Patents

Literature

88results about How to "Increase catalytic rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

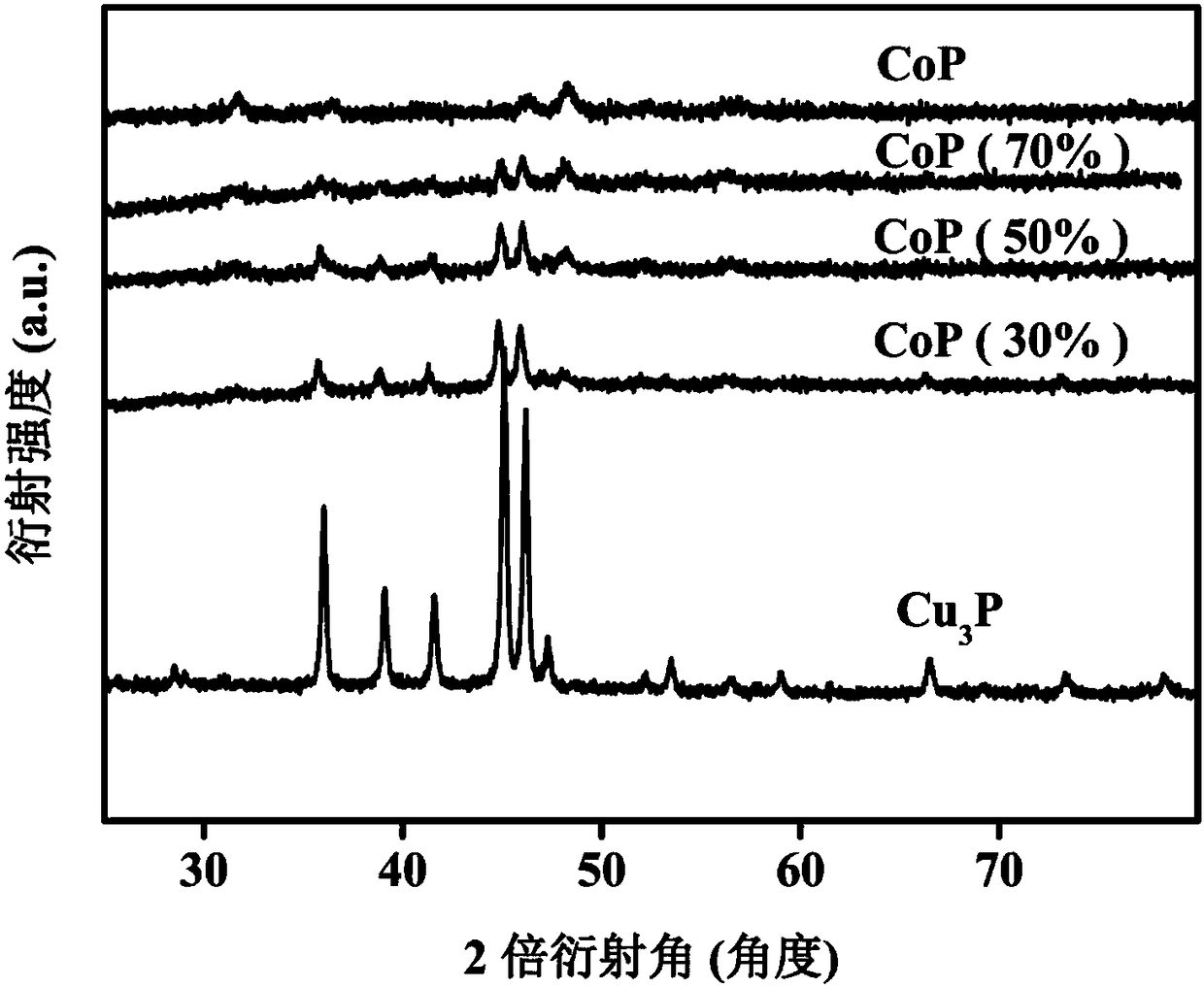

Hydrogen storage material hydrolysis and hydrogen releasing system taking monodispersed or supported phosphorus-containing metal compound as catalyst

ActiveCN108525685ASave raw materialsHigh catalytic efficiencyPhysical/chemical process catalystsHydrogen productionHydrolysisAqueous solution

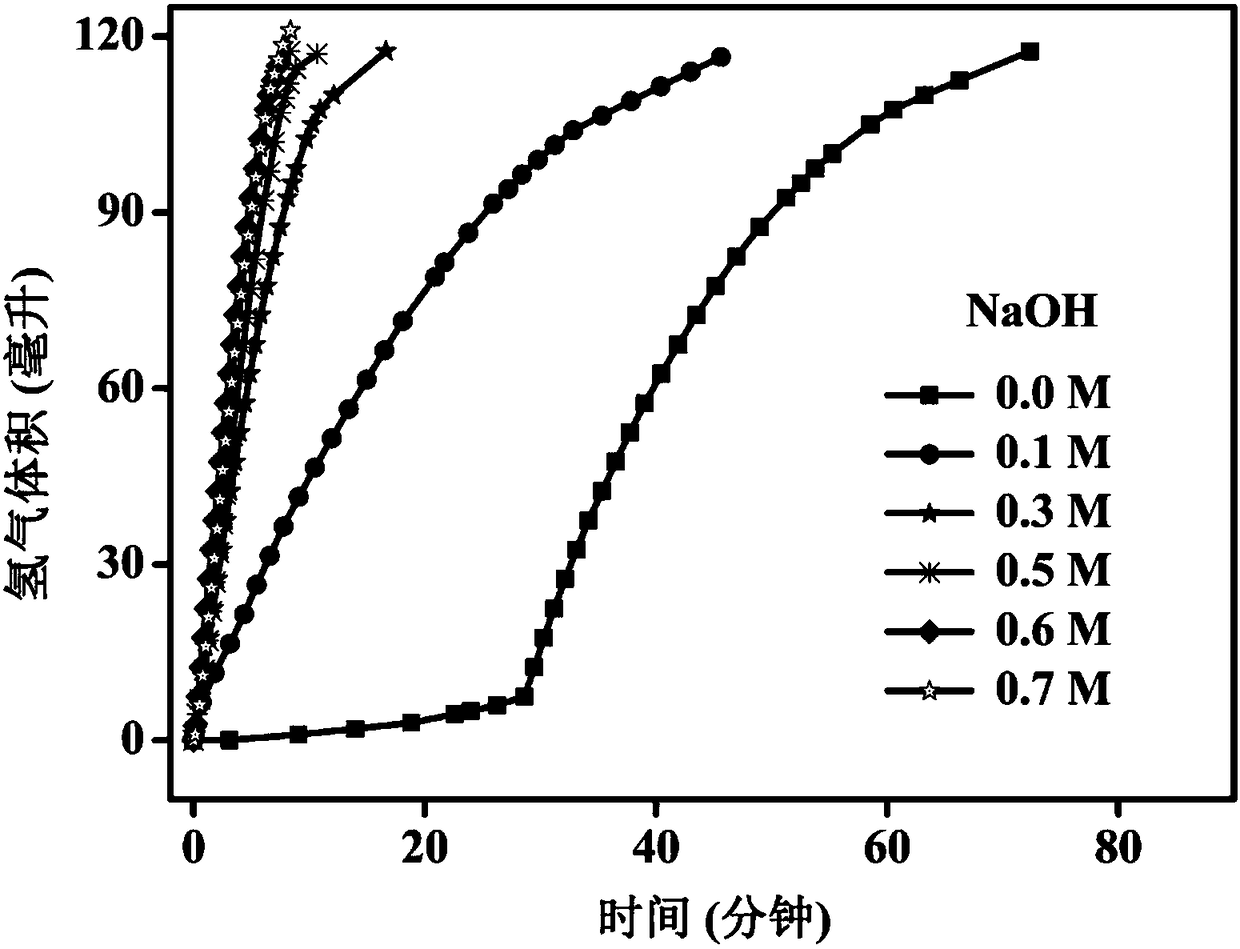

The invention discloses a hydrogen storage material hydrolysis and hydrogen releasing system taking a monodispersed or supported phosphorus-containing metal compound as a catalyst. The system comprises a hydrogen storage material and water, and further comprises a catalyst, wherein the catalyst is one or multiple of a monodispersed multi-metal phosphide, a supported multi-metal phosphide, a monodispersed single-metal and multi-non-metal phosphorus-containing compound, a supported single-metal and multi-non-metal phosphorus-containing compound, a monodispersed multi-metal multi-non-metal phosphorus-containing compound and a supported multi-metal multi-non-metal phosphorus-containing compound. Alkali is added into an aqueous solution of the monodispersed or supported phosphorus-containing metal to improve the catalytic rate of the catalyst and shorten the induction period. The catalysis efficiency of the supported catalyst is higher than that of the monodispersed catalyst. The system provides a batch of efficient novel catalysts for hydrolysis and hydrogen releasing of the hydrogen storage material, and provides a method for increasing the hydrolysis rate of the hydrogen storage material under the catalysis of the phosphorus-containing metal compound.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

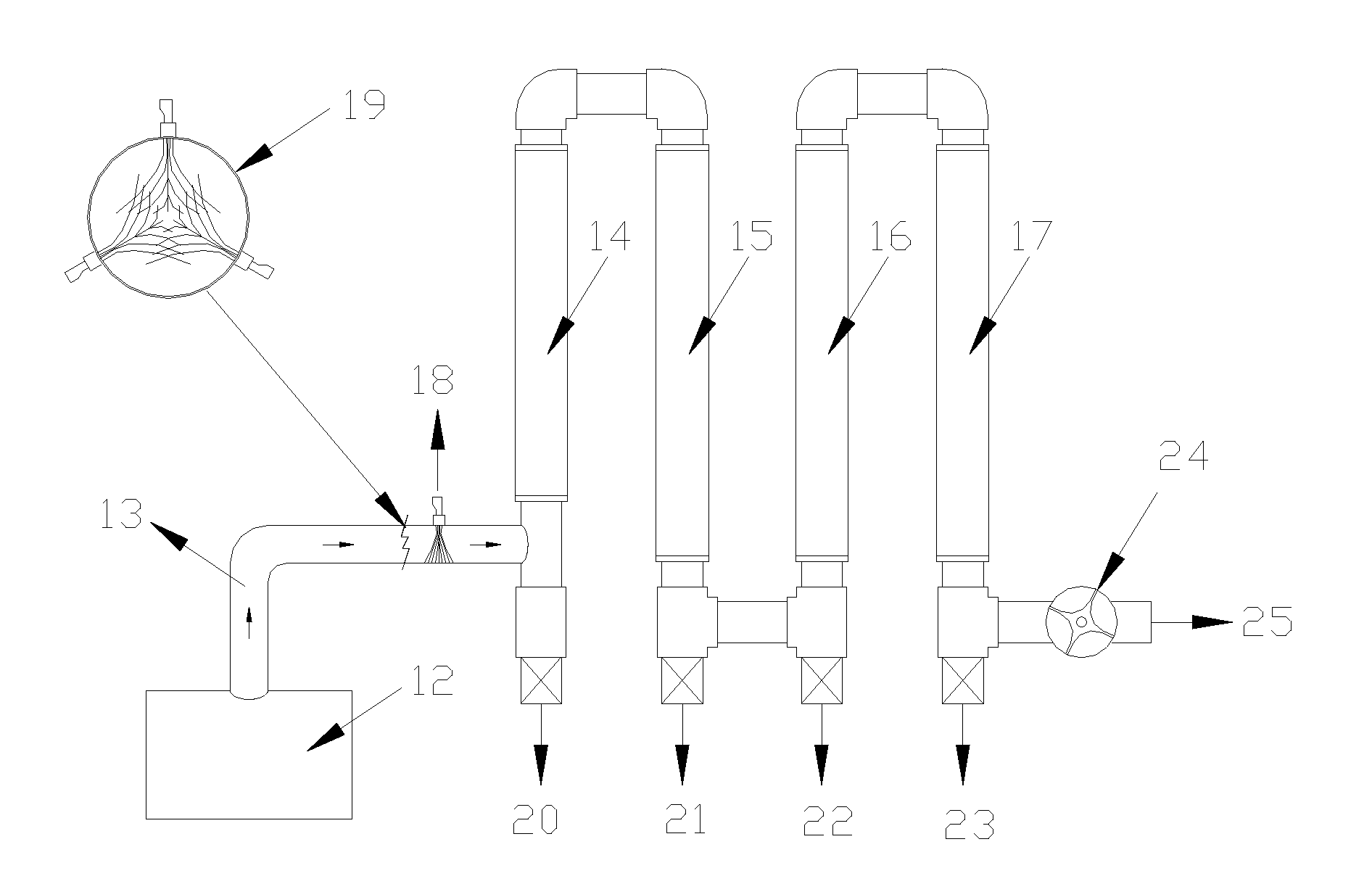

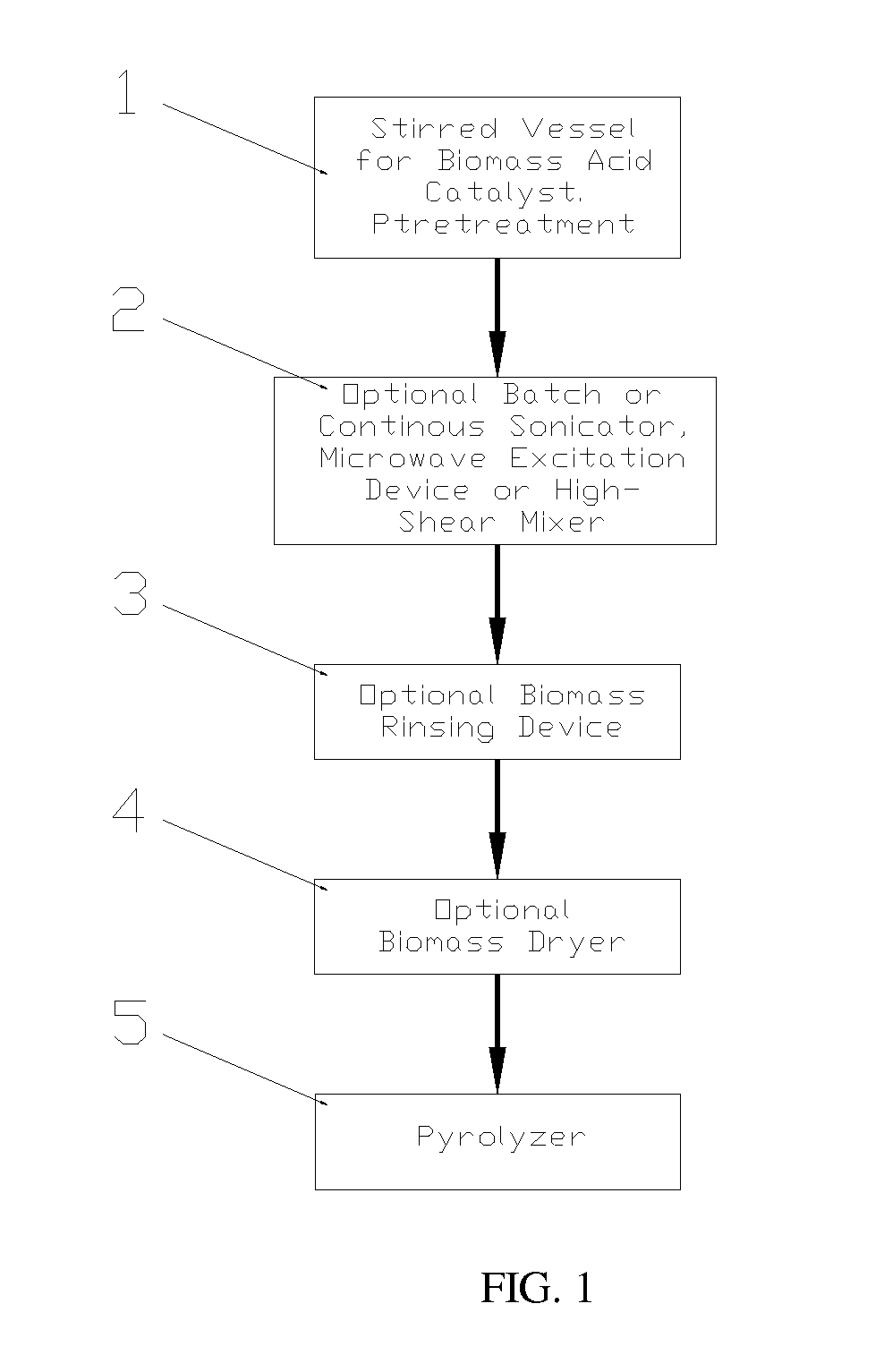

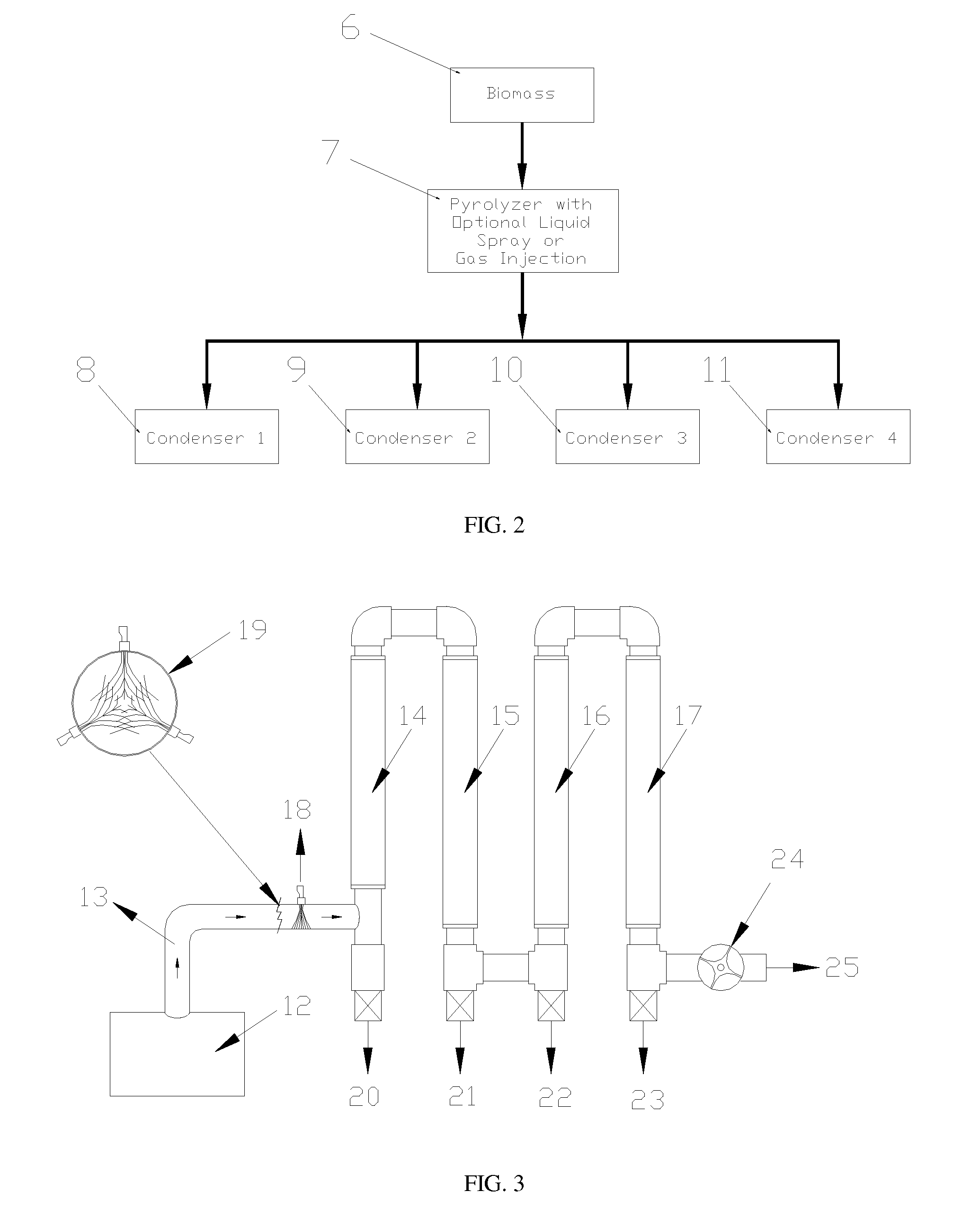

Method of increasing anhydrosugars, pyroligneous fractions and esterified bio-oil

