Conductive aerogel and preparation method thereof

A technology of airgel and conductive layer, applied in the direction of electrospinning, rayon manufacturing, fiber chemical characteristics, etc., can solve the problems of high preparation conditions, complicated preparation methods, and easy oxidation, so as to improve mechanical properties, The preparation method is simple and the effect of increasing the variety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

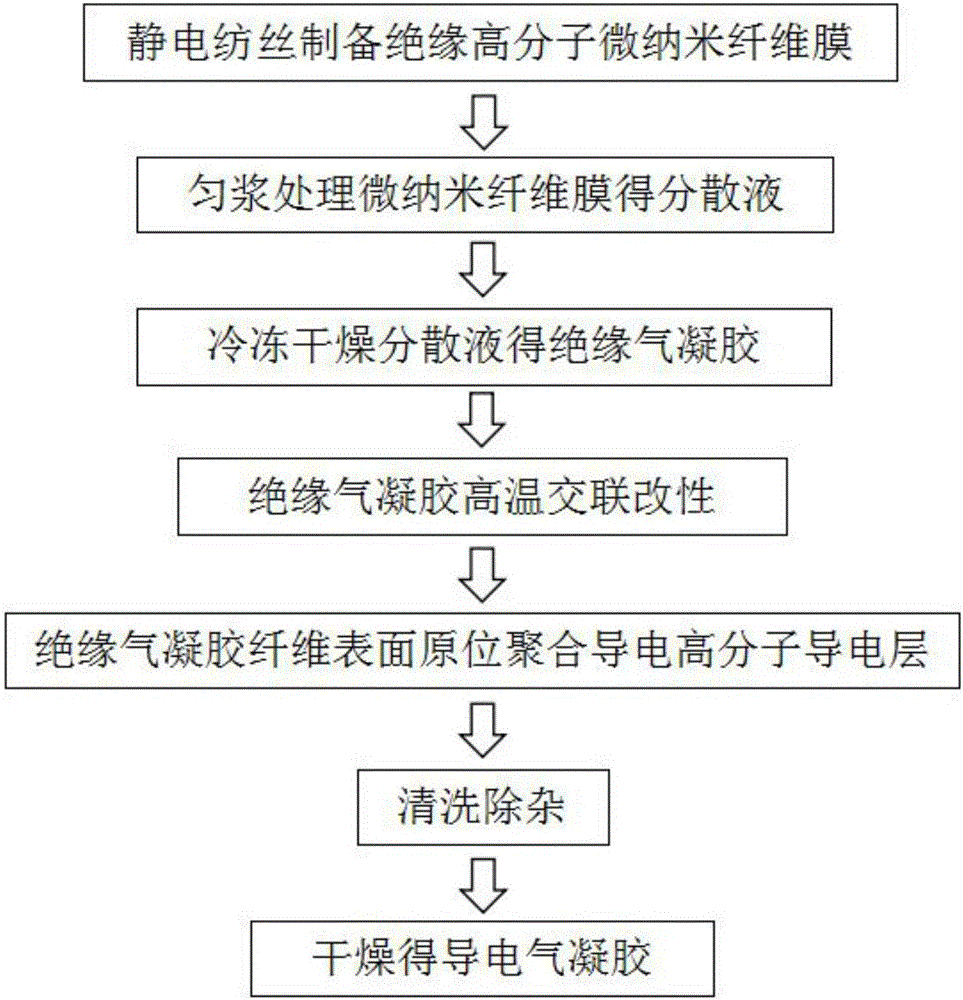

[0037] A preparation method of conductive airgel, comprising the following steps (flow chart as figure 1 shown):

