In-situ polymerization composite surface sizing system and surface sizing craft for needle punching non-woven fabrics

A technology of needle-punched non-woven fabrics and in-situ polymerization, which is applied in the directions of grafted polymer adhesives, devices for coating liquids on surfaces, adhesives, etc. angle, enhanced interfacial adhesion, improved sizing uniformity and dipping depth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be further described below in conjunction with the accompanying drawings and embodiments. It should be noted that the following description is only for explaining the present invention and not limiting its content.

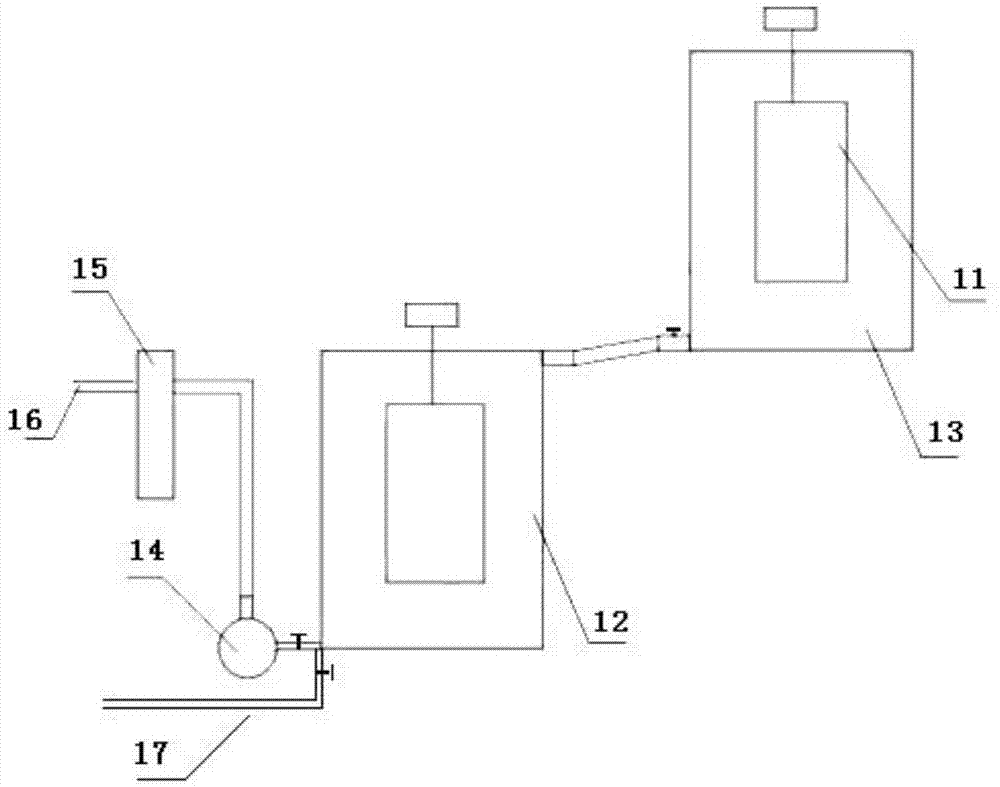

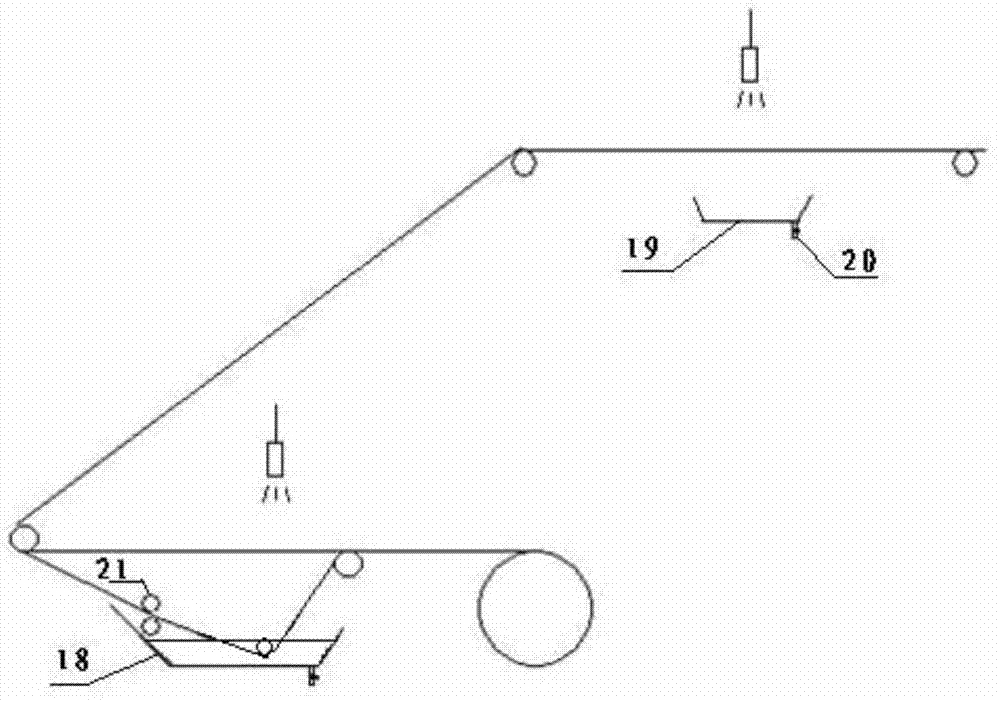