InactiveUS20110245489A1Increase productionIncrease catalytic rateBiofuelsWaste based fuelMicrowaveIt technology

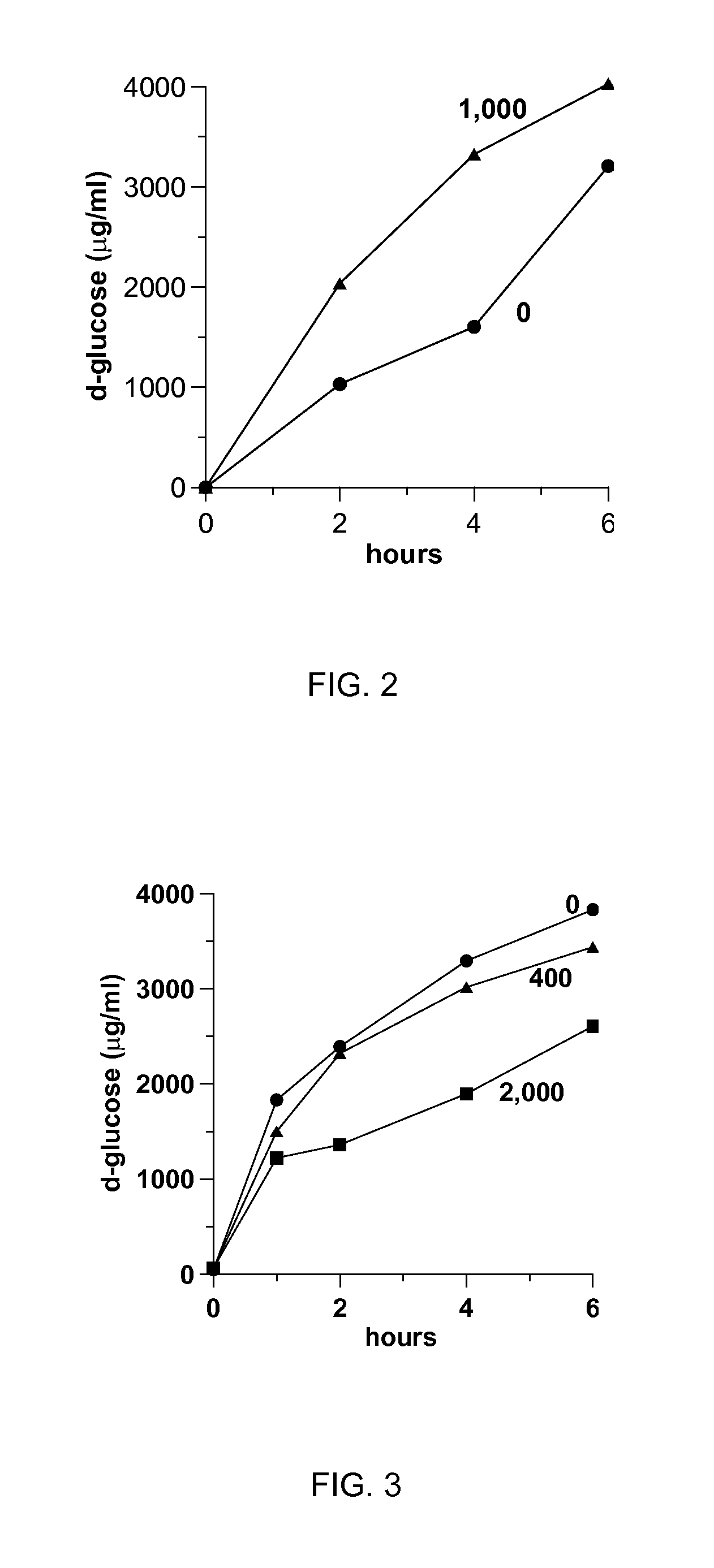

The device and method of this invention provides a means to increase anhydrosugars yield during pyrolysis of biomass. This increase is achieved by injection of a liquid or gas into the vapor stream of any pyrolysis reactor prior to the reactor condensers. A second novel feature of our technology is the utilization of sonication, microwave excitation or shear mixing of the biomass to increase the acid catalyst rate for demineralization or removal of hemicellulose prior to pyrolysis. The increased reactivity of these treatments reduces reaction time as well as the required amount of catalyst to less than half of that otherwise required. A fractional condensation system employed by our pyrolysis reactor is also a novel element of our technology. This system condenses bio-oil pyrolysis vapors to various desired fractions by differential temperature manipulation of individual condensers comprising a condenser chain.

Owner:MISSISSIPPI STATE UNIVERSITY

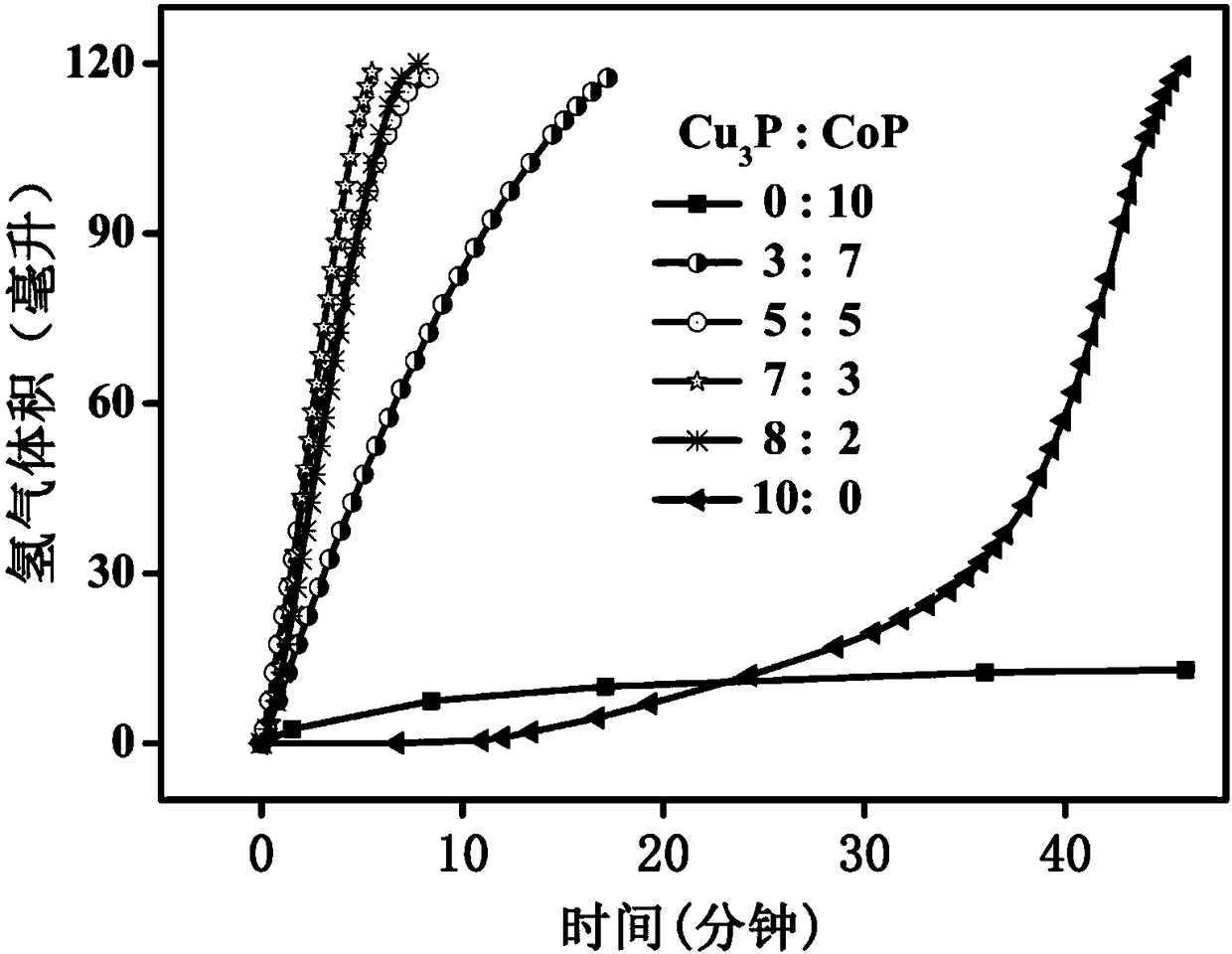

Hydrogen storage material decomposing and hydrogen release system

ActiveCN109225284ASave raw materialsIncrease catalytic rateReversible hydrogen uptakeChemical recyclingOrganic solventSolvent

The invention discloses a hydrogen storage material decomposing and hydrogen release system. The system comprises a hydrogen storage material, a catalyst and a solvent, wherein the catalyst is a mixture of two or more of metal compounds mixed in any proportion. The invention provides the cheap and stable catalytic hydrogen storage material decomposing and hydrogen release system, and the raw materials for catalyst preparation are cheap. The catalyst has stable properties and high hydrogen release efficiency when applied to catalysis of a hydrogen storage material; the catalytic hydrogen release system is heterogeneous catalytic reaction, and the catalyst is convenient to recycle; if the catalytic hydrogen release system is conducted in an organic solvent, the catalytic reaction can be conducted at a temperature of 273 K or lower; in the catalytic hydrogen release system, when the hydrogen storage material is ammonia borane and methanol is used as a solvent, ammonia borane can be obtained again from NH4B(OCH3)4 obtained after alcoholysis under certain conditions.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

