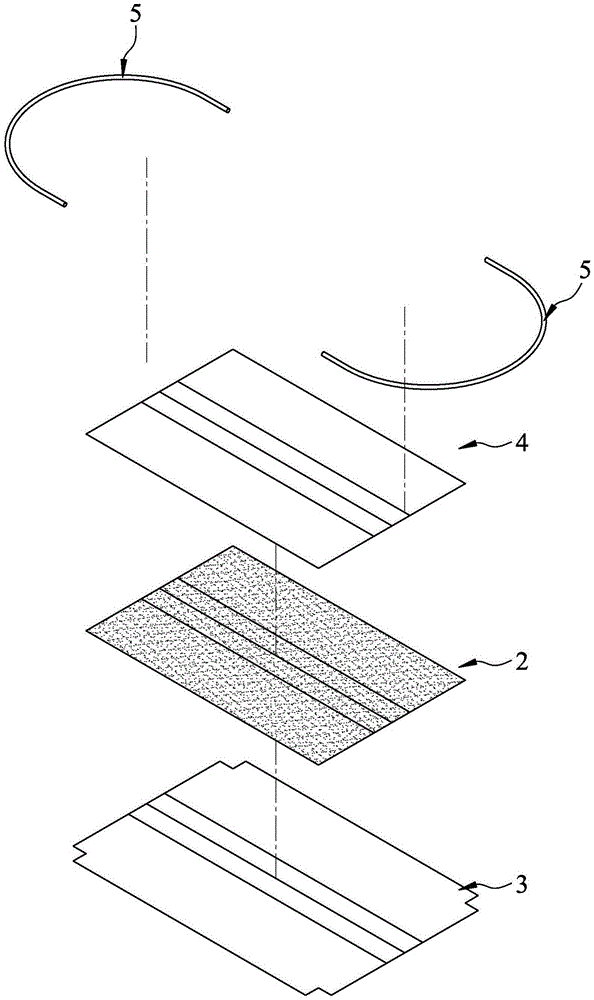

A technology of composite nanofiber and filter layer, which is applied in the direction of fiber treatment, synthetic resin layered products, layered products, etc., can solve the problems of air pollutant filtering ability to be improved and high price, and achieve a strong barrier against dust particles and Bacteria, save manufacturing cost, easy to pass effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] [Preparation of electrospinning solution]

[0031] 0.5g carboxymethyl-β-cyclodextrin (CM-β-CD, synthesized according to the method disclosed by ZhanhuaHuang et al. in Carbohydrate Polymers, 2012, 88, 609-617), 0.5g chitosan, 2.0g polymethyl Methyl acrylate (PMMA, purchased from CHONEYEPURE CHEMICAL, with a weight average molecular weight of 120,000) and 25 mL of formic acid were mixed, stirred with a magnet for 1 day until uniformly dissolved, and electrospinning solution S1 was obtained.

[0032] [Electrospinning]

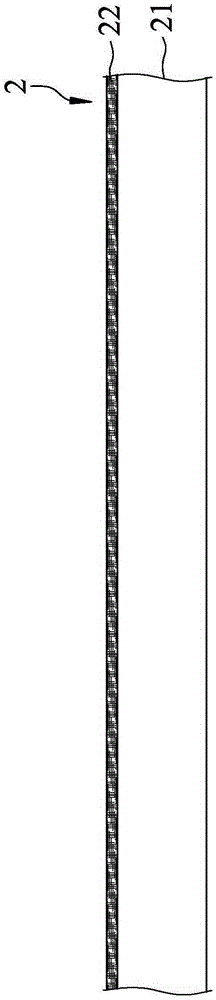

[0033] The above-mentioned electrospinning solution S1 was contained in a glass injection syringe, and the syringe was connected to a stainless steel needle through a polytetrafluoroethylene (PTFE) tube, and installed on a micropump. A high voltage is provided at the stainless steel needle, so that the electrospinning solution S1 is electrospun, and the formed spinning product E1 is collected with a polypropylene melt-blown non-woven fabric, so that the sp...

Embodiment 2-7

[0035] The preparation method of the electrospinning solutions S2-S7 of Examples 2-7 is similar to Example 1, except that the amount of polymethyl methacrylate (PMMA) is changed to 2.5g, 3g, 3.5g, 4g, 4.5g g, 5g. The spinning products E2-E7 were respectively obtained after performing the above-mentioned electrospinning.

[0036] [Scanning electron microscope (SEM) observation]

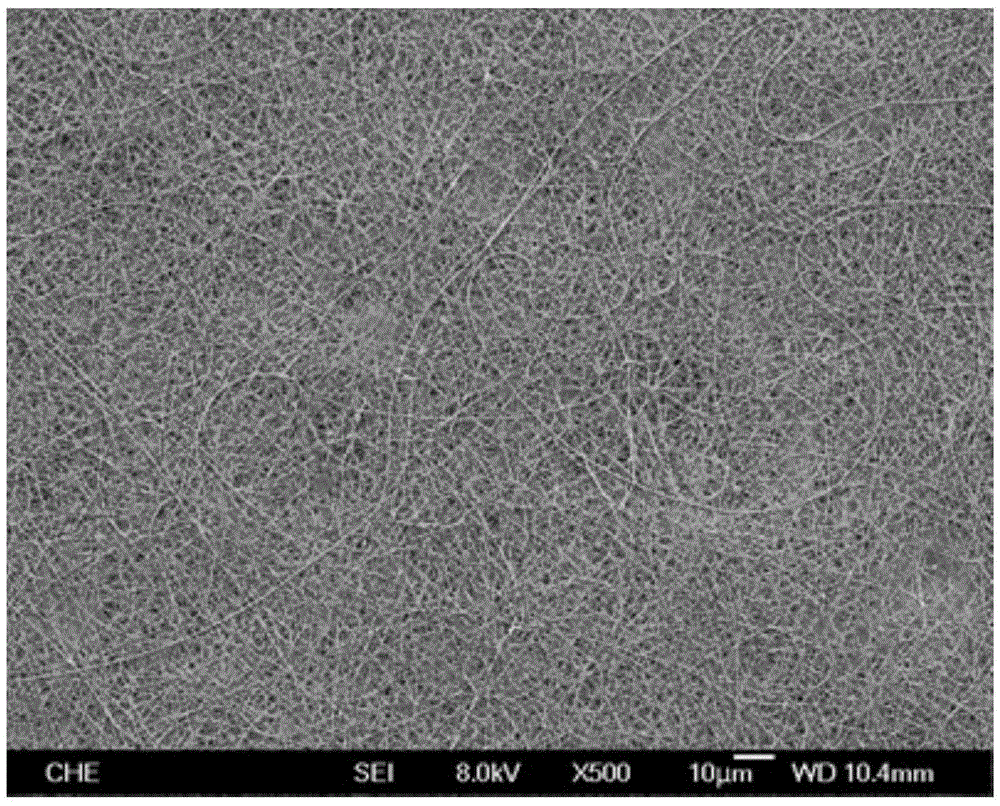

[0037] Utilize scanning electron microscope to observe the filtering layer 22 that embodiment 4 obtains, the result is as follows figure 2 As shown, the spinning product E4 is shown to be nanoscale fibers.

[0038] Statistical analysis and calculation with ImageJ software figure 2 The diameter of the nanofibers (sampled 20 times), the result shows that the average diameter of the spinning product E4 is 200nm.

[0039] [Porosity test]

[0040] The test samples were prepared by the aforementioned electrospinning method. Wherein, the base layer 21 is replaced by a grounded barbed wire, and the for...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electric potential / voltage | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com