Carbon-coated metal nanoparticle-loaded PVDF (Polyvinylidene Fluoride) membrane as well as preparation method and application thereof

A technology of metal nanoparticles and carbon coating, applied in chemical instruments and methods, catalyst activation/preparation, metal/metal oxide/metal hydroxide catalysts, etc. cumbersome, high cost of film-making process, etc., to achieve the effect of high degradation rate, easy industrial application, and avoid secondary pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] This embodiment first prepares carbon-coated iron nanoparticles loaded PVDF membrane catalyst according to the following steps:

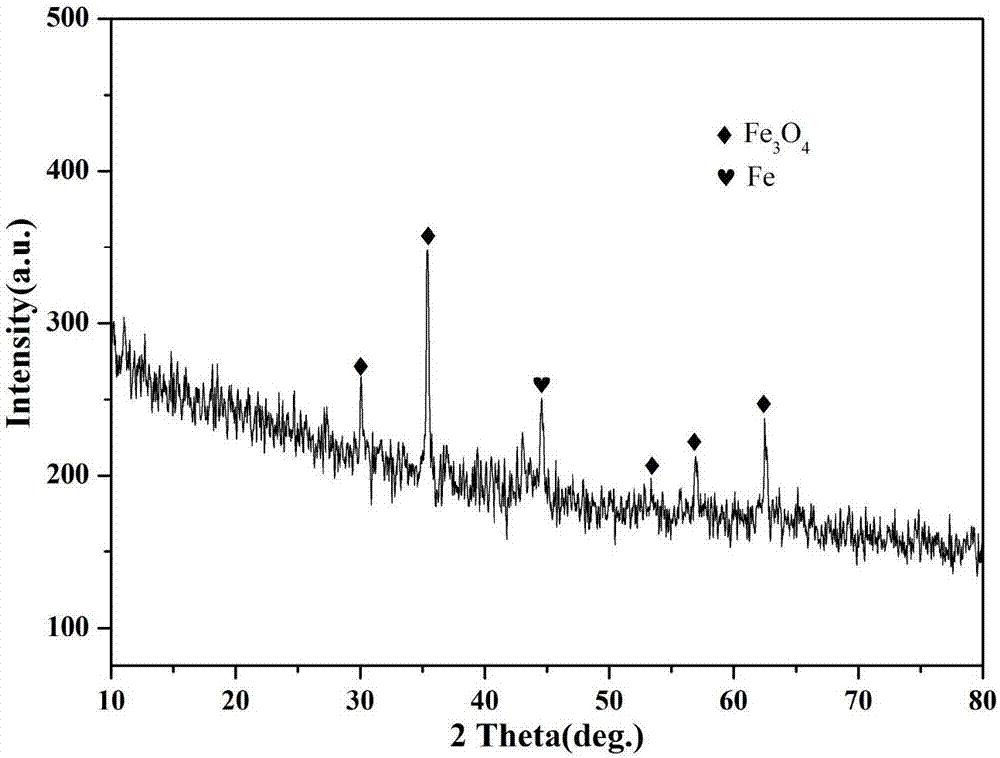

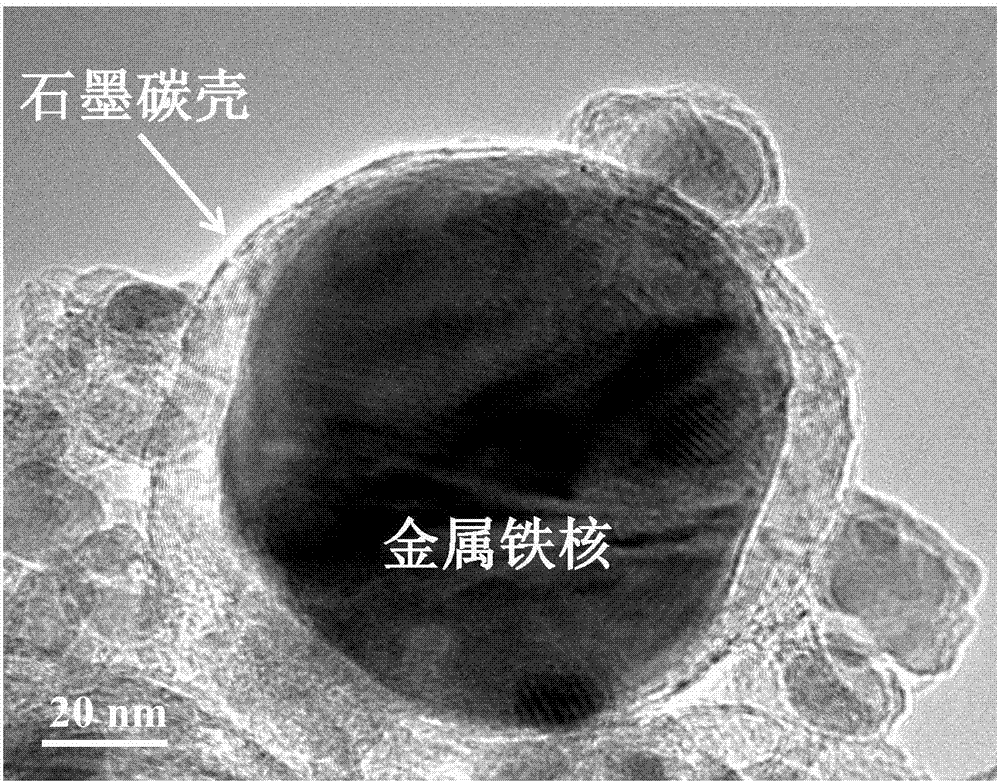

[0033](1) Weigh 2g (10.06mmol) ferrous chloride tetrahydrate (FeCl 2 4H 2 O), 5g (59.47mmol) dicyandiamide (C 2 h 4 N 4 ) and 2g (12.66mmol) sodium thiosulfate (Na 2 S 2 o 3 ) in 200mL methanol solution at 50°C and stirred evenly, then evaporated, dried, and ground to obtain a homogeneous powder; place the homogeneous powder in a quartz tube, and place the quartz tube in the uniform temperature zone of a tubular resistance furnace, In a high-purity nitrogen atmosphere with a flow rate of 0.2mL / min, the temperature was raised to 700°C at a rate of 10°C / min, and calcined at a constant