Exterior wall heat preservation decorative lamination integration system and its production and mounting method

A technology for external thermal insulation of external walls and production methods, applied in thermal insulation, climate change adaptation, building components, etc., can solve problems such as long construction period, low thermal insulation performance, and prone to cracking on the surface, so as to reduce construction costs and save construction The effect of short time and construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

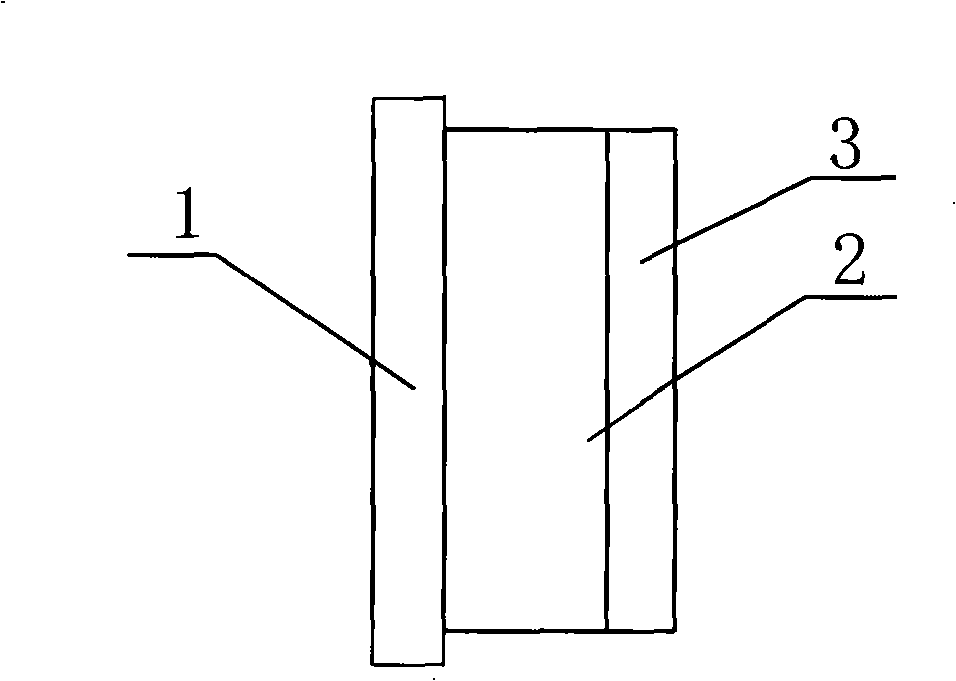

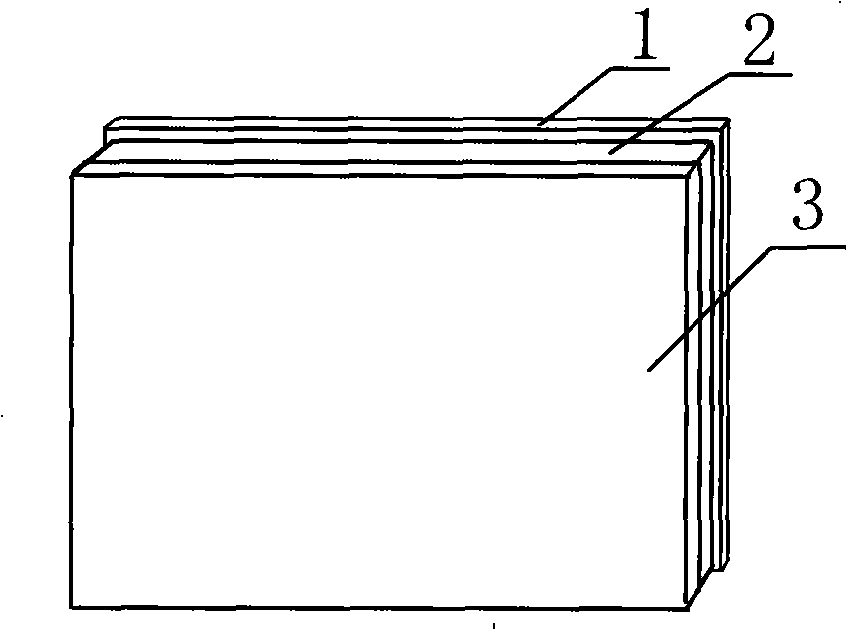

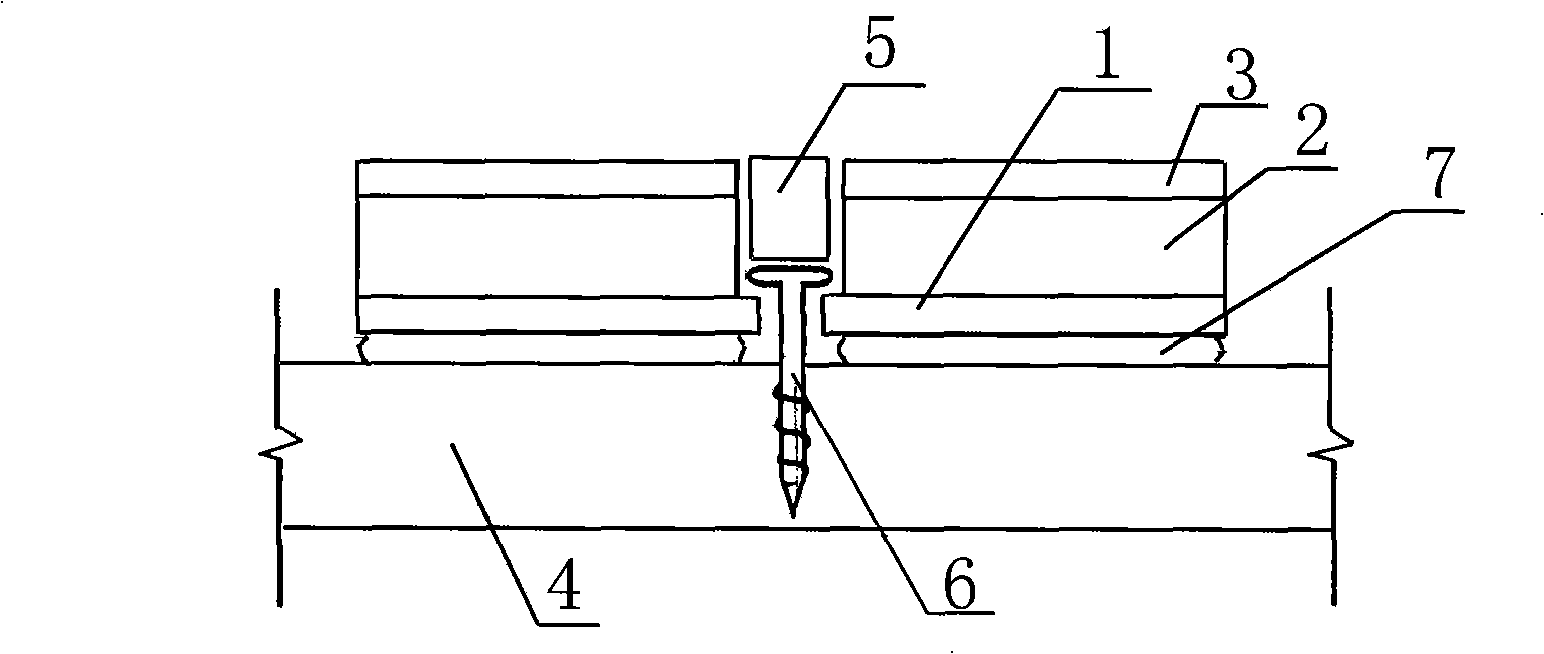

[0035] A rigid flame-retardant polyurethane foam material 2 is filled between the inorganic fireproof bottom layer 1 and the decorative surface layer 3 to form an integral polyurethane insulation board.

[0036] The inorganic fireproof bottom layer 1 includes cement board or fireproof glass magnesium board.

[0037] The decorative surface layer 3 includes marble, granite, stainless steel, aluminum-plastic composite board, ceramic board, clay board or plastic-steel composite board.

[0038] Described flame-retardant rigid polyurethane foam material 2 comprises A material and B material, and A material and B material are mixed together during use; Wherein A material comprises polyether or polyester polyol; B material comprises crude MDI (polyphenyl polymethylene polyisocyanate).

[0039] The production method of described polyurethane external wall insulation material is as follows:

[0040](1) Raw materials: It is a combination of material A and material B, and material A is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com