Cement concrete pavement patching material and preparation method thereof

A cement concrete and pavement repair technology, applied in the field of cement pavement maintenance technology and materials, can solve the problems of high polymer and fiber addition, high weather conditions, and insufficient compatibility, so as to achieve rapid curing and prevent diffusion and spread , The effect of convenient construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0057] 1. Preparation of repair materials

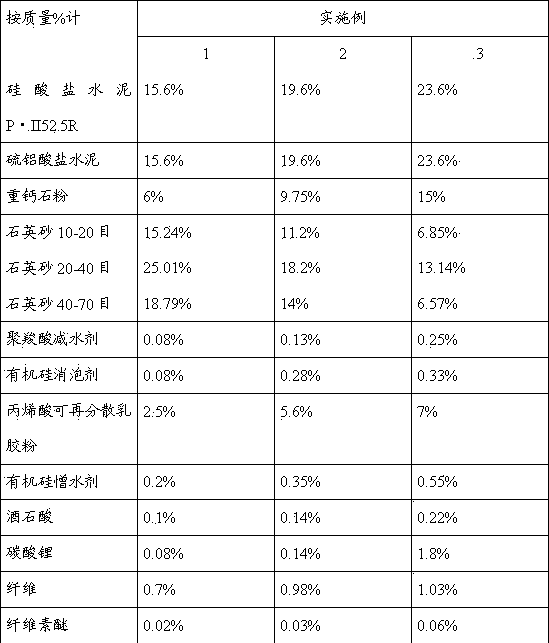

[0058] According to 3 different batching methods in Table 1, and adopt the following preparation method to prepare the repairing material of the present invention.

[0059] 1) Take the corresponding proportion of Portland cement, sulfate cement and fiber and stir it with a mixer for 10-15 minutes;

[0060] 2) Combine the mixture obtained in the above 1) with heavy calcium stone powder, quartz sand, polycarboxylate water reducer, silicone defoamer, silicone water repellent, redispersible latex powder, tartaric acid, carbonic acid Put lithium and cellulose ether into the mixer and stir for 30-45 minutes;

[0061] 3) Packing and packaging the materials prepared above.

[0062] Table 1

[0063]

[0064] In the embodiment, the fibers are mainly polyvinyl alcohol fibers and carbon fibers, and the usage ratio is not particularly limited, but polyvinyl alcohol fibers:carbon fibers=5:1 is preferred. In addition, the type of sulphoalum...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com