Hybrid proton exchange membrane based on polyacid/piperidine aryl copolymer and preparation method of hybrid proton exchange membrane

A proton exchange membrane and piperidine aryl technology, applied in the field of proton exchange membranes, can solve the problems of adverse effects on properties of electrolyte membrane fuel cells, degradation of mechanical properties, etc., achieve high proton conductivity and mechanical stability, and improve mechanical properties. , the effect of improving dimensional stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

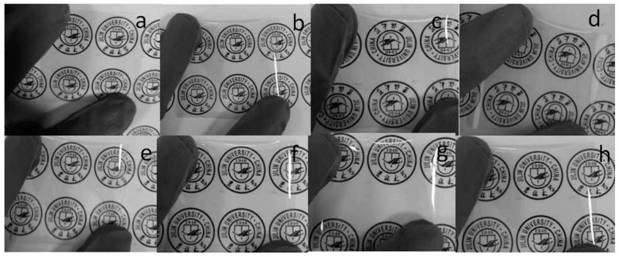

Image

Examples

preparation example Construction

[0025] The invention provides a method for preparing a hybrid proton exchange membrane based on polyacid / piperidine aryl copolymer, comprising the following steps:

[0026] The polyacid and the piperidine aryl polymer solution are mixed, poured to form a membrane, and dried to obtain a hybrid proton exchange membrane.

[0027] In the present invention, if there is no special requirement, the preparation raw materials used are commercially available products well known to those skilled in the art.

[0028] In the present invention, the polyacid is preferably a heteropolyacid, more preferably phosphotungstic acid and / or silicotungstic acid.

[0029] In the present invention, based on the total mass of the polyacid and the piperidine aryl polymer solution in the piperidine aryl polymer solution, the mass fraction of the polyacid is preferably 0.05% to 85%, more preferably 20% ~50%, more preferably 30~40%.

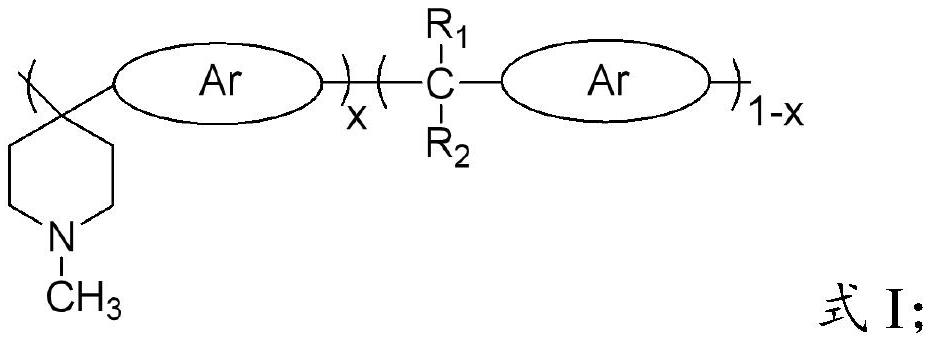

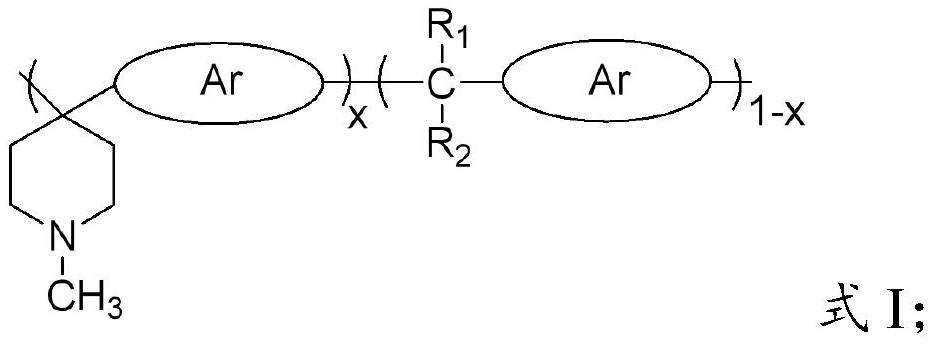

[0030] In the present invention, the solute of the piperidine aryl poly...

Embodiment 1

[0057]

[0058] Add 26mmol of biphenyl to a three-neck flask equipped with a stirrer and a constant pressure dropping funnel, add 8.6mL of CH 2 Cl 2 Make it dissolve, then add 3mmol N-methylpiperidone and 30mmol 1,1,1-trifluoroacetone, ice-bath, add 34mmol trifluoroacetic acid (TFA) in the constant pressure dropping funnel for 1-2 seconds Add 233mmol trifluoromethanesulfonic acid (TFSA) into the three-necked flask at a rate of 1-2 seconds / drop, and then add 233mmol trifluoromethanesulfonic acid (TFSA) into the three-necked flask at a rate of 1-2 seconds / drop, and polymerize for 6 hours in an ice bath. , pour the resulting product into 1.0mol L- 1 NaOH solution, washed with ethanol for 5-6 times, and baked in a vacuum oven at 80°C for 24 hours to obtain a piperidine aryl polymer.

[0059] Dissolve 0.11 g of the piperidine aryl polymer in 3.0 mL of N-methylpyrrolidone (NMP), and stir to dissolve it to obtain a piperidine aryl polymer solution; then add 0.05 g of phosphotung...

Embodiment 2

[0061]

[0062] Add 26mmol of biphenyl to a three-neck flask equipped with a stirrer and a constant pressure dropping funnel, add 8.6mL of CH 2 Cl 2 Make it dissolve, then add 3mmol N-methylpiperidone and 30mmol 1,1,1-trifluoroacetone, ice-bath, add 34mmol trifluoroacetic acid (TFA) in the constant pressure dropping funnel for 1-2 seconds Add 233mmol trifluoromethanesulfonic acid (TFSA) into the three-necked flask at a rate of 1-2 seconds / drop, and then add 233mmol trifluoromethanesulfonic acid (TFSA) into the three-necked flask at a rate of 1-2 seconds / drop, and polymerize for 6 hours in an ice bath. , pour the resulting product into 1.0mol L- 1 NaOH solution, washed with ethanol for 5-6 times, and baked in a vacuum oven at 80°C for 24 hours to obtain a piperidine aryl polymer.

[0063] Dissolve 0.11g of the piperidine aryl polymer in 3.0mL of NMP, and stir to dissolve it to obtain a piperidine aryl polymer solution; then add 0.03g of silicotungstic acid, stir to dissolv...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

| tensile strength at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com