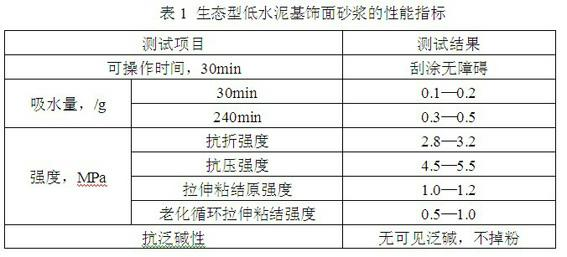

Ecological low cement-based finishing mortar

A facing mortar and cement-based technology, which is applied in the field of chemical materials, can solve the problems of easy efflorescence, high production cost, and high price, and achieve the effects of easy storage of dry powder, good weather resistance, and convenient transportation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] An ecological low cement-based finishing mortar, in terms of weight percentage, consists of the following components:

[0020] White cement (32.5) is 12.5%, 0.1-0.5mm high whiteness quartz sand is 50%, 400 mesh ground calcium carbonate is 30%, cellulose Bermocoll M30 is 0.15%, lignocellulose is 0.35%, water repellent ELotex ? SEAL80 is 0.4%, rebase inhibitor ELotex ? ERA100 is 0.2%, redispersible latex powder is 6%, starch ether ELotex ? ELOSET 542 is 0.4%; mix the above raw materials evenly, then add 18% water of the total weight of the above raw materials, and mix evenly to obtain the ecological low cement-based finishing mortar of the present invention. Among them, cellulose ether Bermocoll M30; pan- Alkali Inhibitor ELotex ? ERA100; Hydrophobic agent ELotex ? SEAL80; starch ether is starch ether ELotex ? ELOSET 542 etc. are products produced by AkzoNobel.

Embodiment 2

[0022] An ecological low cement-based finishing mortar, in terms of weight percentage, consists of the following components:

[0023] White cement (32.5) is 12.5%, 0.1-0.5mm high whiteness quartz sand is 50%, 400-mesh ground calcium carbonate is 30%, cellulose ether Bermocoll M30 is 0.2%, lignocellulose is 0.3%, hydrophobic Agent ELotex ? SEAL80 is 0.3%, pan- Alkali Inhibitor ELotex ? ERA100 is 0.2%, redispersible latex powder is 6%, starch ether ELotex ? ELOSET 542 is 0.5%; mix the above raw materials evenly, then add 18% water of the total weight of the above raw materials, and mix evenly to obtain the ecological low cement-based finishing mortar of the present invention.

Embodiment 3

[0025] An ecological low cement-based finishing mortar, in terms of weight percentage, consists of the following components:

[0026] White cement (32.5) is 12.5%, 0.1-0.5mm high whiteness quartz sand is 50%, 400-mesh ground calcium carbonate is 30%, cellulose ether Bermocoll M30 is 0.2%, lignocellulose is 0.4%, hydrophobic Agent ELotex ? SEAL80 is 0.2%, pan- Alkali Inhibitor ELotex ? ERA100 is 0.2%, redispersible latex powder is 6%, starch ether ELotex ? ELOSET 542 is 0.5%; mix the above raw materials evenly, then add 18% water of the total weight of the above raw materials, and mix evenly to obtain the ecological low cement-based finishing mortar of the present invention.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com