Method for preparing photocatalytic air purification rod-like titanium dioxide particle composite fibrofelt

A technology of photocatalytic particles and composite fiber mats, applied in chemical instruments and methods, botanical equipment and methods, separation methods, etc., can solve problems such as lack, achieve high activity, fast photocatalytic response, and improve antibacterial and bactericidal effects. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 3

[0024] The basalt fiber of embodiment 3 selects mass percentage component to be SiO 2 : 53.5%, Al 2 o 3 : 15%, Fe 2 o 3 : 4%, FeO: 7%, CaO: 8%, Na 2 O: 5.5%, K 2 O: 2%, MgO: 3.5% and TiO 2 : 1.5% pure natural basalt is used as raw material, melted at high temperature in a kiln at 1475°C to form a uniform lava, and then the basalt lava at 1250°C flows into a 400-hole platinum-rhodium alloy bushing plate made of PtRh10, and finally Basalt fibers are formed by rapid drawing.

Embodiment 1-3

[0026] Embodiment 1-3 is implemented according to the following steps:

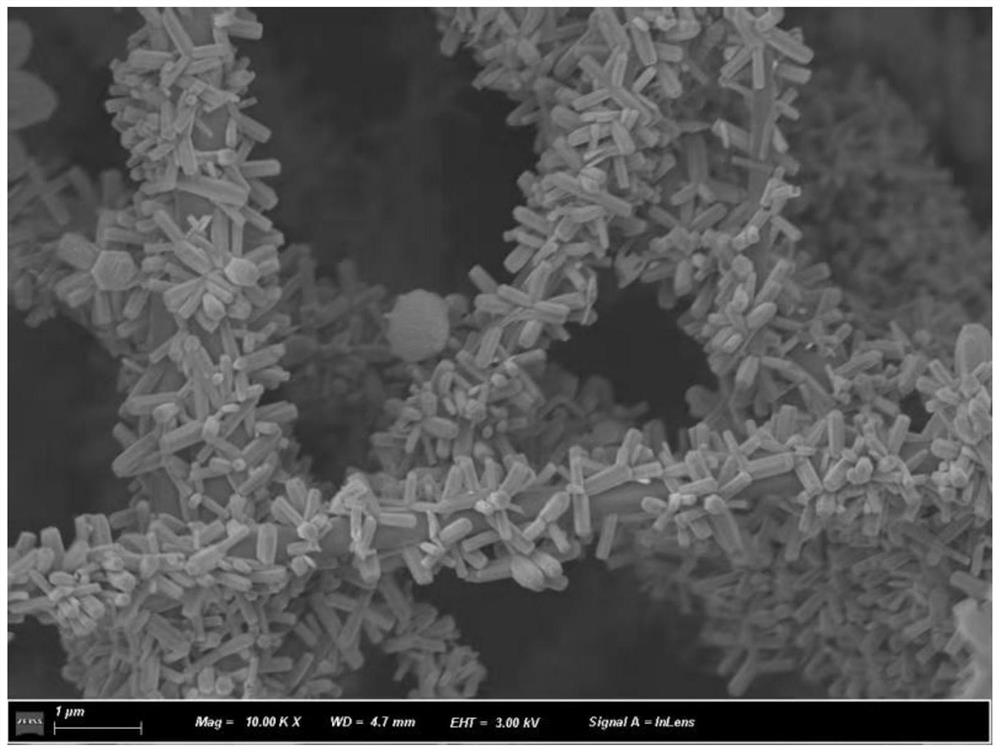

[0027] The method for preparing photocatalytic air purification rod-shaped titanium dioxide particle composite fiber felt comprises the following steps:

[0028] Step 1, configure the titanium dioxide precursor solution: dissolve the mixture of titanium isopropoxide and titanium tetrachloride in deionized water, control the precipitation by adding ammonia water, filter the precipitate and dry it, and precipitate into titanium ammonium complex , and then take the precipitated and suction-filtered titanium ammonium complex, add ammonia water and water to configure a titanium dioxide precursor solution with an optimal molar concentration of 2.5mol / L;