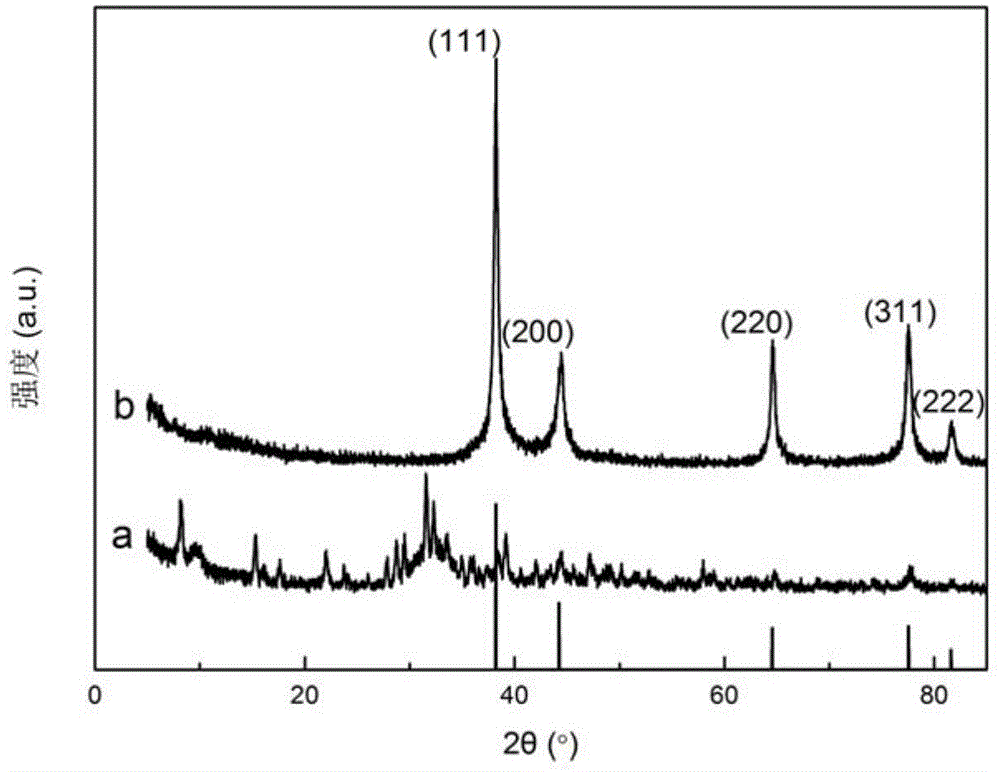

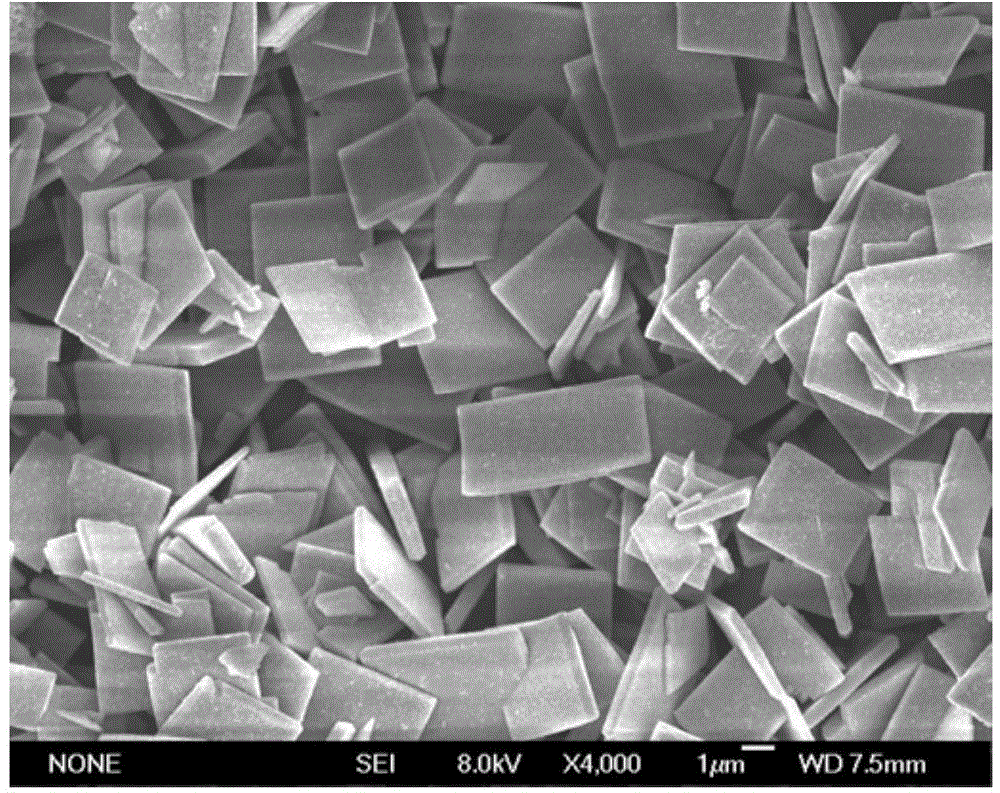

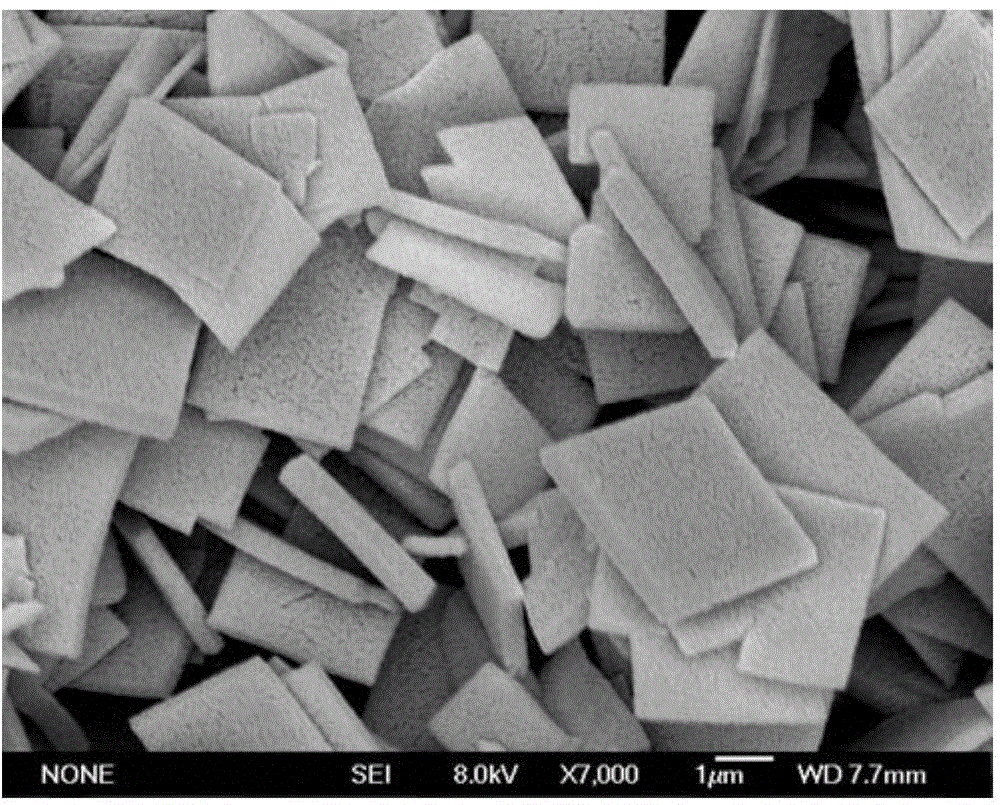

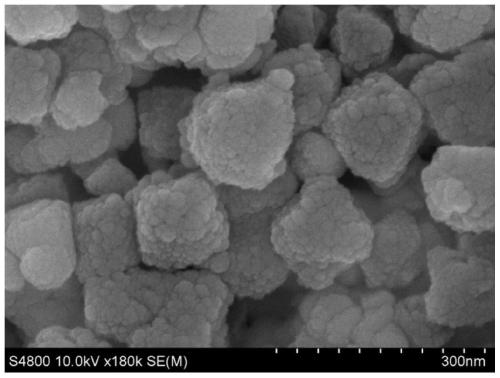

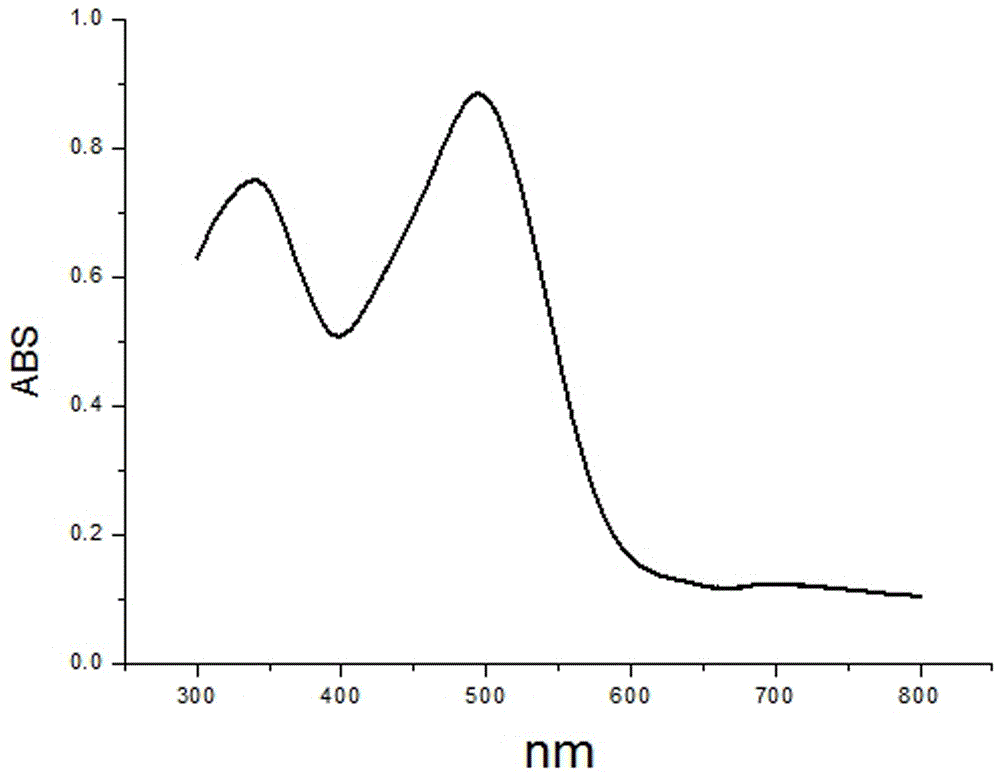

Porous silver micro-nano structure and shape and size controllable preparation method thereof

InactiveCN104525937ABreakthrough hazardReduce post processingMaterial nanotechnologyMicro nanoMaterials science

The invention provides a porous silver micro-nano structure and a shape and size controllable preparation method of the porous silver micro-nano structure, and belongs to the technical field of precious metal porous nano-crystalline structures. The overall appearance shape of the porous silver micro-nano structure is a hexagonal sandwich shape or a quadrilateral shape or a strip shape and is formed by stacking 30-50-nanometer silver basic composition units, and multiple pores are formed by stacking silver basic composition units. The preparation method includes the steps that sodium citrate, sodium carbonate and citric acid are dissolved in deionized water, a silver nitrate solution and a D-glucose solution are added in sequence, the mixture is stirred and sinks, and a precursor is obtained after centrifugal drying; the porous silver micro-nano structure is obtained after heat treatment is conducted on the precursor. The method is simple, environmentally friendly and controllable in shape and size; the prepared porous silver micro-nano structure is uniform in size distribution, large in specific surface area, good in permeability and higher in catalytic rate for p-nitrophenol, and has potential application in the precious metal catalytic aspect.

Owner:JILIN UNIV

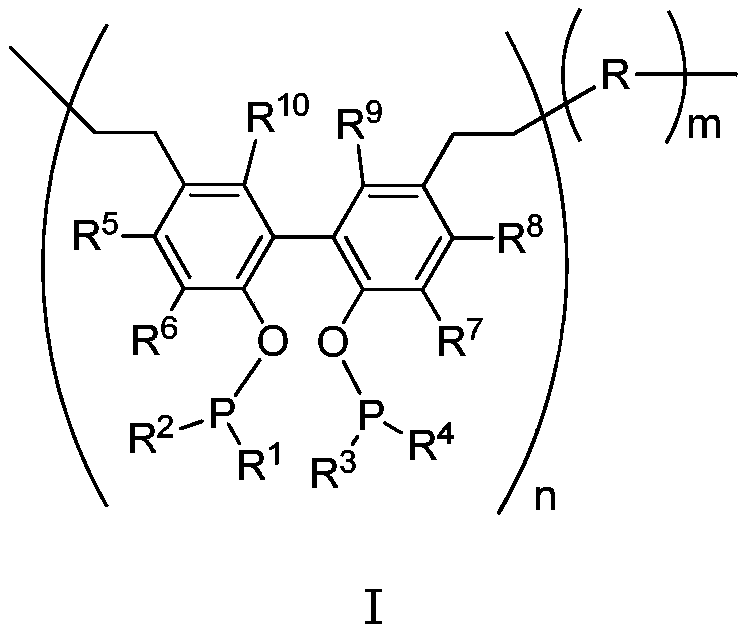

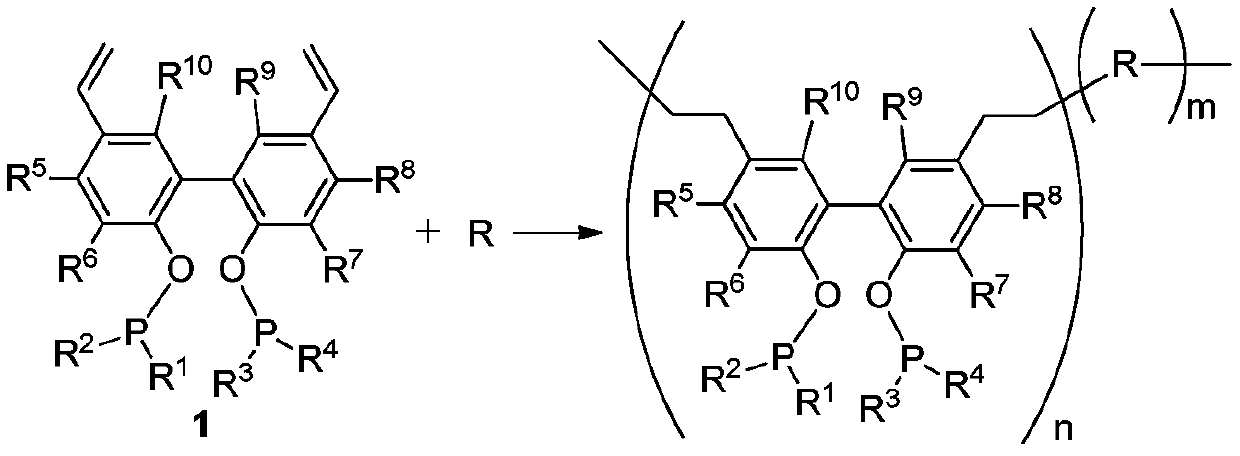

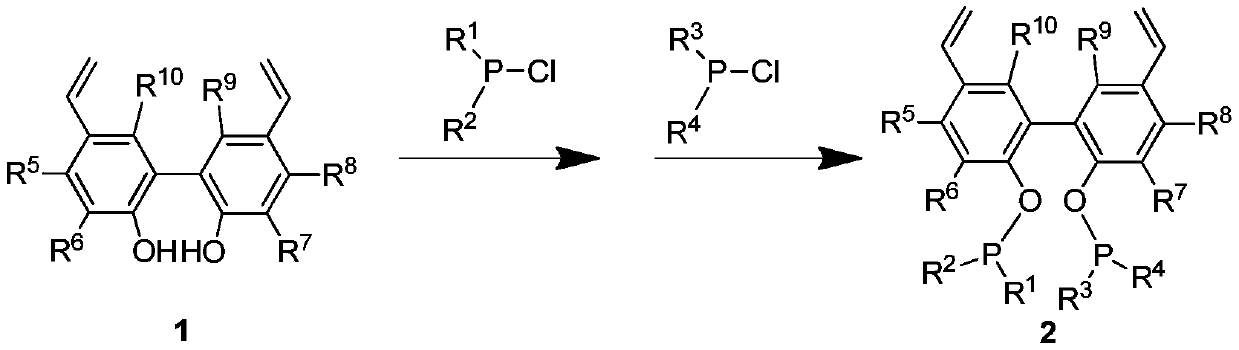

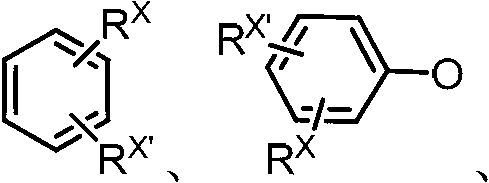

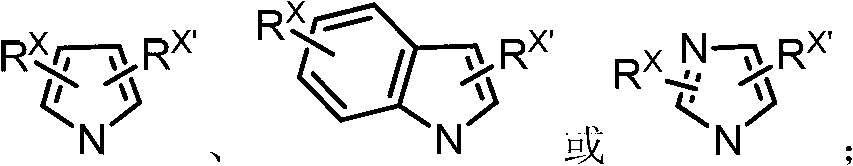

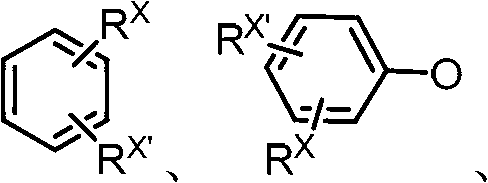

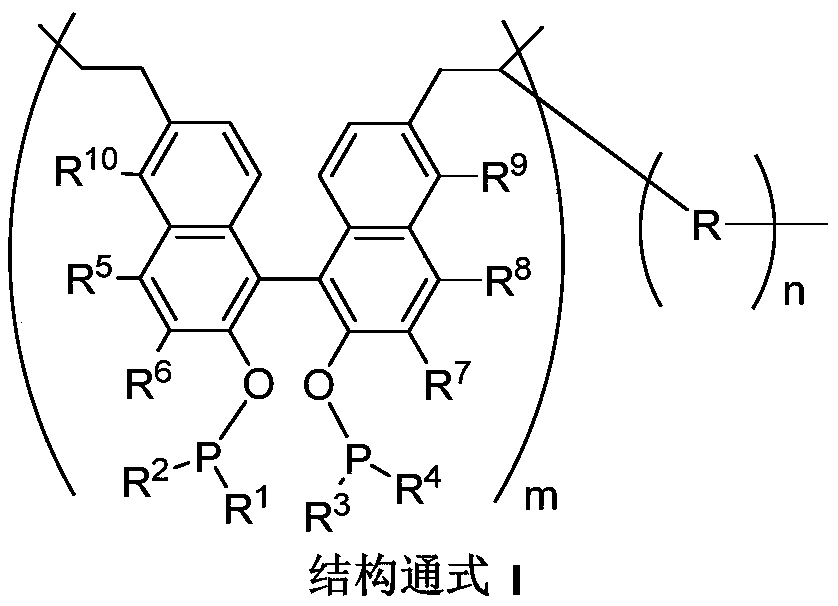

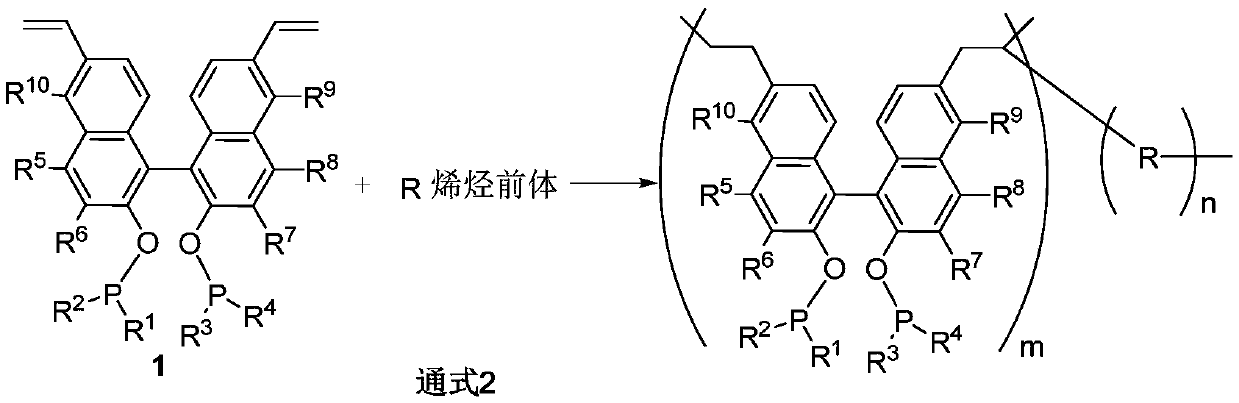

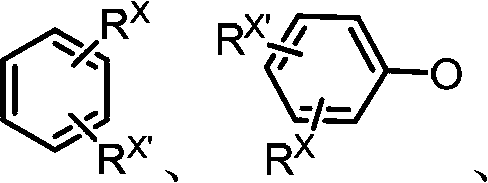

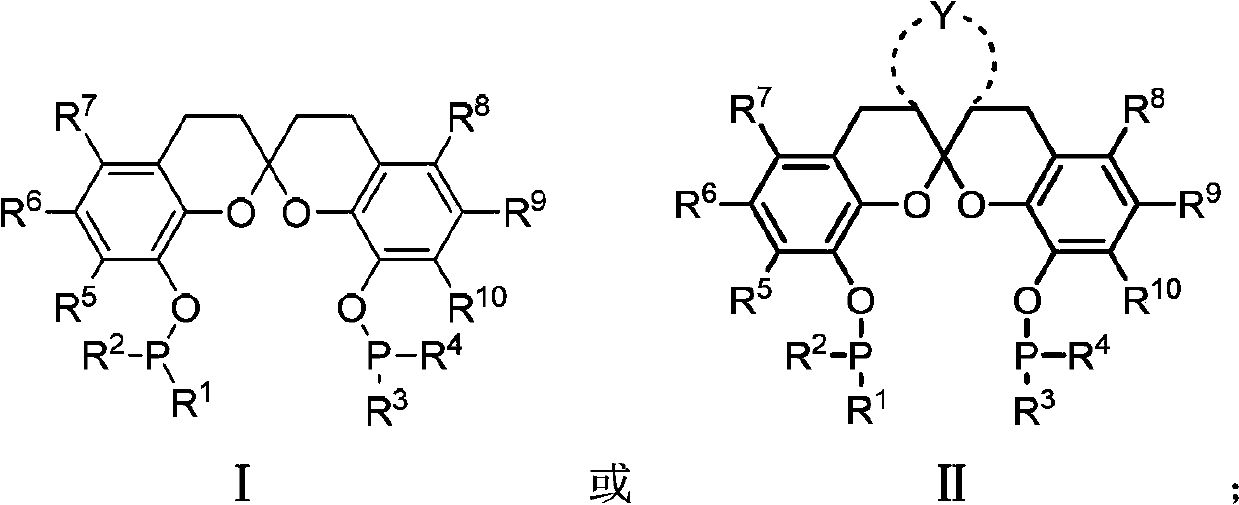

Porous organic polymer containing bidentate phosphoramidite ligands, as well as preparation method and application thereof

ActiveCN109942750AHigh mole percentageIncrease catalytic rateOrganic-compounds/hydrides/coordination-complexes catalystsPreparation by carbon monoxide reactionIsomerizationOrganic polymer

The invention discloses a porous organic polymer containing bidentate phosphoramidite ligands, as well as a preparation method and application thereof. The polymer has a general formula as shown in the specification, and is prepared from compounds through polymerization. After being formed from the porous organic polymer containing bidentate phosphoramidite ligands and transition metal salt, a catalyst can be used in hydroformylation of terminal olefin and isomerization-hydroformylation reaction of nonterminal olefin, has high catalyzing speed and good selectivity and cyclicity, and has practical values.

