Preparation method of purple cabbage anthocyanin-collagen chitosan composite intelligent membrane

A collagen and purple cabbage technology, applied in the food field, can solve the problems of low stability of anthocyanins, poor mechanical properties, high water solubility, and achieve the effects of good film-forming properties, good performance and high adsorption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0058] Embodiment 1, a kind of preparation method of purple cabbage anthocyanin-collagen chitosan composite intelligent film, carries out following steps successively:

[0059] 1), the preparation of purple cabbage anthocyanin (RCE) powder:

[0060] 500g of fresh purple cabbage is subjected to enzyme-inactivating treatment first, and then squeezed for juice. The slurry obtained by squeezing the juice is extracted with an aqueous ethanol solution, filtered, centrifuged at low temperature, and the supernatant is rotary evaporated, placed at low temperature for 24-48 hours, and then vacuum freeze-dried. Obtain purple cabbage anthocyanin powder (about 10g).

[0061] in:

[0062] The temperature for inactivating the enzyme is 100°C, and the time is 5 minutes;

[0063] The volume ratio of absolute ethanol and deionized water in the ethanol aqueous solution is 65:35, and the extraction material-liquid ratio is 1:5, that is, the volume ratio of the juice obtained by squeezing the ju...

Embodiment 2

[0079] Embodiment 2, a kind of preparation method of purple cabbage anthocyanin-collagen chitosan composite intelligent film:

[0080] Change the consumption of purple cabbage anthocyanin powder in step 3) of embodiment 1 from 30 mg to 60 mg, and the rest are equal to embodiment 1.

[0081] In this example 2, the purple cabbage anthocyanin powder is 2% of the total mass of collagen and chitosan, so the composite film obtained is named CA-CS-RCE 2%.

Embodiment 3

[0082] Embodiment 3, a kind of preparation method of purple cabbage anthocyanin-collagen chitosan composite intelligent film:

[0083] Change the amount of purple cabbage anthocyanin powder from 30mg to 90mg in step 3) of Example 1, and the rest are equal to Example 1.

[0084] In Example 3, the purple cabbage anthocyanin powder is 3% of the total mass of collagen and chitosan, so the composite film obtained is named CA-CS-RCE 3%.

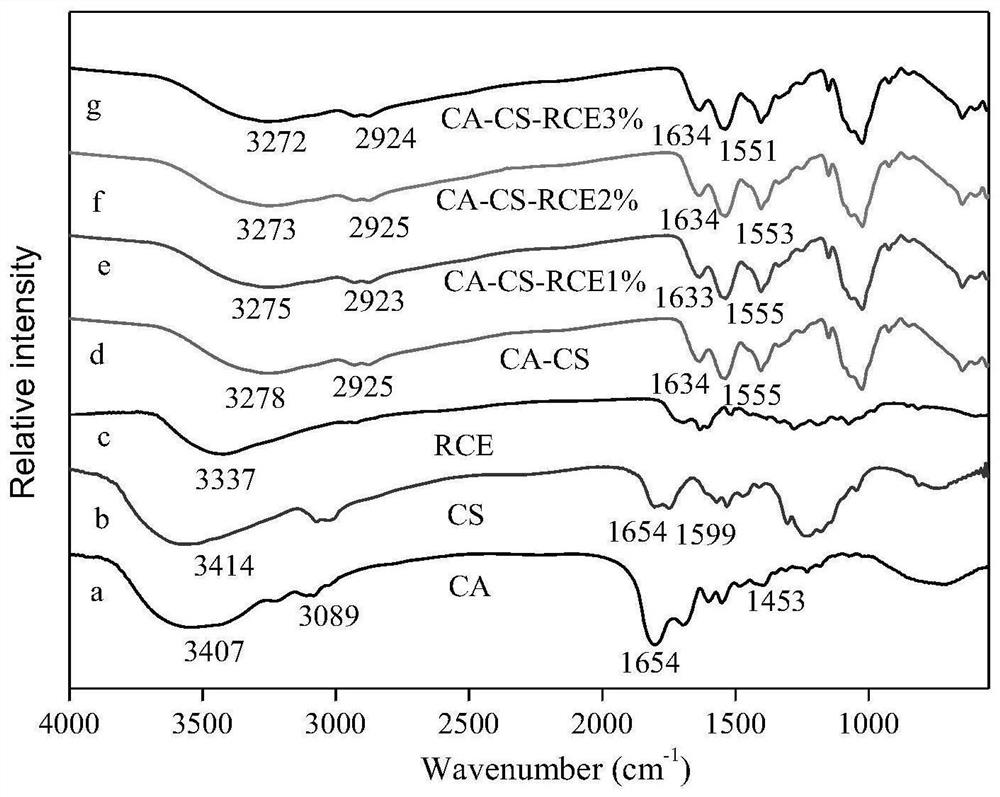

[0085] Experiment 1, to the composite film (CA-CS-RCE 1%, CA-CS-RCE 2%, CA-CS-RCE3%) of embodiment 1~embodiment 3 gained, and collagen chitosan (CA-CS ) film, purple cabbage anthocyanin (RCE) powder, chitosan (CS), and collagen (CA) are detected with a Fourier transform infrared spectrometer (FTIR), and the resulting Fourier transform infrared image is as follows figure 1 mentioned.

[0086] according to figure 1 , it can be known that anthocyanins can combine with collagen chitosan through hydrogen bonds, hydrophobic interactions or electrost...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com