Composite silicon based electrode material, preparation method and application thereof

An electrode material, silicon-based technology, applied in battery electrodes, circuits, electrical components, etc., can solve the problems of poor electrode cycle performance, low Coulomb efficiency, solvent instability, etc., to suppress capacity decay, reduce volume change rate, First Coulomb Efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

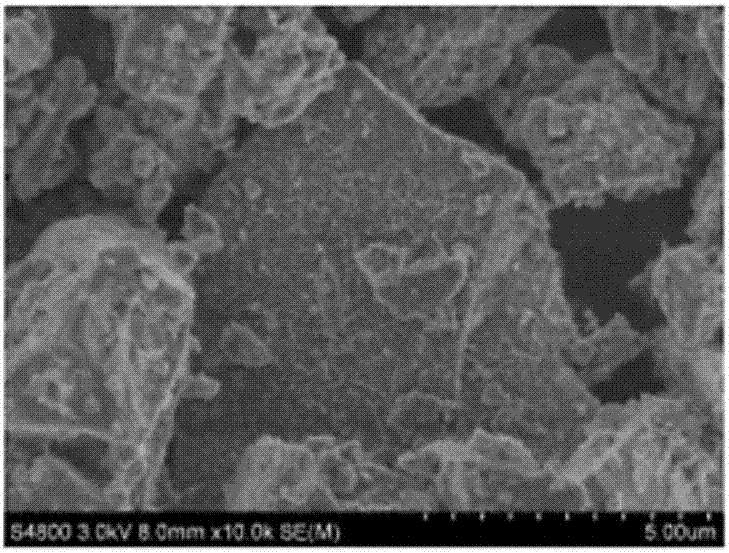

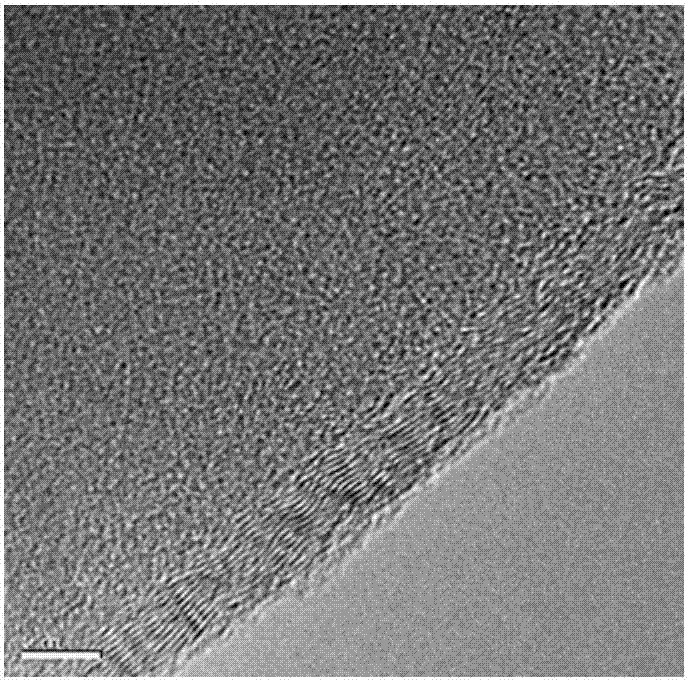

[0046] In a second aspect, the present invention provides a method for preparing a composite silicon-based electrode material, comprising the following steps: firstly oxidize the pre-lithiated silicon-based core, and then carry out carbon coating. The composite silicon-based electrode material can be obtained after the graphene layer is formed outside the nucleus. The preparation method of the above-mentioned composite silicon-based electrode material is simple in process, high in controllability, and suitable for industrial continuous production. First, the pre-lithiated silicon-based core is oxidized to form an oxide layer on the surface of the pre-lithiated silicon-based core. Graphene provides a large number of nucleation centers for the nucleation and growth of graphene, and then carbon coating is carried out to obtain the composite silicon-based electrode material. The composite silicon-based electrode material prepared by this method has high environmental stability , s...