Owner:QINGDAO UNIV OF SCI & TECH

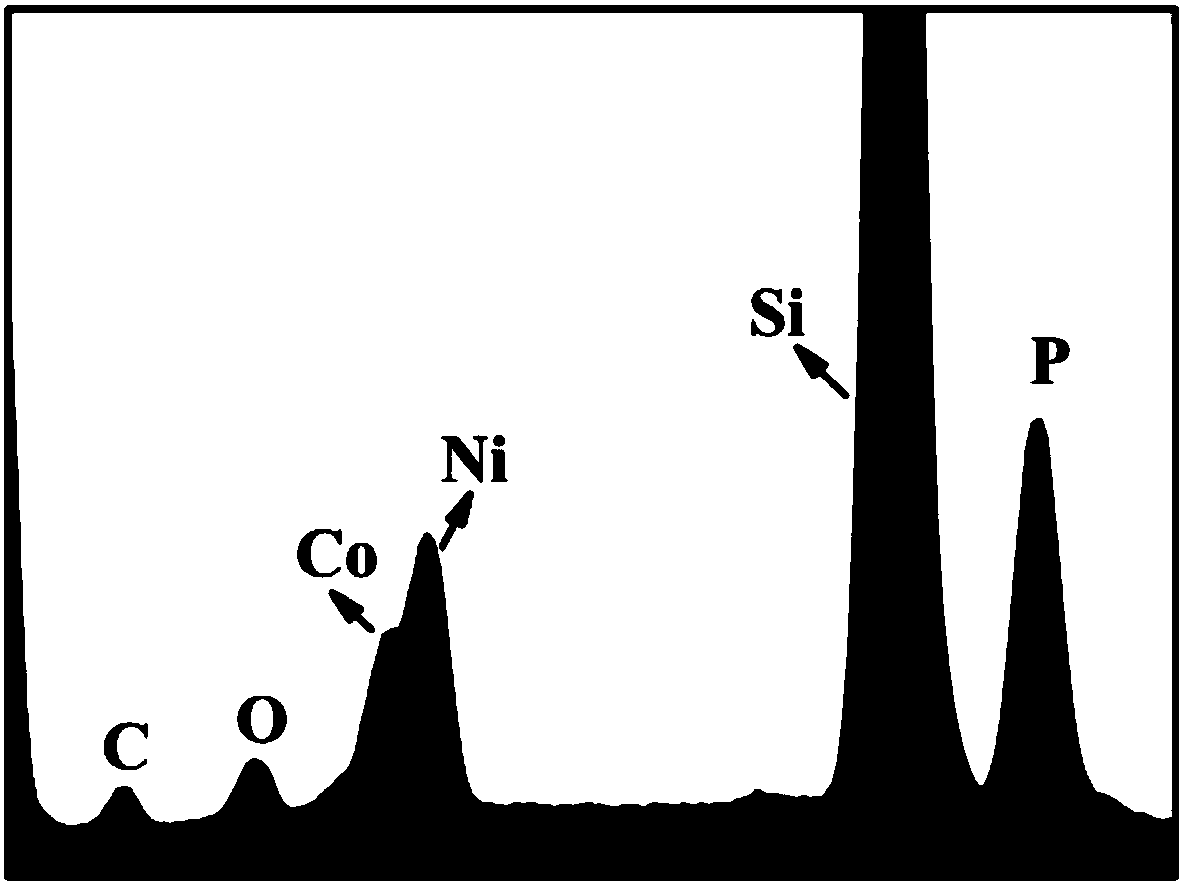

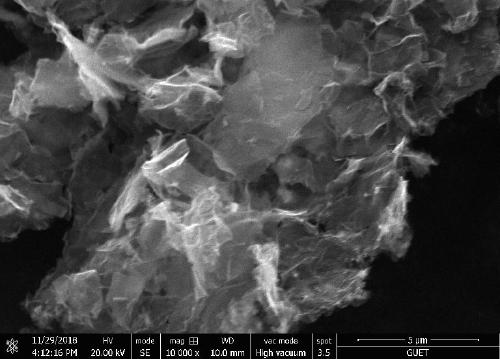

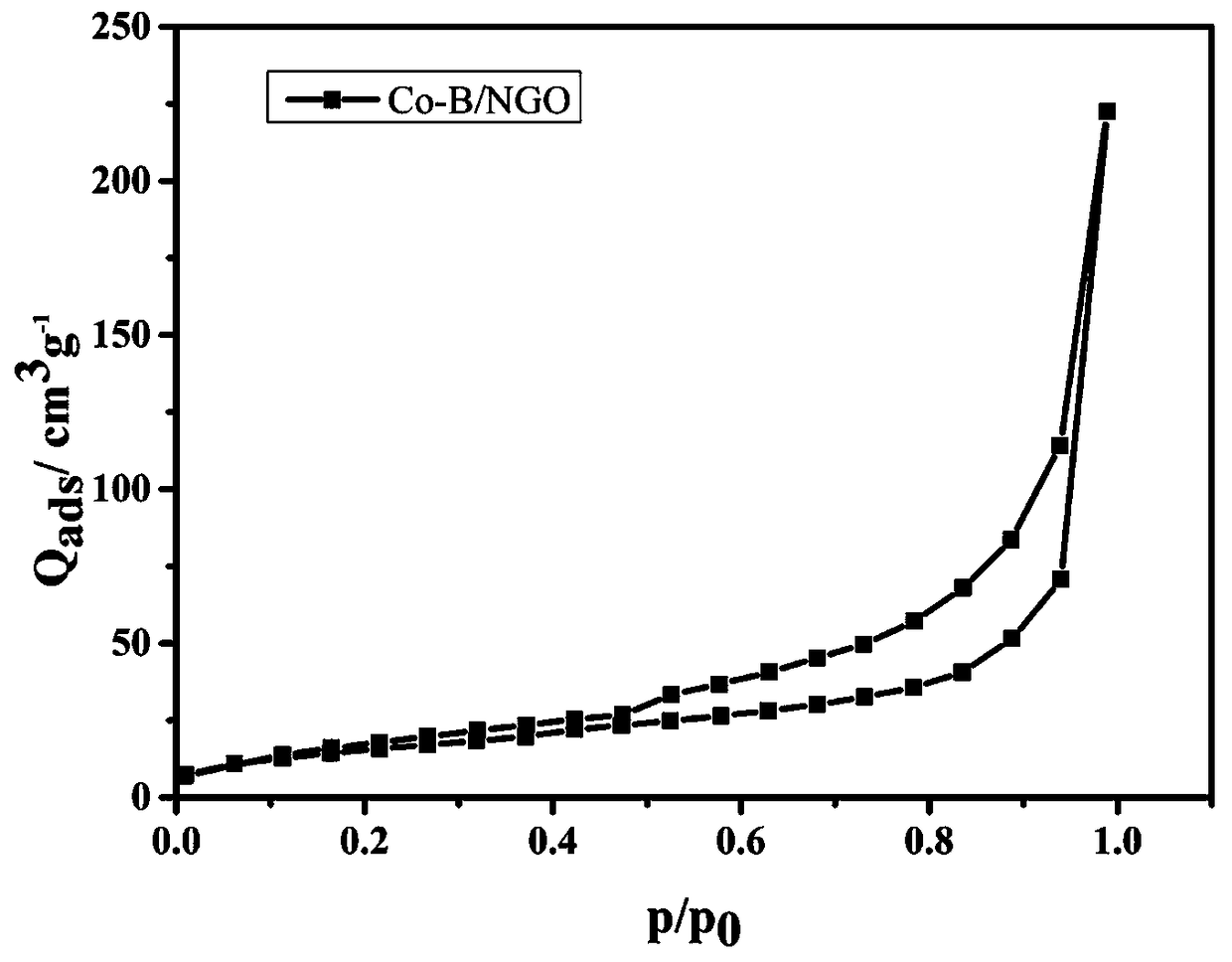

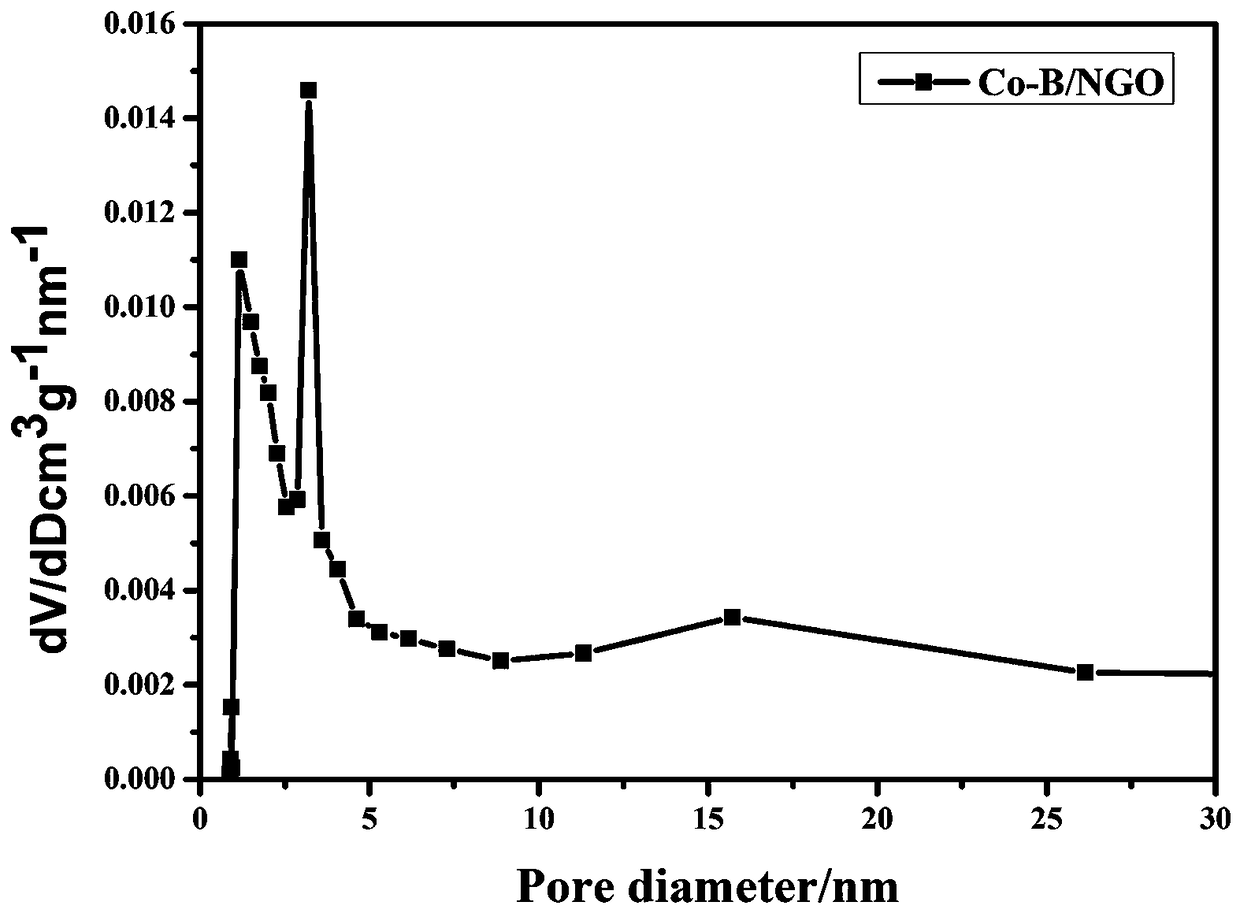

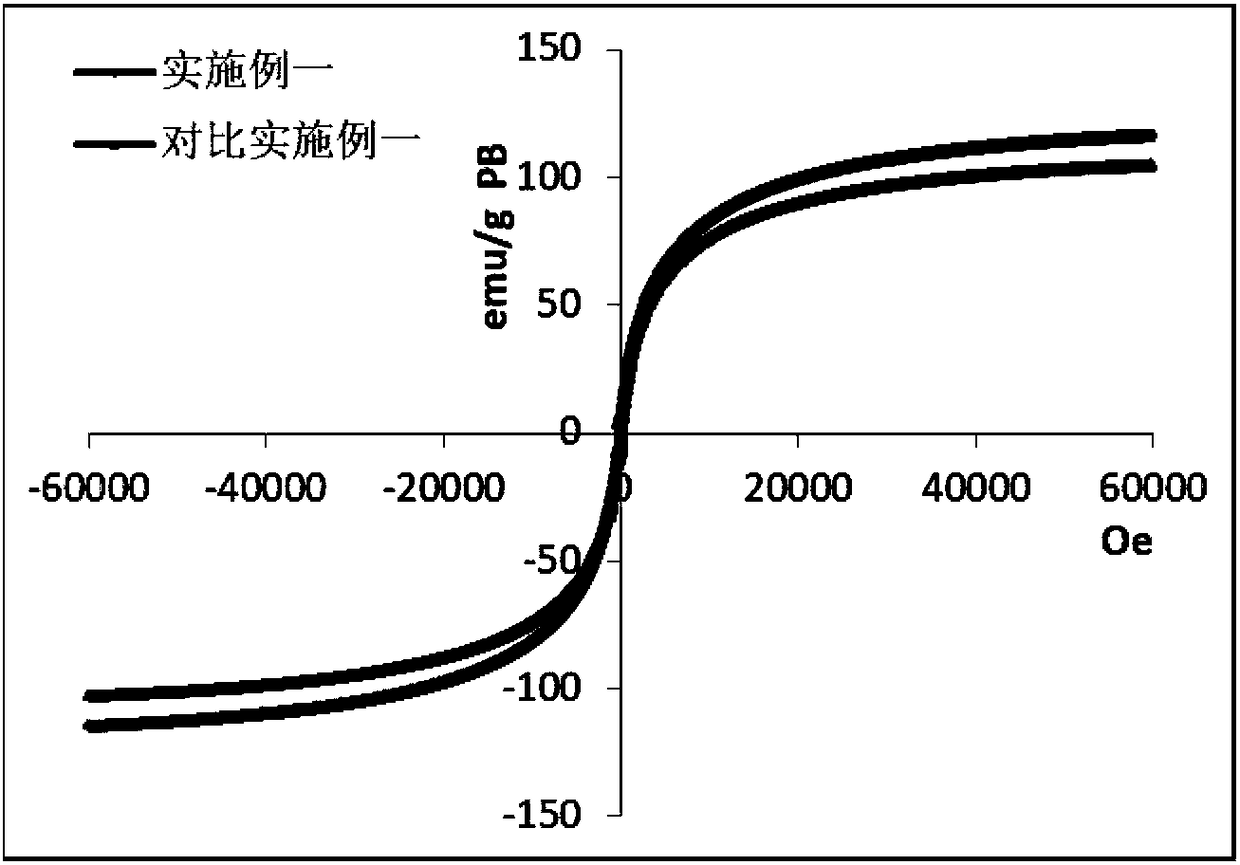

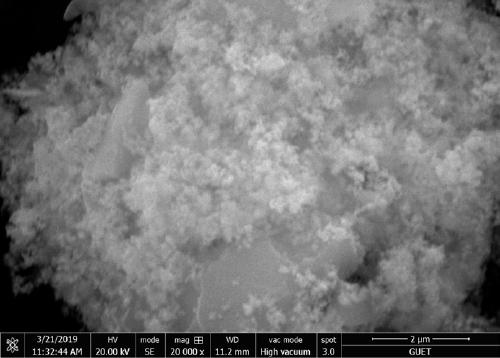

Co-B/NGO composite nanometer material as well as preparation method and application thereof

InactiveCN109499576AChange catalytic performanceLower activation energyMaterial nanotechnologyCatalyst activation/preparationFreeze-dryingHydrogen desorption

The invention discloses a Co-B / NGO composite nanometer material. The Co-B / NGO composite nanometer material is prepared by firstly performing in-site reduction on nitrogen-doped graphene and inorganiccobalt salt through sodium borohydride and then performing freezing-drying, the specific area is 40-100 m<2>g<-1>; the material is magnetic, and can be attracted by a magnet. When the composite nanometer material is used as a catalyst for hydroboron hydrogen generation by hydrolysis, the hydrogen desorption rate is 500-1700mL / min<-1>g<-1>, and the hydrogen production rate is 100%; the material canbe adsorbed and recycled by the magnet, the recycling rate reaches 99.5%, and the hydrogen production rate after being circulated is maintained at 100-1530mL min<-1>g<-1>, namely, maintaining 50-85%of the initial hydrogen production rate. The preparation method comprises the following steps: 1) precursor preparation: adding nitrogen-doped graphene and inorganic cobalt salt in an aqueous solutionfor ultrasonic dispersion mixing, reducing by using sodium borohydride, and finally centrifuging and washing to obtain a precursor; 2) preparation of the Co-B / NGO composite nanometer material: freeze-drying the precursor to obtain the Co-B / NGO composite nanometer material. The Co-B / NGO composite nanometer material disclosed by the invention is simple in preparation, has more excellent catalysis performance, and has an extensive application prospect in the application field of the hydroboron hydrogen generation by hydrolysis.

Owner:GUILIN UNIV OF ELECTRONIC TECH

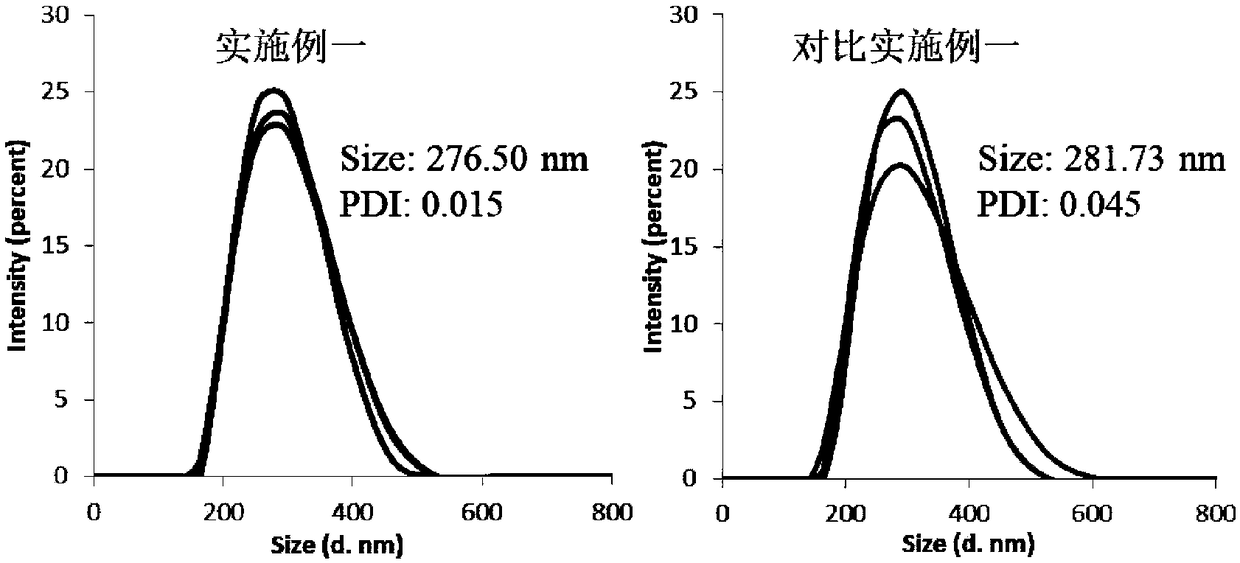

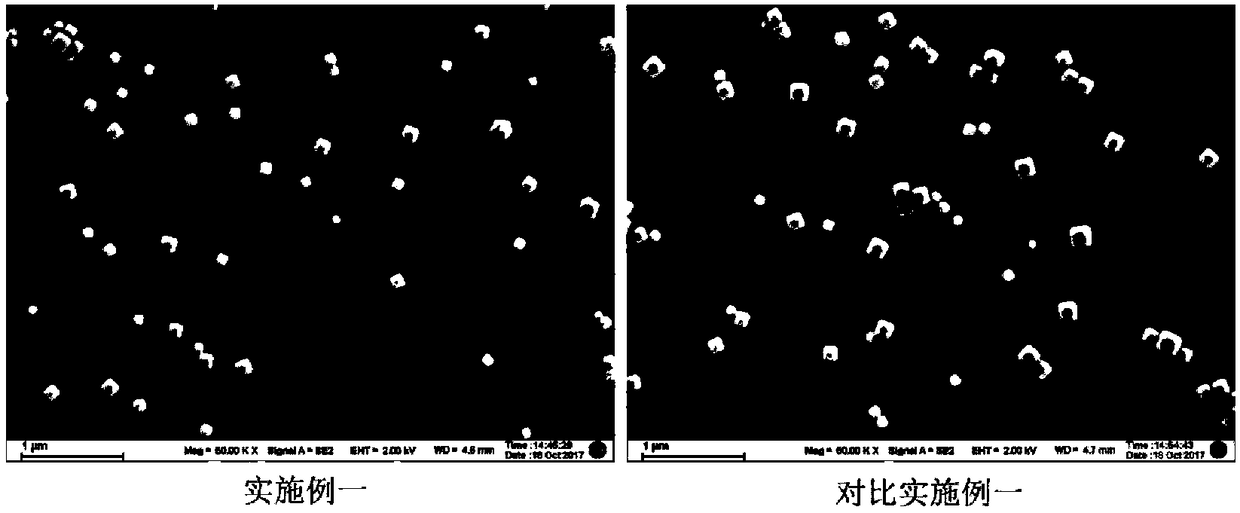

Preparation method of PVP modified prussian blue nanometer material

ActiveCN108324733AQuality improvementUniform particle size distributionHeavy metal active ingredientsAntinoxious agentsFreeze-dryingPrussian blue

The invention provides a preparation method of a PVP modified prussian blue nanometer material. The method concretely comprises the following steps of (1) dissolving PVP and precursors into water formixing; (2) adding hydrochloric acid for regulating the pH to an acid state; (3) performing reaction under the electromagnetic induction heating; (4) performing ethanol water centrifugal washing, dialysis and freeze drying to obtain a finished product. According to the method, magnetic inner heat is used for replacing an ordinary external heating mode; in a shorter reaction time, the high-qualityprussian blue nanometer material can be obtained. The PVP modified prussian blue nanometer material prepared by the method has the advantages of small polydispersity coefficient, uniform particle dimension distribution, higher magnetism and higher nanometer enzymatic activity.

