Preparation method of energy-saving, environment-protecting and sag-resistant water-based instant adhesive

An energy-saving, environmentally friendly, water-based technology, applied in adhesive types, climate sustainability, sustainable manufacturing/processing, etc., can solve problems such as poor flow resistance, glue sticking, poor water resistance, etc. High bonding strength and good flow resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

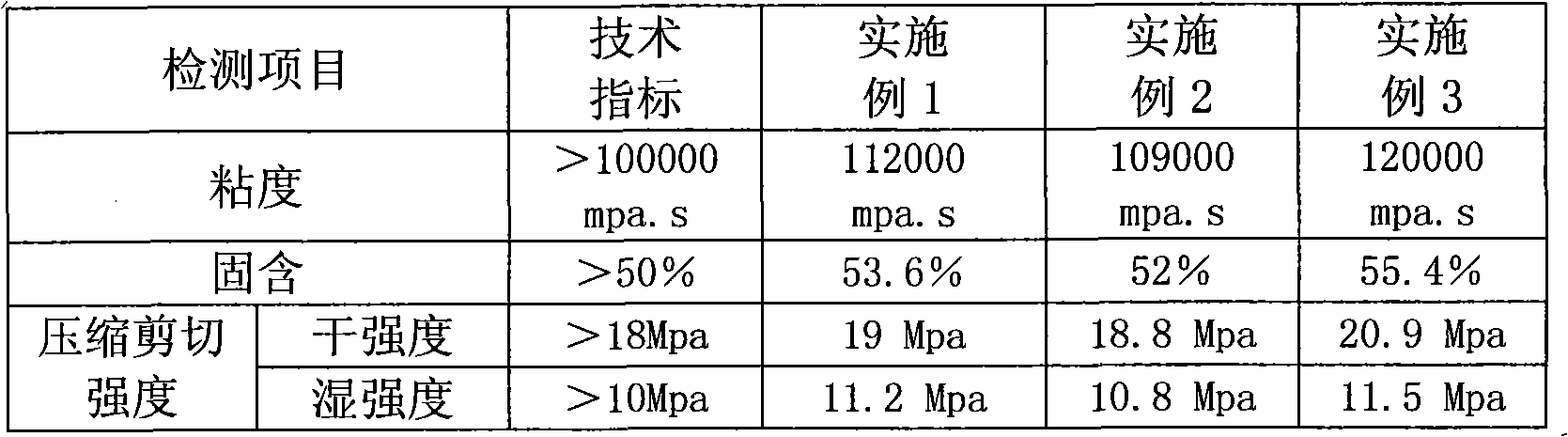

Examples

Embodiment 1

[0020] (1) Add 100kg of deionized water into the reaction kettle, start stirring, control the stirring speed at 70 rpm, add 6kg of acetoacetylated polyvinyl alcohol (PVOH) while stirring, heat up to 88°C after confirming the dispersion After 2 hours, after completely dissolving, cool down to 40°C to form a protective colloid, take out 63kg of the protective colloid, and pump it into the dropping tank for standby;

[0021] (2) 0.2kg ammonium persulfate is diluted with water in a ratio of 1:20 to form an ammonium persulfate solution for subsequent use;

[0022] (3) In the stirring state, the stirring rate is controlled at 60 rpm, and 0.5 kg of fatty alcohol polyoxyethylene ether (AO-9) and 10 kg of vinyl acetate are added to the above reaction kettle, and the temperature is raised to 58 °C after stirring for 10 minutes. , add 1.2 kg of ammonium persulfate solution, react naturally for 1 hour, and the temperature rises to 75°C-85°C to initiate polymerization to form a seed emulsi...

Embodiment 2

[0026] (1) Add 100kg of deionized water into the reaction kettle, start stirring, control the stirring speed at 65 rpm, add 8kg of acetoacetylated polyvinyl alcohol (PVOH) while stirring, heat up to 90°C after confirming the dispersion After 1 hour, after completely dissolving, cool down to 50°C to form a protective colloid, take out 65kg of the protective colloid, and pump it into the dripping tank through a diaphragm pump;

[0027] (2) 0.3kg ammonium persulfate is diluted with water in a ratio of 1:20 to form an ammonium persulfate solution for subsequent use;

[0028] (3) In the stirring state, the stirring speed is controlled at 55 rpm, and 0.1 kg of emulsifier (O) and 18 kg of vinyl acetate are added to the reaction kettle, and the temperature is raised to 60 ° C after stirring for 10 minutes, and ammonium persulfate solution 2.4 kg, natural reaction for 1.5 hours, the temperature rises to 75°C-85°C, and the polymerization is initiated to form a seed emulsion;

[0029] (...

Embodiment 3

[0032] (1) Add 100kg of deionized water into the reactor, start stirring, control the stirring speed at 75 rpm, add 15kg of acetoacetylated polyvinyl alcohol (PVOH) while stirring, heat up to 85°C after confirming the dispersion After 3 hours, after completely dissolving, cool down to 45°C to form a protective colloid, take out 69kg of the protective colloid and send it into the dropping tank through a diaphragm pump;

[0033] (2) the ammonium persulfate of 0.1kg is diluted with water in a ratio of 1: 20 to form an ammonium persulfate solution for subsequent use;

[0034] (3) In the stirring state, the stirring speed is controlled at 65 rpm, add 0.8kg of emulsifier (EFS-470) and 6kg of vinyl acetate into the above reaction kettle, stir for 10 minutes and then raise the temperature to 65°C, add persulfuric acid Ammonium solution 1kg, natural reaction for 1 hour, the temperature rises to 75°C-85°C, triggers polymerization to form seed emulsion;

[0035] (4) Stirring speed is cont...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com