temperature for 2 hours; after the reaction was completed, the quartz tube was cooled to room temperature in a high-purity nitrogen atmosphere to obtain Pyrolysis product carbon-coated iron nanoparticles;

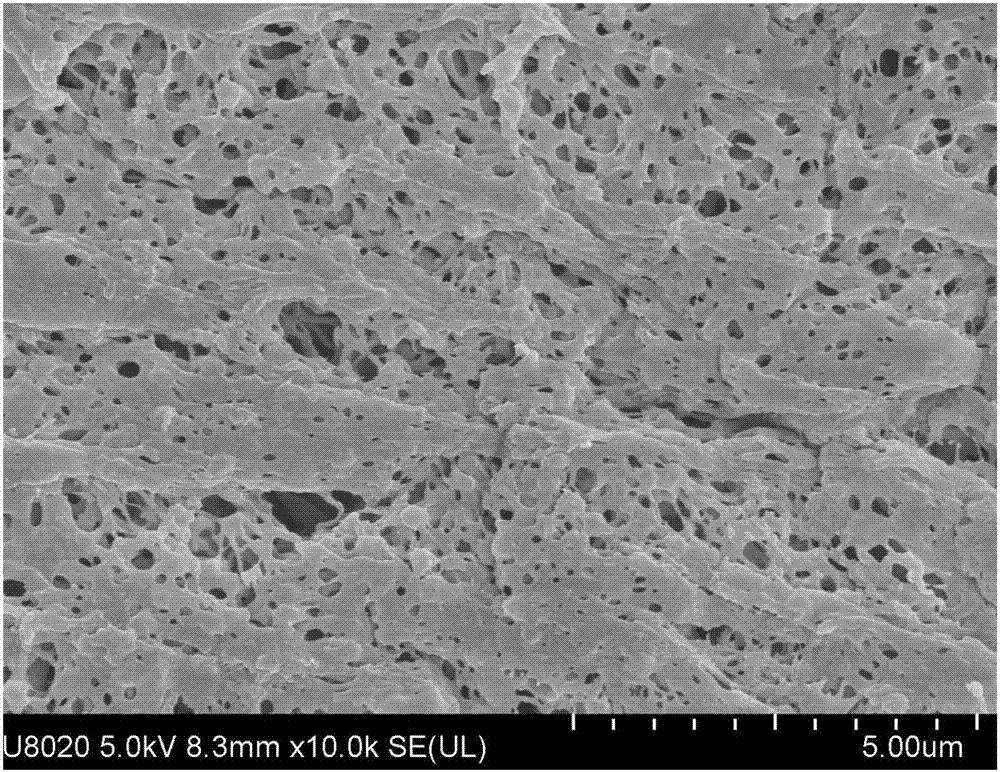

[0034] (2) Weigh 50 mg of the pyrolysis product c...

Embodiment 2

[0041] In this embodiment, the same carbon-coated iron nanoparticle-loaded PVDF membrane catalyst as in Example 1 is used to construct the same catalytic membrane reactor device to process the following organic pollutant solution: prepare 20 mg / L methylene blue solution to simulate organic pollutant wastewater (V=250mL), and at the same time, 150mg of oxidant permonomonosulfate (PMS) was added.

[0042] After testing, the degradation rate of organic pollutants reaches 100%.

Embodiment 3

[0044] In this embodiment, the same carbon-coated iron nanoparticle-loaded PVDF membrane catalyst as in Example 1 is used to construct the same catalytic membrane reactor device to process the following organic pollutant solution: prepare 20 mg / L rhodamine B solution to simulate organic pollutant wastewater (V=250mL), and at the same time, 150mg of oxidant permonomonosulfate (PMS) was added.

[0045] After testing, the degradation rate of organic pollutants reaches 100%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com