Four-edge board cutting machine for cutting carpentry veneer and four-edge cutting method of carpentry veneer

A cutting machine and veneer technology, which is used in wood processing appliances, special forming/shaping machines, manufacturing tools, etc., can solve the problem of not being able to cut the four sides of the veneer, and reduce the probability of separation and lamination. The effect of reducing production energy consumption and ensuring quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] Embodiment 1: a four-side cutting machine for cutting woodworking veneers.

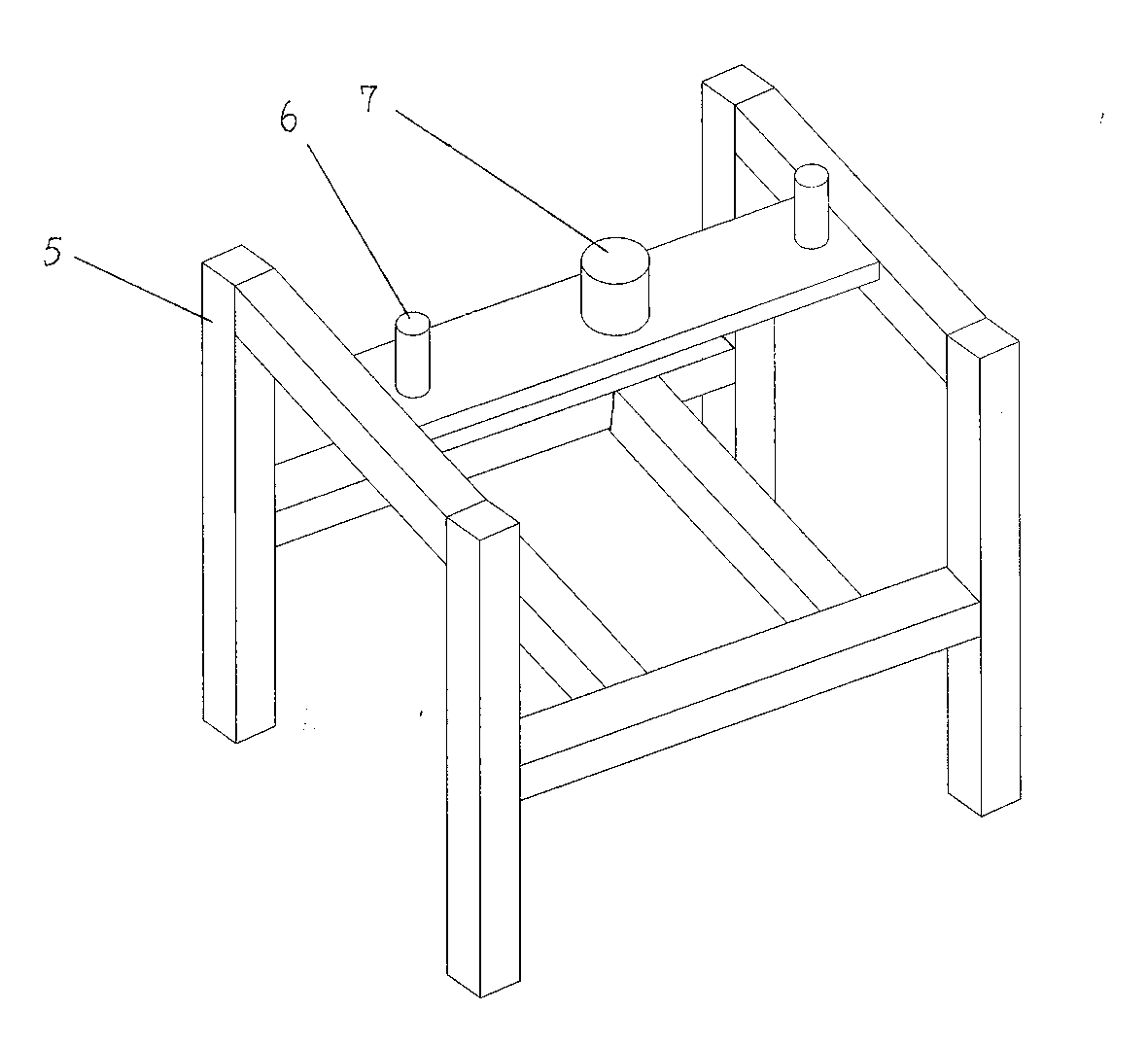

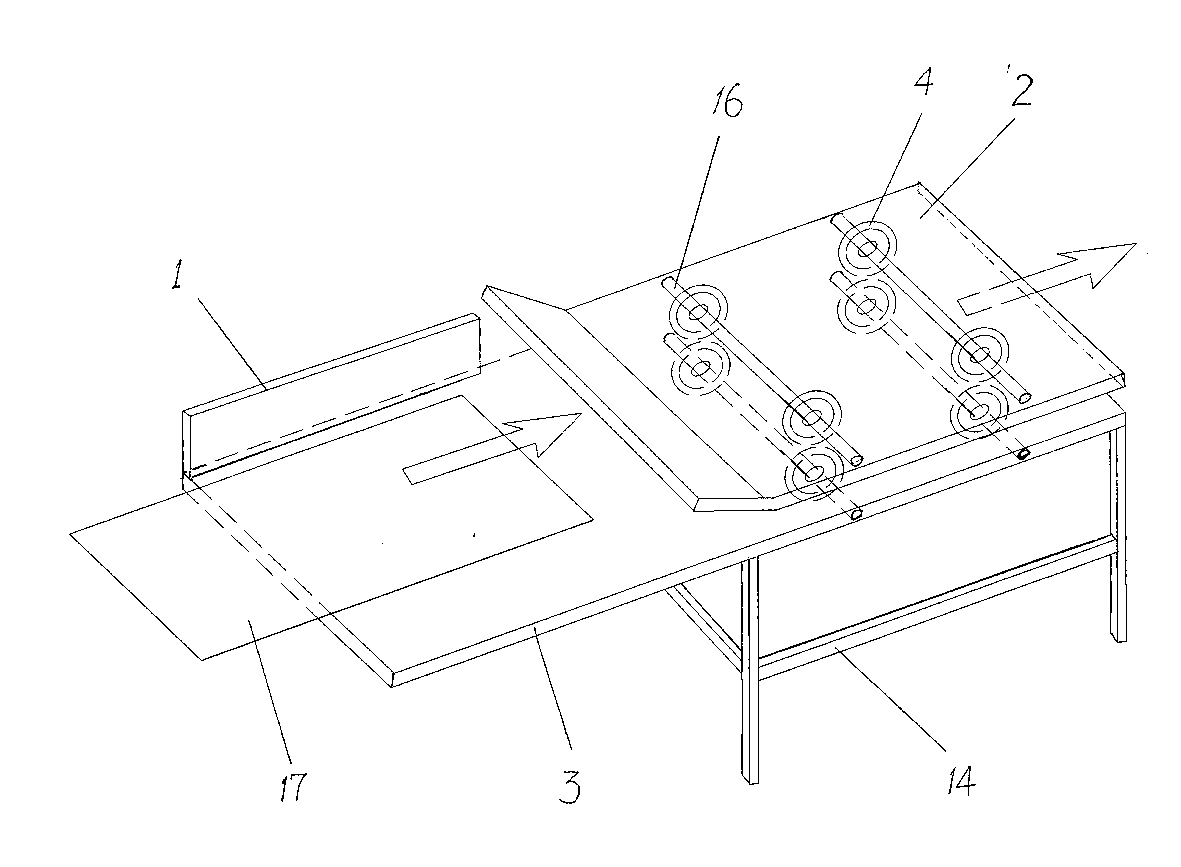

[0040] Such as figure 1 , figure 2 As shown, the frame 5 of the four-side panel cutting machine of the present invention includes four uprights and crossbeams connected thereto, lower beams, etc., and a top beam is connected between the two crossbeams. A rectangular pressure bearing platform 11 is fixed on the lower beam of the frame 5, and inside the pressure bearing platform 11, there are two transverse roller installation shafts (the number can be increased) at the front and rear. A row of rollers 12 constitute the lower toggle rollers of the veneer transmission mechanism. The roller installation shaft and the frame 5 are elastic structures that can float up and down and connect, so that the roller installation shaft constitutes an elastic pressing shaft. Have some small windows on the top surface of the bearing platform 11, opposite to each roller 12, the upper edge of the roller 12 is ...

Embodiment 2

[0053] Embodiment 2: the four-side cutting method of carpentry veneer.

[0054] refer to figure 1 — Figure 5 , the four-side cutting method of woodworking veneer of the present invention comprises the following steps:

[0055] a. Use the veneer feeding mechanism in the four-side panel cutting machine of the present invention to laterally transport a piece of carpentry veneer 16 to be cut to the pressure table 11 in the frame 5 .

