Wire spring plug bush

A technology of wire springs and sockets, which is applied in the direction of electrical components, coupling devices, circuits, etc., can solve the problems of large space occupied by front-end sleeves, cumbersome process, and high manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

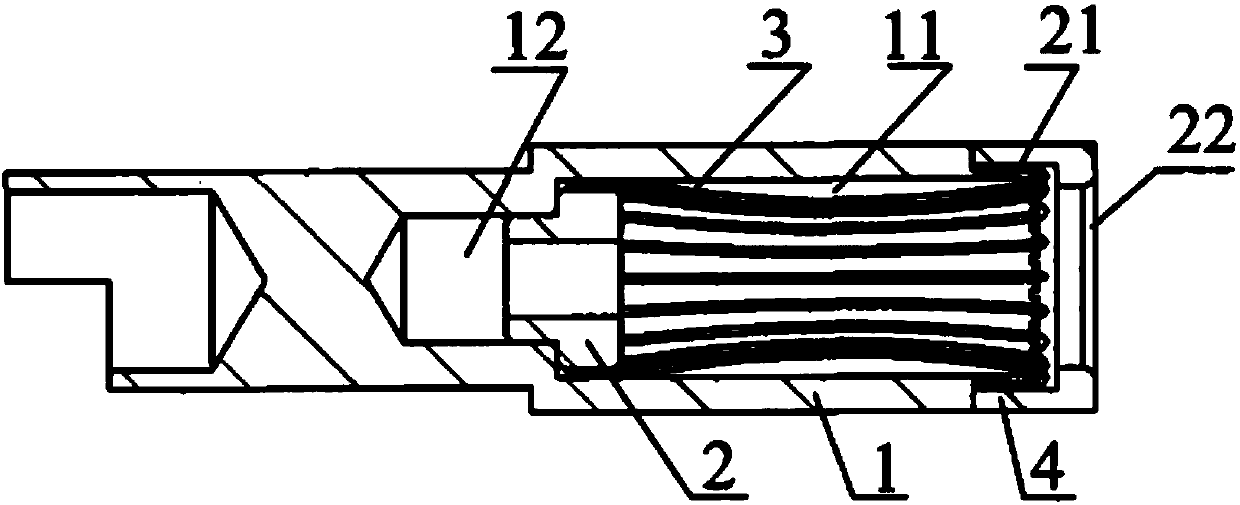

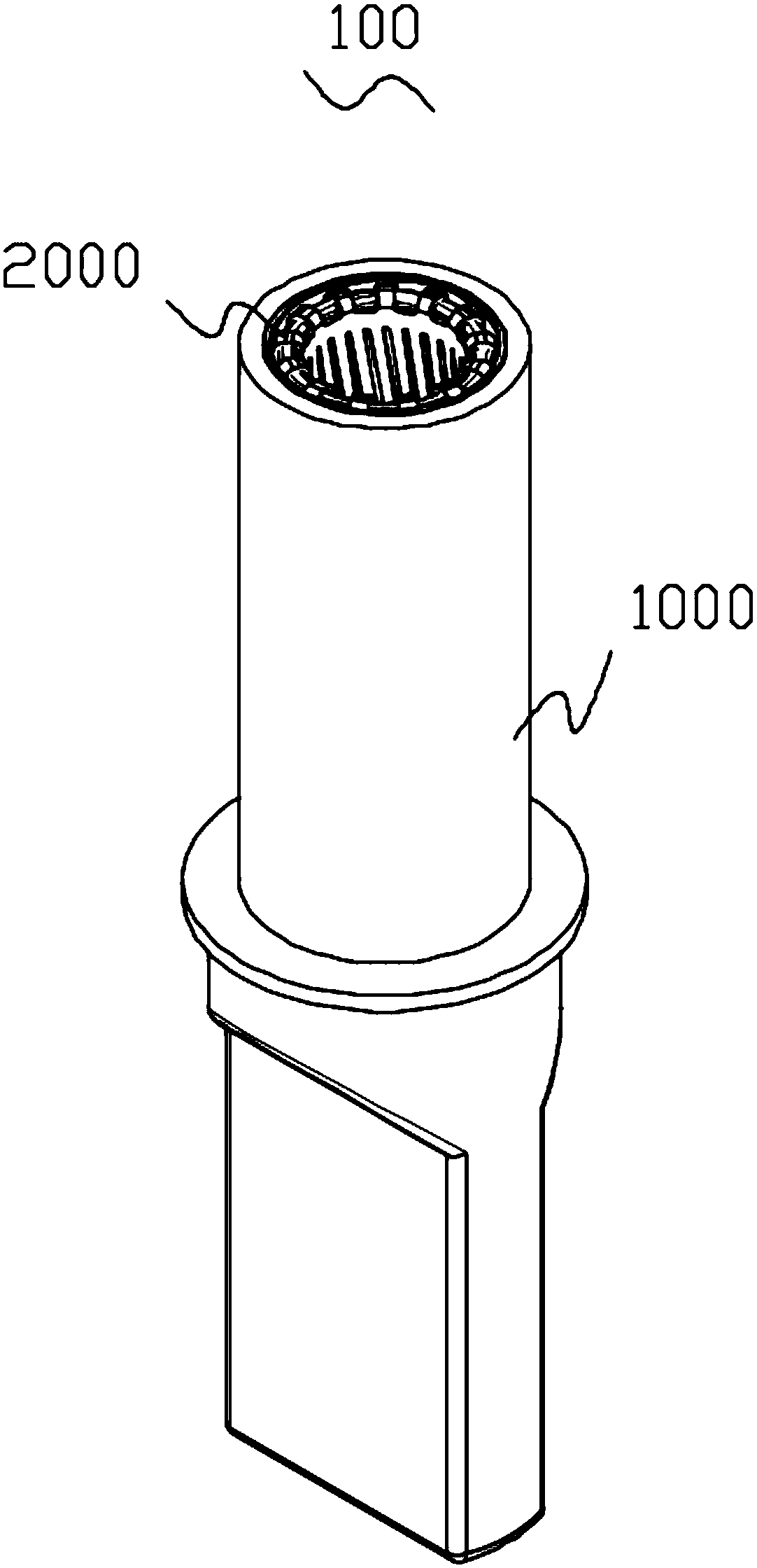

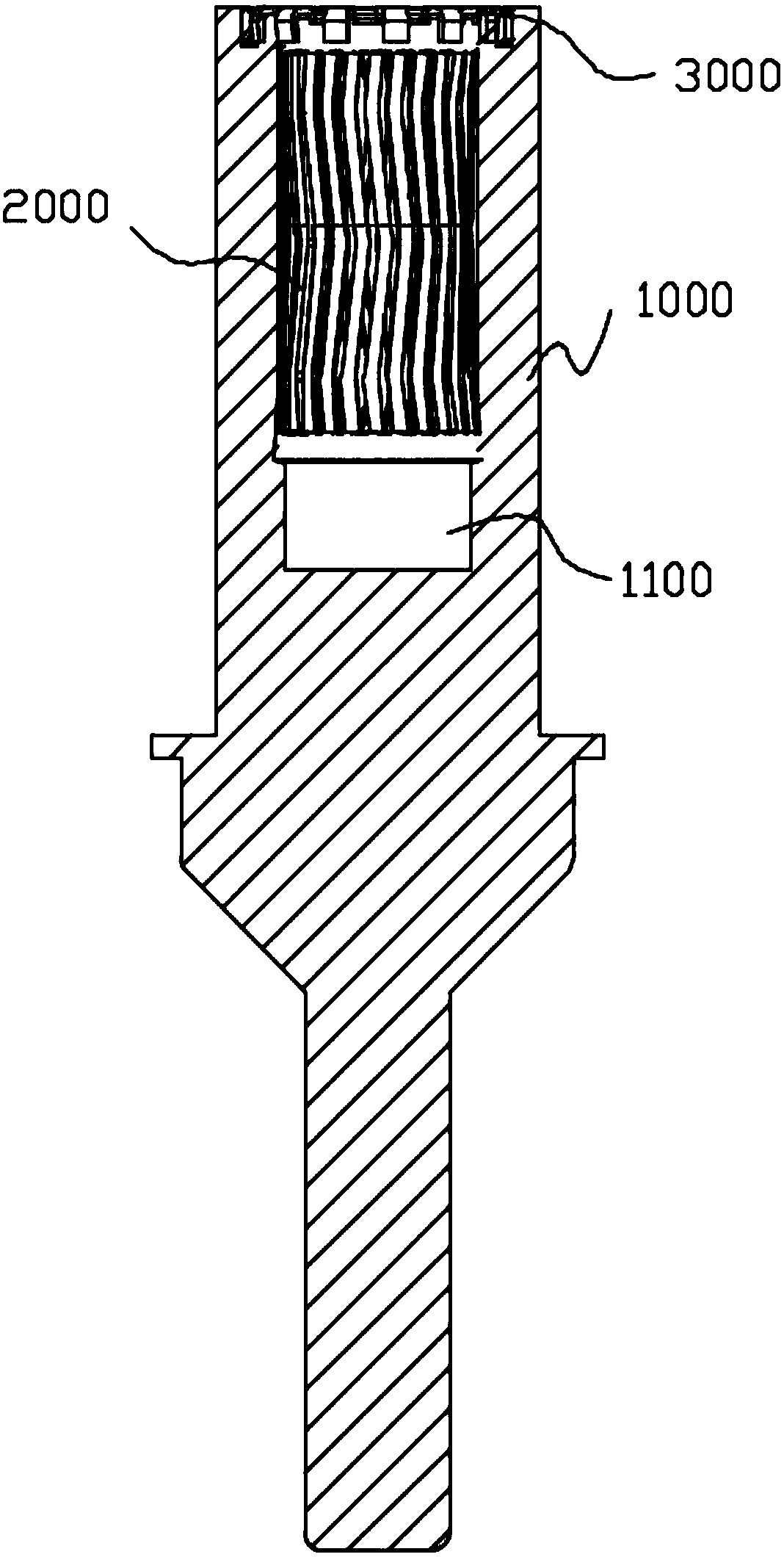

[0035] This implementation provides a wire spring socket 100, which is used in the technical field of conductive connectors. It cooperates with pins. When the pins are inserted into the wire spring socket 100, the conduction of circuits between different electrical components can be realized.

[0036] Specifically, see figure 2 , image 3 , Figure 4 with Figure 5 , The wire spring socket 100 includes an outer sleeve 1000 , a wire spring 2000 and a snap ring 3000 .

[0037] Wherein, the outer sleeve 1000 refers to the sleeve located on the outermost side of each sub-component of the wire spring sleeve 100 . It should be noted that, in this embodiment, a sleeve refers to any object with a hollow structure such as an internal through hole, a blind hole, etc., and its interior includes but is not limited to a circular, polygonal, tapered central hole or other forms. Hollow structure, its shape includes but not limited to cylinder, polyhedron and so on.

[0038] As a prefer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com