Embodiment 1

[0064] A composite silicon-based electrode material, mainly composed of a pre-lithiated silicon-based core and a graphene layer coated on the outside of the pre-lithiated silicon-based core. The pre-lithiated silicon-based core is mainly composed of a silicon source and a Lithium reagent was prepared.

[0065] The above-mentioned composite silicon-based electrode material is mainly prepared by the following method:

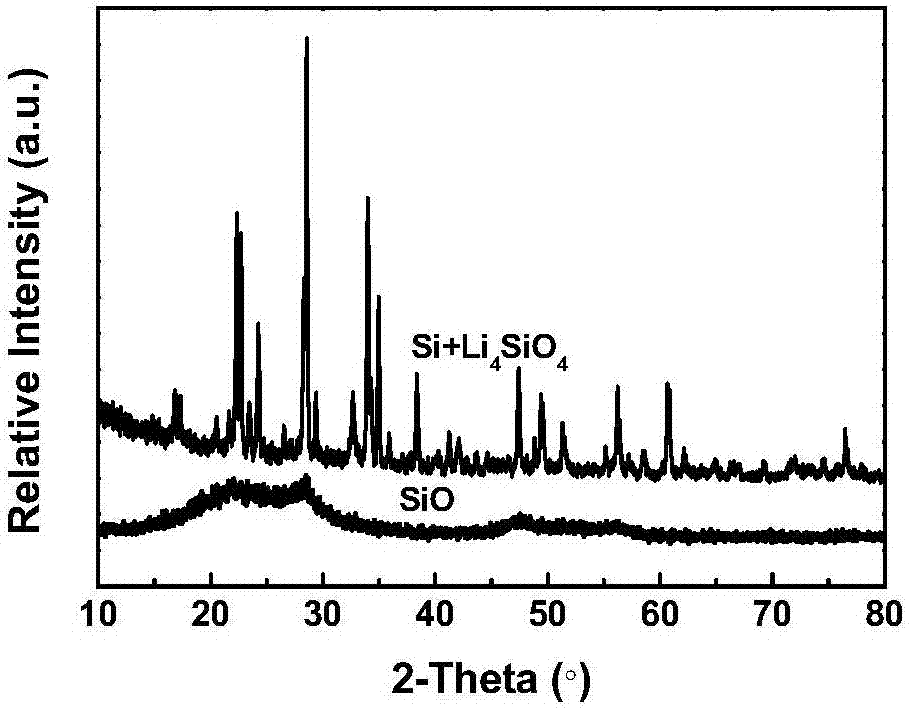

[0066] (a) Mix silicon monoxide powder (with a particle size of 5 μm) and LiH evenly in a mortar with a mass ratio of 7:1, place it in an atmospheric tube furnace under an argon atmosphere, and calcinate at 800 °C for 1 h, The pre-lithiated silicon-based core is obtained, and its XRD pattern is as follows figure 1 shown;

[0067] (b) Carry out oxidation treatment in the weak oxidation atmosphere with the pre-lithiated silicon-based core obtained in step (a), the weak oxidation atmosphere is O 2 and argon gas mixture, where O 2 The volume fraction is 1%, the fl...

Embodiment 2

[0071] A composite silicon-based electrode material, mainly composed of a pre-lithiated silicon-based core and a graphene layer coated on the outside of the pre-lithiated silicon-based core. The pre-lithiated silicon-based core is mainly composed of a silicon source and a Lithium reagent was prepared.

[0072] The above-mentioned composite silicon-based electrode material is mainly prepared by the following method:

[0073] (a) Mix silicon monoxide powder (with a particle size of 10 nm) and LiH evenly in a mortar with a mass ratio of 3:1, place in an atmospheric tube furnace under an argon atmosphere, and calcinate at 400°C for 2 hours;

[0074] (b) Carry out oxidation treatment in the weak oxidation atmosphere with the pre-lithiated silicon-based core obtained in step (a), the weak oxidation atmosphere is O 2 and argon gas mixture, where O 2 The volume fraction is 10%, the flow rate of the mixed gas is 20sccm; the oxidation temperature is 400°C, and the oxidation time is 5m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com