Polycarboxylate-type water reducing agent for gypsum-based self-leveling mortar and preparation method and use method thereof

A technology of self-leveling mortar and polycarboxylic acid series, which is applied in the field of water reducing agent, can solve the problems of poor adaptability and achieve the effects of increasing the length of the main chain, good water reducing effect and high polyether activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] A kind of preparation method of polycarboxylate water reducer, it comprises the following steps:

[0026] (1) At 0°C and in a stirring state, add solution A and solution B dropwise to the polymerization reactor that has been put into the base material C to carry out the polymerization reaction. The time of the polymerization reaction is to continue to mature after the solution A and solution B are dropped. The reaction time is 90 minutes;

[0027]Among them, the timing of adding solution B is earlier than that of solution A, the addition rate of solution A is based on the addition of 10 minutes at a constant speed, and the addition of solution B is based on the addition of 20 minutes at a constant speed; the composition of solution A is: 10 parts of acrylic acid, rich 1 part of malic acid, 0.5 part of dimethyl diallyl ammonium chloride, 0.01 part of diethylene glycol divinyl ether, 0.01 part of triethylene glycol divinyl ether, 0.01 part of mercaptopropionic acid, 0.01 ...

Embodiment 2~5

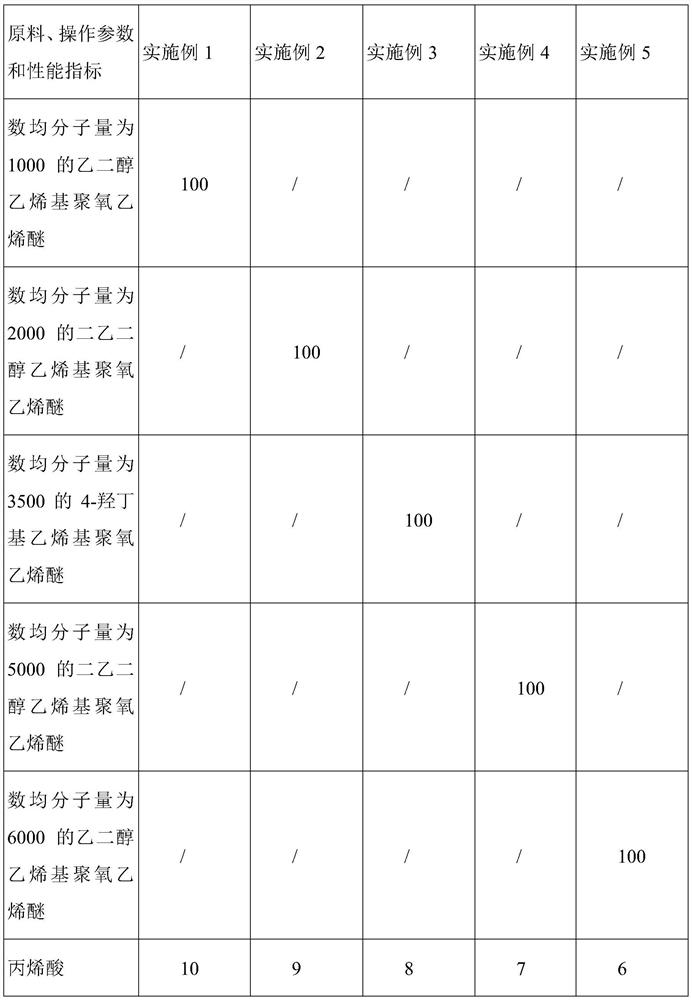

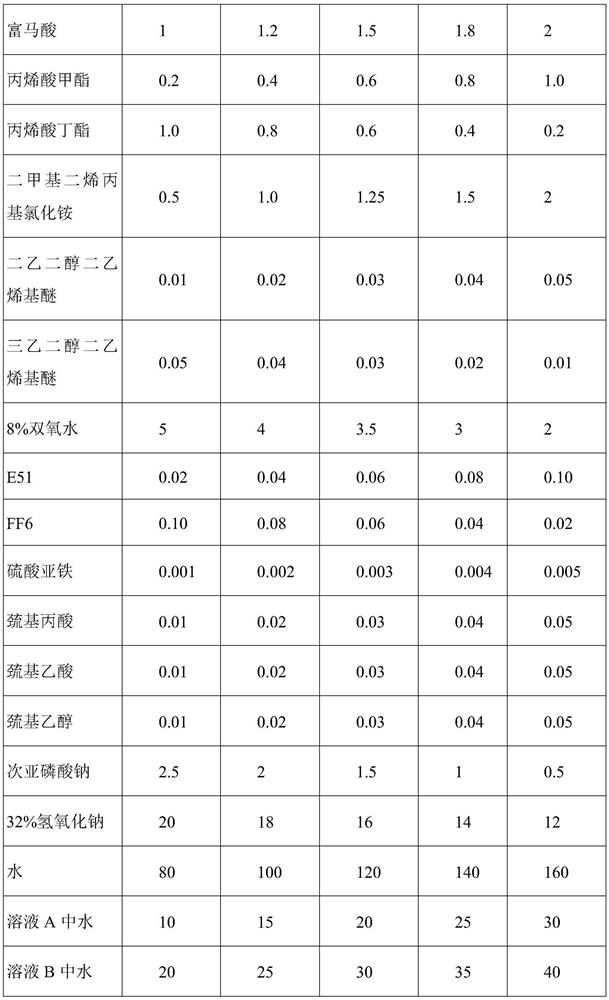

[0032] According to the method and steps of Example 1, according to the formula and operating parameters in Table 1, a polycarboxylate water reducer was prepared.

[0033] Table 1

[0034]

[0035]

[0036]

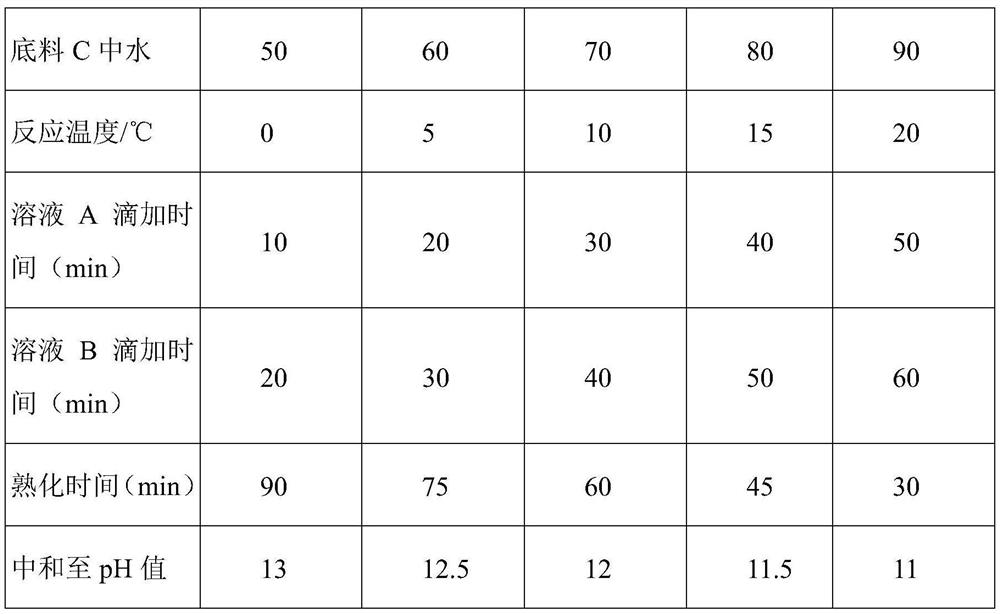

[0037] The polycarboxylate water reducer obtained in the above Examples 1-5 was added to the gypsum-based self-leveling mortar, and its performance was tested.

[0038] See Table 2 below.

[0039]

[0040] Among them, Comparative Example 1 is a commercially available naphthalene-based water reducer, provided by Weifang Yingda Chemical Co., Ltd.; Comparative Example 2 is a commercially available polycarboxylate-based water reducer ZJ-8300, provided by Jiangsu Zhaojia Building Materials Technology Co., Ltd.

[0041] The performance testing results of the polycarboxylate water reducers prepared in Examples 1-5 are shown in Table 2. It can be seen from Table 2 that when the polycarboxylate water-reducer of the present invention is added to the gypsum-based self-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| flexural strength | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com