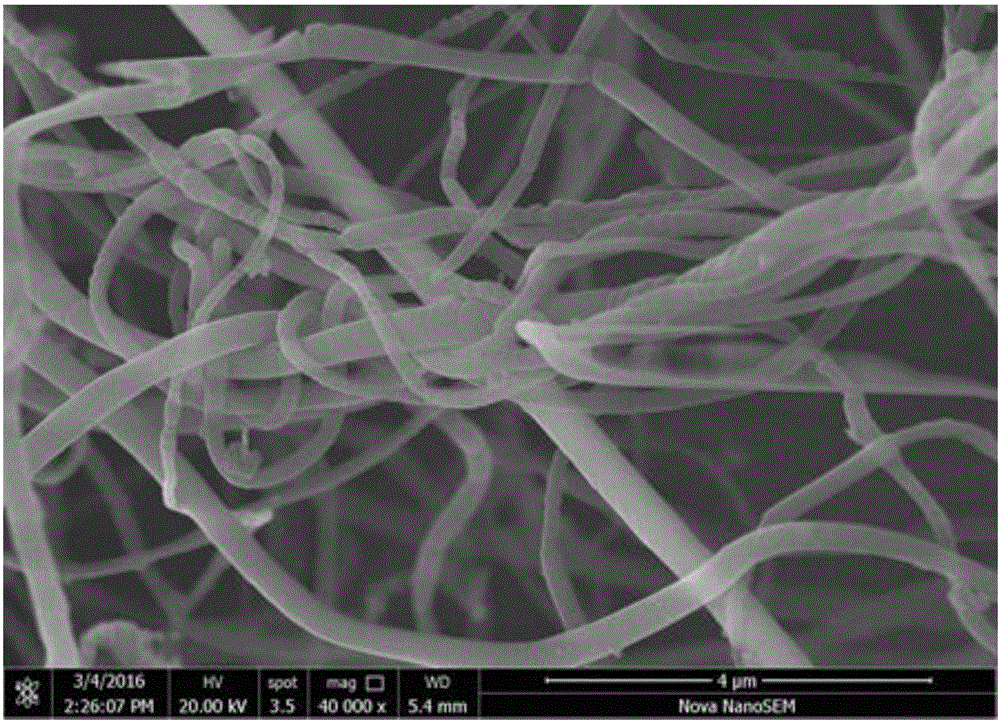

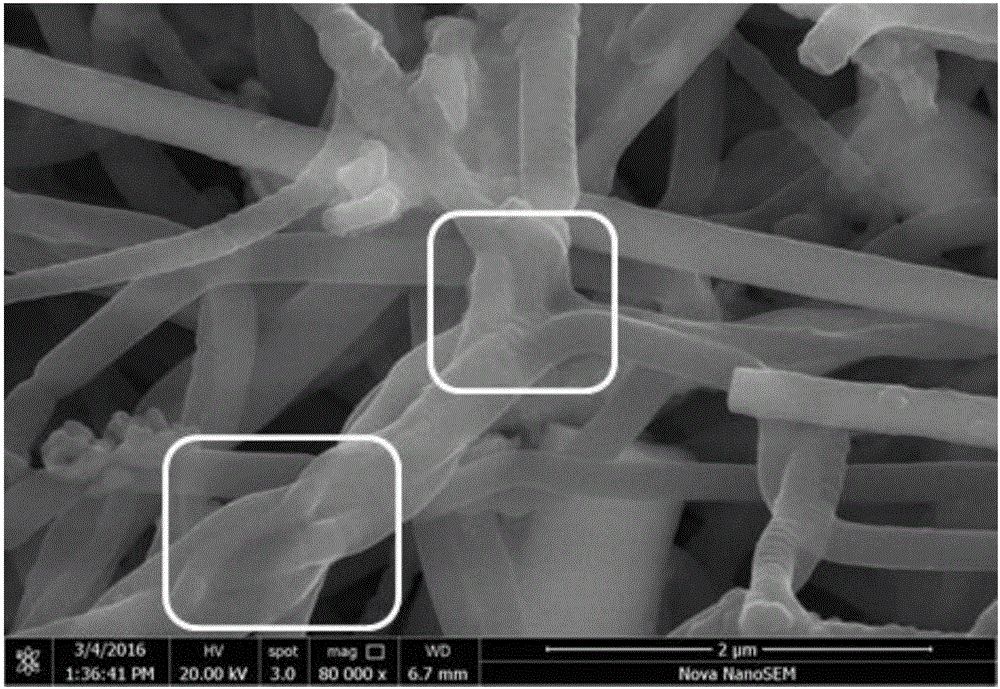

[0038] 1. Spinning and preparing insulating airgel: said step 1. includes (1) mixing N,N dimethylformamide, polyacrylonitrile (PAN, molecular weight M w=500000) mass ratio 87:13 mixed, magnetic stirrer stirred for 12 hours, was mixed with the electrospinning precursor solution, carried out electrospinning with the electrospinning precursor solution, the spinning voltage was 18 kilovolts, and the spinning receiving distance was 15 centimeters. The polyacrylonitrile micro-nanofiber film is collected on the collector; (2) Homogenization treatment: the polyacrylonitrile micro-nanofiber film obtained by silicon carbide whiskers, step (1), tert-butyl alcohol, and deionized water are mixed according to the mass ratio Mix at a ratio of 1:3:80:320, stir with a high-speed stirrer at 10,000 rpm for 30 minutes to obtain a uniformly dispersed dispersion; (3) freeze-dry the di...

Embodiment 2

[0044] A preparation method of conductive airgel, comprising the following steps:

[0045] 1. spin to prepare insulating airgel: said step 1. includes (1) acetone, N,N dimethylformamide, polyvinylidene fluoride (PVDF, M w =550000), silicon carbide whiskers were mixed according to the mass ratio of 39:39:21:1, stirred by a magnetic stirrer for 24 hours, prepared into an electrospinning precursor solution, and electrospinning was carried out with the electrospinning precursor solution, and the spinning voltage was 15 k V, the spinning receiving distance is 12 centimeters, and the polyvinylidene fluoride micro-nanofiber film is collected on the collecting pole; (2) homogenization treatment: the polyvinylidene fluoride micro-nanofiber film obtained in step (1), tert-butanol 1. Deionized water is mixed in the ratio of mass ratio 1:80:20, with a high-speed stirrer at 10000 rpm, stirred to obtain a uniformly dispersed dispersion for 30 minutes; (3) freezing the dispersion obtained in...

Embodiment 3

[0051] A preparation method of a conductive airgel, which is similar to Example 2, except that silicon carbide is not added to the electrospinning precursor solution prepared in step ①. The content of polyaniline in the resulting conductive airgel is 17wt%, and the conductivity of the conductive airgel is 1.54×10 -5 S / cm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com