Owner:SOUTHEAST UNIV

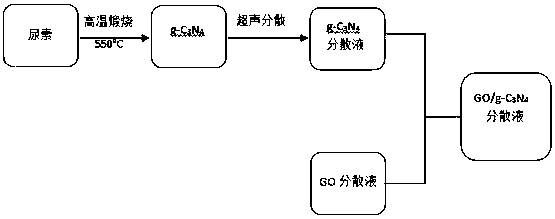

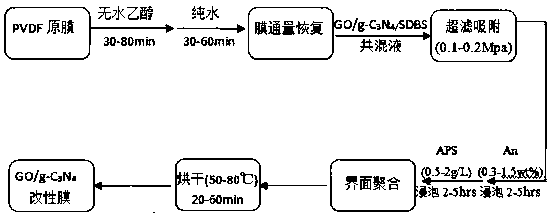

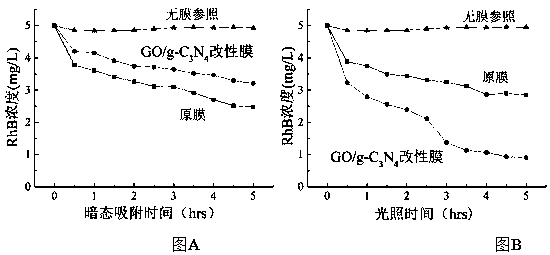

Graphene oxide and graphite-phase carbon nitride composite modified membrane material and preparation method thereof

ActiveCN109433013AImprove hydrophilicityImprove pollutionMembranesPhysical/chemical process catalystsAnilineMembrane function

The invention discloses a GO (graphene oxide) and g-C3N4 composite modified membrane material. A preparation method includes steps: activating an original membrane to recover original membrane flux; adding a surfactant into GO and g-C3N4 mixed dispersion liquid to obtain mixed liquid; soaking the activated original membrane into the mixed liquid to realize ultrafiltration adsorption, and soaking the membrane into aniline hydrochloric acid solution; taking out after soaking is finished, and soaking in hydrochloric acid solution of ammonium persulfate immediately to enable interface polymerization reaction; finally, drying the membrane to obtain the composite modified membrane material. By an ultrafiltration adsorption and interface polymerization combined modification method, GO and g-C3N4are combined for surface composite modification of the membrane material, and a visible light responsive catalytic modified membrane is developed. The novel modified membrane is low in preparation cost and recyclable, pollution resistance is remarkably improved, firmness in modifying agent and photocatalyst loading is achieved, the visible catalytic performance and hydrophilic performance are remarkably enhanced, the forbidden bandwidth of a membrane function layer is decreased, the problem of secondary pollution is avoided, and a promising application prospect is achieved.

Owner:GUANGDONG UNIV OF TECH

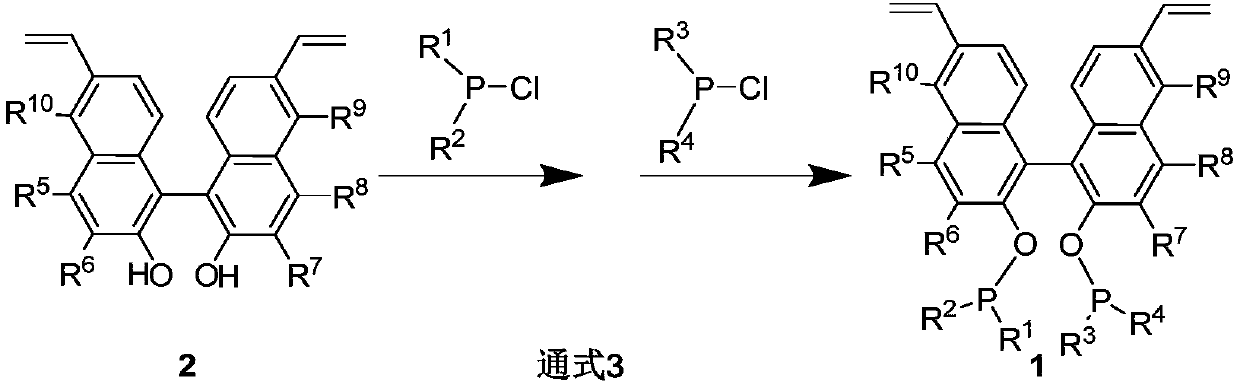

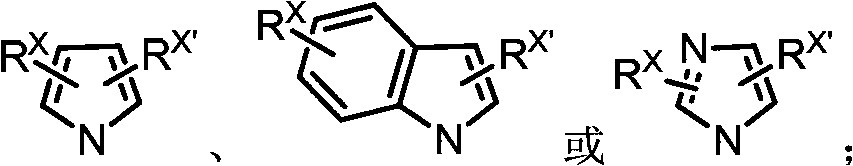

Spiroketal frame bidentate phosphoramidite ligand as well as preparation method and application thereof

ActiveCN102746338AHigh mole percentageIncrease catalytic rateOrganic-compounds/hydrides/coordination-complexes catalystsGroup 5/15 element organic compoundsIsomerizationDiastereomer

The invention discloses a spiroketal frame bidentate phosphoramidite ligand as well as a preparation method and an application thereof. The ligand is the compound shown in a formula I or II or the enantiomer, racemate or diastereoisomer of the compound; and the ligand is prepared by condensation reaction of the compound in the formula I or II, and phosphorus-chlorine compounds. The spiroketal frame bidentate phosphoramidite ligand disclosed by the invention and transition metal salt form a complex, and the complex can be used for terminal olefine hydroformylation or isomerization-hydroformylation of internal olefins; and moreover, the spiroketal frame bidentate phosphoramidite ligand has high catalytic rate, good selectivity and practical value.

Owner:SHANGHAI INST OF ORGANIC CHEM CHINESE ACAD OF SCI

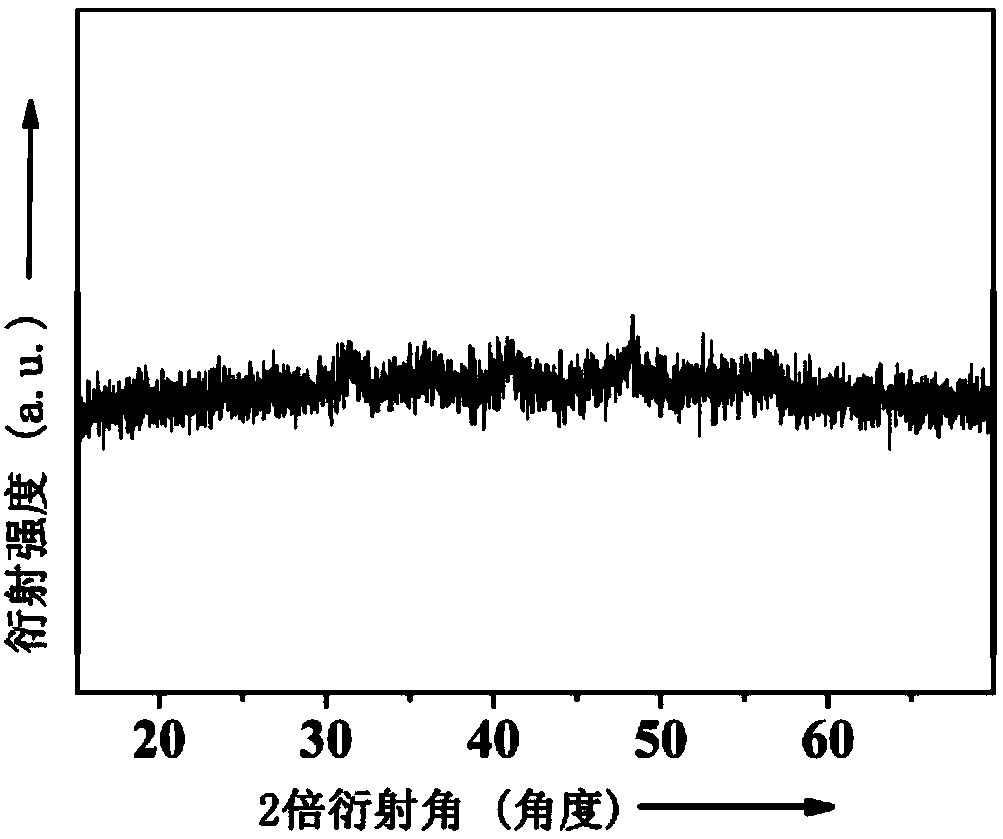

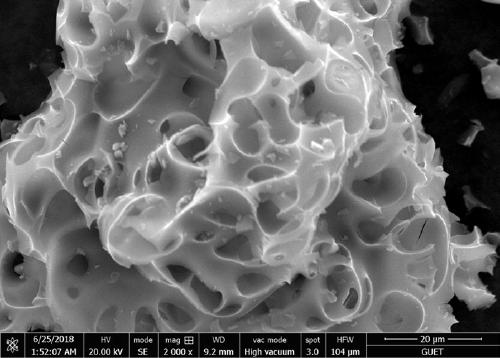

Nitrogen-doped porous carbon material supporting CoB nanoparticles, preparation method and application thereof

ActiveCN110124721AChange catalytic performanceUniform pore size distributionCatalyst activation/preparationHydrogen productionActivation methodHydrogen

The invention discloses a nitrogen-doped porous carbon material loaded with CoB nanoparticles. A nitrogen-containing compound is added to a porous carbon material, and the irregular spherical nitrogen-doped porous carbon material is produced by a hydrothermal method, an activation method and a high-temperature heat treatment method; and then CoB is supported on the nitrogen-doped porous carbon material by an in-situ reduction method to obtain the nitrogen-doped porous carbon material loaded with CoB nanoparticles. CoB nanoparticles are uniformly supported on the surface and in pores of the irregular spherical nitrogen-doped porous carbon material, the final product is in a regular spherical shape finally, the specific surface area of the final product is 1359-2524 m<2> / g, and the pore sizedistribution of the final product is 1.60-2.40 nm. The preparation method comprises the following steps: 1) preparing a nitrogen-doped porous carbon material; and 2) supporting the CoB nanoparticles.The material serves as a sodium borohydride hydrolytic hydrogen-releasing catalyst, the hydrogen desorption rate reaches 1200-2500 ml / min*g, the cycle performance is good, and the hydrogen-releasingquantity is maintained at 50-60%. The material is simple to prepare, has more excellent catalytic performance, and has a wide application prospect in the fields of application of hydrogen energy, fuelcells and the like.

Owner:GUILIN UNIV OF ELECTRONIC TECH

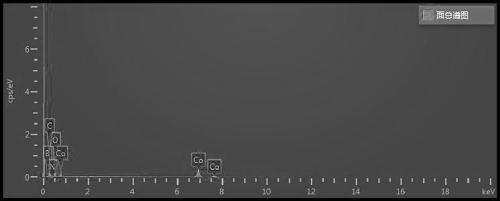

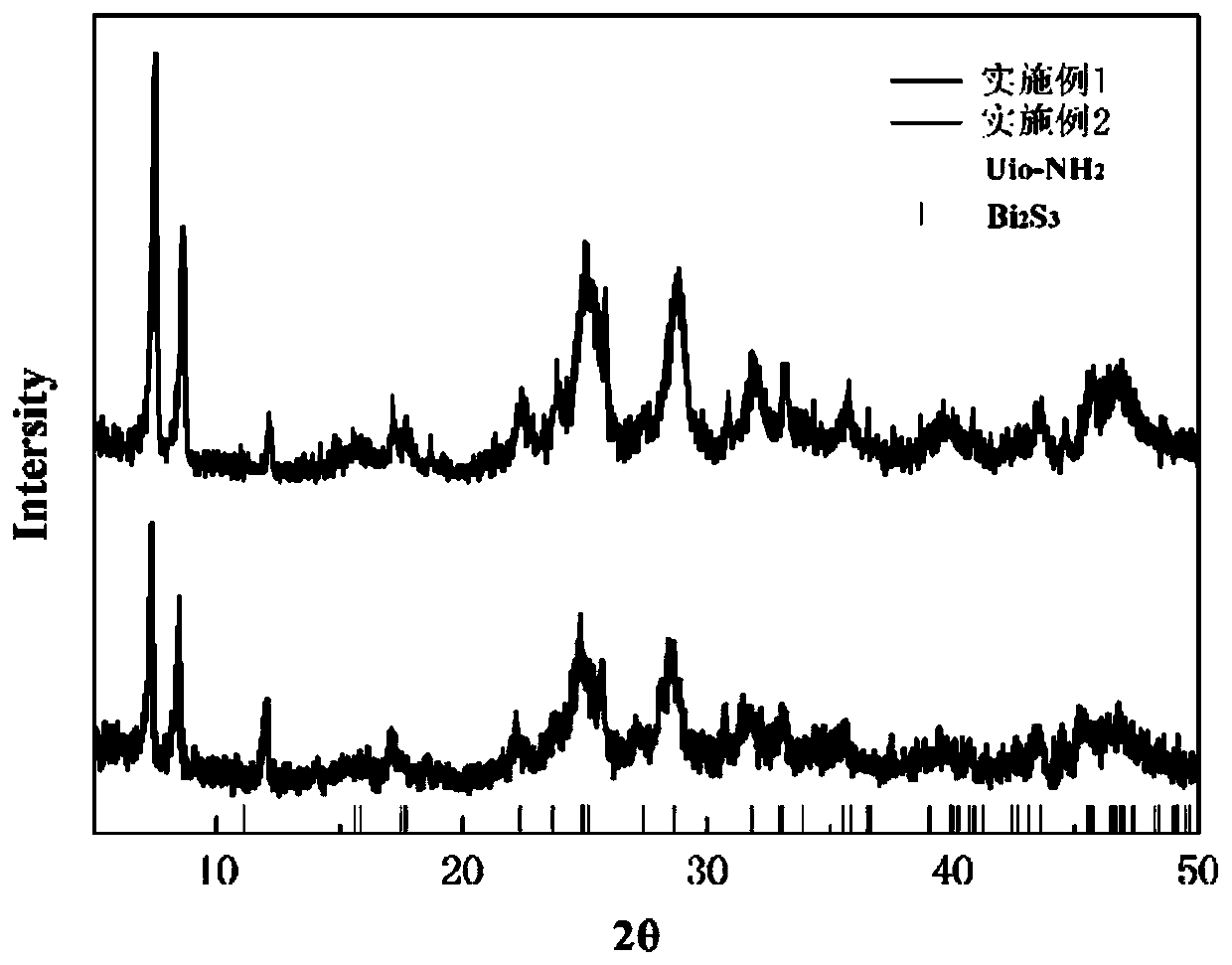

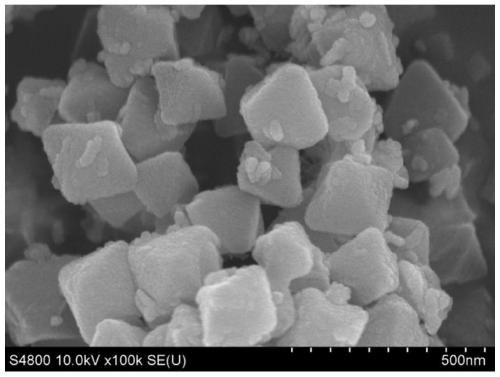

Bismuth sulfide based composite visible-light-induced photocatalyst and preparation method thereof

InactiveCN111359666AImprove interface tightnessIncrease profitWater/sewage treatment by irradiationWater treatment compoundsBismuth sulfideOrganic dye

The invention discloses a preparation method of a Bi2S3@UiO-66-NH2-SH based visible-light-induced photocatalyst with a core-shell structure and a preparation method thereof. The ratio of Bi: Zr of Bi2S3 and UiO-66-NH2 is 1-4:2. The preparation method comprises the following steps: preparing UiO-NH2 with a regular octahedron morphology by adopting a solvothermal method, and then modifying UiO-NH2 by mercapto-acetic acid to uniformly load bismuth sulfide nano particles on the surface of UiO-NH2, thereby obtaining the composite visible-light-induced photocatalyst taking UiO-NH2 as a core and Bi2S3 as a shell. The preparation method of the composite visible-light-induced photocatalyst is simple; the composite visible-light-induced photocatalyst has high visible-light response and better photocatalytic effect than that of pure bismuth sulfide, methyl orange can be degraded by 95% within 90 min under visible-light irradiation, and the composite visible-light-induced photocatalyst is expectedto be applied to the fields of photocatalytic degradation of organic dyes, antibiotics and the like on a large scale.

