Grey brick mechanically manufactured from lime sludge and construction wastes and method for manufacturing same

A technology of construction waste and manufacturing method, which is applied in the field of building blocks to achieve the effects of strong adhesion, increased impermeability, and pollution avoidance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

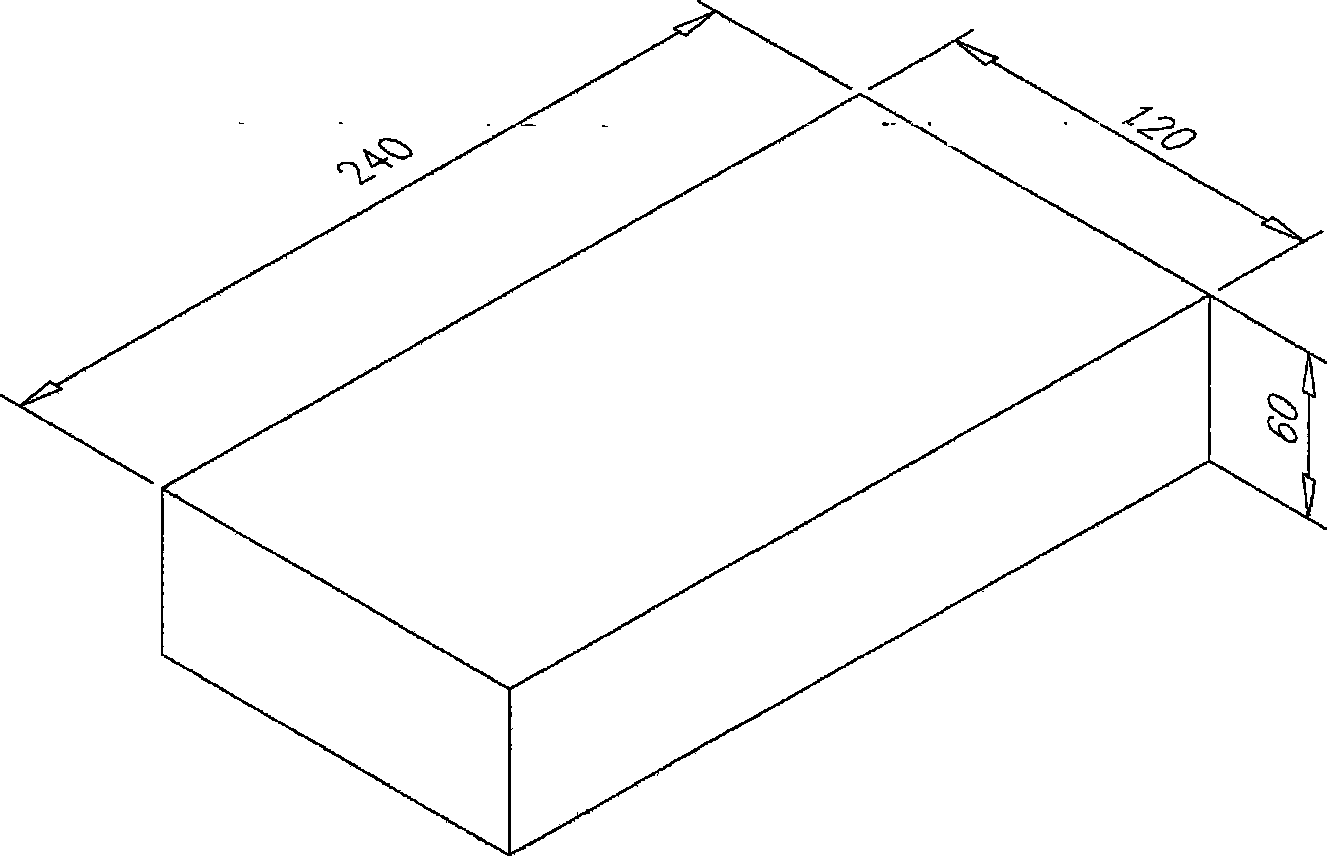

[0045] like figure 1 Shown, it is the machine-made black brick of common brick type of the present invention, and its preparation material contains the raw material of following parts by weight: 1028 parts are made of sintered products (such as clay bricks, earthen pots and broken glass fragments, etc.) Garbage broken material, 280 parts of cement, 910 parts of lime sludge soil, 67 parts of blue ash and 115 parts of water; wherein the particle size of the construction waste broken material is below 10 mm.

[0046] In order to make the color of the machine-made green brick closer to that of the fired clay brick, 0.5 part of pigment is added to the preparation to adjust the color.

[0047] The manufacture method of the machine-made green brick of common brick type of the present embodiment comprises:

[0048] - Classify the construction waste first, and first pick up and screen the construction waste materials of sintered products (such as clay bricks, crock pots and broken glass...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com