Thermal insulation structure of thermal medium storage tank and thermal medium pipe of solar photo-thermal power generation system

A technology of photothermal power generation and heat medium, applied in pipeline protection, pipeline protection through heat insulation, heat preservation, etc., can solve problems such as difficulties in manufacturing, operation and maintenance, and achieve good heat insulation effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

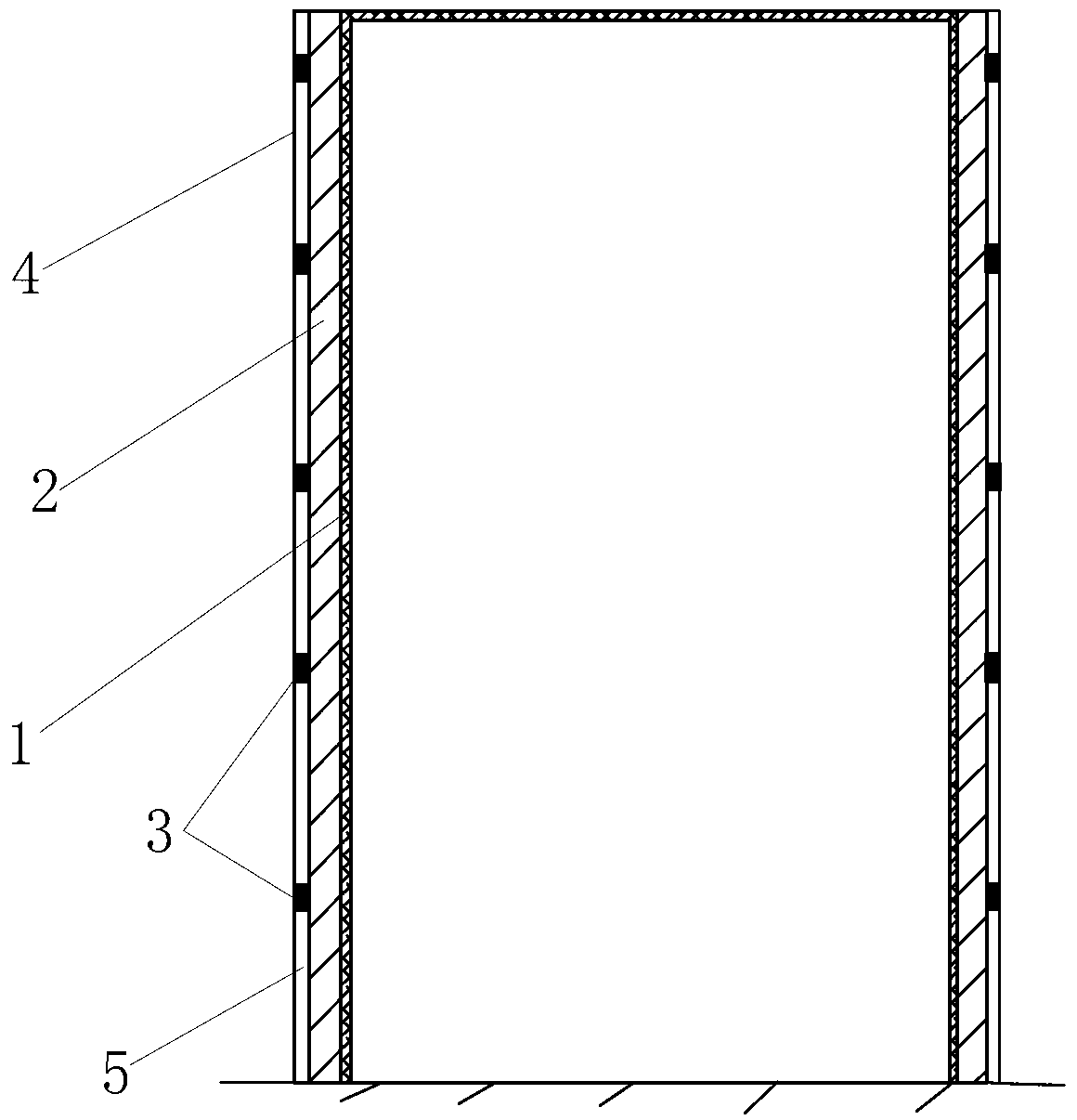

[0042] (Example 1, thermal insulation structure of heat medium storage tank)