[0039] Such as Figure 1~4 Shown, the present invention comprises glue-making device, dipping / spraying sizing device and drying device, and described glue-making device comprises batching tank 13 and mixing tank 12 that high and low positions are installed, so that the pre-mixing tank 12 in batching tank 13 Polymer water emulsion can spontaneously flow into the mixing tank 12;

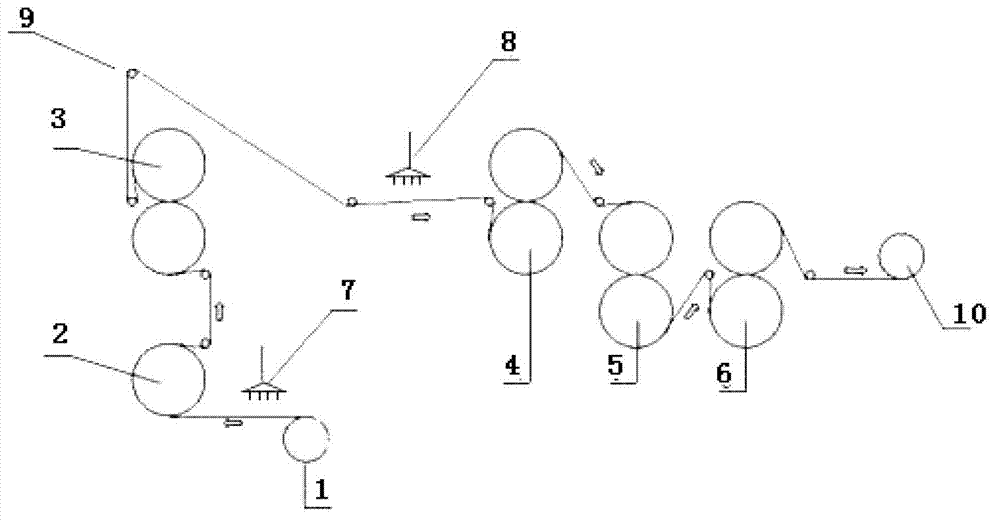

[0040] The drying device includes unwinding roll 1, preheating roll 2, heat roll group I3, heat roll group II4, heat roll group III5, heat roll group IV6 and winding roll 10 connected in sequence, and any adjacent There are several cloth guide rollers 9 between the two; wherein, the hot roller group I3, the hot roller group II4, the hot roller group III5,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com