Owner:SHANGHAI INST OF TECH

First-class porous organic polymer containing phosphine ligand as well as preparation method and application of first-class porous organic polymer

ActiveCN110330591AIncrease catalytic rateGood choiceOrganic compound preparationOrganic chemistry methodsChemical compoundAlkyne

The invention discloses a first-class porous organic polymer containing a phosphine ligand as well as a preparation method and application of the first-class porous organic polymer. The polymer comprises the following formula I; the polymer is prepared by polymerizing compounds in the formula. After reacting with transition metal salt to generate a catalyst, the porous organic polymer containing the phosphine ligand is used for catalyzing hydroformylation reaction of alkyne; the porous organic polymer containing the phosphine ligand is high in catalyzing rate, high in selectivity and cycling performance and high in practical value.

Owner:QINGDAO UNIV OF SCI & TECH

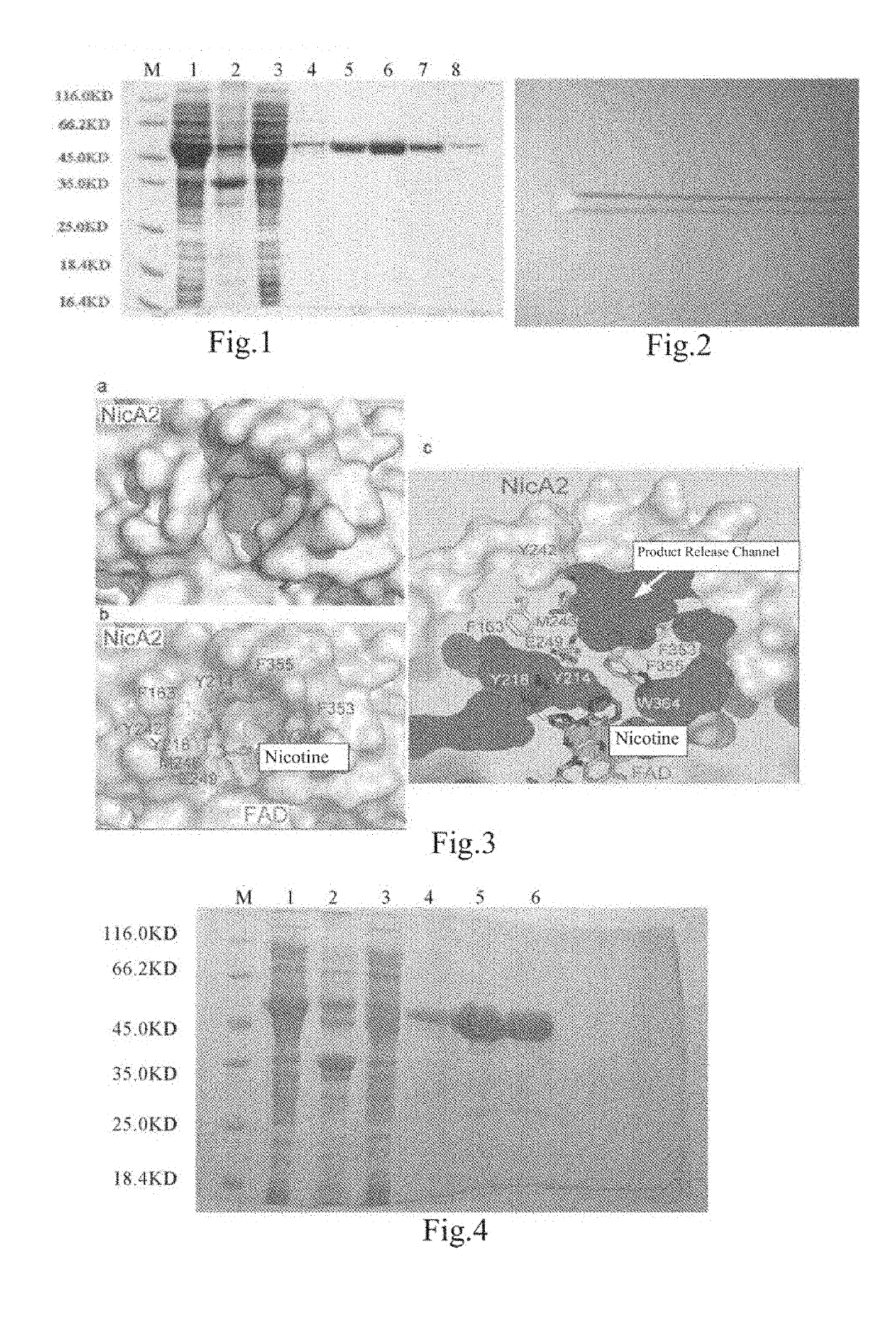

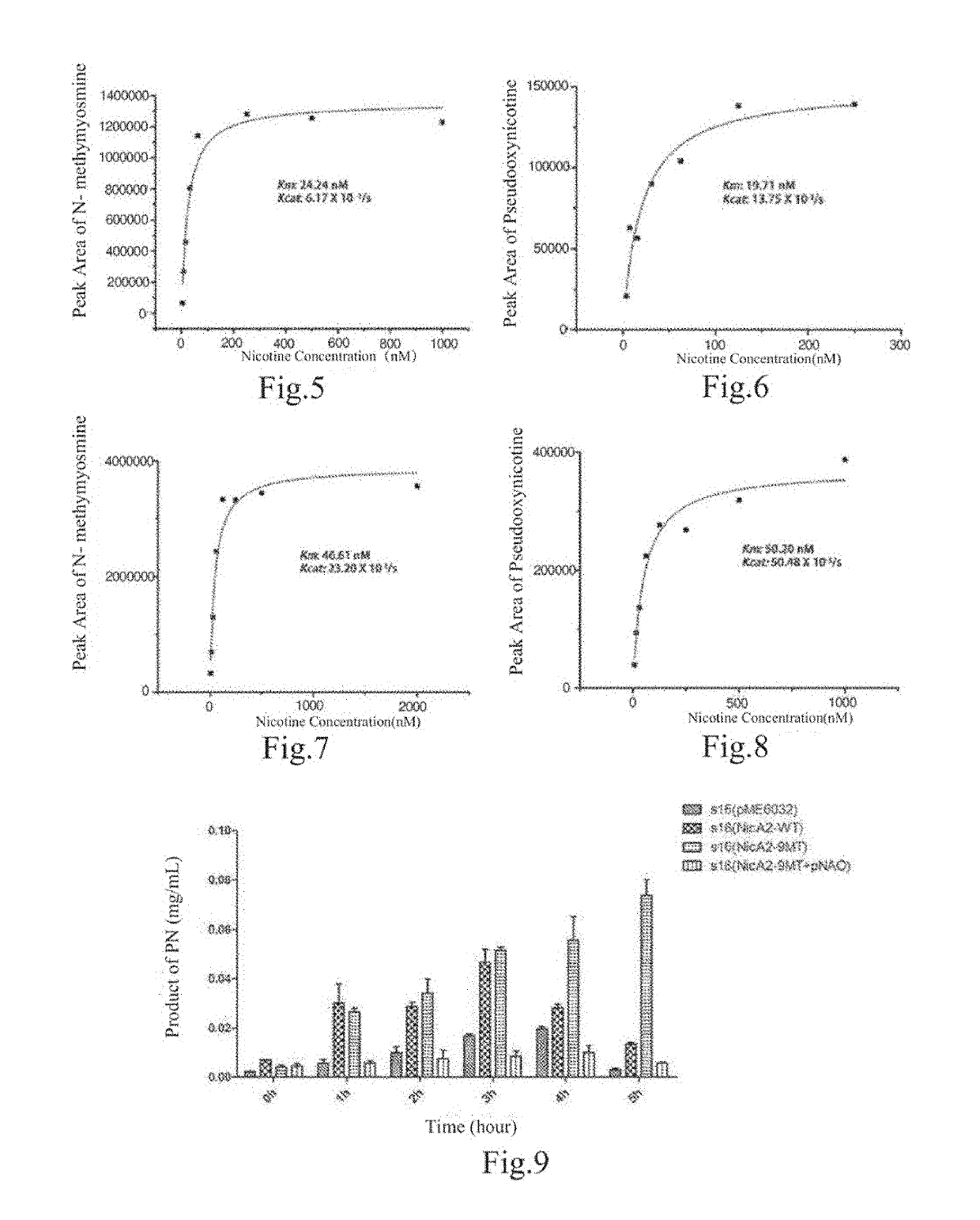

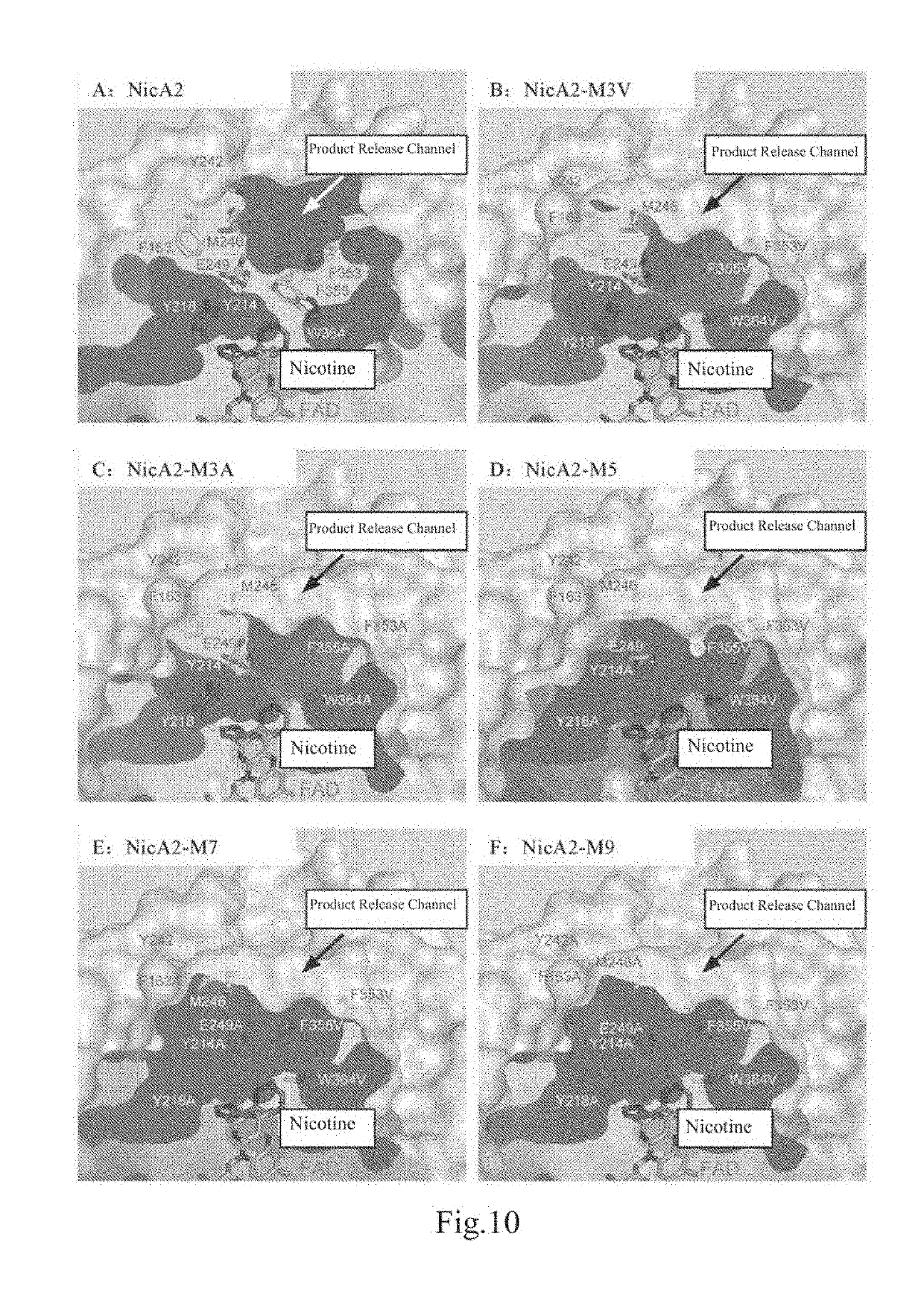

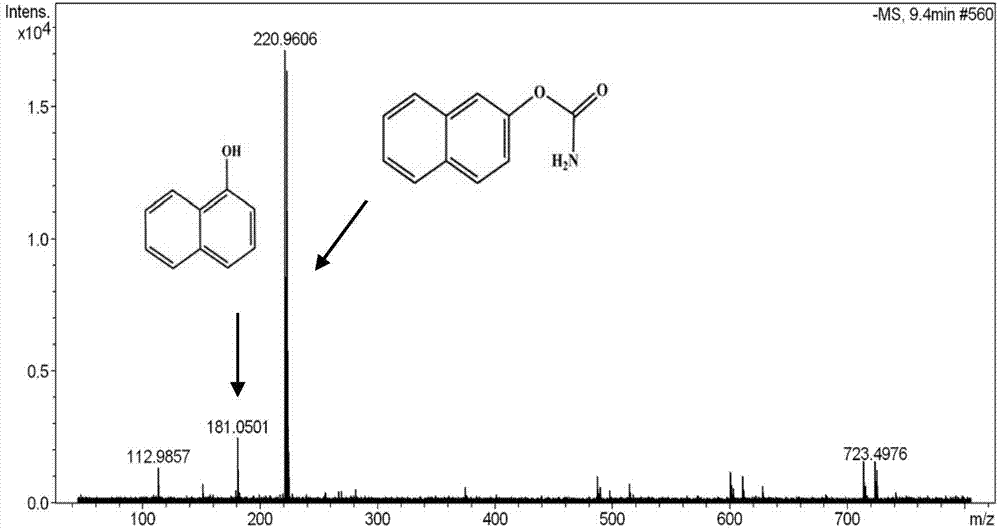

Enzyme and application thereof

ActiveUS20190153403A1High catalytic efficiencyImprove nicotine transformation abilityNervous disorderPeptide/protein ingredientsArtificial enzymeSide chain

Provides an artificial enzyme obtained by improving upon a sequence of a natural nicotine dehydrogenase, wherein the improvement comprises replacing at least one amino acid hindering product release with an amino acid with smaller side chains, thereby improving a catalytic rate.

Owner:SHANGHAI JIAO TONG UNIV

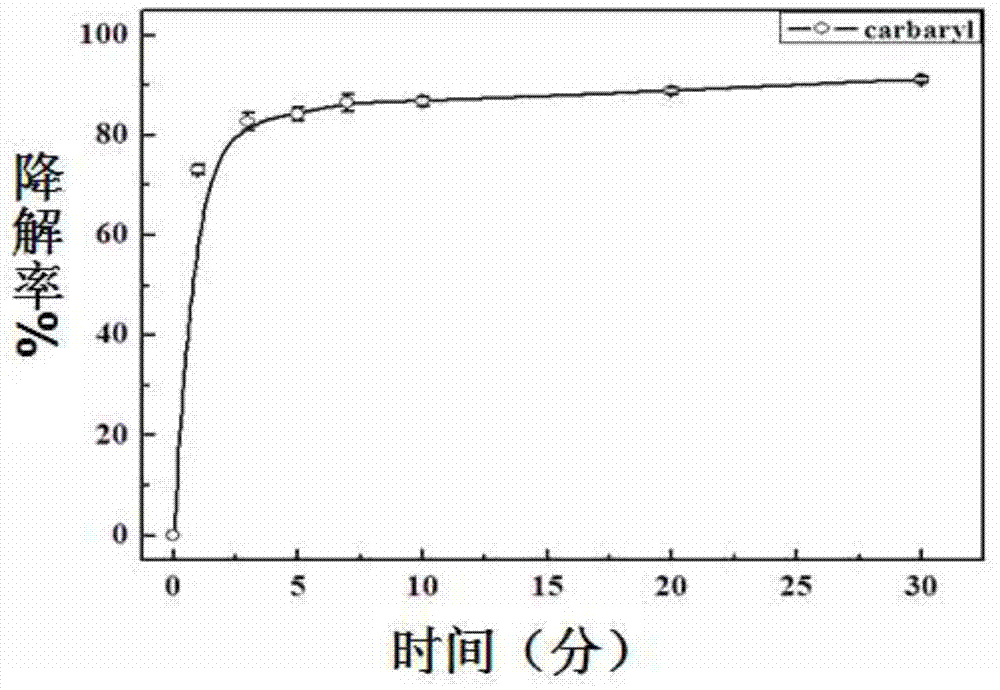

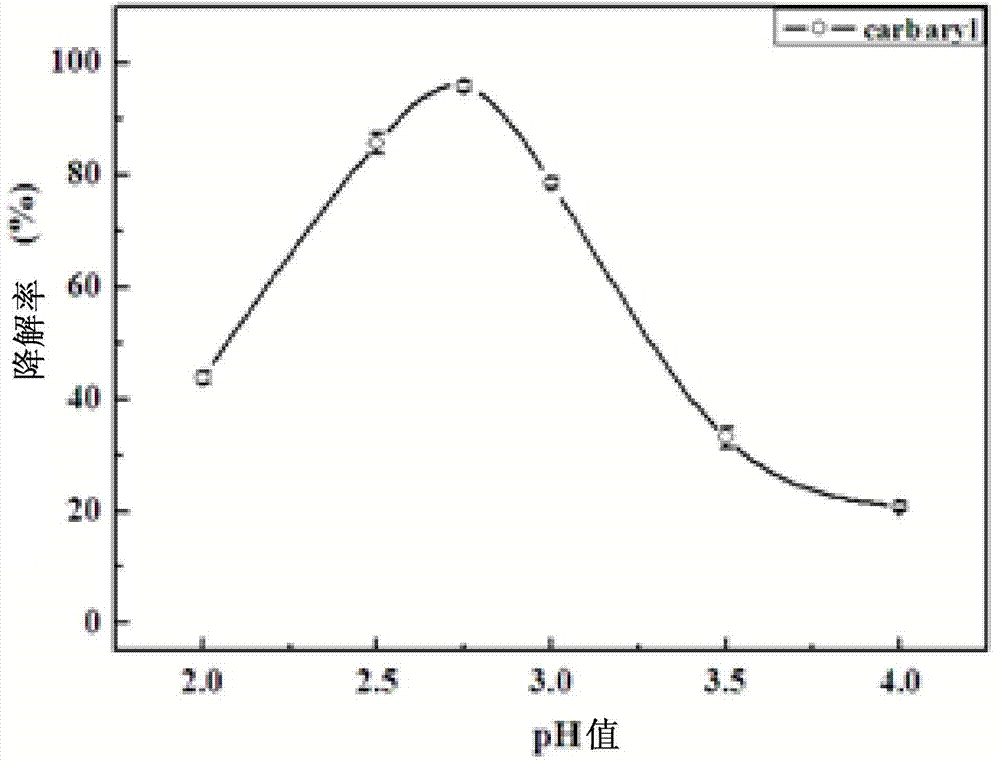

Ionic liquid regulation-control bio-enzyme, method for degrading environmental hormone carbaryl by same, and method for determining degradation rate

