Enclosed power distribution cabinet

A power distribution cabinet and closed technology, which is applied in the field of closed power distribution cabinets, can solve the problems of poor heat dissipation capacity, high heat, and damage to power distribution cabinets in the heat dissipation part, so as to improve strain capacity, increase area, and improve safety. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

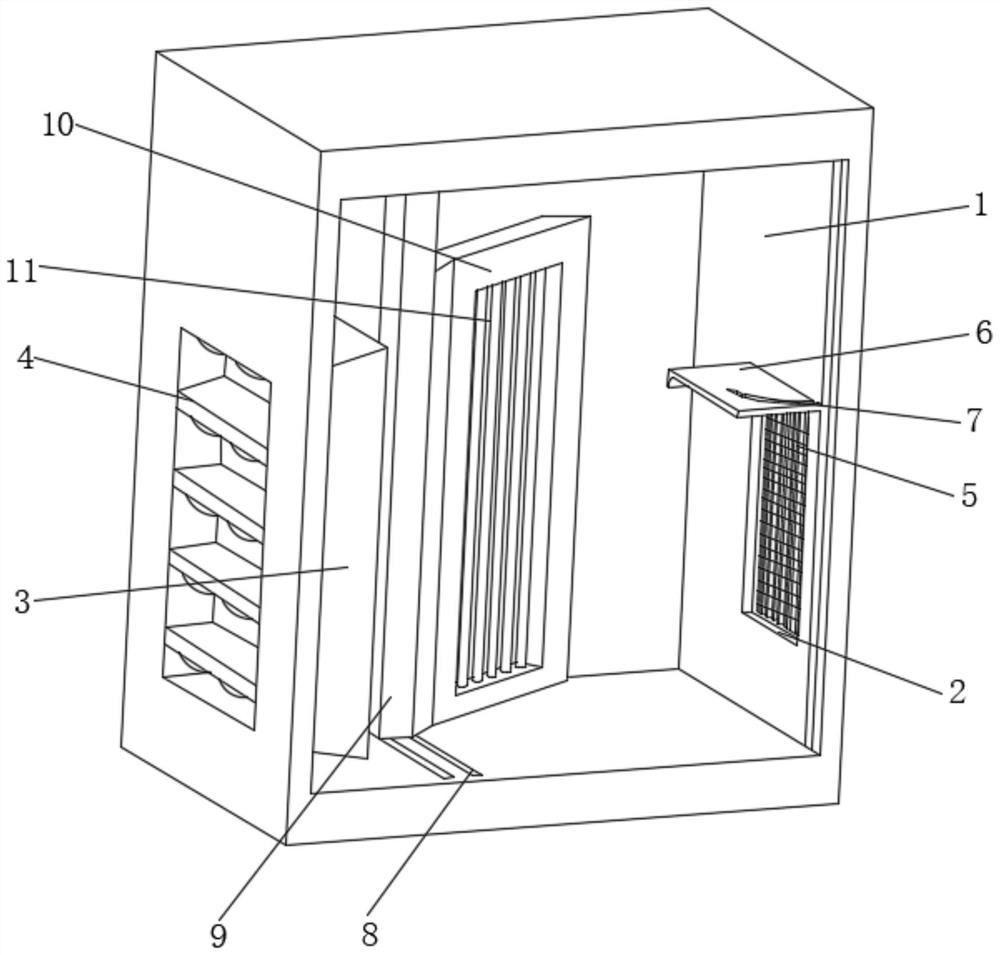

[0029] see Figure 1-2 , the present invention provides a technical solution: a closed power distribution cabinet, including a box body 1, windows 2 are opened on the left and right sides of the outer surface of the box body 1, and a tapered frame is fixedly connected to the inner surface of the left window 2 3. The inner surface of the conical frame 3 is fixedly connected with a dust removal mechanism 4, the inner surface of the right window 2 is rotatably connected with a retractable mechanism 5, and the inner wall of the box body 1 is fixedly connected with a fixed plate above the right window 2 6. The outer surface of the fixed plate 6 is provided with an arc-shaped groove 7, and the bottom of the inner surface of the box body 1 is provided with a sliding groove 8. The inner surface of the sliding groove 8 is slidably connected with a sliding column 9, and the outer surface of the sliding column 9 is connected to the box body. The inner surface of 1 is slidingly connected,...

