Patents

Literature

74results about How to "Act as a crosslinking agent" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Multifunctional cotton fabric finishing agent and method for making same

The invention relates to a multifunctional cotton fabric finishing agent with anti-ultraviolet rays, improved fabric light fastness, antibacterial and wrinkle resistance and a preparation method thereof. The steps of the preparation method include: preparing a water phase; preparing an oil phase; preparing an emulsion; preparation. The invention solves the compatibility problem between functional components, the finishing agent has good stability, and there is a promotion effect between functional components, polycarboxylic acid, polycarboxylic acid and chitosan play the role of crosslinking agent, Improves the durability of various functions.

Owner:SOUTH CHINA UNIV OF TECH +1

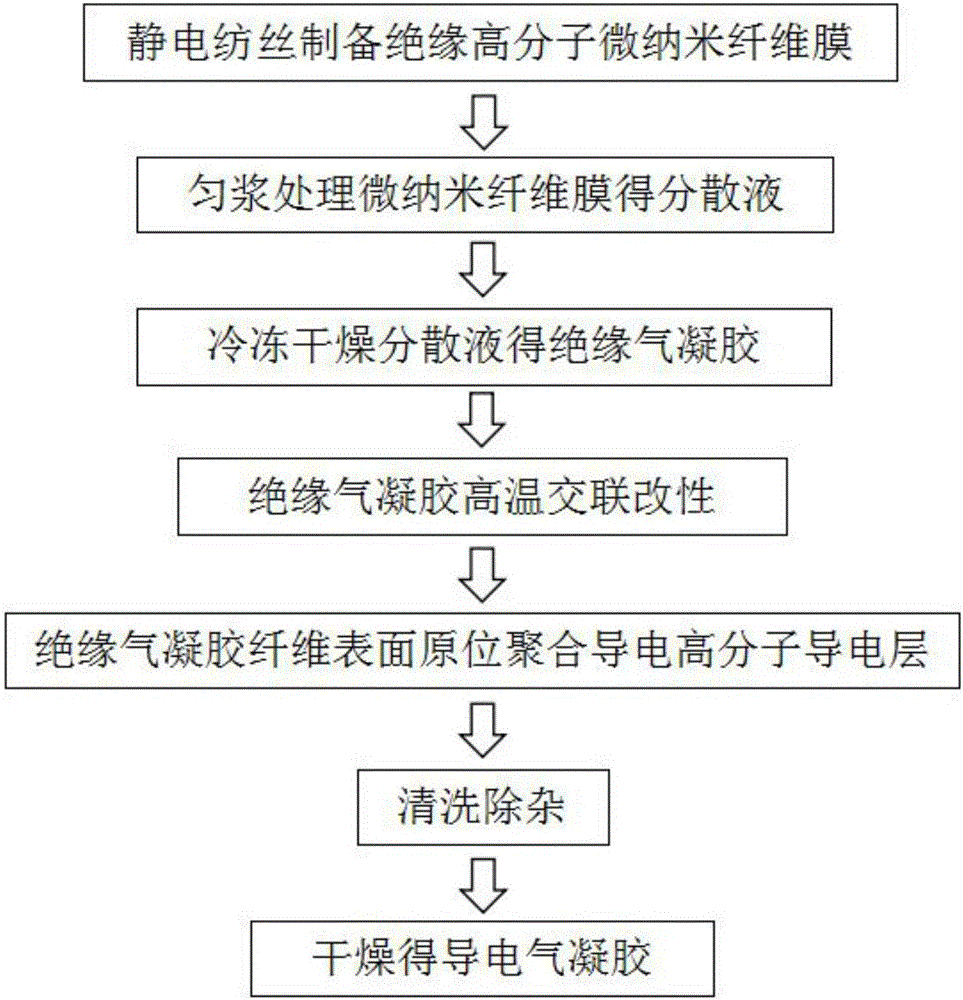

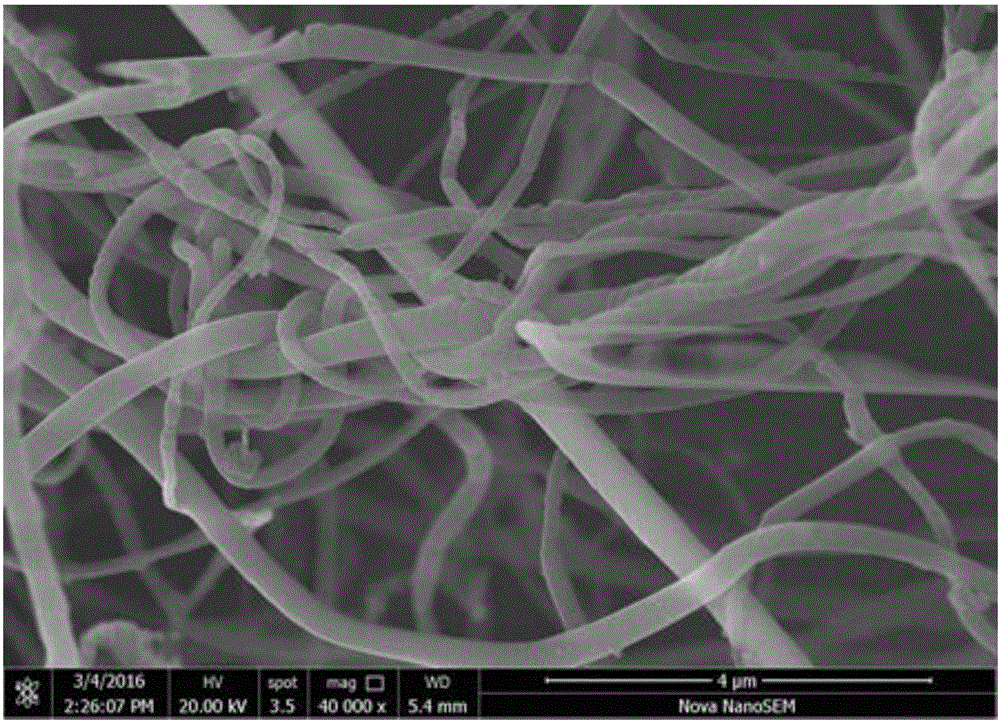

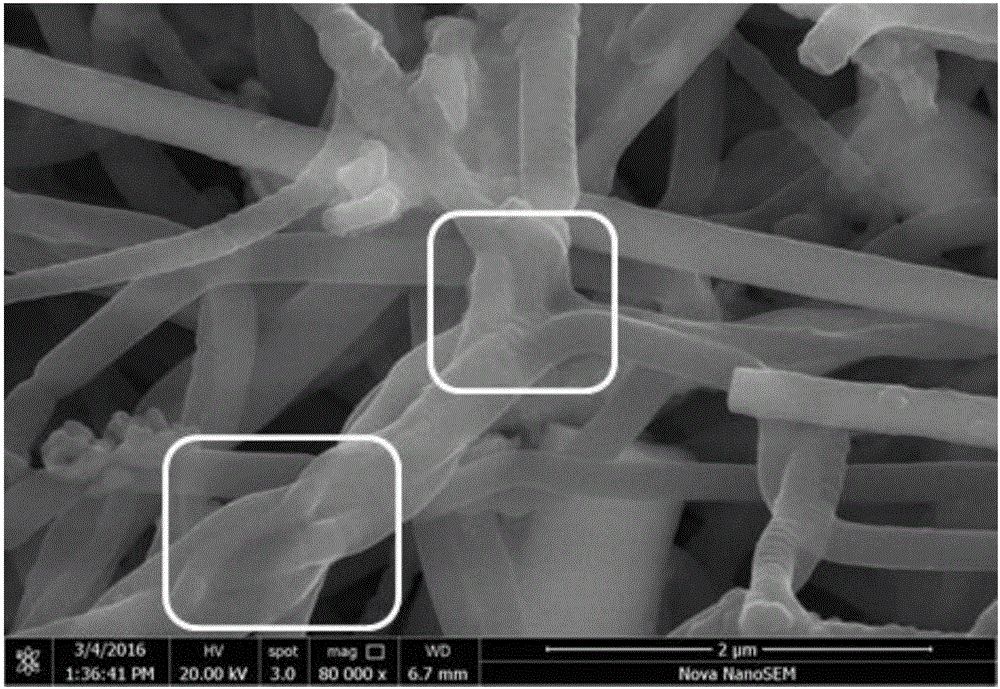

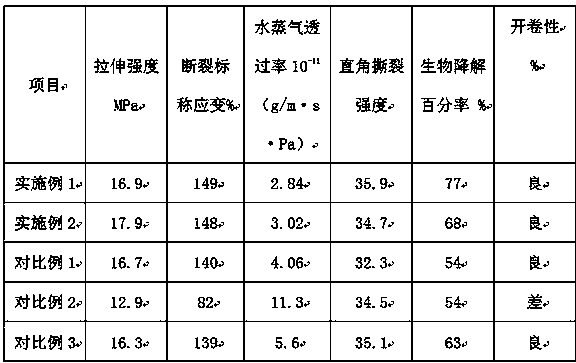

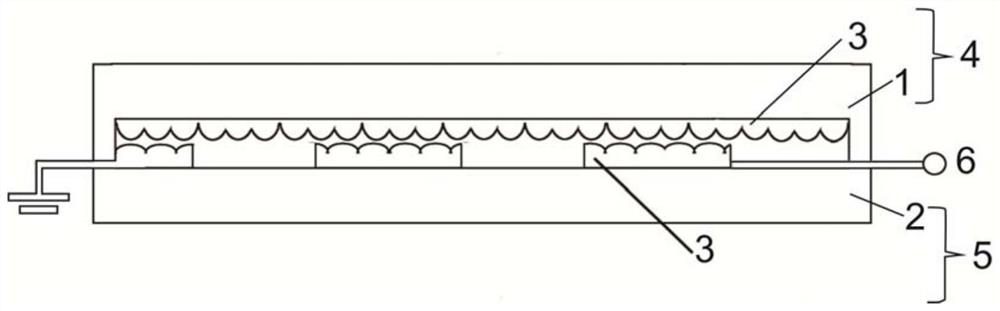

Conductive aerogel and preparation method thereof

ActiveCN105820372AEasy to prepareImprove conductivityElectro-spinningNon-woven fabricsFiberElectrospinning

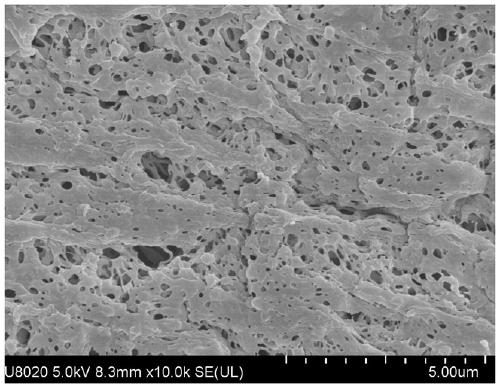

The invention discloses conductive aerogel and a preparation method thereof. Coaxial composite micro-nanofibers are adopted as fibers for preparing the aerogel, an insulated macromolecular micro-nanofiber prepared through electrostatic spinning serves as the axis of the coaxial composite micro-nanofibers, and the outer surface of the insulated macromolecular micro-nanofiber is coated with a conductive layer through an in-situ polymerization reaction of a conductive polymer material. The conductive aerogel has the good conductivity, the preparation method of the aerogel is simple, has the universality and is suitable for large-scale preparation, and the types of the conductive aerogel can be greatly increased through the preparation method.

