Lightweight high-strength flame-retardant material and preparation method thereof

A flame-retardant material and high-strength technology, applied in the field of flame-retardant materials, can solve problems such as poor use effect and easy agglomeration, and achieve the effects of improving light resistance, ensuring intrinsic flame retardancy, and improving mechanical properties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

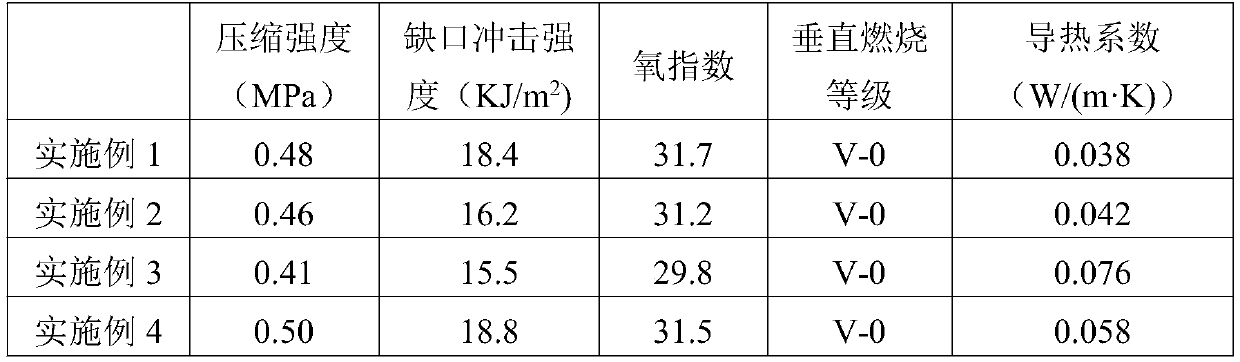

Embodiment 1

[0042] This example provides a lightweight high-strength flame-retardant material and its preparation method:

[0043] The raw material composition used in this embodiment is:

[0044] Norbornane diisocyanate oligomer 18.5 parts

[0045] Polycaprolactone polyol 10.5 parts

[0046] Polyglycolic acid grafted starch copolymer 11 parts

[0047] Trihydroxymethyl phosphine oxide 3.2 parts

[0048] 2.4 parts of bis(4-hydroxybutyl)phenyl phosphate

[0049] 2 parts melamine cyanurate

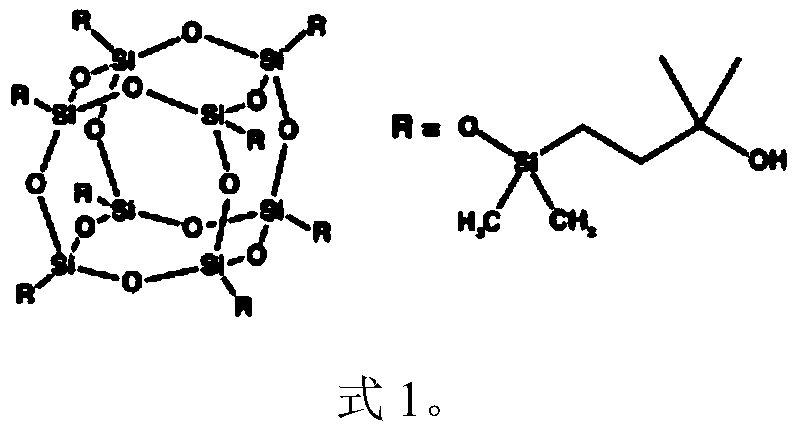

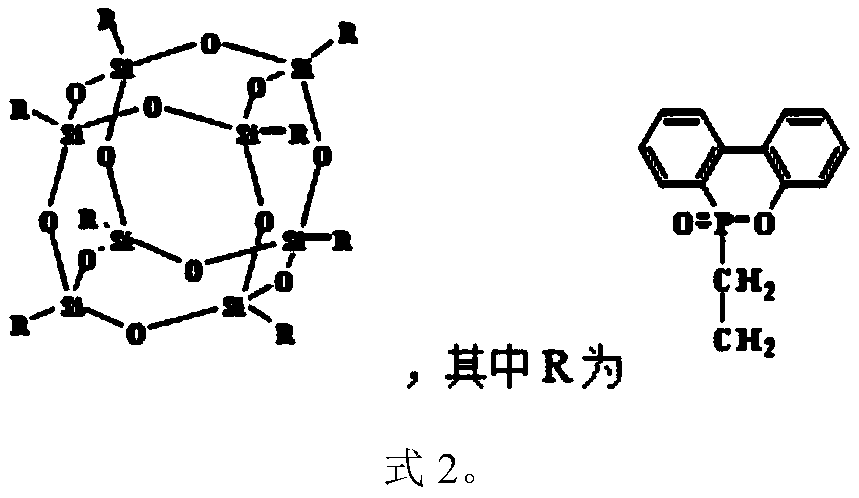

[0050] 1.1 parts of 9,10-dihydro-9-oxa-10-phosphaphenanthrene-10-oxide grafted cage polysilsesquioxane

[0051] Eight-armed hydroxybutyl cage polysilsesquioxane 0.9 parts

[0052] Antioxidant 1.5 parts

[0053] Wherein, the molecular weight of the norbornane diisocyanate oligomer is 6000-8000, and the NCO content is 19.6%.

[0054] The polyglycolic acid grafting rate in the polyglycolic acid grafted starch copolymer accounts for 34.5% of the total mass of the substance.

[0055] The molecular weig...

Embodiment 2

[0061] This example provides a lightweight high-strength flame-retardant material and its preparation method:

[0062] The raw material composition used in this embodiment is:

[0063] Norbornane diisocyanate oligomer 20 parts

[0064] Polycaprolactone polyol 12 parts

[0065] Polyglycolic acid grafted starch copolymer 9.5 parts

[0066] Trihydroxymethyl phosphine oxide 3.2 parts

[0067] 2.2 parts of bis(4-hydroxybutyl)phenyl phosphate

[0068] 2 parts melamine cyanurate

[0069] 0.8 parts of 9,10-dihydro-9-oxa-10-phosphaphenanthrene-10-oxide grafted cage polysilsesquioxane

[0070] Eight-armed hydroxybutyl cage polysilsesquioxane 1 part

[0071] Antioxidant 1.5 parts

[0072] Wherein, the molecular weight of the norbornane diisocyanate oligomer is 4500-5500, and the NCO content is 22%.

[0073] The grafting rate of polyglycolic acid in the polyglycolic acid grafted starch copolymer is 32% based on its total mass percentage.

[0074] The molecular weight of the polyc...

Embodiment 3

[0080] This example provides a lightweight high-strength flame-retardant material and its preparation method:

[0081] The raw material composition used in this embodiment is:

[0082] Norbornane diisocyanate oligomer 15 parts

[0083] Polycarbonate diol 8 parts

[0084] Polyglycolic acid grafted starch copolymer 6 parts

[0085] Trihydroxymethylphosphine oxide 2 parts

[0086] Bis(4-hydroxypentyl)phenyl phosphate 1.5 parts

[0087] 1.5 parts of melamine cyanurate

[0088] Eight-armed hydroxybutyl cage polysilsesquioxane 1 part

[0089] Antioxidant 1 part.

[0090] Wherein, the molecular weight of the norbornane diisocyanate oligomer is 1800-5000, and the NCO content is 15%.

[0091] The polyglycolic acid grafting rate in the polyglycolic acid grafted starch copolymer accounts for 24% of the total mass of the substance.

[0092] The molecular weight of the polycaprolactone polyol is 4000-12000.

[0093] The preparation step of described material comprises:

[0094] S...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com