A kind of preparation method and application of hyperbranched sulfone polymer

A polymer and reaction technology, which is applied in the field of preparation of hyperbranched sulfone polymers, can solve the problems of large temperature difference, difficulty in uniform melting, and difficult molding of materials, so as to increase the reaction rate, increase the glass transition temperature and viscous flow temperature, shape-preserving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

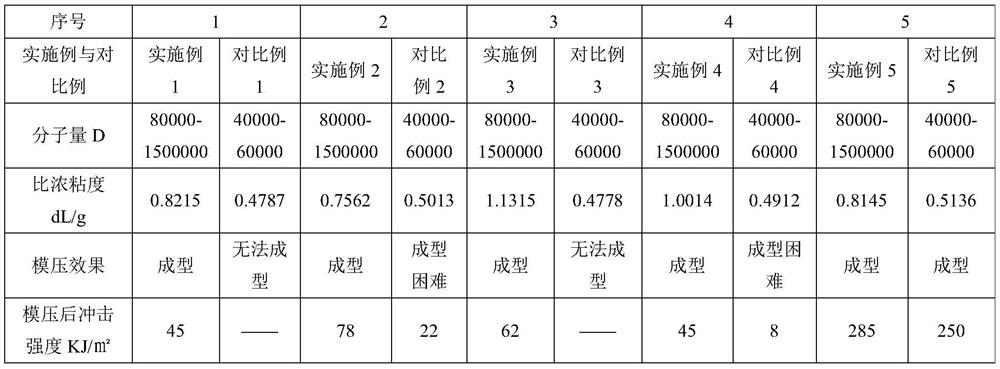

Examples

Embodiment 1

[0059] Catalyst preparation:

[0060] Add 21.8g of pyromellitic dianhydride to 153g of N,N-dimethylformamide, stir and heat up to 50°C, after the dianhydride is dissolved, add 6.4g of methanol, and control the material temperature at 80°C until the reaction solution is transparent; Add 1.74g potassium fluoride powder, 1.74g cesium chloride powder, 0.44g aluminum trifluoride, 0.11g polyethylene glycol and continue to react at this reaction temperature for 40 minutes, cool down to 50°C, add 0.11g deionized water, 5 Add 0.11g of simethicone after 1 minute, and adjust the rotation speed to 5 rpm; naturally cool down to room temperature. The prepared solution was mixed with 24.5g of pure MDI and stirred rapidly to foam. After the molding was stable, it was placed in a vacuum oven, and vacuum-dried at 150°C and 340°C and -0.098MPa for 2h and 3h, respectively. After taking it out, carry out high-temperature carbonization at 570° C. for 3 hours in a high-temperature furnace and pulve...

Embodiment 2

[0069] Catalyst preparation:

[0070] Add 29.4g of biphenyltetracarboxylic dianhydride to 235g of N,N-dimethylacetamide, start stirring and heat up to 50°C, after the dianhydride is dissolved, add 6.7g of methanol, and control the material temperature at 90°C until the reaction solution is transparent; Add 2.94g of potassium fluoride powder, 2.94g of cesium chloride, 2.94g of aluminum trifluoride, 0.24g of polyethylene glycol and continue to react at this reaction temperature for 50 minutes, cool down to 50°C, add 0.18g of deionized water for 5 minutes Then add 0.26g of simethicone oil, adjust the speed to 10 rpm; cool down to room temperature naturally. The prepared solution was mixed with 17.2g of TDI and stirred rapidly to foam. After the molding was stable, it was placed in a vacuum oven, and vacuum dried at 160°C and 280°C and -0.098MPa for 3h and 3h, respectively. After taking it out, carry out high-temperature carbonization at 600° C. for 4 hours in a high-temperature ...

Embodiment 3

[0079] Catalyst preparation:

[0080] Add 32.2g of benzophenone tetracarboxylic dianhydride to 290g of N-methylpyrrolidone, stir and heat up to 50°C, after the dianhydride is dissolved, add 7.0g of methanol, control the material temperature at 95°C until the reaction liquid is transparent; add 4.83g Potassium fluoride powder, 5.15g cesium fluoride, 4.83g aluminum trifluoride, 0.32g polyethylene glycol continue to react at this reaction temperature for 60 minutes, cool down to 50°C, add 0.16g deionized water, and add 0.48 g simethicone oil, adjusted to a speed of 12 rpm; naturally cooled to room temperature. The prepared solution was mixed with 17.4g of TDI and stirred rapidly to foam. After the molding was stable, it was placed in a vacuum oven, and vacuum-dried at 200°C and 290°C and -0.099MPa for 1h and 3h, respectively. After taking it out, carry out high-temperature carbonization at 700° C. for 5 hours in a high-temperature furnace and pulverize to prepare carbonized BTDA...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com