Owner:QINGDAO UNIV

Environment-friendly degradable edible film packaging material

InactiveCN109054105AHigh strengthAct as a crosslinking agentFlexible coversWrappersNon toxicityPermeation

The invention discloses an environment-friendly degradable edible film packaging material. The environment-friendly degradable edible film packaging material is prepared from the following raw materials in parts by weight: 43-77 parts of modified starch, 22-61 parts of dandelion extract, 13-17 parts of konjac gelatin powder, 32-57 parts of edible gelatin, 21-37 parts of modified casein, 10-15 parts of carboxymethyl cellulose, 3-9 parts of chitosan, 2-7 parts of plasticizers, 7-13 parts of agar, 1-3 parts of citric acid, 2-4 parts of antibacterial liquid, 0.5-1.5 parts of plant extract, 2-4 parts of cactus juice, 2-6 parts of glutinous rice juice and 2-7 parts of carrot powder. The environment-friendly degradable edible film packaging material has the advantages of edibility, capability ofpackaging food, preventing oxygen permeation and protecting the original taste of fatty food, high nutritional value after eating, capability of meeting environmental safety requirements, non-toxicity, safety, high oxygen permeation resistance, water and oil resistance, high temperature resistance, easiness in degradation, high strength, good comprehensive performance and high cost performance.