[0043] See figure 1 , The thermal insulation structure of the heat medium storage tank of the solar thermal power generation system in this embodiment includes a thermal insulation composite layer 2 , a fixing piece, a support bar 3 and an outer protective layer 4 . Fixing parts are galvanized iron wire. The heat medium in the heat medium storage tank is molten salt or heat transfer oil. There are 4 to 6 groups of thermal insulation composite layers 2, and each group of thermal insulation composite layers 2 is wrapped group by group on the outer peripheral surface of the tank body 1 of the heat medium storage tank in sequence from the inside to the outside, and is bound group by group by the iron wire of the fixing part fixed on the tank body 1. That is, the first group of thermal insulation composite layers 2 is wrapped around the tank body 1 and fixed by iron wires; the second group of thermal ...

Embodiment 2

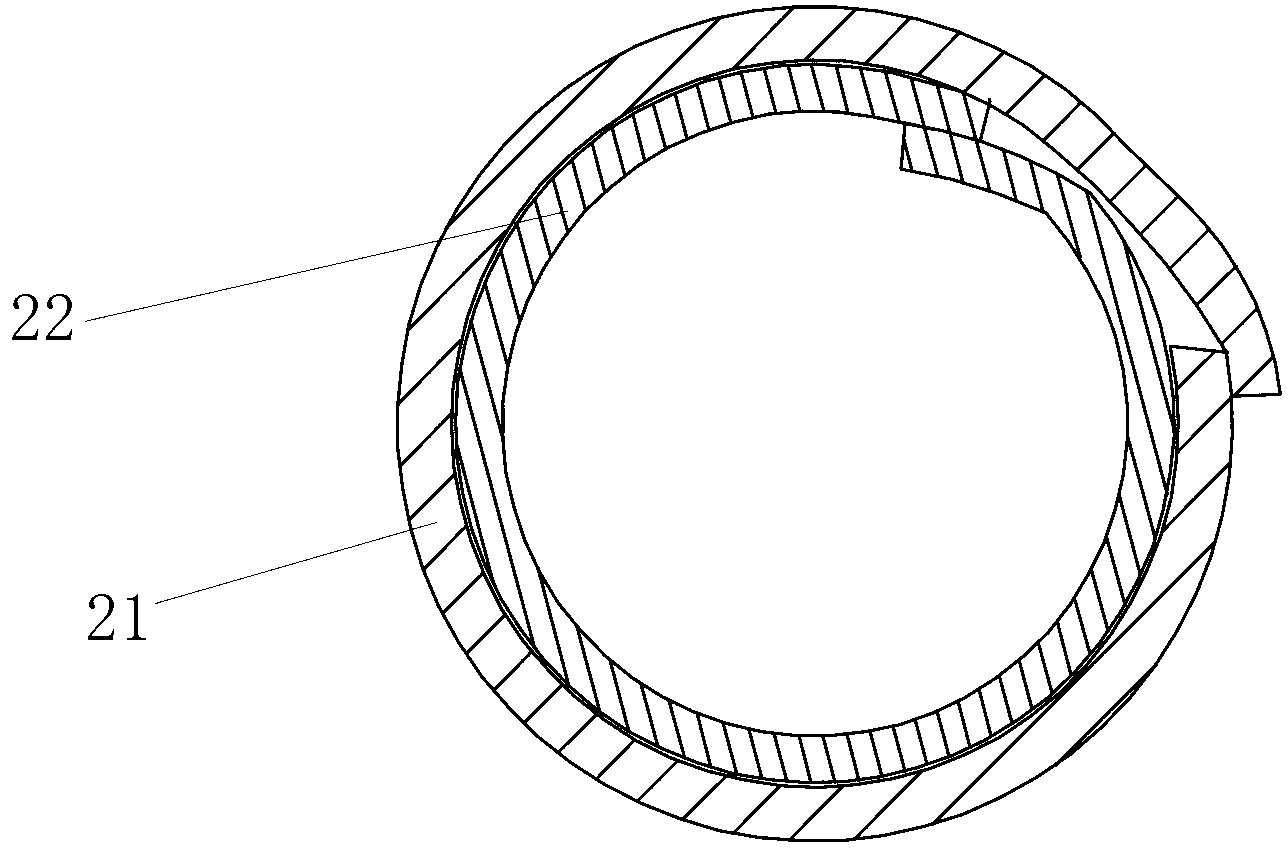

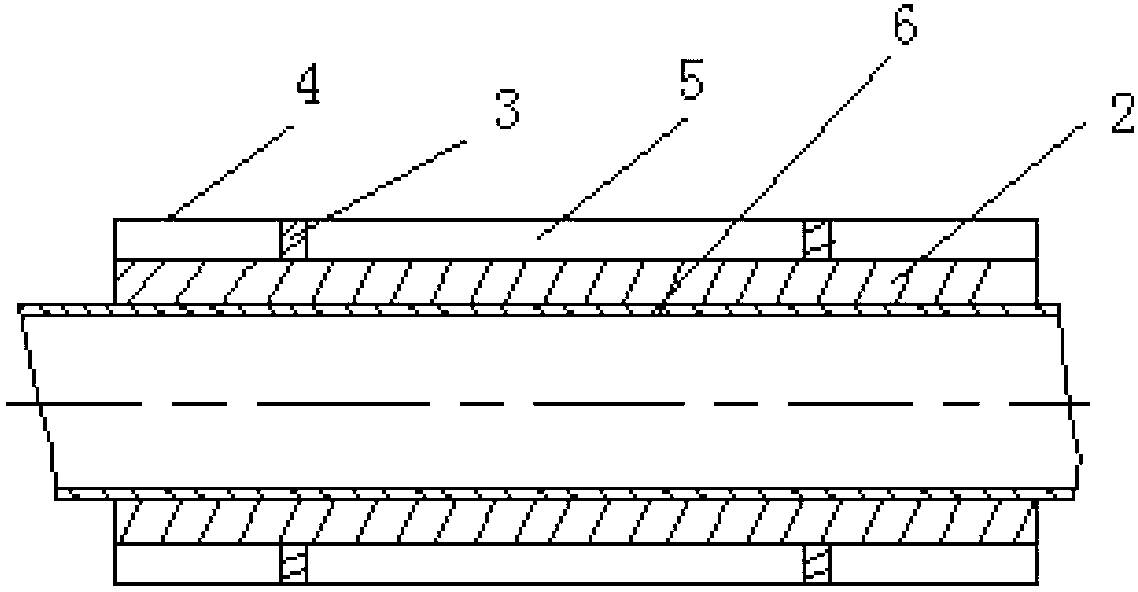

[0065] (Example 2, insulation structure of heat medium pipeline)

[0066] The thermal insulation structure of the heat medium pipeline of the solar thermal power generation system in this embodiment includes a thermal insulation composite layer 2 , a fixing piece, a support bar 3 and an outer protective layer 4 . Fixing parts are galvanized iron wire. There are 1 to 6 groups of thermal insulation composite layers 2, and each group of thermal insulation composite layers 2 is wrapped on the outer peripheral surface