Double-pressurizing-channel packer applied to oil tube sealing and detection

A technology of sealing detection and double pressurization, which is applied in the directions of sealing/isolation, wellbore/well components, earthwork drilling and production, etc. It can solve the problem that the setting pressure of the packer cannot be adjusted, the sealing performance of the rubber cylinder cannot be guaranteed, and the sealing The problem of large volume of the inner cavity of the device can be solved, so as to reduce the operation risk, save the detection time, and shorten the setting time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

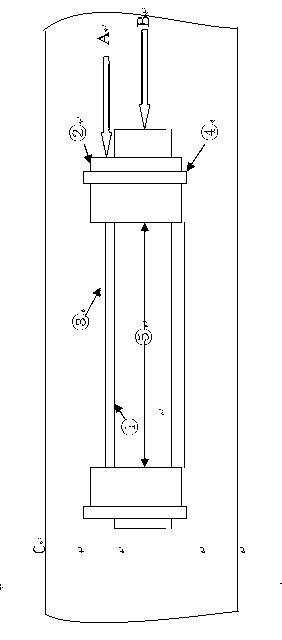

[0026] As a preferred embodiment of the present invention, the present invention is mainly composed of a mandrel 1, a liquid cylinder 2, an outer cylinder 3, a well gauge 4, and a rubber cartridge. Inject hydraulic oil, push the piston to move down along the mandrel 1 and squeeze the rubber tube together with the well gauge 4, and expand it to realize setting. After setting, pump high-pressure mixed gas into the packer through channel B, and the high-pressure The mixed gas continues to pressurize to the detection pressure value in the trap space between the rubber cylinder and the inner wall C of the oil pipe through the pressure transmission hole on the outer cylinder 3 . After the test is finished, the test gas in the trapped space is released first, and then the setting pressure is released, the liquid cylinder 2 is reset, the rubber tube shrinks, and then the seal is unsealed. In the design of the invention, different pressurization channels are used for setting and detect...

Embodiment 2

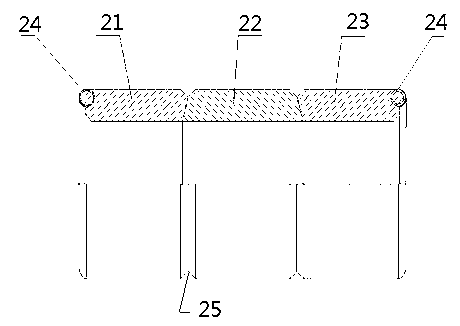

[0028] As the best embodiment of the present invention, the rubber cartridge includes a rubber cartridge body, the rubber cartridge body includes a head end rubber cartridge body 21, a middle rubber cartridge body 22 and an end rubber cartridge body 23, the head end rubber cartridge body 21, The middle rubber cartridge body 22 and the end rubber cartridge body 23 have an integrated structure, and the hardness of the head rubber cartridge body 21 and the end rubber cartridge body 23 is higher than that of the middle rubber cartridge body 22 . The rubber cartridge body is a three-stage structure, including the head rubber cartridge body 21, the end rubber cartridge body 23 and a middle rubber cartridge body, and the head end rubber cartridge body 21 and the end rubber cartridge body 23 are connected with the middle rubber cartridge body. A deformation space 25 is provided at the junction. A metal support member 24 is disposed in the head rubber cartridge body 21 and the end rubb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com