Owner:合肥旭亚新材料科技有限公司

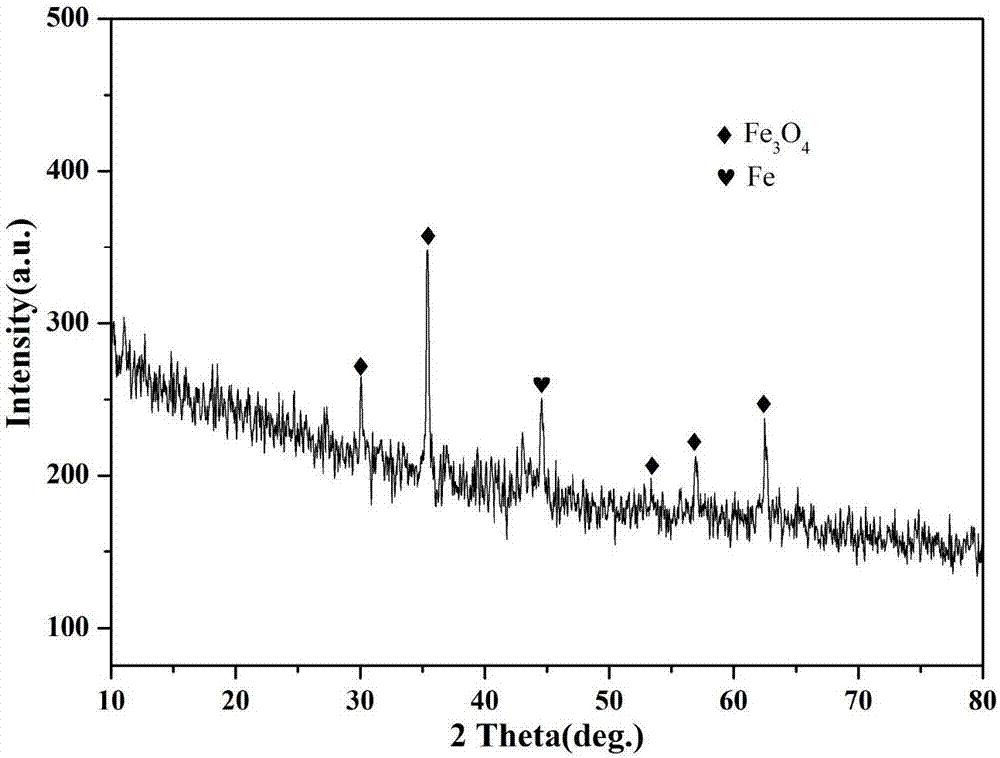

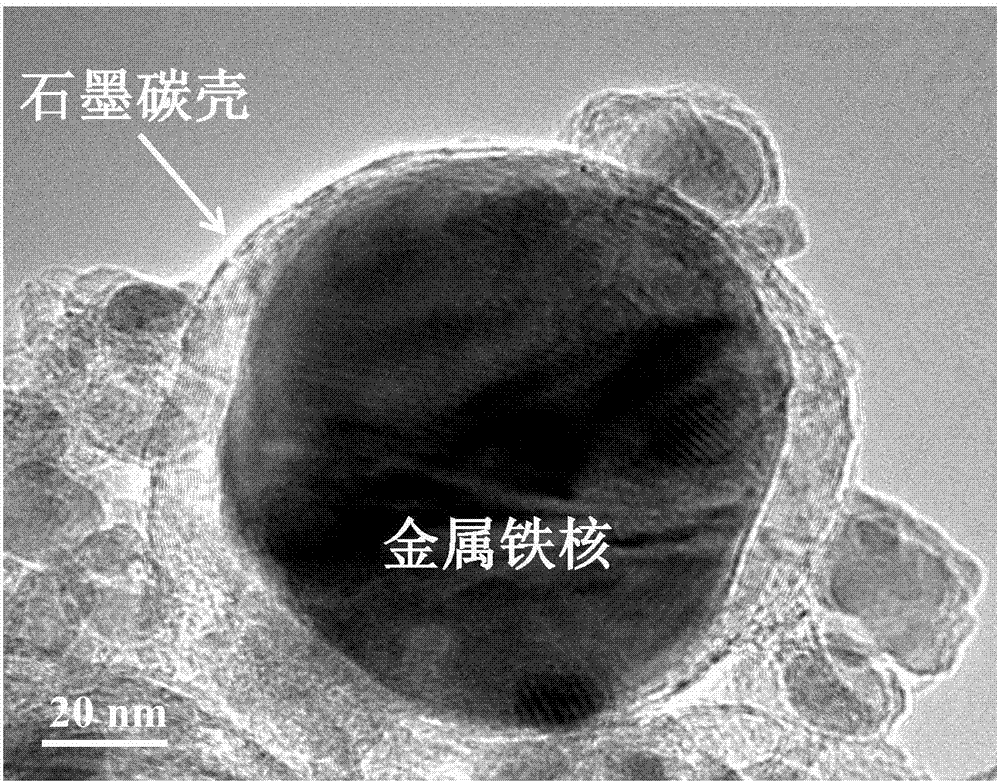

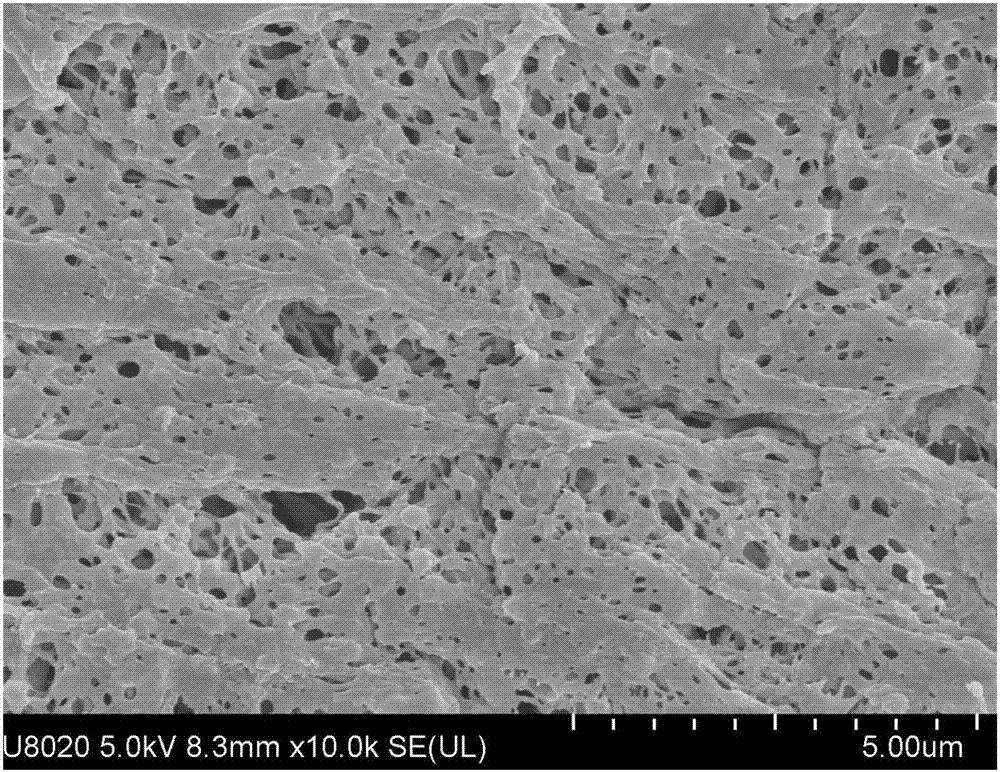

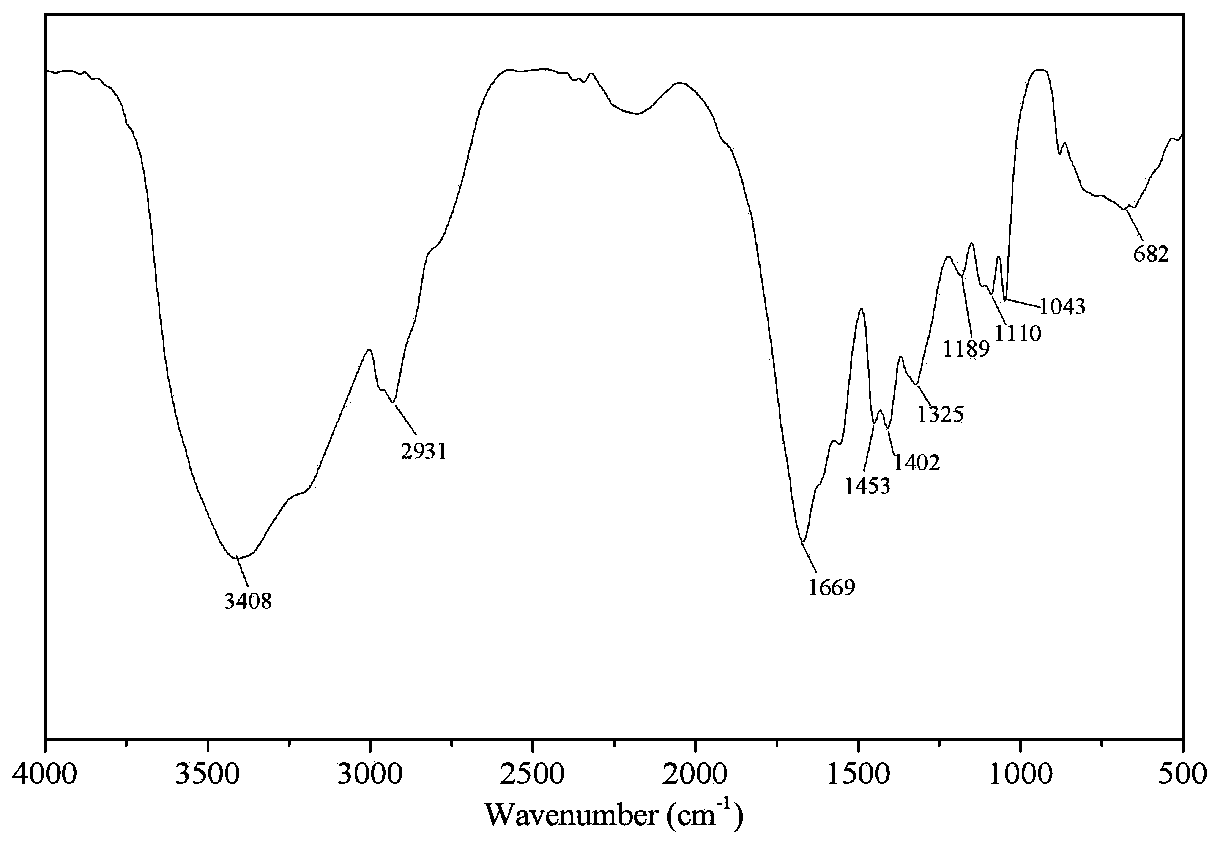

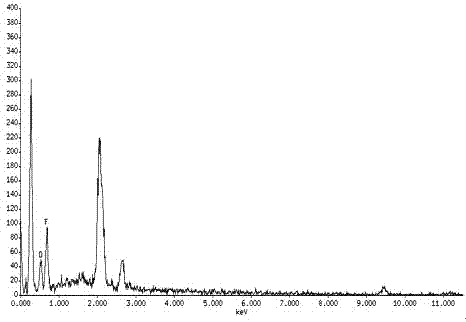

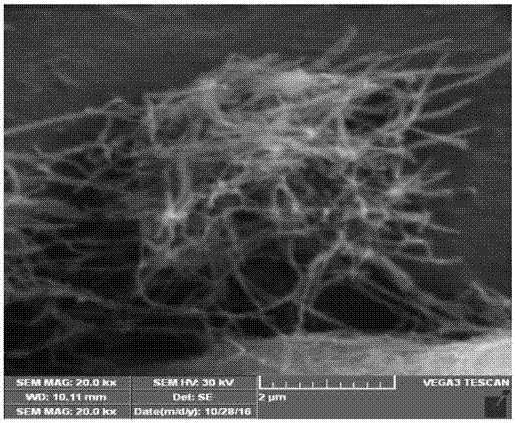

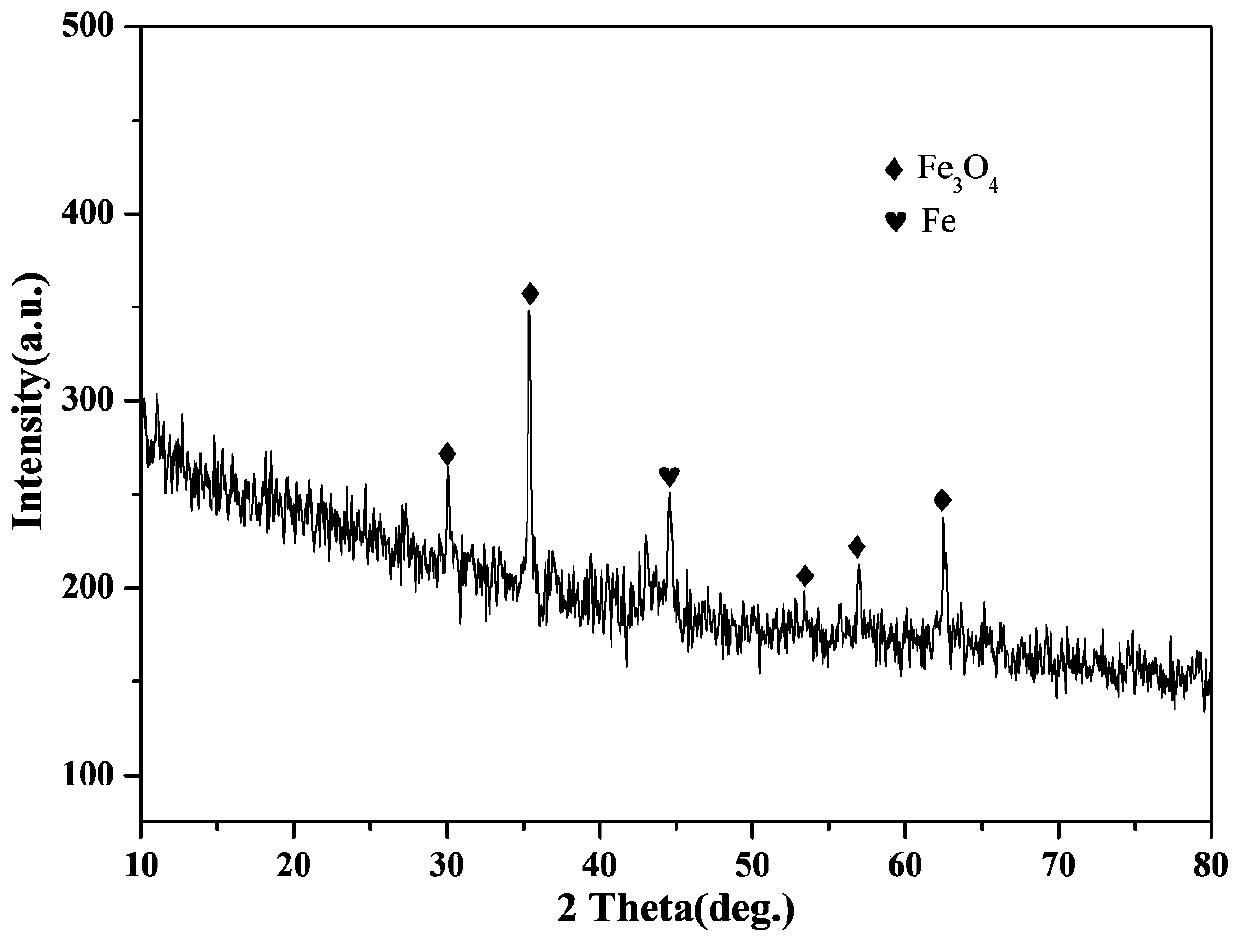

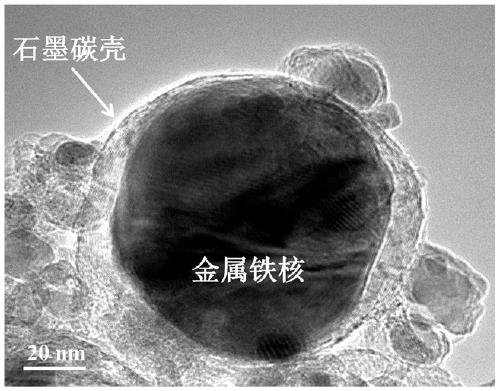

Carbon-coated metal nanoparticle-loaded PVDF (Polyvinylidene Fluoride) membrane as well as preparation method and application thereof

ActiveCN107118477AEasy reunionAvoid secondary pollutionWater treatment compoundsOrganic-compounds/hydrides/coordination-complexes catalystsPolyvinylidene difluoridePolyvinylidene fluoride

The invention discloses a carbon-coated and metal nanoparticle-loaded PVDF (Polyvinylidene Fluoride) membrane as well as a preparation method and application thereof. The preparation method comprises the following steps: firstly, synthesizing carbon-coated metal nanoparticles; secondly, mixing the carbon-coated metal nanoparticles with polyvinylidene fluoride powder, an organic additive and a dispersion medium and stirring to obtain a casting membrane solution; thirdly, obtaining a target product by a solution phase conversion method. The carbon-coated and metal nanoparticle-loaded PVDF membrane disclosed by the invention disclosed by the invention can efficiently mineralize toxic organic pollutants in a water body and is high in degradation rate; a catalytic membrane reactor is constructed to carry out a catalytic degradation reaction of the organic pollutants; macromolecular organic pollutants are prevented from passing through on the basis of a micronano separation effect of a membrane pore structure, so an interception effect is realized, conversion rate and selectivity of degradation are improved, the technical problems that metal nanoparticles are easy to agglomerate and lose are solved, and potential secondary pollution to the water body is avoided; in addition, the preparation method has the advantages of lower cost, simple process, controllable structure, high maneuverability, easiness for industrial application and the like.

Owner:HEFEI UNIV OF TECH

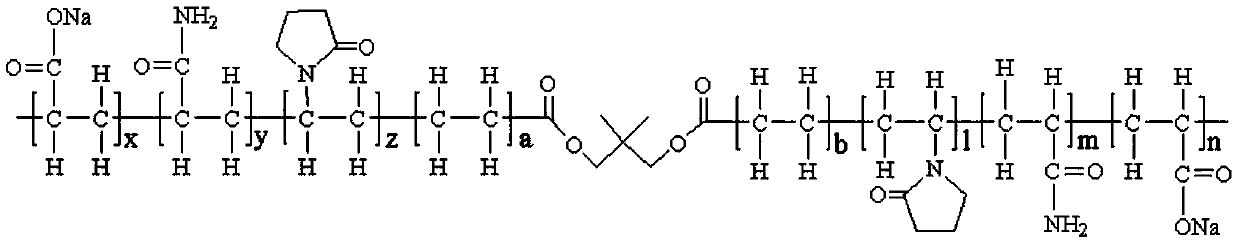

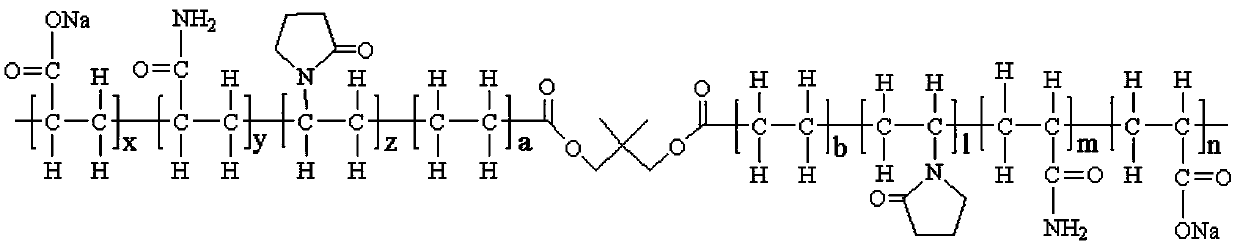

Water-soluble AA-AM-NVP-NGD quadripolymer temporary plugging agent for fracturing and synthesis method of water-soluble AA-AM-NVP-NGD quadripolymer temporary plugging agent

