Environmentally-friendly plastic and preparation method thereof

A technology of environmentally friendly plastics and beta-cyclodextrin, applied in the field of plastics, can solve the problems of poor processing fluidity, non-automatic degradation, environmental pollution, etc., to achieve improved flame retardancy, strong biodegradability, and low equipment requirements high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

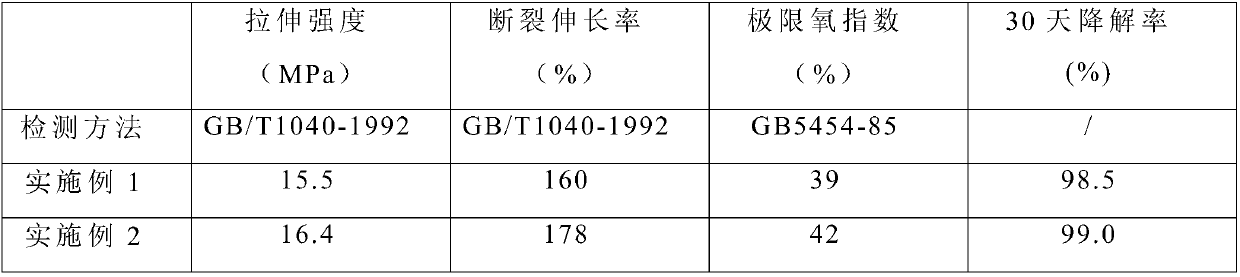

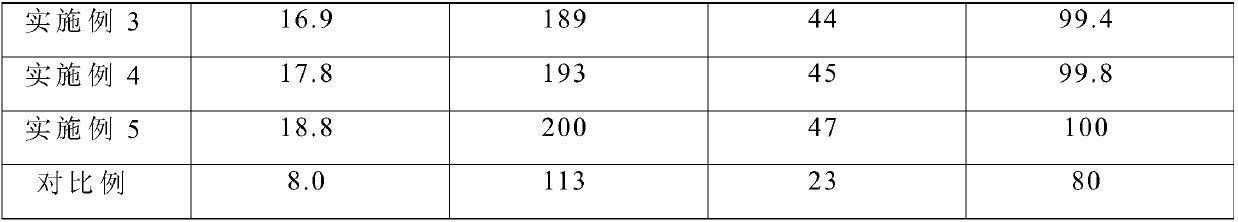

Examples

Embodiment 1

[0027] A preparation method of environmentally friendly plastics, comprising the steps of:

[0028] 1) Preparation of polymerized monomer: Dissolve 100g of all-aminobeta cyclodextrin in 800g of dimethyl sulfoxide, then add 200g of 4-vinylbenzyl chloride to it, stir and react at 30°C for 5 hours, then pour into A precipitate was precipitated in acetone, filtered and washed 3 times with ether, and the solvent was extracted under reduced pressure;

[0029] 2) Preparation of copolymer: 90 g of polymerized monomers, 15 g of vinylpyrrolidone, 15 g of vinyl ferrocene, 60 g of L-vinylglycine, and 0.6 g of azobisisobutyronitrile prepared through step 1) were dissolved in two In 450g of methyl sulfoxide, polymerize at 60°C for 2 hours under a nitrogen atmosphere, then pour into acetone to precipitate, filter, and dry the filter cake in a vacuum oven at 60°C for 10 hours;

[0030] 3) Ion exchange: soak 100 g of the copolymer prepared in step 2) in 10000 g of an aqueous solution of sodiu...

Embodiment 2

[0034] A preparation method of environmentally friendly plastics, comprising the steps of:

[0035] 1) Preparation of polymerized monomers: Dissolve 100 g of all-aminobeta cyclodextrin in 900 g of dimethyl sulfoxide, then add 220 g of 4-vinylbenzyl chloride, stir and react at 32°C for 5.5 hours, then pour into A precipitate was precipitated in acetone, filtered and washed 4 times with ether, and the solvent was extracted under reduced pressure;

[0036] 2) Preparation of copolymer: 70 g of polymerized monomers, 10 g of vinylpyrrolidone, 10 g of vinyl ferrocene, 45 g of L-vinyl glycine, and 0.6 g of azobisisoheptanonitrile prepared by step 1) were dissolved in N , in 350g of N-dimethylformamide, polymerized at 63°C for 2.3 hours under a helium atmosphere, then poured into acetone to precipitate, filtered, and dried the filter cake in a vacuum oven at 62°C for 12 hours;

[0037] 3) Ion exchange: Soak 100 g of the copolymer prepared in step 2) in 9000 g of an aqueous solution of...

Embodiment 3

[0041] A preparation method of environmentally friendly plastics, comprising the steps of:

[0042] 1) Preparation of polymerized monomer: Dissolve 100g of all-aminobeta cyclodextrin in 1000g of dimethyl sulfoxide, then add 240g of 4-vinylbenzyl chloride to it, stir and react at 36°C for 6 hours, then pour into A precipitate was precipitated in acetone, filtered and washed 5 times with ether, and the solvent was extracted under reduced pressure;

[0043] 2) Preparation of copolymer: 80 g of polymerized monomers, 10 g of vinyl pyrrolidone, 10 g of vinyl ferrocene, 50 g of L-vinyl glycine, and 0.7 g of azobisisobutyronitrile prepared in N - In 400g of methylpyrrolidone, polymerize for 2.6 hours under a neon atmosphere at 66°C, then pour into acetone to precipitate, filter, and dry the filter cake in a vacuum oven at 66°C for 13 hours;

[0044] 3) Ion exchange: Soak 100 g of the copolymer prepared in step 2) in 8000 g of an aqueous solution of sodium lignosulfonate with a mass fra...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com