Cement clinker and preparation method thereof

A cement clinker and raw material technology, applied in cement production, etc., can solve the problems of insufficient resistance to chloride ion penetration and sulfate erosion, less cementing material consumption, and high maintenance costs, so as to increase resistance to seawater erosion ability, dense hydration slurry, and good impermeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

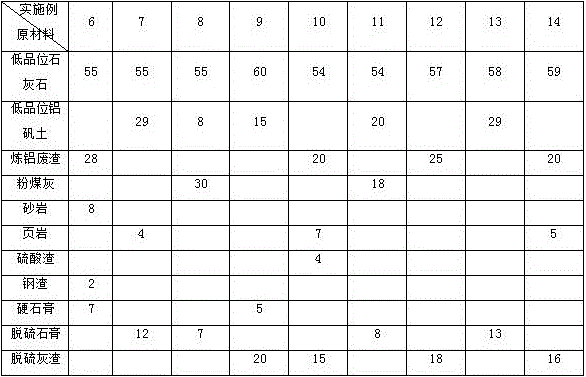

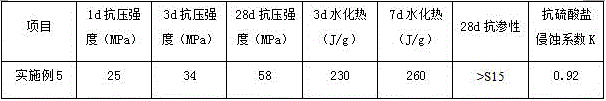

Examples

Embodiment 1

[0024] A cement clinker is composed of the following raw materials by mass percentage: 50% low-grade limestone, 9% sandstone, 34% high-iron bauxite, and 7% desulfurized gypsum.

[0025] The clinker preparation method of the present embodiment is as follows:

[0026] After crushing and grinding the aforementioned raw materials, they are mixed, and then the mixed raw materials are calcined at a temperature of 1100-1350° C. for 10 minutes, and cooled to obtain the clinker.

Embodiment 2

[0028] A preparation method of cement clinker, comprising the following steps:

[0029] a. Ingredients: 49% of low-grade limestone, 11% of shale, 32% of aluminum smelting waste, and 8% of desulfurized gypsum; the ingredients refer to crushing and grinding of each raw material before mixing.

[0030] b. Calcining: calcining the mixed raw meal at a temperature of 1100-1350° C. for 90 minutes, and obtaining the clinker after cooling.

Embodiment 3

[0032] A preparation method of cement clinker, comprising the following steps:

[0033] a. Ingredients: 50% of low-grade limestone, 7% of shale, 25% of high-iron bauxite, and 18% of desulfurization ash; the ingredients refer to crushing and grinding of each raw material before mixing.

[0034] b. Calcining: calcining the mixed raw meal at a temperature of 1100-1350° C. for 50 minutes, and then obtaining the clinker after cooling.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com