ActiveCN111484578AImprove temporary blocking strengthImprove rigidityDrilling compositionNeopentylglycol diacrylatePyrrolidinones

The invention relates to the technical field of oilfield chemistry. The invention discloses a water-soluble AA-AM-NVP-NGD quadripolymer temporary plugging agent for fracturing and a synthesis method of the water-soluble AA-AM-NVP-NGD quadripolymer temporary plugging agent. The temporary plugging agent is a quadripolymer mainly prepared from the following raw material monomers in percentage by mass: 30% to 40% of acrylic acid, 59.4% to 68.0% of acrylamide, 0.5% to 1.5% of N-vinyl pyrrolidone and 0.1% to 0.5% of neopentyl glycol diacrylate. According to the temporary plugging agent, the N-vinylpyrrolidone with a five-membered ring structure is introduced into a temporary plugging agent molecular chain, so that the rigidity and the stability of the temporary plugging agent molecular chain can be improved, and the temporary plugging strength of the temporary plugging agent is improved; the neopentyl glycol diacrylate with two carbon-carbon double bonds is used for synthesizing the temporary plugging agent, and plays a role of a cross-linking agent, so that the temporary plugging agent becomes a water-swelling body after absorbing water, and cracks can be plugged; the blocking removalmechanism of the temporary plugging agent is different from that of an existing water-soluble temporary plugging agent, no blocking removal agent needs to be additionally added in the blocking removalprocess, complete blocking removal only needs to be achieved under the action of temperature and water, and the blocking removal performance is good.

Owner:SICHUAN UNIVERSITY OF SCIENCE AND ENGINEERING

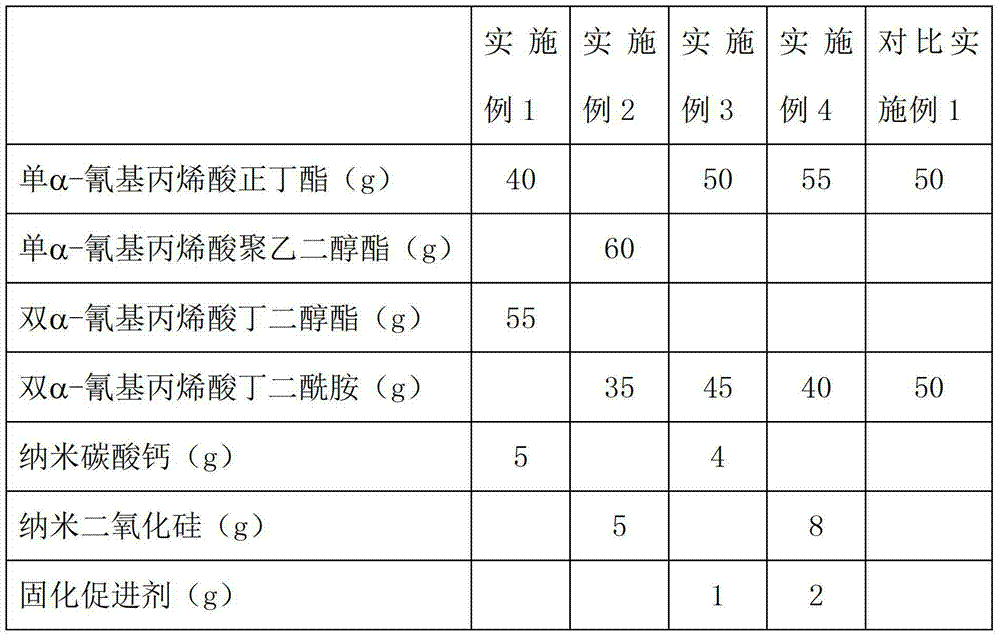

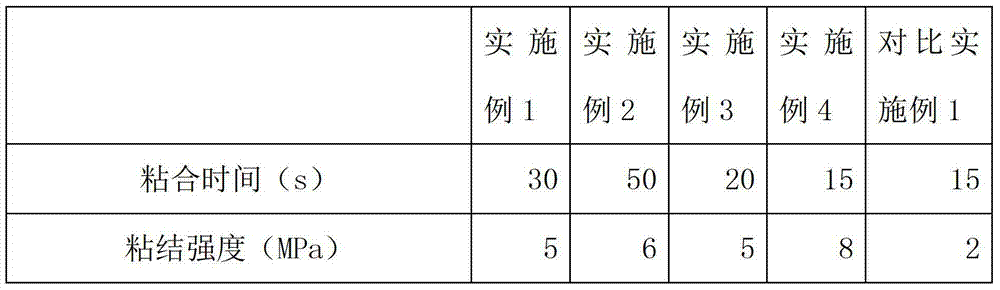

Adhesive composition

InactiveCN103173138AFast curingCause poisonNon-macromolecular adhesive additivesOrganic non-macromolecular adhesiveOrganic solventAdhesive

The invention relates to an adhesive composition. The adhesive composition comprises at least one single-alpha-cyanoacrylate (a), at least one dual-alpha-cyanoacrylate glycol or dual-alpha- cyanoacrylate diamide (b) and at least one additive (c). The adhesive composition can be rapidly cured, does not contain organic solvents and can be used for food packaging, lunch boxes, bioengineering materials and medical adhesives; and curing products can be degraded and is non-toxic.

Owner:汕头市新侨药用防粘纸科技有限公司

Self-suspension propping agent and preparation method thereof

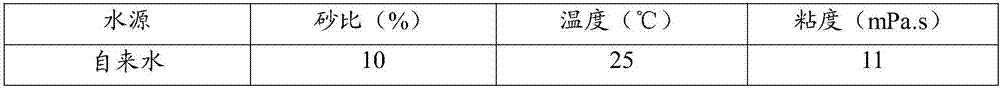

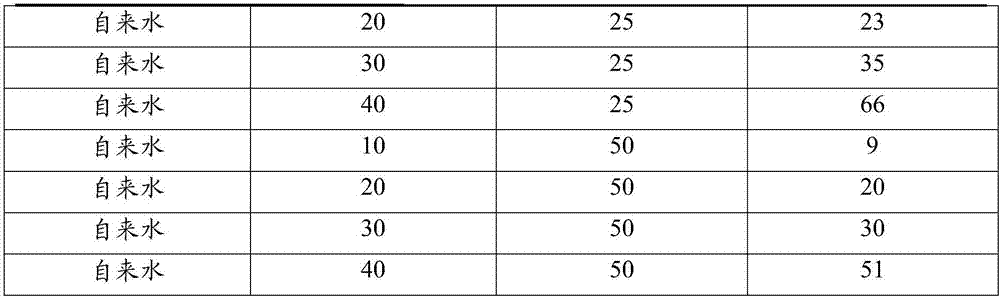

ActiveCN107033871AStrong shearStrong shear resistanceFluid removalDrilling compositionChemistrySilane coupling

The invention provides a preparation method of a self-suspension propping agent. The preparation method comprises the following steps: mixing a pre-heated propping agent matrix and a polymer capable of being swollen with water; in a stirring process, spraying a silane coupling agent solution into a mixture; and reacting for 3h to 4h at a temperature of 60 DEG C to 80 DEG C to obtain the self-suspension propping agent. According to the preparation method of the self-suspension propping agent, the silane coupling agent and the polymer capable of being swollen with the water are used for coating the propping agent matrix so that a cross-linking agent is realized; the silane coupling agent is connected with the propping agent matrix by adopting a siloxane chemical bond and is also subjected to a chemical reaction with the polymer to form a chemical bond; the self-suspension propping agent provided by the invention has a good anti-shearing capability and a great buoyant force; the self-suspension propping agent has long suspension time in clean water; a toxic organic solvent does not need to be added and a gel breaking performance is good; and gel breaking liquid has a relatively good anti-swelling performance and a strong crack backward flowing capability.

Owner:GUANGHAN HUAXING NEW TECH DEV INST GENERAL PARTNERSHIP +1

Lightweight high-strength flame-retardant material and preparation method thereof

