Two-component silicone sealant for solar cell modules and its injection process

A solar cell and silicone sealant technology, which is applied in the direction of electrical components, circuits, adhesives, etc., can solve the problems of heavy operation, waste of glue, and low efficiency, so as to ensure various performances, convenient operation and labor-saving, and improve the efficiency of glue injection Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

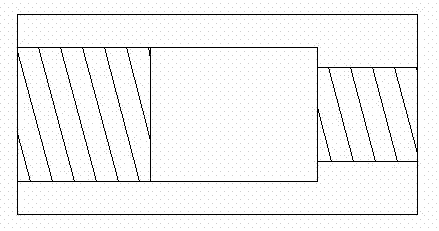

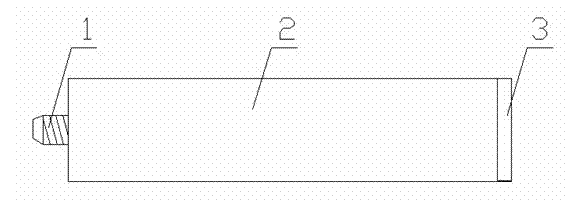

Image

Examples

Embodiment 1

[0048] A component

[0049] 20000cp hydroxyl terminated polydimethylsiloxane 60 kg

[0050] 50000cp alkyl terminated polydimethylsiloxane 60 kg

[0051] 100cp alkyl terminated polydimethylsiloxane 40 kg

[0052]Activated calcium carbonate 50 kg

[0053] Inactive calcium carbonate 50 kg

[0054] Fumed silica 5kg

[0055] Magnesium hydroxide 100 kg

[0056] B component

[0057] Methyltriethoxysilane 10kg

[0058] Methyltrimethoxysilane 2 kg

[0059] γ-(2.3 Glycidoxy)propyltrimethoxysilane 1 kg

[0060] Dibutyltin diacetate 0.1 kg

[0061] 4-Benzoyloxy-2,2,6,6-tetramethylpiperidine 0.02 kg

[0062] The weight ratio of A component and B component is 8:1.

Embodiment 2

[0064] A component

[0065] 10000cp hydroxy-terminated polydimethylsiloxane 100 kg

[0066] 80000cp hydroxy-terminated polydimethylsiloxane 50 kg

[0067] 500 cp alkyl terminated polydimethylsiloxane 60 kg

[0068] 2000 cp Alkyl-terminated polydimethylsiloxane 20 kg

[0069] Activated calcium carbonate 120 kg

[0070] Precipitated silica 20 kg

[0071] Aluminum hydroxide 50kg

[0072] B component

[0073] Vinyltrimethoxysilane 13kg

[0074] Dimethyldimethoxysilane 1 kg

[0075] Bis(3-triethoxysilylpropyl)amine 3 kg

[0076] Dibutyldioctin 0.05 kg

[0077] 4-Benzoyloxy-2,2,6,6-tetramethylpiperidine 0.03 kg

[0078] The weight ratio of A component and B component is 12:1.

Embodiment 3

[0080] A component

[0081] 3000cp hydroxyl terminated polydimethylsiloxane 60 kg

[0082] 50000cp alkyl terminated polydimethylsiloxane 80 kg

[0083] 50cp alkyl terminated polydimethylsiloxane 50 kg

[0084] 5000cp alkyl terminated polydimethylsiloxane 10 kg

[0085] Activated calcium carbonate 70 kg

[0086] Silica powder 40 kg

[0087] Fumed silica 15kg

[0088] Precipitated silica 10 kg

[0089] Zinc borate 60 kg

[0090] B component

[0091] Diethyldiethoxysilane 11kg

[0092] Methyltriethoxysilane 3 kg

[0093] γ-(2.3 Glycidoxy)propyltrimethoxysilane 2 kg

[0094] Dibutyltin dilaurate 0.1 kg

[0095] Hexamethylphosphoric triamide 0.05 kg

[0096] The weight ratio of A component and B component is 16:1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com