AB glue dispensing device based on electrostatic spraying principle

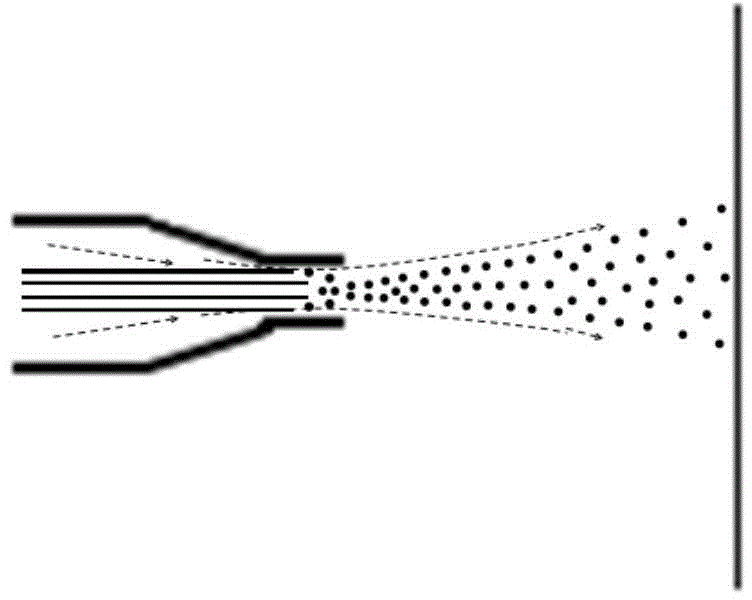

An electrostatic spraying and principle technology, applied in the direction of spray discharge device, spraying device, liquid spraying device, etc., can solve the problems of divergence of atomized particles, poor dispensing orientation, low glue application efficiency, etc., and achieve high bonding quality. The effect of reducing the amount of glue and precisely controlling the dispensing position