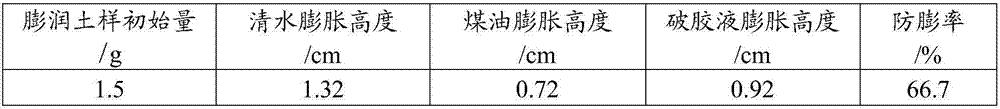

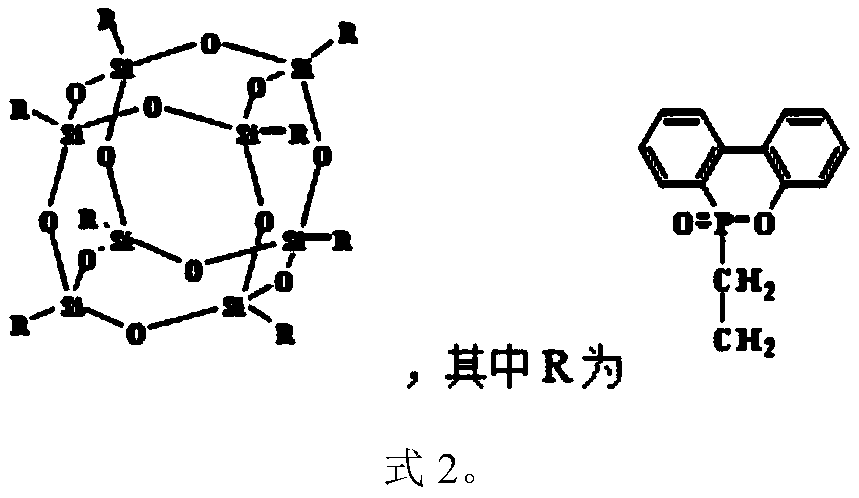

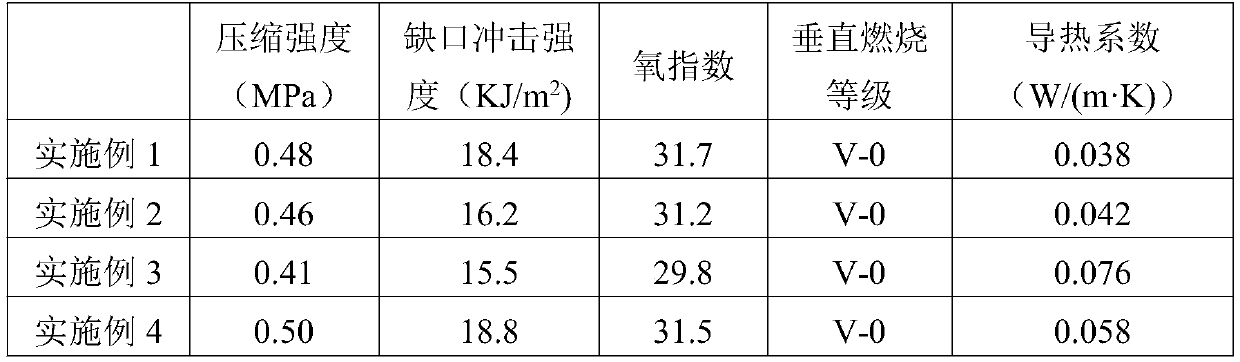

The invention discloses a lightweight high-strength flame-retardant material. According to the present invention, a norbornane diisocyanate oligomer, polyester polyol, a starch copolymer, phosphinylidynetrimethanol, hydroxyl phosphate, melamine cyanurate, polyhedral oligomeric silsesquioxane and an antioxidant are used as raw materials; by utilizing the structural design and the interaction of thecomponents, a polyglycolic acid grafted starch copolymer and a phosphorus-containing substance are used as a carbon source, a cyanamide substance is used as a gas source, a phosphoric acid substanceis used as an acid source, a compact carbon layer is formed after heating combustion, and excellent flame retardancy is achieved through puffing flame-retardant effect; by adding and dispersing polyhedral oligomeric silsesquioxane to the matrix, the flame retardancy and the mechanical property of the material can be further improved; and by adopting the high-pressure foaming and rapid cooling technology after pre-reaction, the uniform foam holes can be effectively ensured, the foaming ratio is high, the material strength is high, the buffer performance is good, and the obtained material can beused as a fireproof core board or an outer board.

Owner:HUNAN ZHENQIU FIRE FIGHTING IND

Preparation method of high-performance resin adhesive for rock wool sizing

ActiveCN103555235ASolve the lack of dilution differenceIncreased water dilutionAldehyde/ketone condensation polymer adhesivesPolyvinyl alcoholResin adhesive

The invention provides a preparation method of a high-performance resin adhesive for rock wool sizing, and relates to the field of resins. The high-performance resin adhesive is prepared from the following raw materials: phenol, concentrated sulfuric acid, formaldehyde, carbohydrazide, polyvinyl alcohol, liquid alkali and the like. The synthesis process of the high-performance resin adhesive comprises the following four reaction phases: in the first reaction phase, performing a sulfonation reaction on partial phenol and concentrated sulfuric acid at 100 DEG C to 110 DEG C so as to generate p-hydroxybenzenesulfonic acid; in the second reaction phase, condensing the majority of phenol remaining in the first reaction phase and p-hydroxybenzenesulfonic acid generated by the first reaction phase with formaldehyde under an alkali condition so as to generate a phenol formaldehyde resin adhesive; in the third reaction phase, adding carbohydrazide to be condensed with incompletely-reacted phenol, intermediates and formaldehyde so as to generate a phenol-carbohydrazide-formaldehyde resin adhesive; in the last reaction phase, adding polyvinyl alcohol to react with residual formaldehyde so as to generate a polyvinyl formal adhesive. The high-performance resin adhesive is long in storage life, high in water dilutability and low in free phenol and formaldehyde content, thereby being suitable for the fields of rock wool sizing and the like.

Owner:HEBEI SANKAISHENFA SCI & TECH CORP LTD +1

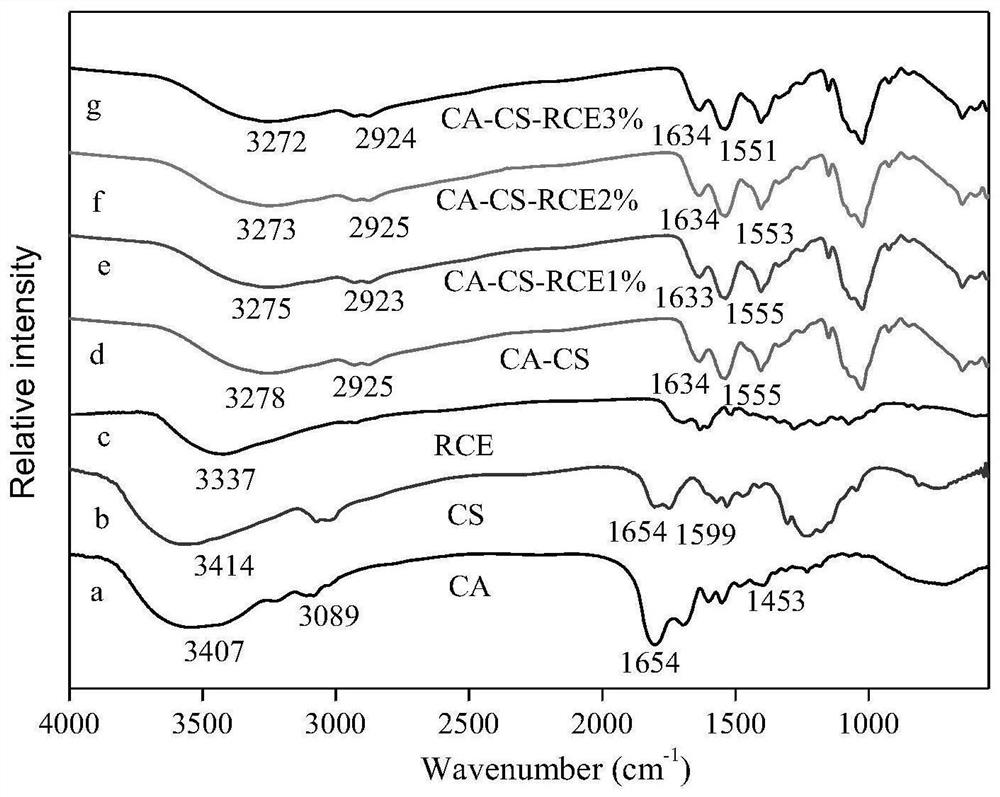

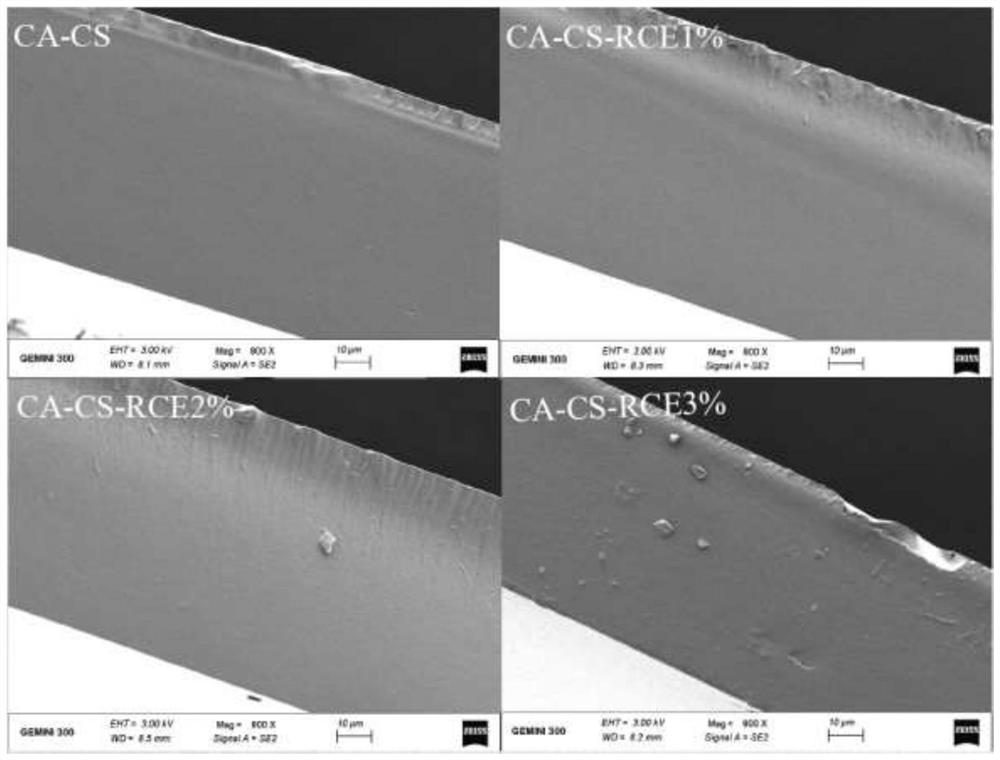

Preparation method of purple cabbage anthocyanin-collagen chitosan composite intelligent membrane

The invention discloses a preparation method of a purple cabbage anthocyanin-collagen chitosan composite intelligent film. The preparation method comprises the following steps: preparing purple cabbage anthocyanin powder from purple cabbage; then adding chitosan into an acetic acid aqueous solution, adding a collagen aqueous solution, continuously adding glycerol and sodium citrate, heating and stirring the mixture in a water bath, and cooling the mixture to obtain a collagen chitosan solution; and adding the purple cabbage anthocyanin powder into the collagen chitosan solution, uniformly stirring the solution, performing standing foaming treatment, injecting the obtained mixed solution into a mold, and drying the solution to obtain the purple cabbage anthocyanin-collagen chitosan composite membrane. The purple cabbage anthocyanin-collagen chitosan composite intelligent film can be applied to freshness indication and fresh-keeping storage of fresh products.

Owner:ZHEJIANG GONGSHANG UNIVERSITY

Preparation method of copolymerized PVDF resin for lithium battery binder

ActiveCN112159493AImprove adhesionLow rotational viscosityCell electrodesLi-accumulatorsPolymer scienceFluoride

The invention discloses a preparation method of copolymerized PVDF resin for a lithium battery binder. The preparation method comprises the following steps: reacting 300-600 parts of deionized water,0.04-0.25 part of a pH buffer regulator, 85-99.5 parts of a vinylidene fluoride (VDF) monomer, 0.5-15 parts of a comonomer, 0.3-3 parts of a metallocene synergist, 0.2-1.0 part of an initiator and 0.08-0.35 part of a dispersing agent at 40-65 DEG C under 5.5-8.0 Mpa, recovering unreacted monomers after the reaction is finished, washing, filtering and drying to obtain the copolymerized PVDF resin.According to the copolymerized PVDF resin for the lithium battery binder, the bonding performance of the PVDF resin to a positive electrode active substance and a current collector is improved, the rotary viscosity of an NMP solution is reduced, and meanwhile, the preparation and dispersion requirements on PVDF resin slurry are reduced.