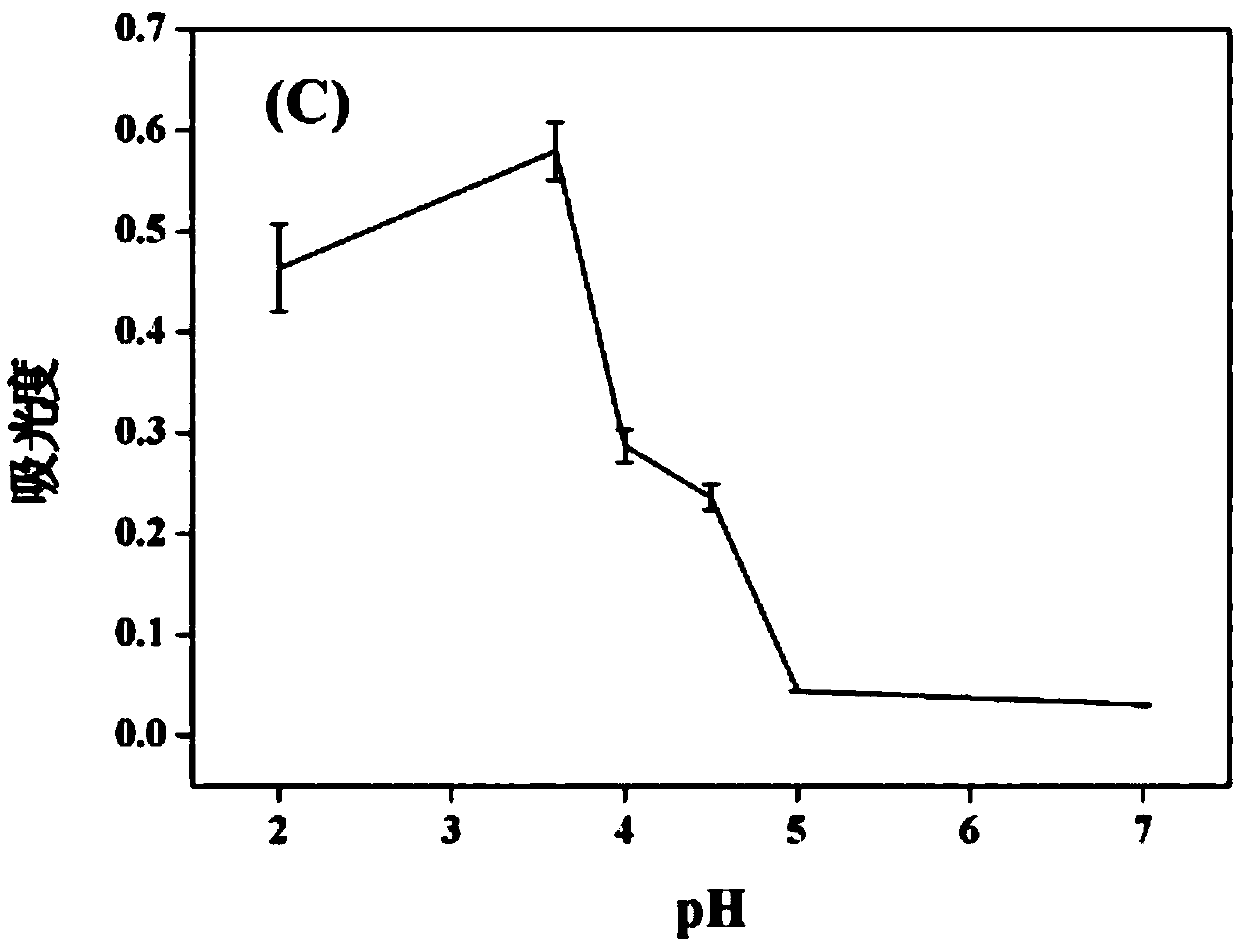

InactiveCN104726441AImprove stabilityImprove effective utilizationComponent separationWater contaminantsSolubilityPeroxidase

The invention relates to an ionic liquid regulation-control bio-enzyme, a method for degrading environmental hormone carbaryl by the same, and a method for determining the degradation rate. The ionic liquid regulation-control bio-enzyme comprises the mixed solution formed by adding chloroperoxidase, quaternary ammonium salt ionic liquids and H2O2 in a phosphate buffer solution with a pH value of 2-5, wherein in the mixed solution, the concentration of chloroperoxidase is 0.005-0.05mu mol.L<-1>, the concentration of ammonium salt ionic liquids is 0.06-0.20mol.L<-1>, and the concentration of H2O2 is 0.05-0.5mmol.L<-1>. According to the ionic liquid regulation-control bio-enzyme, the method for degrading environmental hormone carbaryl by the same, and the method for determining the degradation rate disclosed by the invention, the chloroperoxidase is used as a biocatalyst, the ammonium salt ionic liquids are used as regulation-control factors, the ammonium salt ionic liquids have a cosolvent effect on the chloroperoxidase, and can be used for improving the stability of the chloroperoxidase, increasing the enzyme catalysis speed and increasing the effective utilization rate of the chloroperoxidase; the ionic liquid regulation-control bio-enzyme is capable of effectively improving the solubility of carbaryl and increasing the degradation rate in case of being applied to degradation for carbaryl.

Owner:SHAANXI NORMAL UNIV

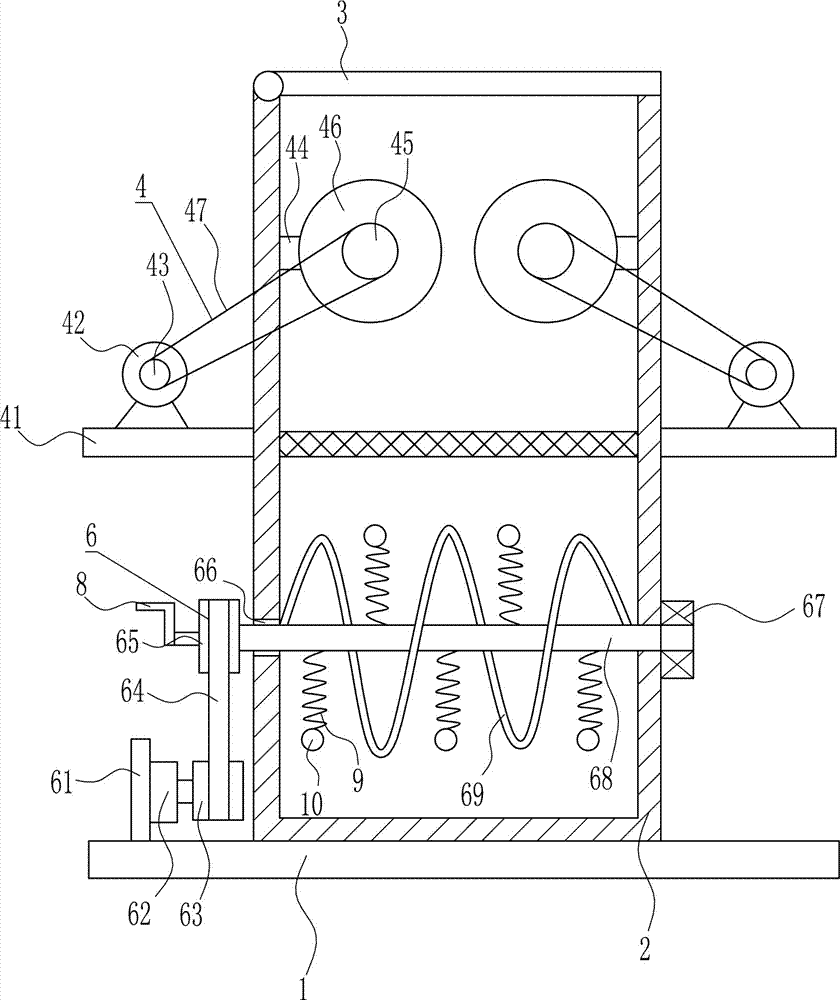

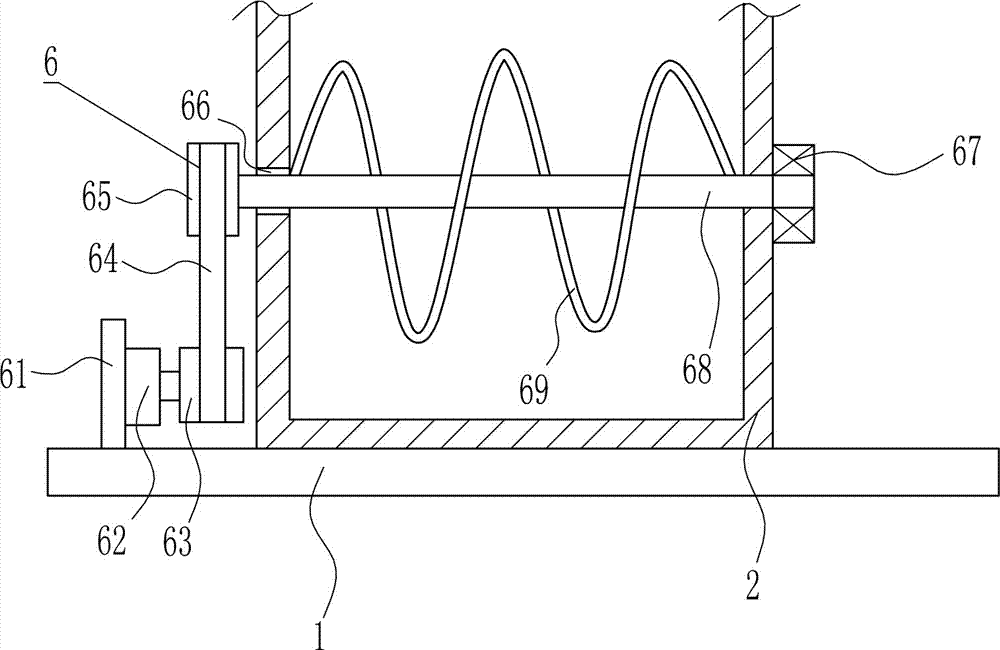

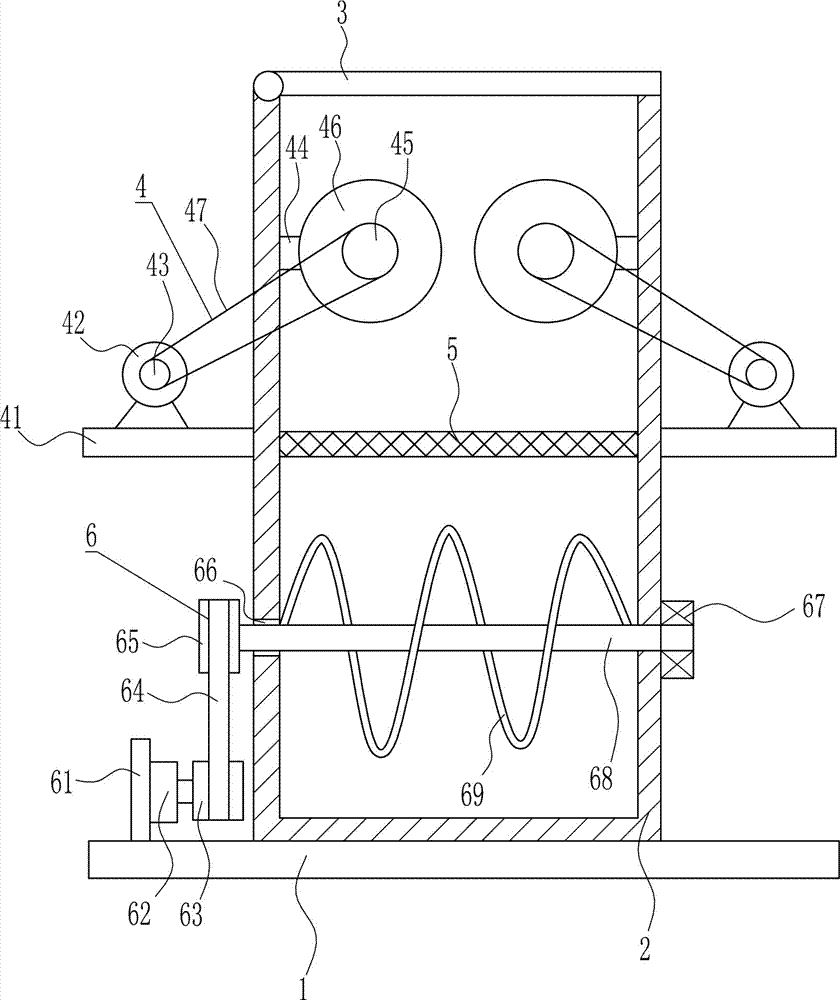

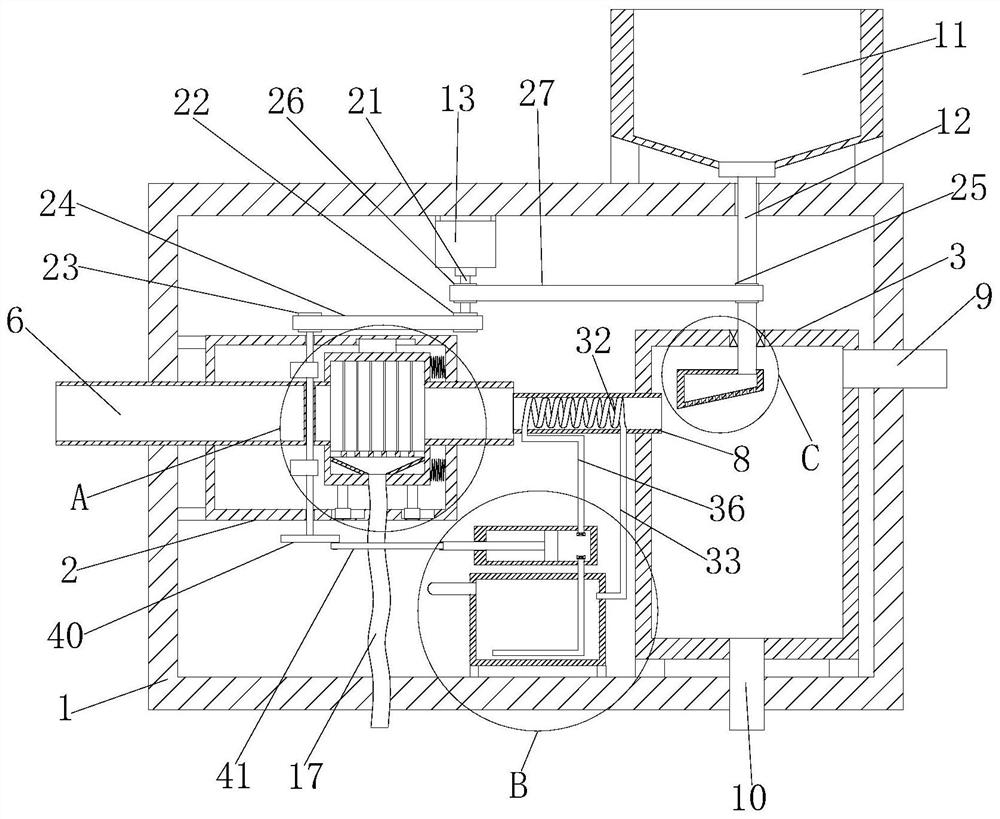

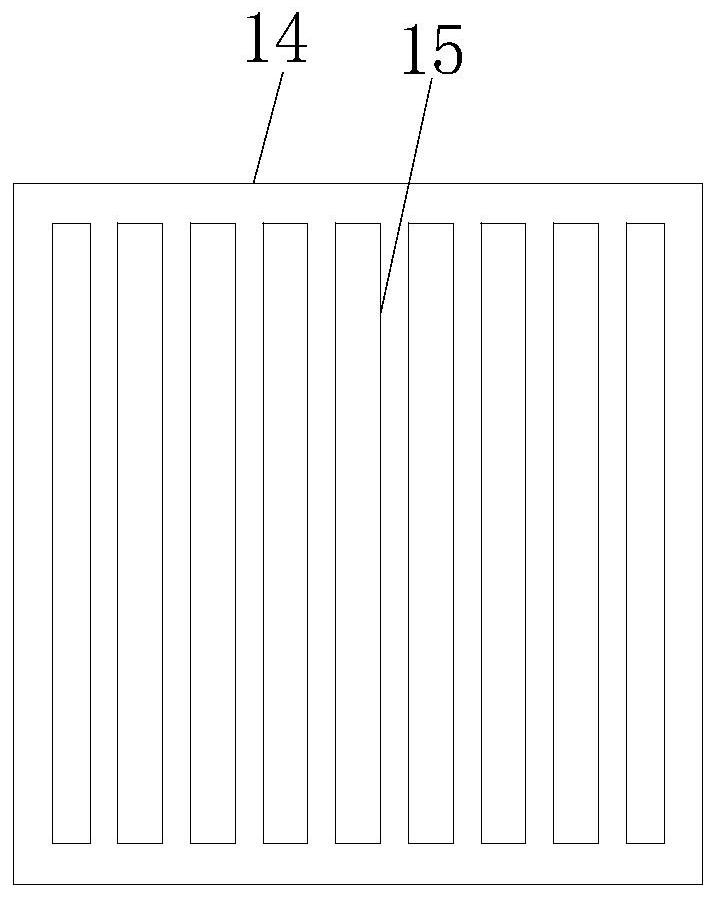

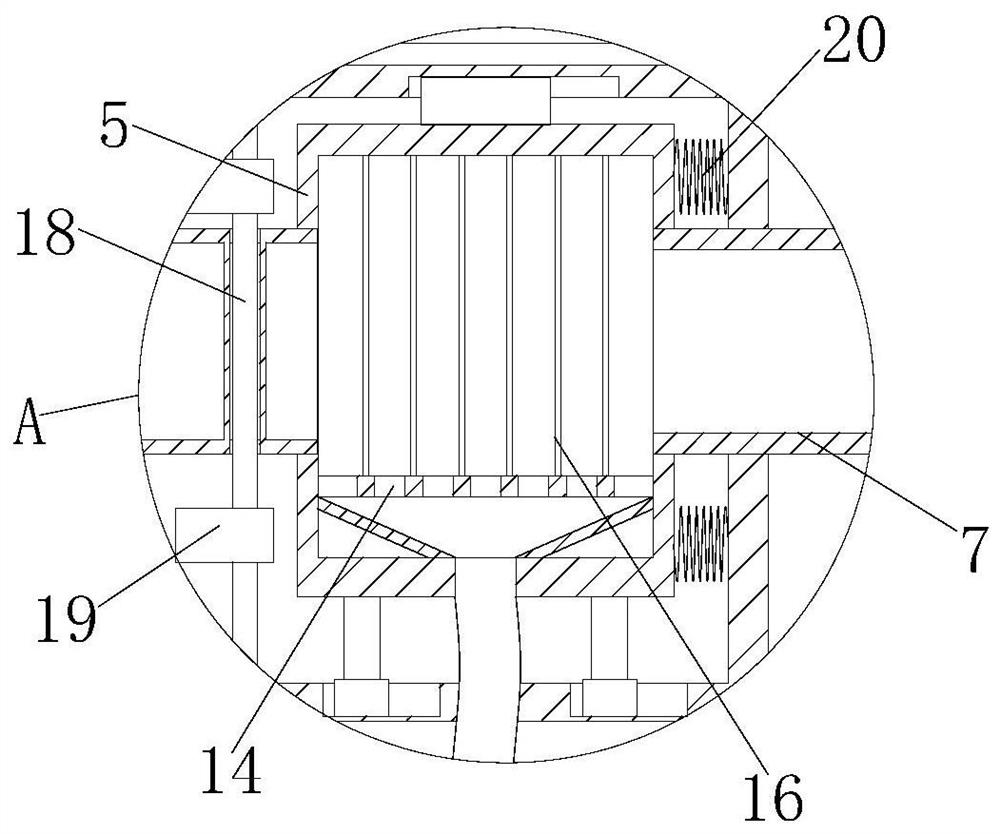

Stirring device for refining petroleum in Chemical industry

InactiveCN107570089AIncrease catalytic rateStir wellRotary stirring mixersMixer accessoriesChemical industryPetroleum