[0056] b. Under the control of the lowering platform lifting control mechanism in the four-side panel cutting machine, the lowering platform 13 located at the upper position in the frame 5 is pressed down on the pressure platform 11, and will be sent into the pressure platform 11 table The wood veneer to be cut on the board is flattened.

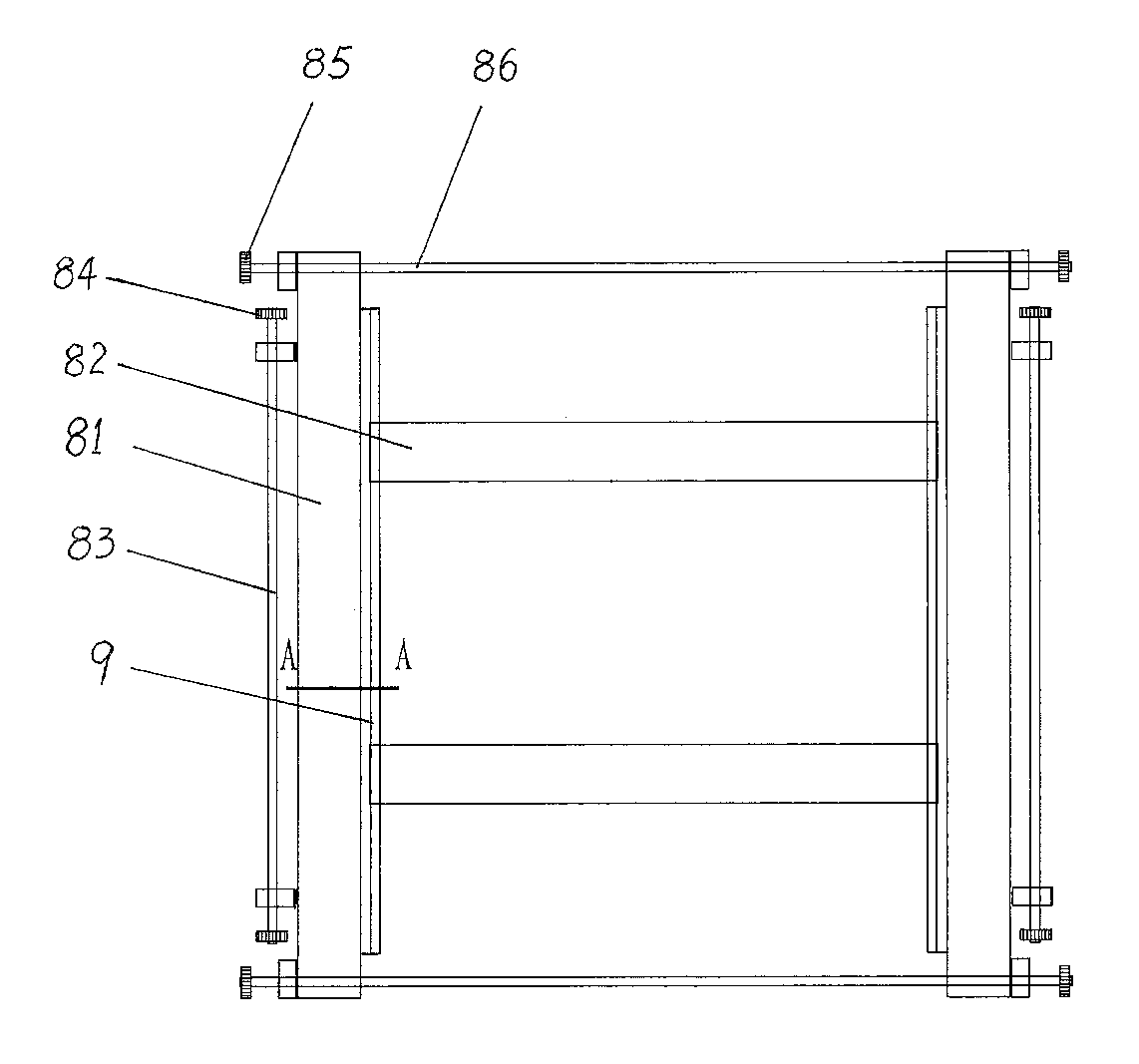

[0057] c. Under the control of the movable knife rest lifting control mechanism in the four-side panel cutting machine, the movable knife rest 8 arranged on the periphery of the pressing platform 13 is moved do...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com