Heavy metal ion adsorption film and preparation method thereof

A technology of heavy metal ions and adsorption membranes, which is applied in the fields of alkali metal compounds, chemical instruments and methods, adsorption water/sewage treatment, etc., and can solve the problems of expensive polytetrafluoroethylene emulsions, poor performance stability, and poor compatibility. Good and other problems, to achieve the effect of improving the adsorption effect, improving mechanical properties and performance stability, and good adsorption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

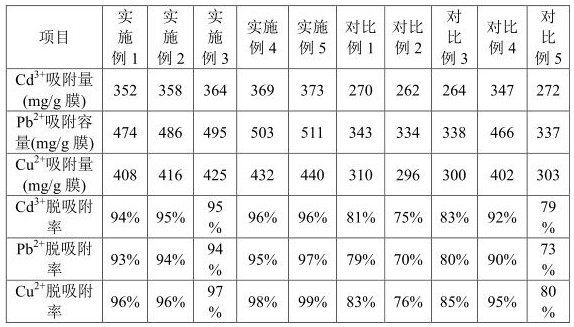

Examples

Embodiment 1

[0030] Embodiment 1 provides a kind of preparation method of heavy metal ion adsorption membrane, is characterized in that, comprises the steps:

[0031] Step S1, preparation of 3-fluorocintosilicic acid-modified diaminocalixarene derivatives: add 3-fluorocintosilicic acid and diaminocalixarene derivatives to an organic solvent and mix well, then add 2-ethanediol to it Oxy-1-ethoxycarbonyl-1,2-dihydroquinoline, at 45°C, stirred and reacted for 6 hours under an inert gas atmosphere, and then the solvent and by-products were removed by rotary evaporation to obtain modified 3-fluorosilicic acid Sexual diaminocalixarene derivatives;

[0032] Step S2, preparation of vinyl β-cyclodextrin quaternary ammonium salt based on carboxyl metal organic framework: adding vinyl β-cyclodextrin quaternary ammonium salt and carboxyl metal organic framework to hexafluoroisopropanol, Stir the reaction at 30°C for 3 hours, and then remove the hexafluoroisopropanol by rotary evaporation to obtain a ...

Embodiment 2

[0040] Embodiment 2 provides a kind of preparation method of heavy metal ion adsorption membrane, is characterized in that, comprises the steps:

[0041] Step S1, preparation of 3-fluorocintosilicic acid-modified diaminocalixarene derivatives: add 3-fluorocintosilicic acid and diaminocalixarene derivatives to an organic solvent and mix well, then add 2-ethanediol to it Oxygen-1-ethoxycarbonyl-1,2-dihydroquinoline, at 47°C, stirred and reacted for 7 hours under an inert gas atmosphere, and then the solvent and by-products were removed by rotary evaporation to obtain modified 3-fluorosilicic acid Sexual diaminocalixarene derivatives;

[0042] Step S2, preparation of vinyl β-cyclodextrin quaternary ammonium salt based on carboxyl metal organic framework: adding vinyl β-cyclodextrin quaternary ammonium salt and carboxyl metal organic framework to hexafluoroisopropanol, The reaction was stirred at 35°C for 3.5 hours, and then the hexafluoroisopropanol was removed by rotary evapora...

Embodiment 3

[0050] Embodiment 3 provides a kind of preparation method of heavy metal ion adsorption membrane, is characterized in that, comprises the steps:

[0051] Step S1, preparation of 3-fluorocintosilicic acid-modified diaminocalixarene derivatives: add 3-fluorocintosilicic acid and diaminocalixarene derivatives to an organic solvent and mix well, then add 2-ethanediol to it Oxy-1-ethoxycarbonyl-1,2-dihydroquinoline, stirred and reacted for 7.5 hours under an inert gas atmosphere at 50°C, and then the solvent and by-products were removed by rotary evaporation to obtain modified 3-fluorosilicic acid Sexual diaminocalixarene derivatives;

[0052] Step S2, preparation of vinyl β-cyclodextrin quaternary ammonium salt based on carboxyl metal organic framework: adding vinyl β-cyclodextrin quaternary ammonium salt and carboxyl metal organic framework to hexafluoroisopropanol, The reaction was stirred at 40°C for 4 hours, and then the hexafluoroisopropanol was removed by rotary evaporation...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com