Owner:ZHEJIANG QUZHOU JUSU CHEM IND CO LTD +2

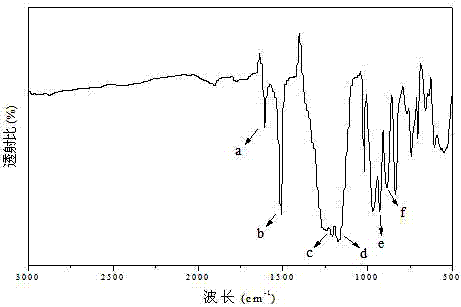

Preparation method of modified sodium alginate/polyacrylic acid composite thickener

ActiveCN111303344AAchieve perfect compoundGood thickening effectDyeing processFunctional monomerComposite material

The invention discloses a preparation method of a modified sodium alginate / polyacrylic acid composite thickener. The preparation method comprises the following steps: modifying sodium alginate macromolecular chains by allyl alcohol glycidyl ether by utilizing the reaction activity of hydroxyl and carboxyl on the macromolecular chains of sodium alginate, and introducing double bonds on the macromolecular chains of sodium alginate; and then adding the modified sodium alginate in the process of preparing the polyacrylic acid thickener through inverse emulsion polymerization, and selecting 4-methacryloyloxyethyltrimellitic anhydride as a functional monomer to be copolymerized with an acrylic acid monomer so as to obtain the modified sodium alginate / polyacrylic acid composite thickener with excellent performance.

Owner:CHANGZHOU UNIV

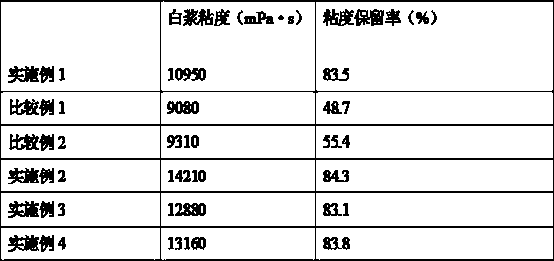

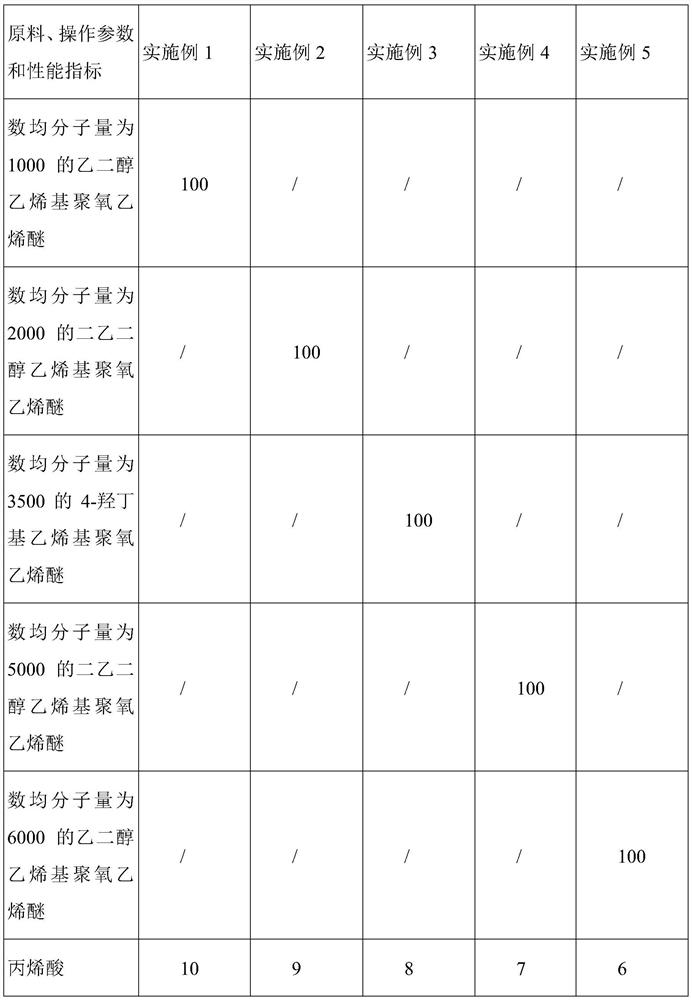

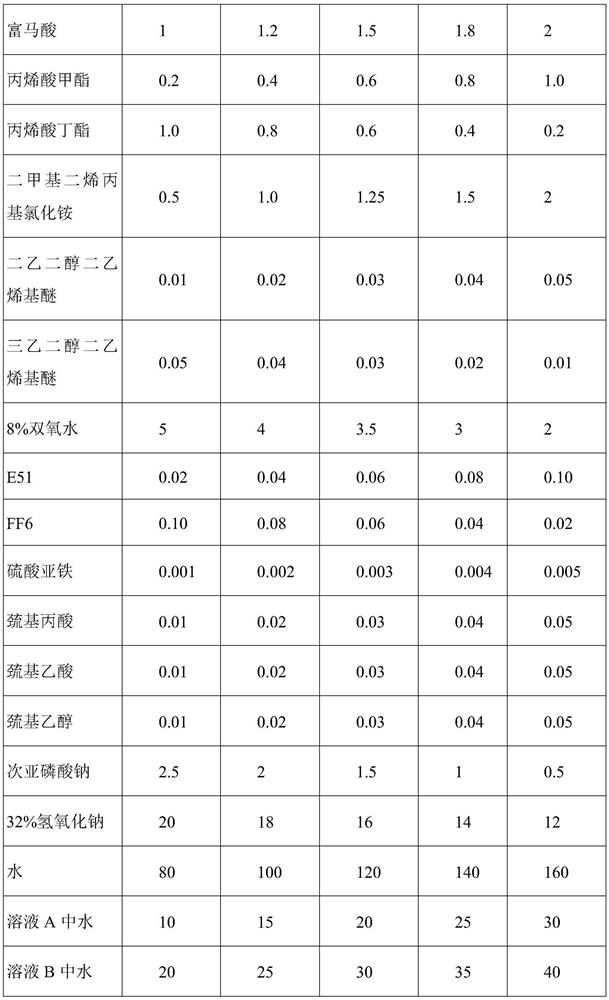

Polycarboxylate-type water reducing agent for gypsum-based self-leveling mortar and preparation method and use method thereof

ActiveCN113527592AReduced molecular weight distribution widthIncrease the length of the main chainVinyl etherPhosphorous acid

The invention discloses a polycarboxylate-type water reducing agent for gypsum-based self-leveling mortar and a preparation method and a use method thereof. The polycarboxylate-type water reducing agent is prepared from the following components in parts by weight: 100 parts of polyether, 6 to 10 parts of acrylic acid, 1 to 2 parts of fumaric acid, 0.2 to 1 part of methyl acrylate, 0.2 to 1 part of butyl acrylate, 0.5 to 2 parts of dimethyl diallyl ammonium chloride, 0.01 to 0.05 part of diethylene glycol divinyl ether, 0.01 to 0.05 part of triethylene glycol divinyl ether, 2 to 5 parts of hydrogen peroxide, 0.02 to 0.1 part of a reducing agent E51, 0.02 to 0.1 part of a reducing agent FF6, 0.001 to 0.005 part of ferrous sulfate, 0.01 to 0.05 part of mercaptopropionic acid, 0.01 to 0.05 part of mercaptoacetic acid, 0.01 to 0.05 part of mercaptoethanol, 0.5 to 2.5 parts of sodium hypophosphite, 12 to 20 parts of sodium hydroxide and 80 to 160 parts of water. The invention provides polycarboxylate-type water reducing agent for the gypsum-based self-leveling mortar and the preparation method and the use method thereof. The polycarboxylate-type water reducing agent is good in adaptability to byproduct gypsum, high in water reducing rate, good in slump retaining effect, fast in coagulation, small in shrinkage and high in strength, and can be widely applied to the field of gypsum-based self-leveling mortar.

Owner:连云港石化有限公司

Antibacterial and mildew-proof fabric

InactiveCN111607889ASimple manufacturing methodSuitable for continuous large-scale productionWeft knittingMonocomponent synthetic polymer artificial filamentFiberPolymer science

The invention provides an antibacterial and mildew-proof fabric. The antibacterial and mildew-proof fabric is characterized in that a preparation method of the antibacterial and mildew-proof fabric comprises the following steps of: S1, preparing an aloe neoglycoside D / N-[4-(sulfonamide) phenyl ] acrylamide / (Z)-2-(2-aminothiazole-4-yl)-2-pentenoic acid / enadenine copolymer; S2, preparing copolymer fibers; S3, weaving; and S4, carrying out after-finishing. The antibacterial and mildew-proof fabric disclosed by the invention has excellent comprehensive performance, remarkable antibacterial andmildew-proof effects, good weather resistance, antistatic property, air permeability and moisture absorption performance and wearing comfort, and has relatively high economic value and social value.

Owner:江兰春

Beta-cyclodextrin cross-linked graphene functional cotton fiber and preparation method thereof

The invention discloses a beta-cyclodextrin cross-linked graphene functional cotton fiber and a preparation method thereof. The preparation method comprises the following steps: dipping a cotton fiberinto an oxidized monochlorotriazine-beta-cyclodextrin solution with a mass friction of 1%-10%, and reacting at 60-80 DEG C for 30-300 minutes, so as to obtain monochlorotriazine-beta-cyclodextrin grafted cotton fiber; and dipping the monochlorotriazine-beta-cyclodextrin grafted cotton fiber into aminated graphene ethanol dispersion liquid with a mass friction of 1%-10%, adding a certain amount ofa cross-linking agent, and stirring at a constant speed at the normal temperature for 60-600 minutes, so as to obtain the beta-cyclodextrin cross-linked graphene functional cotton fiber. By utilizingoxidized monochlorotriazine-beta-cyclodextrin as a cross-linking agent, the cotton fiber can be endowed with certain properties of electric conduction, antibiosis, ultraviolet protection, flame retardance, washing resistance and the like by aminated graphene.

Owner:钱景

Nano composite hydrogel and preparation method thereof

InactiveCN108409901AGood dispersionImprove the strengthening and toughening effectIn situ polymerizationSilicon dioxide

Owner:SOUTHEAST UNIV

Flame-retardant and fireproofing material for new energy automotive power battery and preparation method thereof

The invention discloses a preparation method of a flame-retardant and fireproofing material for a new energy automotive power battery, wherein the preparation method includes the following steps: (1)preparation of a main-chain phenylsilane adamantane polyphenyl ether prepolymer; (2) preparation of a phosphorus-containing polycondensation polymer; (3) preparation of Al-Si-O; and (4) moulding. Theinvention also discloses the flame-retardant and fireproofing material for the new energy automobile power battery, wherein the flame-retardant and fireproofing material is prepared according to the preparation method of the flame-retardant and fireproofing material for the new energy automobile power battery. The flame-retardant and fireproofing material for the new energy automotive power battery has the advantages of low cost, antioxidant performance, solvent resistance, ultraviolet aging resistance, radiation resistance, good weather resistance, good mechanical properties and excellent flame-retardant effect.

