Conductive resin for 3D printing technology, and preparation method and application thereof

A conductive resin and 3D printing technology, applied in the field of 3D printing materials, can solve the problems of poor flexibility and elasticity of resin, affect the mechanical properties and conductivity of printing materials, and uneven mixing of conductive fillers and resins, so as to improve adsorption, Effect of improving conductivity stability, increasing tensile strength and elongation at break

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

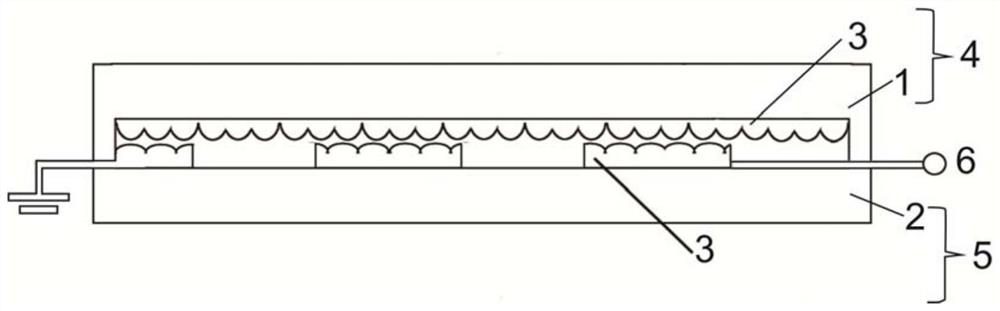

Image

Examples

Embodiment 1

[0028] The conductive resin used in 3D printing technology in this embodiment includes: by weight, 60 parts of polymerization reaction materials, 20 parts of conductive materials and 0.5 parts of photoinitiator;

[0029] The polymerization reaction material includes: hydroxyethyl acrylate, polyethylene glycol diacrylate, polyvinyl alcohol, acrylamide and acrylate-modified polydimethylsiloxane, the mass ratio of which is 0.5:0.01:0.1:0.5 : 0.1.

[0030] The conductive material includes: silver nanowires.

[0031] The photoinitiator includes: (2,4,6-trimethylbenzoyl)diphenylphosphine oxide.

[0032] The preparation method of the conductive resin used for 3D printing technology of the present embodiment comprises the following steps:

[0033] Disperse the conductive material into water or ethanol to obtain a dispersion liquid, then mix the polymerization reaction materials evenly, heat and evaporate the water in the mixed system, and then introduce a photoinitiator to obtain a ...

Embodiment 2

[0035] The conductive resin used in 3D printing technology in this embodiment includes: by weight, 70 parts of polymerization reaction material, 25 parts of conductive material and 1 part of photoinitiator.

[0036] The polymerization reaction material includes: hydroxyethyl acrylate, polyethylene glycol diacrylate, polyvinyl alcohol, acrylamide and acrylate modified polydimethylsiloxane, the mass ratio of which is 0.6:0.05:0.1:0.6 : 0.2.

[0037] The conductive material includes: carbon nanotubes.

[0038] The photoinitiator includes: (2,4,6-trimethylbenzoyl)diphenylphosphine oxide.

[0039] The preparation method of the conductive resin used for 3D printing technology of the present embodiment comprises the following steps:

[0040]Disperse the conductive material into water or ethanol to obtain a dispersion liquid, then add the polymerization reaction material and mix evenly, heat and evaporate the water in the mixed system, and then introduce a photoinitiator to obtain a...

Embodiment 3

[0042] The conductive resin used for 3D printing technology in this embodiment includes: by weight, 75 parts of polymerization reaction materials, 27 parts of conductive materials and 1.5 parts of photoinitiator;

[0043] The polymerization reaction material includes: hydroxyethyl acrylate, polyethylene glycol diacrylate, polyvinyl alcohol, acrylamide and acrylate-modified polydimethylsiloxane, the mass ratio of which is 0.7:0.1:0.15:0.7 : 0.3.

[0044] The conductive material includes: poly(3,4-ethylenedioxythiophene):poly(styrenesulfonate) (PEDOT:PSS).

[0045] The photoinitiator includes: (2,4,6-trimethylbenzoyl)diphenylphosphine oxide.

[0046] The preparation method of the conductive resin used for 3D printing technology of the present embodiment comprises the following steps:

[0047] Disperse the conductive material into water or ethanol to obtain a dispersion liquid, then add the polymerization reaction material and mix evenly, heat and evaporate the water in the mix...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com