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

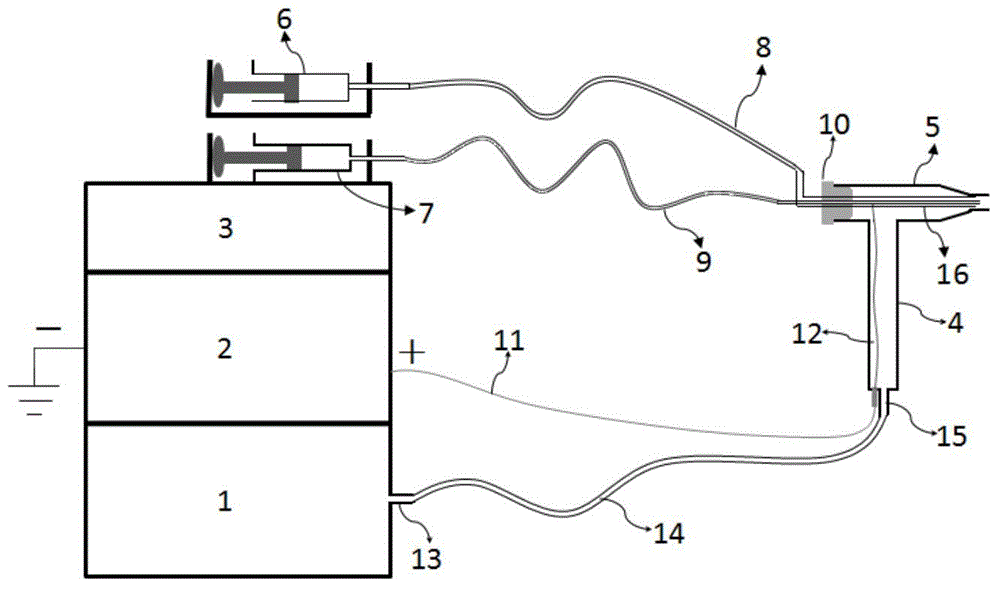

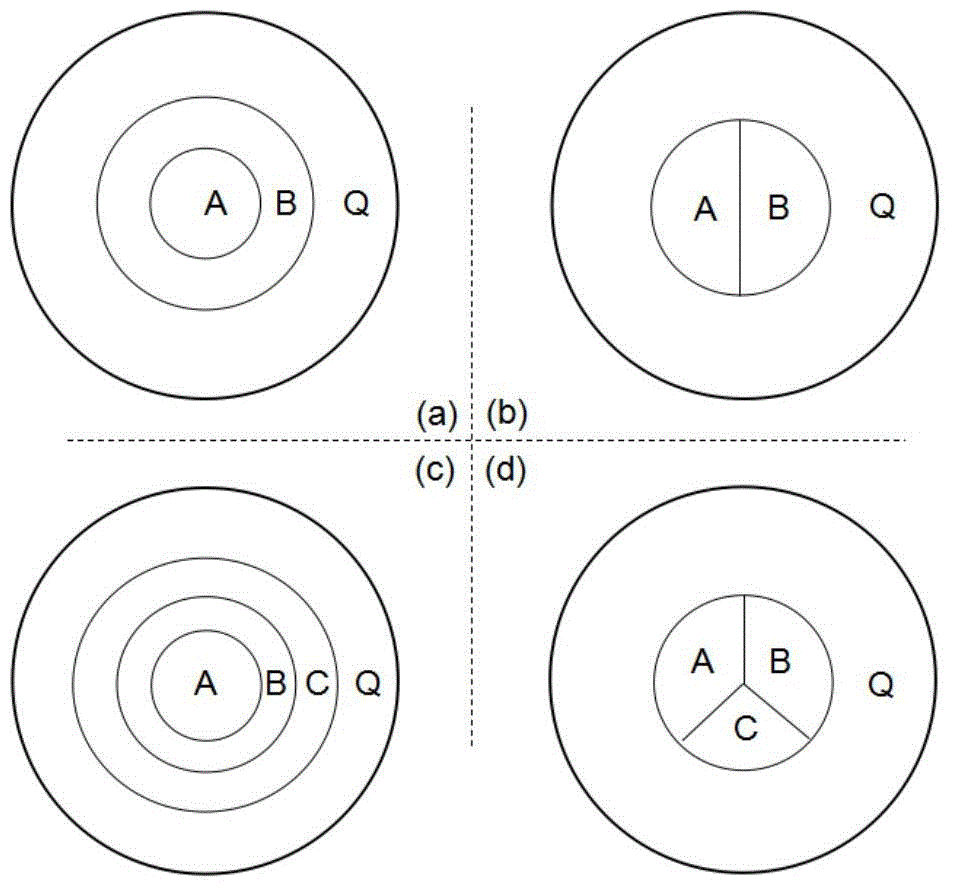

[0012] The main structure of this embodiment includes an air pump 1, a high-voltage electrostatic generator 2, a propulsion pump 3, a spray gun handle 4, a spray gun tube 5, a first syringe 6, a second syringe 7, a first liquid inlet pipe 8, and a second liquid inlet pipe 9. Pipe plug 10, external wire 11, internal wire 12, airflow conduit socket 13, airflow conduit 14, socket 15 and electrospray needle 16; spray gun handle 4 is connected with spray gun tube 5 to form a spray gun, and spray gun handle 4 is arranged on spray gun tube 5 Below: the air pump 1 and the propulsion pump 3 are electrically connected to the high-voltage electrostatic generator 3 respectively, the positive pole of the high-voltage electrostatic generator 2 is electrically connected to the spray gun through an external wire 11, and the negative pole is grounded; The needle 16 is a two-component coaxial electrospray needle that is coaxial with the spray gun tube 5; an air flow channel Q with a ring structu...

Embodiment 2

[0016] The present embodiment adopts the same structure as that of Embodiment 1, and the electrospray needle 16 is changed into a three-component side-by-side electrospray needle or a three-component coaxial electrospray needle coaxial with the spray gun tube 5, such as figure 2 As shown in c and 2d, a third syringe connected to the propeller 3 is added at the same time, and a third liquid inlet pipe is added to connect the third syringe with the electrospray needle 16 to realize the dispensing process of the three-component mixture curing agent.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com