Dispensing machine with accurate positioning performance and consistent dispensing quantity

A technology with accurate positioning and glue output, applied in the field of glue dispensers, can solve the problems of poor quality reliability and flow consistency, increased circuit board failure rate, low product qualification rate, etc. The effect of good glue effect and low rework rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

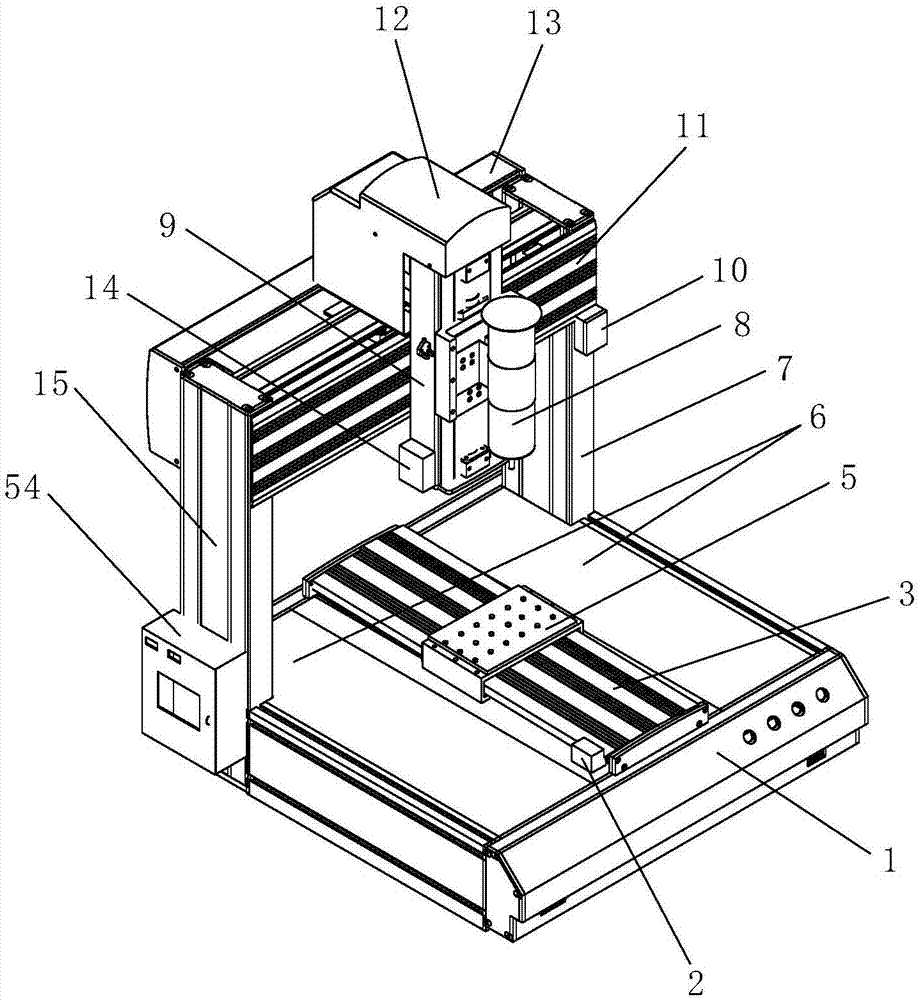

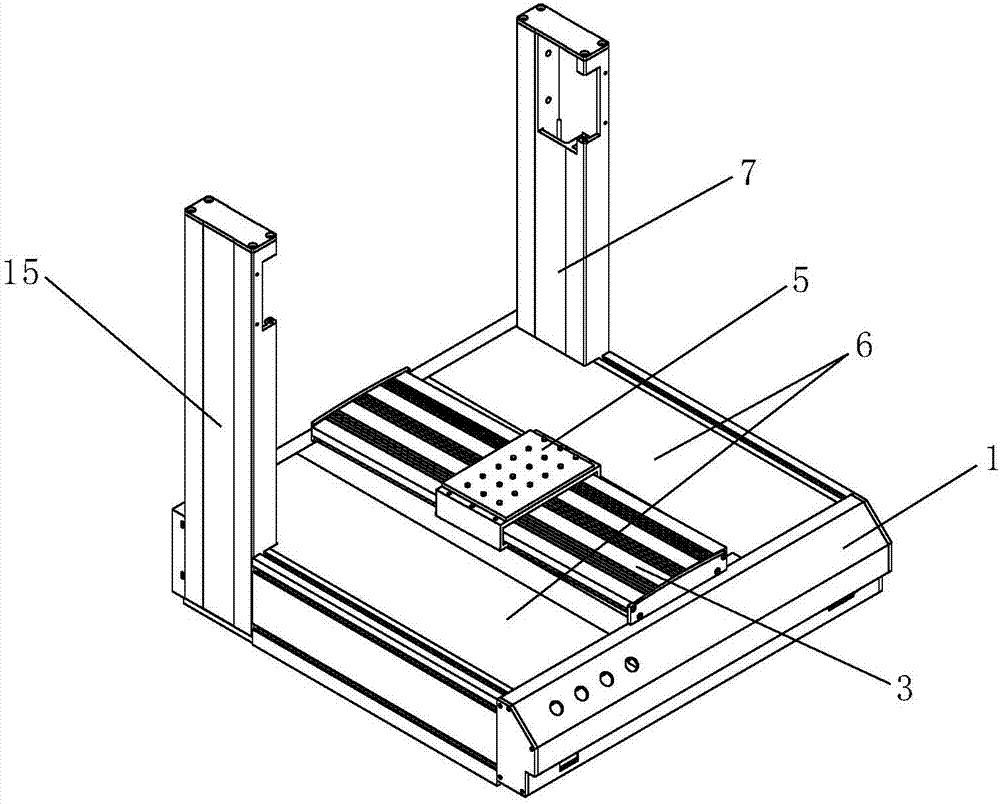

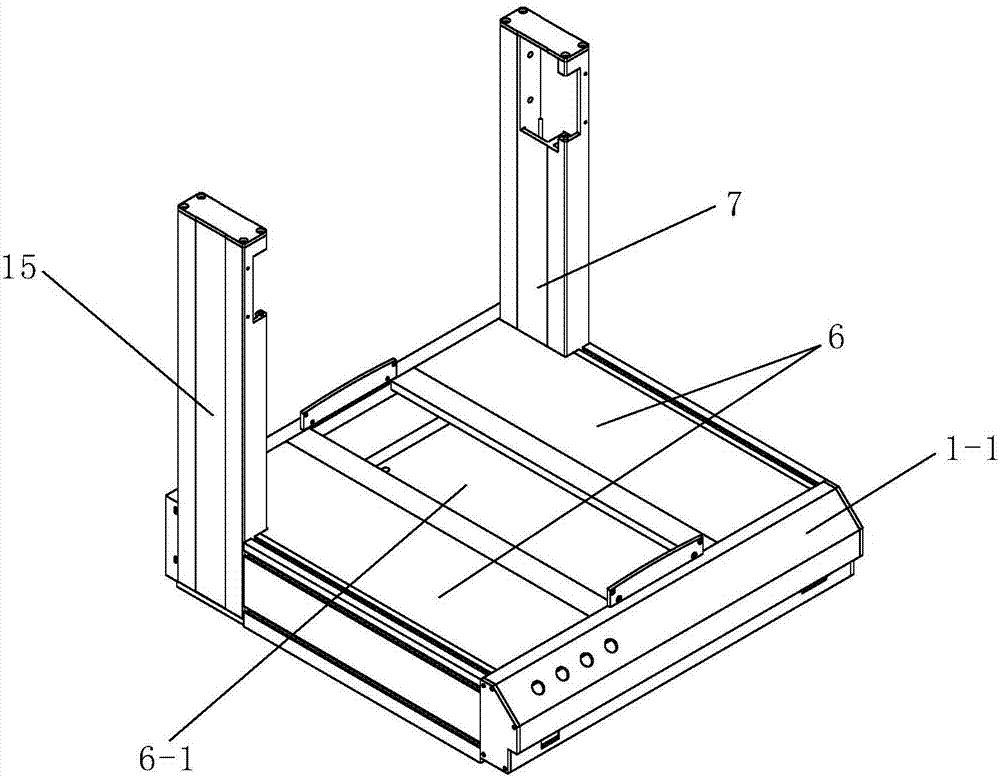

[0055] Such as Figure 1 to Figure 3 As shown, the present invention includes a frame assembly 1, an X-axis assembly 3, a Y-axis assembly 11, a Z-axis assembly 9 and a glue outlet assembly 8. The frame assembly 1 includes a square frame 1-1, a left Support 15 and right support 7, described left support 15 and right support 7 are symmetrically installed on the left and right sides of the rear portion of square frame 1-1, and the left and right sides of described square frame 1-1 are all equipped with horizontal operating platform 6, The area between the horizontal consoles 6 on the left and right sides is the X-axis assembly installation area 6-1, the X-axis assembly 3 is installed in the X-axis assembly installation area 6-1, and the X-axis assembly The front end of the body 3 is connected to the front middle of the square frame 1-1, the rear end of the X-axis assembly 3 is connected to the rear middle of the square frame 1-1, and the left end of the Y-axis assembly 11 is conn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com