Embodiment 2

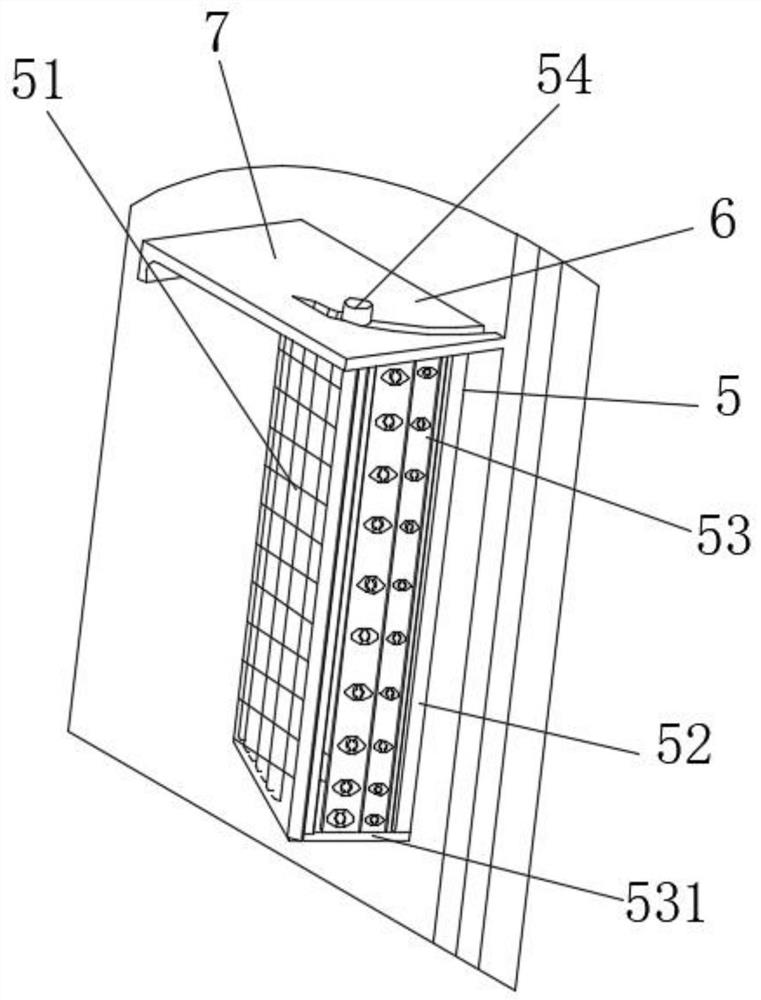

[0031] see figure 2 , the present invention provides a technical solution: the retractable mechanism 5 includes a heat dissipation window 51, the rear of the heat dissipation window 51 is rotatably connected with the inner surface of the right window 2, and the front of the heat dissipation window 51 is rotatably connected with a side window 52, the side window The outer surface of 52 is rotationally connected with the inner surface of right side window 2, and the inner surface of side window 52 is provided with connecting mechanism 53, and the top of heat dissipation window 51 is fixedly connected with sliding block 54 on the side close to side window 52, and sliding block The outer surface of 54 is slidingly connected with the inner surface of arc groove 7 . When the demand for heat dissipation is not large, the side window 52 can be withdrawn to prevent the entry of dust.

Embodiment 3

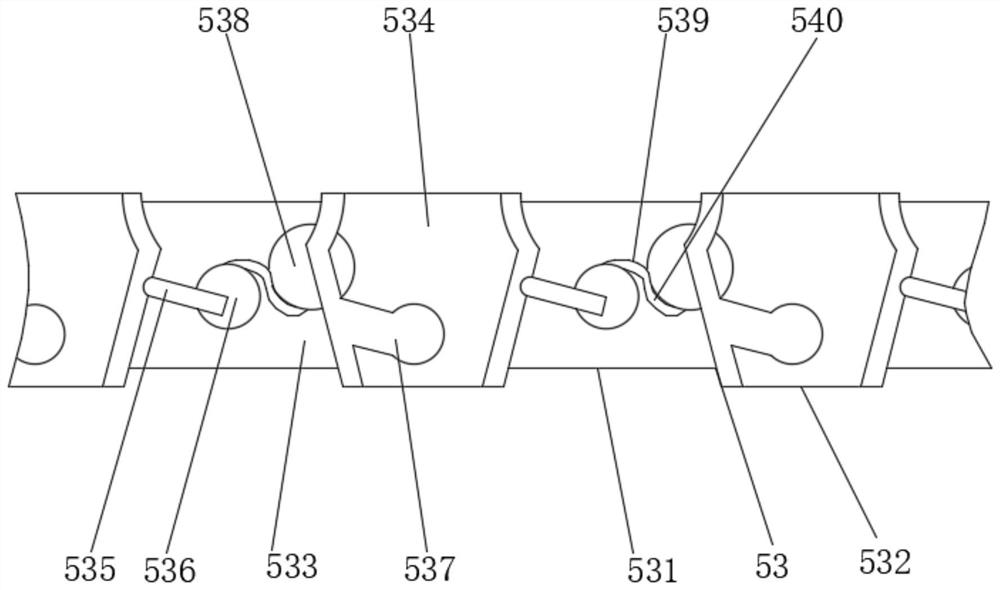

[0033] see Figure 3-4The present invention provides a technical solution: the connection mechanism 53 includes a telescopic rod 531, the left and right ends of the telescopic rod 531 are respectively connected to the outer surface of the heat dissipation window 51 and the inner surface of the right window 2 in rotation, and the outer surface of the telescopic rod 531 is fixed A dustproof plate 532 is connected, and the outer surface of the dustproof plate 532 is respectively provided with a first vertical groove 533 and a second vertical groove 534 .

[0034] The inner surface of the first vertical groove 533 is rotatably connected with a riser 535 , the outer surface of the riser 535 is rotatably connected with an upper rotating rod 536 , the outer surface of the second vertical groove 534 is rotatably connected with a lower rotating rod 538 , the second vertical groove 534 The inner surface of the inner surface is provided with a card slot 537, and the inner surface of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com