Owner:山西都润新材料科技有限公司

Resin microsphere plugging agent and preparation method therefor

ActiveCN108929663AEvenly dispersedUniform particle sizeDrilling compositionResin microsphereFunctional monomer

The invention relates to a resin microsphere plugging agent and a preparation method therefor. The resin microsphere plugging agent is prepared from the following ingredients in parts by mass: 30-60 parts of alkene monomer, 5-40 parts of ester monomer, 5-10 parts of functional monomer, 0.1-1 part of organic dispersant, 0.3-0.5 part of inorganic dispersant, 0.6-1 part of oil-soluble initiator and 80-120 parts of distilled water. The resin microsphere plugging agent is obtained through adding the organic dispersant and the inorganic dispersant into deionized water, carrying out heating, stirringand mixing, adding the oil-soluble initiator into a mixture of the alkene monomer, the ester monomer and the functional monomer, dissolving the oil-soluble initiator, mixing all the ingredients, carrying out a polymerization reaction so as to obtain a dispersion solution of different particle sizes, and carrying out stirring to cool the dispersion solution to room temperature. According to the resin microsphere plugging agent and the preparation method therefor, the technological operations are simple, and prepared resin microspheres have the advantages of uniform particle size, easy-controlled reaction temperature, high yield, good stability, good flexibility, good transparency, good heat resistance and difficulty in degradation.

Owner:HENAN ZHENGJIA ENERGY ENVIRONMENTAL PROTECTION CO LTD

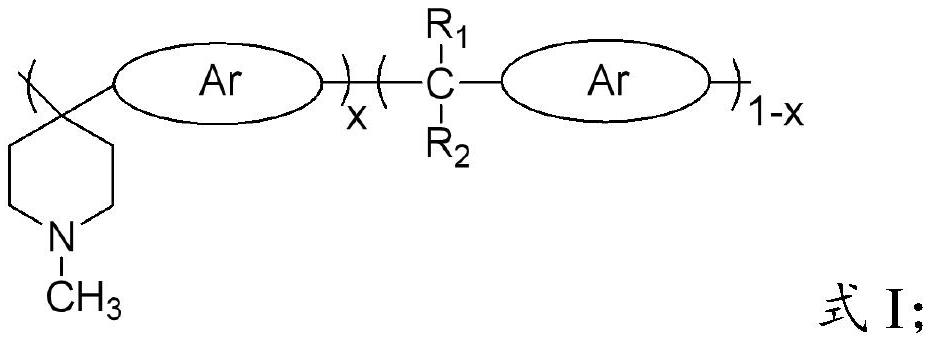

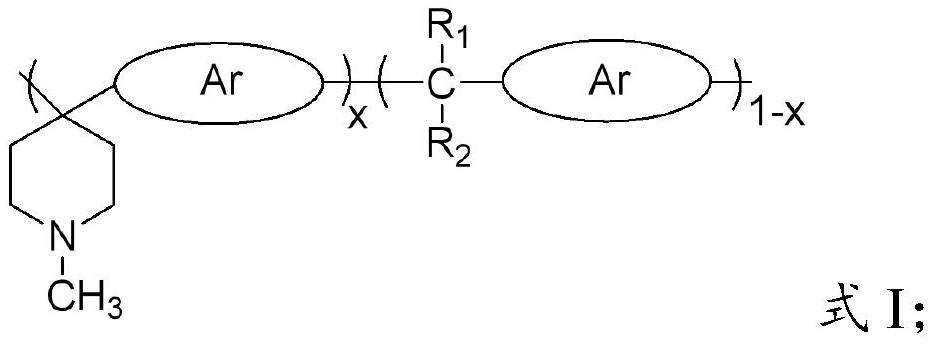

Anion-exchange membrane for fuel cell and preparation method of anion-exchange membrane

ActiveCN108711632AEasy to prepareEquipment and reaction conditions are not demandingSolid electrolytesFuel cellsBenzimidazoleIon-exchange membranes

The invention provides a preparation method of an anion-exchange membrane for a fuel cell. The preparation method comprises the following steps of 1) preparing an aggregation-type 1-(2-ethoxyethyl)-2-(4-piperidyl)-1H-benzimidazole; 2) preparing an aggregation-type 1-(2-ethoxyethyl)-2-(4-piperidyl)-1H-benzimidazole salt; 3) preparing a polymer membrane; and 4) performing ion exchange. The inventionalso discloses the anion-exchange membrane, prepared according to the preparation method of the anion-exchange membrane for the fuel cell, for the fuel cell and an alkaline anion-exchange membrane battery employing the anion-exchange membrane for the fuel cell as a polyelectrolyte membrane. Compared with a traditional quaternary ammonium salt anion-exchange membrane in the prior art, the anion-exchange membrane for the fuel cell, obtained by preparation method has the advantages of higher negative ion conductivity, lower cost, better mechanical property and more excellent stability, alkali resistance and thermal resistance, and the application requirement of the alkali anion-exchange membrane fuel cell is met.

Owner:天朤(江苏)氢能源科技有限公司

Conductive resin for 3D printing technology, and preparation method and application thereof

ActiveCN113956409AImprove conductivity stabilityHigh tensile strengthFluid pressure measurement using piezo-electric devicesAdditive manufacturing apparatusPolymer sciencePolyvinyl alcohol

The invention discloses a conductive resin for a 3D printing technology, and a preparation method and application thereof, and belongs to the technical field of 3D printing materials. The conductive resin comprises, by weight, 70-95 parts of a polymerization reaction material, 20-35 parts of a conductive material and 0.5-3 parts of a photoinitiator, and the polymerization reaction material comprises hydroxyethyl acrylate, polyethylene glycol diacrylate, polyvinyl alcohol, acrylamide and modified polydimethylsiloxane. According to the polymerization reaction material disclosed by the invention, the components are mutually cooperated, and a stable three-dimensional network structure is formed through physical crosslinking and chemical crosslinking, so that the mechanical property of the resin can be effectively improved, and the problem that the conductive material dispersed in water is uniformly dispersed in the resin is solved; therefore, the conductive stability of the conductive resin is improved, and the problem that the mechanical property of conductive hydrogel with similar components becomes poor due to water loss is solved. The resin is simple in preparation method, is manufactured through a photocuring 3D printing technology, and has a huge application prospect in the fields of flexible sensing and the like.

Owner:SOUTHWEST MEDICAL UNIVERISTY

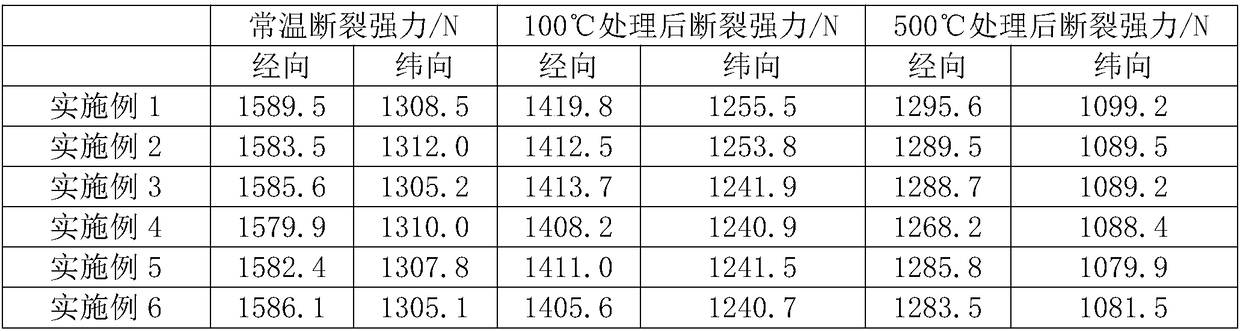

Preparation method of rare earth element modified heat-resistant textile

InactiveCN108385392AUniform porosityHigh porosityBiochemical fibre treatmentGrip property fibresRare-earth elementLanthanum

The invention discloses a preparation method of rare earth element modified heat-resistant textile. The method concretely comprises the following processes: firstly, soaking volcanic rock in sulfuricacid, filtering, collecting filtrate, adding a hydrogen peroxide solution, stirring and precipitating to obtain a porous silicon-aluminum compound; adding deionized water for dispersing so as to prepare dispersion liquid; dissolving molybdenum powder in a hydrogen peroxide solution, adding anhydrous ethanol, citric acid, a lanthanum chloride aqueous solution and the porous silicon-aluminum compound, stirring and mixing, and carrying out a reaction at a certain temperature to obtain modified filler; mixing the obtained modified filler with styrene-acrylic emulsion, deionized water, corn starch,a silane coupling agent, hydroxyethyl cellulose and butyl phthalate to prepare finishing liquid; finally, finishing textile with the finishing liquid to obtain the heat-resistant textile. The textileprepared by the method is soft and comfortable, excellent in antibacterial property, good in heat resistance and mechanical properties and high in safety.

Owner:武汉智达纺织科技有限公司

Method for preparing water-soluble resin

InactiveCN101885792AImprove moisture resistanceHigh strengthPolyureas/polyurethane adhesivesNitrile polymer adhesivesAdhesiveWater soluble

The invention relates to a method for preparing resin, in particular to a method for preparing water-soluble resin. The method for preparing the water-soluble resin is characterized by comprising the following steps of: adding 30 to 50 kilograms of raw materials into a reaction kettle at the temperature of between 190 and 210 DEG C under the pressure of between 1.3 and 1.7MPa, then adding 1 to 3 kilograms of sodium hydroxide and 50 to 70 kilograms of water into the reaction kettle to perform alkaline hydrolysis reaction for 2 to 4 hours, adding 0.2 to 2 liters of low molecular aldehyde substance and 0.3 to 1 liter of silane into the reaction kettle and further reacting for 4 to 5 hours, and obtaining the water-soluble resin after the reaction is finished. The method has the advantages that: the water-soluble resin prepared by the method thoroughly solves the pollution problem of adhesive for casting by using the water as a medium, and has the advantages of low-temperature quick curing, energy conservation, no pollution, no odor, high strength, good collapsibility, wet creep resistance, dry moisture absorption resistance and the like.

Owner:山东良艺化工新材料有限公司

Preparation method of aqueous polyurethane/fluorinated phosphazene nano fiber composite material

InactiveCN107057331AImprove anti-friction and anti-wear propertiesEvenly dispersedMonocomponent synthetic polymer artificial filamentIn situ polymerizationIsophorone diisocyanate

The invention discloses a preparation method of an aqueous polyurethane / fluorinated phosphazene nano fiber composite material. The method comprises the following steps: dissolving hexachlorocyclotriphosphazene and 4,4'-(hexafluoro isopropyl fork) bisphenol into a toluene / acetone composite solution; dropwise adding triethylamine and carrying out nucleophilic substitution reaction under a magnetic power stirring condition, and carrying out post-treatment to obtain fluorinated phosphazene nano fibers; adding the nano fibers into polypropylene glycol; then adding isophorone diisocyanate, a catalyst and 2,2-dimethylolpropionic acid until the reaction is completed; reducing the temperature and adding triethylamine to be neutralized; dispersing into the deionized water to obtain an aqueous polyurethane solution; and casting the aqueous polyurethane solution into an extensible sample strip mould to be naturally solidified to obtain the aqueous polyurethane / fluorinated phosphazene nano fiber composite material. According to the preparation method disclosed by the invention, by adopting a chemical in-situ polymerization method, the reaction is added into an aqueous polyurethane basal body, and the successfully obtained aqueous polyurethane composite material has excellent heat stability, extension performance and friction and abrasion performance.