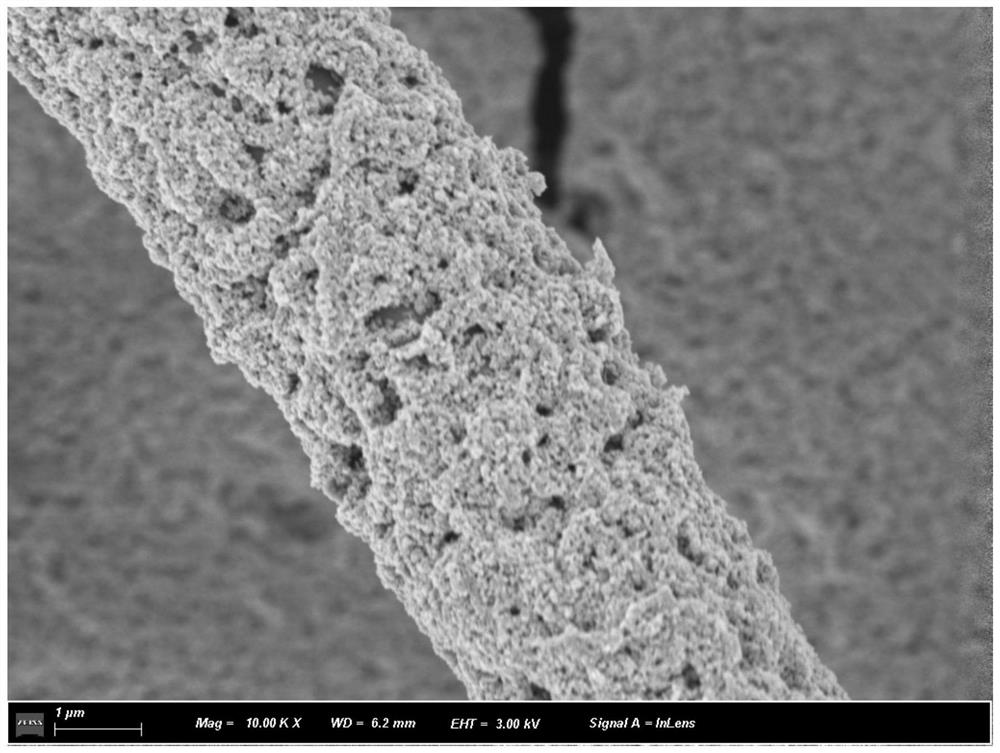

[0029] Step 2: Disperse 6mg / mL photocatalytic nanoparticles with deionized water into 50mL, oscillate ultrasonically for 30min to obtain a dispersion, put ultrafine fibers into the dispersion and ultrasonically 5min, then dry at 135°C Keep for 20min, dipping ...

Embodiment 1

[0032] The source of titanium dioxide and titanium in step 2 is titanium isopropoxide and titanium tetrachloride. In step 2, the photocatalytic nanoparticles are graphene oxide nanoparticles, and the diameter of the particles is 55nm. The superfine fiber in step 2 is a superfine glass fiber with an average diameter of 2.5 μm. A binder is added to the titanium dioxide precursor solution in step 3. The microwave rapid reaction heating temperature in step 3 is 175° C., and the reaction time is 7 minutes. The annealing process in step 3 is H 2 Anneal at 280°C for 2.5h. The photocatalytic degradation performance of the finally prepared photocatalytic air purification rod-shaped titanium dioxide particle composite fiber mat can degrade 95% of the 10mg / L rhodamine B solution in 55 minutes under the condition of visible light; the air filtration performance can reach a quantitative 90g / m 2 , filtration resistance 107Pa, filtration efficiency 93.5% and air flow 240L / m 2 min; the m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com