of the pipeline 6 group by group according to the order from the inside to the outside, and is fixed on the pipeline 6 group by group by fixing iron wires. That is, the first group of thermal insulation composite layers 2 is wrapped on the pipe 6 and fixed by iron wires; the second group of thermal insulation composite layers 2 is wrapped on the first group of thermal insulation composite layers 2 and fixed by iron wires; and so on until the final The outer 1 group o...

Embodiment 3

[0073] (Example 3, insulation structure of heat medium pipeline)

[0074] The rest of the thermal insulation structure of the heat medium pipeline in this embodiment is the same as that in Embodiment 1, except that the pipeline 6 in this embodiment is a pipeline for transporting 300°C steam, and when the steam transportation pipeline 6 is insulated, it is laid sequentially from the inside to the outside 3 sets of thermal insulation composite layers 2.

[0075] The inner first group of thermal insulation composite layer 2 is made up of 3mm thick glass fiber felt and 6mm thick high temperature type airgel thermal insulation blanket. The second group of thermal insulation composite layer 2 consists of a 25mm thick aluminum silicate fiber blanket and a 6mm thick high temperature airgel thermal insulation blanket. The third group of thermal insulation composite layer 2 is composed of 3mm thick glass fiber felt and 6mm thick medium temperature airgel thermal insulation blanket.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com