Owner:ZHEJIANG UNIV OF TECH

Sludge concentration dehydrating agent and preparation method thereof

The invention discloses a sludge concentration dehydrating agent and a preparation method thereof, and belonging to the technical field of sludge treatment. The preparation method comprises the following steps of: modifying crop straw and wood powder, mixing cyclodextrin and diatomite with the modified crop straw and wood powder, adding water, boiling in boiling water for 10-15 min, extracting, collecting an extracted solid product, adding humic acid and volcanic rocks, magnetically stirring for 15-20 min, adding gelatin, heating, evaporating to obtain the sludge concentration dehydrating agent. The dosage of the sludge concentration dehydrating agent is only 0.02-0.03%, the deep dehydration of sludge can be realized while the sludge dehydration time is reduced, one ton of sludge with a water content of 60-99% can be directly dehydrated within 30 minutes to the water content reaching 20-35%, and the subsequent treatment of the sludge can be greatly facilitated.

Owner:JILIN JIANZHU UNIVERSITY

A kind of carbon-coated metal nanoparticle-loaded PVDF film and its preparation method and application

ActiveCN107118477BAvoid secondary pollutionImprove degradation rateWater treatment compoundsOrganic-compounds/hydrides/coordination-complexes catalystsPolyvinylidene difluoridePolyvinylidene fluoride

The invention discloses a carbon-coated metal nanoparticle-loaded PVDF film and its preparation method and application. The carbon-coated metal nanoparticles are first synthesized, and then mixed with polyvinylidene fluoride powder, organic additives and dispersion media. Stir to obtain a casting liquid, and then obtain the target product through the solution phase transformation method. The carbon-coated metal nanoparticle-loaded PVDF membrane of the present invention can efficiently mineralize toxic organic pollutants in water bodies with a high degradation rate; a catalytic membrane reactor is constructed to carry out catalytic degradation of organic pollutants, based on the micro-nano separation effect of the membrane pore structure , blocks the penetration of macromolecular organic pollutants, plays a interception role, improves the conversion rate and selectivity of degradation, solves the technical problem of easy agglomeration and loss of metal nanoparticles, and avoids potential secondary pollution to water bodies; and is prepared The method has the advantages of lower cost, simple process, controllable structure, strong operability, and easy industrial application.

Owner:HEFEI UNIV OF TECH

Multifunctional cotton fabric finishing agent and method for making same

The invention relates to a multifunctional cotton fabric finishing agent with anti-ultraviolet rays, improved fabric light fastness, antibacterial and wrinkle resistance and a preparation method thereof. The steps of the preparation method include: preparing a water phase; preparing an oil phase; preparing an emulsion; preparation. The invention solves the compatibility problem between functional components, the finishing agent has good stability, and there is a promotion effect between functional components, polycarboxylic acid, polycarboxylic acid and chitosan play the role of crosslinking agent, Improves the durability of various functions.

Owner:SOUTH CHINA UNIV OF TECH +1

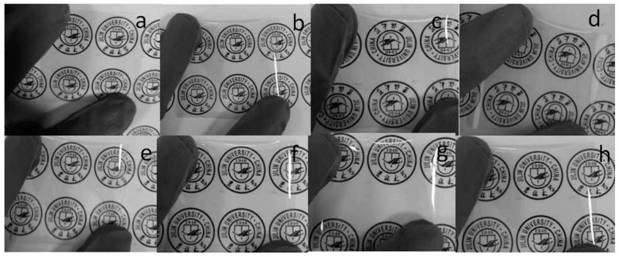

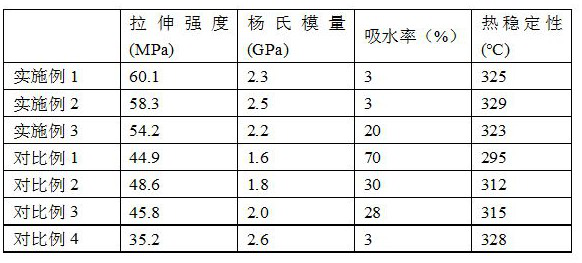

Hybrid proton exchange membrane based on polyacid/piperidine aryl copolymer and preparation method of hybrid proton exchange membrane

The invention provides a hybrid proton exchange membrane based on a polyacid / piperidine aryl copolymer and a preparation method of the hybrid proton exchange membrane, belonging to the technical field of proton exchange membranes. The preparation method of the hybrid proton exchange membrane provided by the invention comprises the following steps: mixing polyacid and a piperidine aryl polymer solution, casting the obtained mixture to form a membrane, and drying the membrane to obtain the hybrid proton exchange membrane. The result of an embodiment shows that the conductivity of the hybrid proton exchange membrane prepared by the invention at 25 DEG C is 14-28 mS.cm<-1>, and the conductivity of the hybrid proton exchange membrane at 80 DEG C is 39-102 mS.cm<-1>; and the hybrid proton exchange membrane has tensile strength at break of 58-64 MPa and elongation at break of 12-18%. Therefore, the hybrid proton exchange membrane prepared by the method has relatively high proton conductivity and mechanical stability at the same time.

Owner:JILIN UNIV

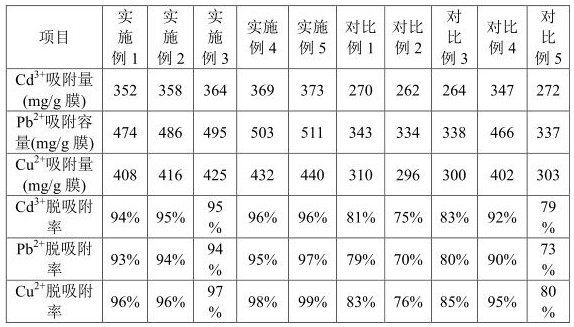

Heavy metal ion adsorption film and preparation method thereof

InactiveCN112111078AEasy to prepareRaw materials are readily availableOther chemical processesWater contaminantsVinylbitalIon adsorption

The invention discloses a preparation method of a heavy metal ion adsorption film. The preparation method is characterized by comprising the following steps: S1, preparing a 3-fluorocinnamic acid modified diaminocalixarene derivative; step S2, preparation of vinyl beta-cyclodextrin quaternary ammonium salt based on a carboxyl-containing metal organic framework; and S3, forming of the heavy metal ion adsorption film. The invention also provides the heavy metal ion adsorption film prepared by using the preparation method of the heavy metal ion adsorption film. The heavy metal ion adsorption filmprovided by the invention is good in heavy metal ion adsorption effect, excellent in mechanical property, corrosion resistance and pollution resistance, good in performance stability, long in servicelife and convenient to recycle and separate.

Owner:王佩

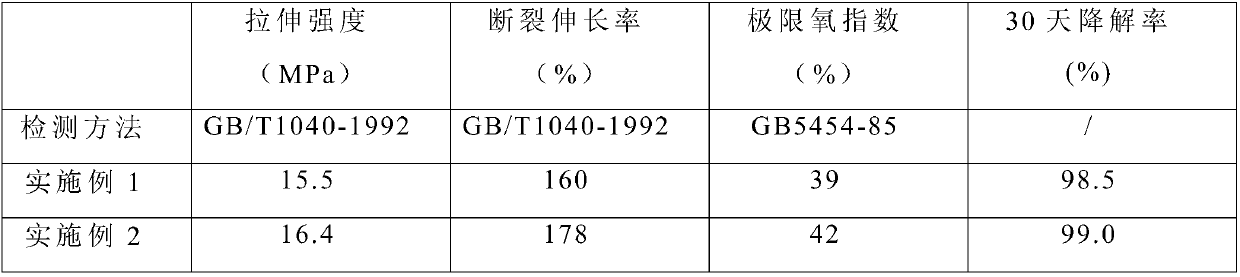

Environmentally-friendly plastic and preparation method thereof

The invention discloses an environmentally-friendly plastic and a preparation method thereof. The environmentally-friendly plastic comprises the steps of polymeric monomer preparation, copolymer preparation, ion exchange, injection molding and the like. The invention also discloses the environmentally-friendly plastic prepared by using the preparation method of the environmentally-friendly plastic. According to the environmentally-friendly plastic disclosed by the invention, the problem that existing traditional plastics cannot be automatically degraded or are slow in degradation so as to pollute the environment is solved, and the problem that more additives are added to cause low dispersion, low compatibility, environmental pollution and low processing flowability is solved; and comparedwith degradable plastics in the prior art, the environmentally-friendly plastic disclosed by the invention is higher in natural degradability, preferable in mechanical comprehensive performance and longer in service cycle.

Owner:陈启磊

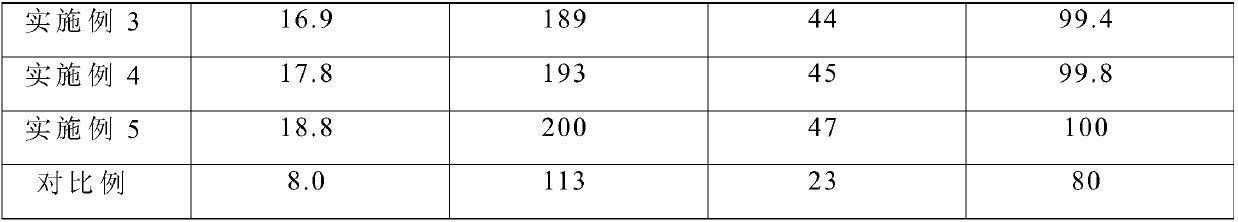

A kind of starch-based biodegradable plastic and preparation method thereof

The invention provides a starch-based biodegradable plastic and a preparation method thereof. The starch-based biodegradable plastic includes a combination of starch, glycerin, polylactic acid and lignin-modified nano-mica; the nano-mica has the characteristics of nano-size effect , and it is limited to lignin-modified nano-mica, which improves the compatibility between the nano-mica and other components, and at the same time uses it to bridge other components to build a "brick-mud" structure , thereby significantly improving the mechanical properties, water resistance and heat resistance of the final starch-based biodegradable plastic; at the same time, the starch-based biodegradable plastic also has the advantages of low cost, high efficiency, green process and environmental friendliness. It has important research significance.

Owner:中科南京绿色制造产业创新研究院 +2

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com