The invention relates to a stirring device, in particular to the stirring device for refining petroleum in Chemical industry. The technical problem to be solved in the invention is to provide the stirring device for refining petroleum in Chemical industry with uniform stirring, impurity filtering and high catalytic speed. In order to solve the technical problem, the invention provides the stirringdevice for refining petroleum in Chemical industry, which comprises a bottom plate and the like, wherein a catalytic tank is arranged at the top of the bottom plate, and a cover plate is connected atthe top of the left side of the catalytic tank in a hinging way; a screen plate is arranged in the middle of the inside of the catalytic tank, and a mixing device is arranged at the upper part of thecatalytic tank; a stirring device is arranged at the lower part of the catalytic tank. The stirring device for refining petroleum in Chemical industry provided by the invention achieves the effects of stirring evenly, filtering impurities and increasing the catalytic speed. The device firstly mixes the crude oil and the catalyst by a stirring roller, then filters the impurities through the screenplate, and then stirs the crude oil and the catalyst by the stirring device to achieve the effect of fully catalyzed mixing.

Owner:曾祥胜

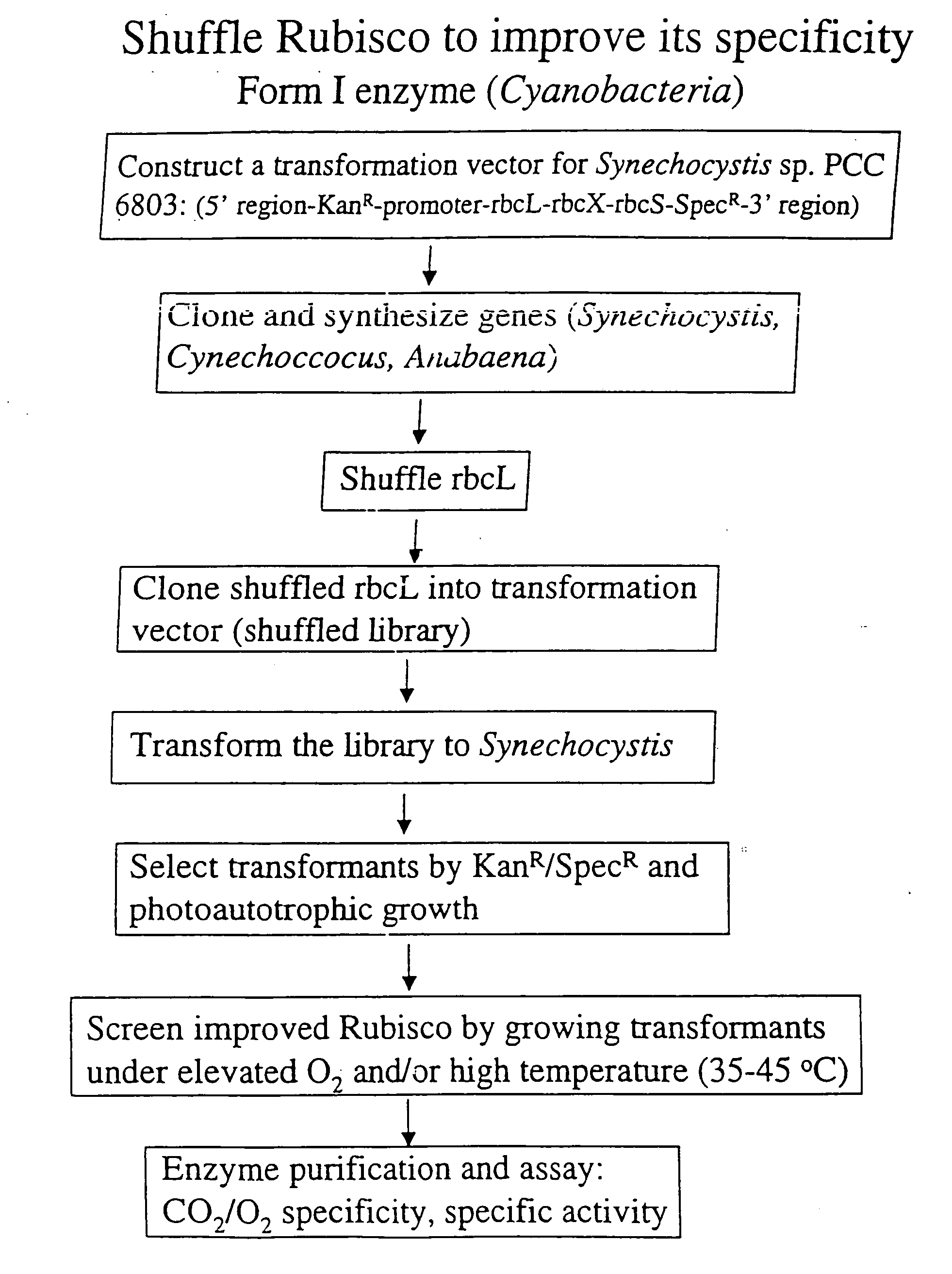

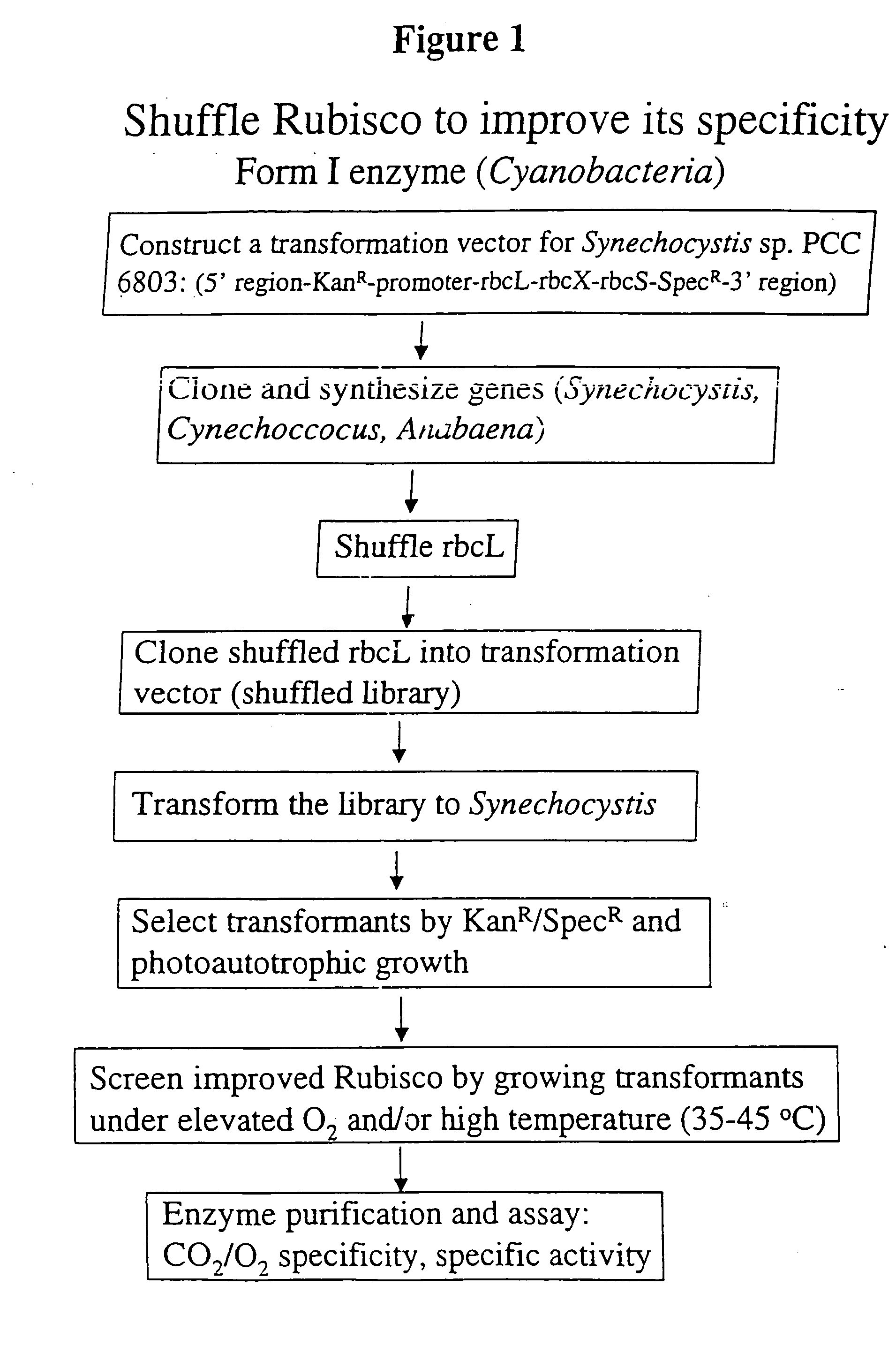

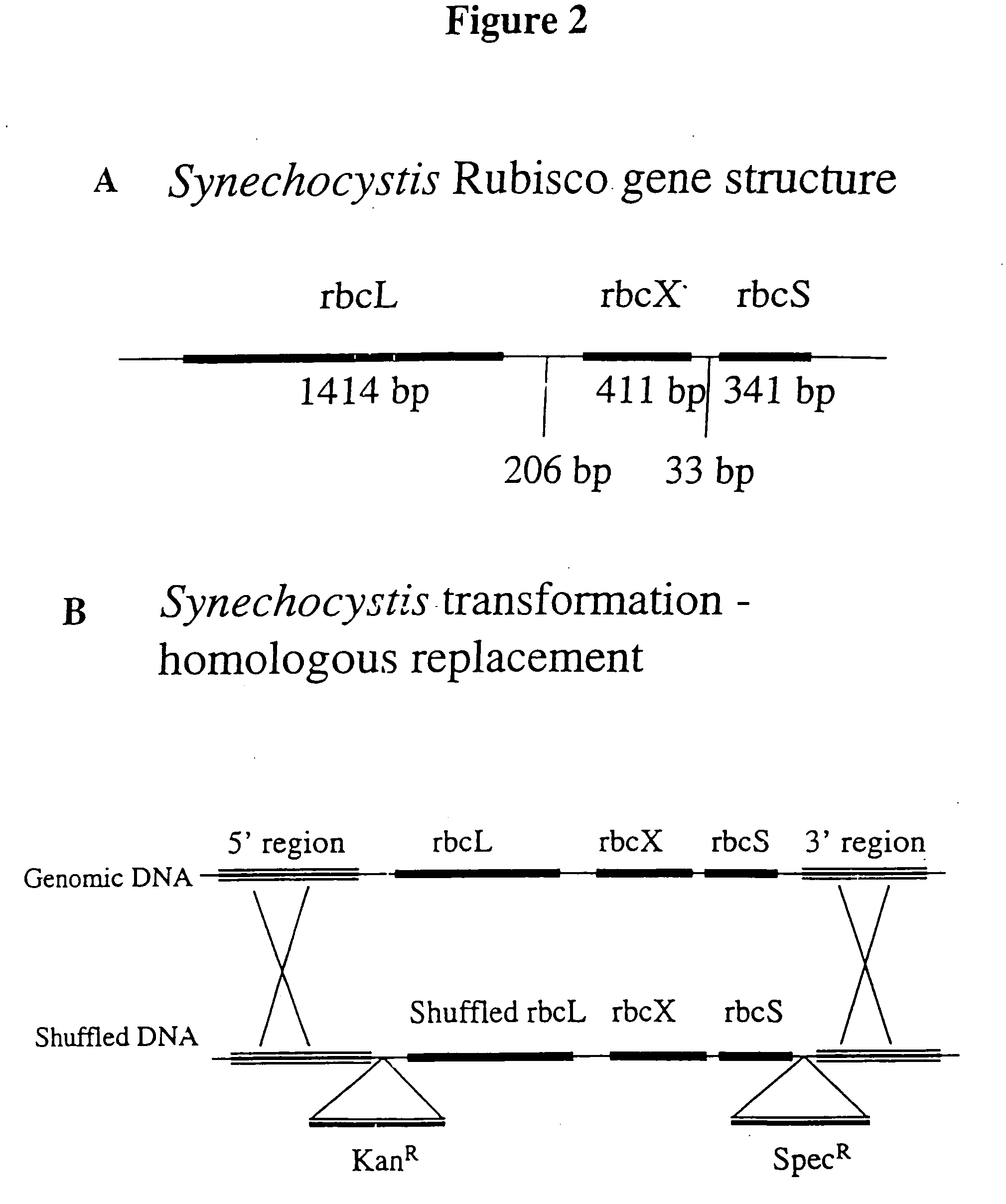

Modified ribulose 1,5-bisphosphate carboxylase/oxygenase for improvement and optimization of plant phenotypes

InactiveUS20060117409A1Elevated carbon fixation activityIncrease catalytic rateMicrobiological testing/measurementOther foreign material introduction processesENCODERibulose

The invention relates to methods and compositions for generating, modifying, adapting, and optimizing polynucleotide sequences that encode proteins having Rubisco biosynthetic enzyme activities which are useful for introduction into plant species, agronomically-important microorganisms, and other hosts, and related aspects.

Owner:MAXYGEN

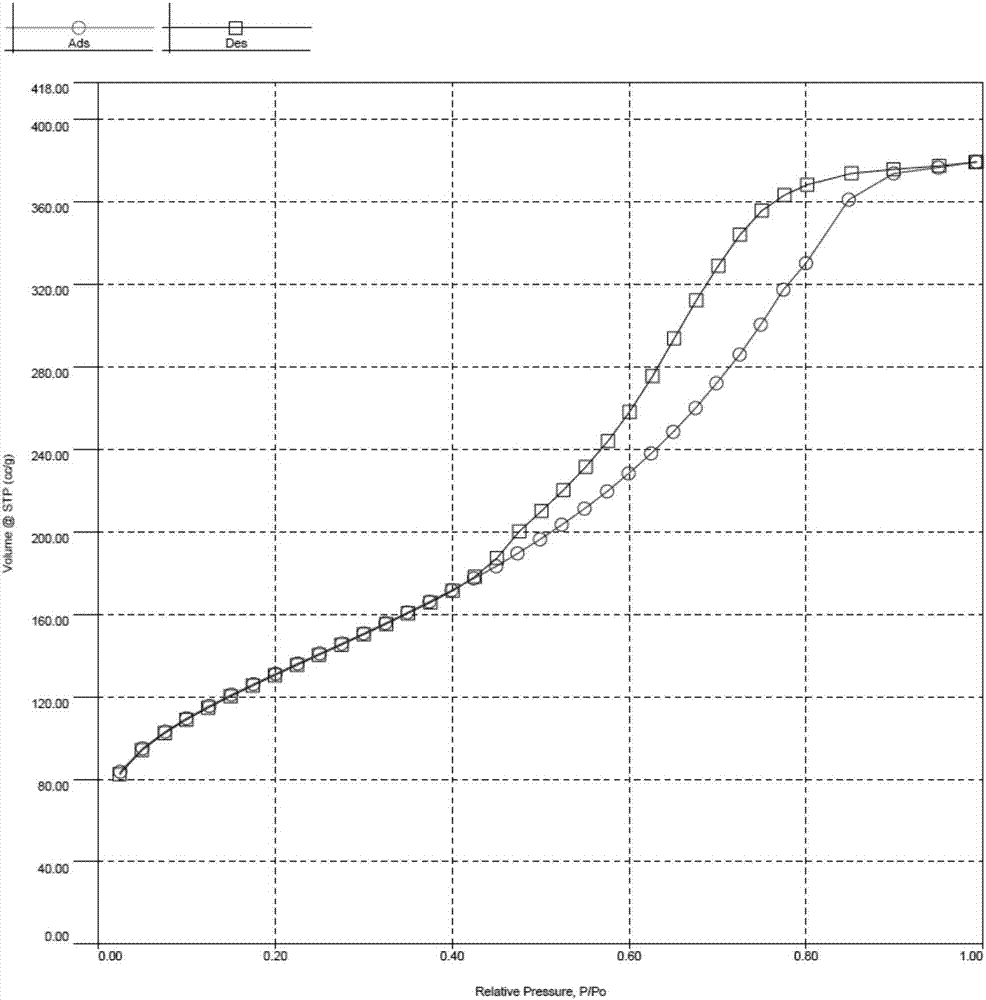

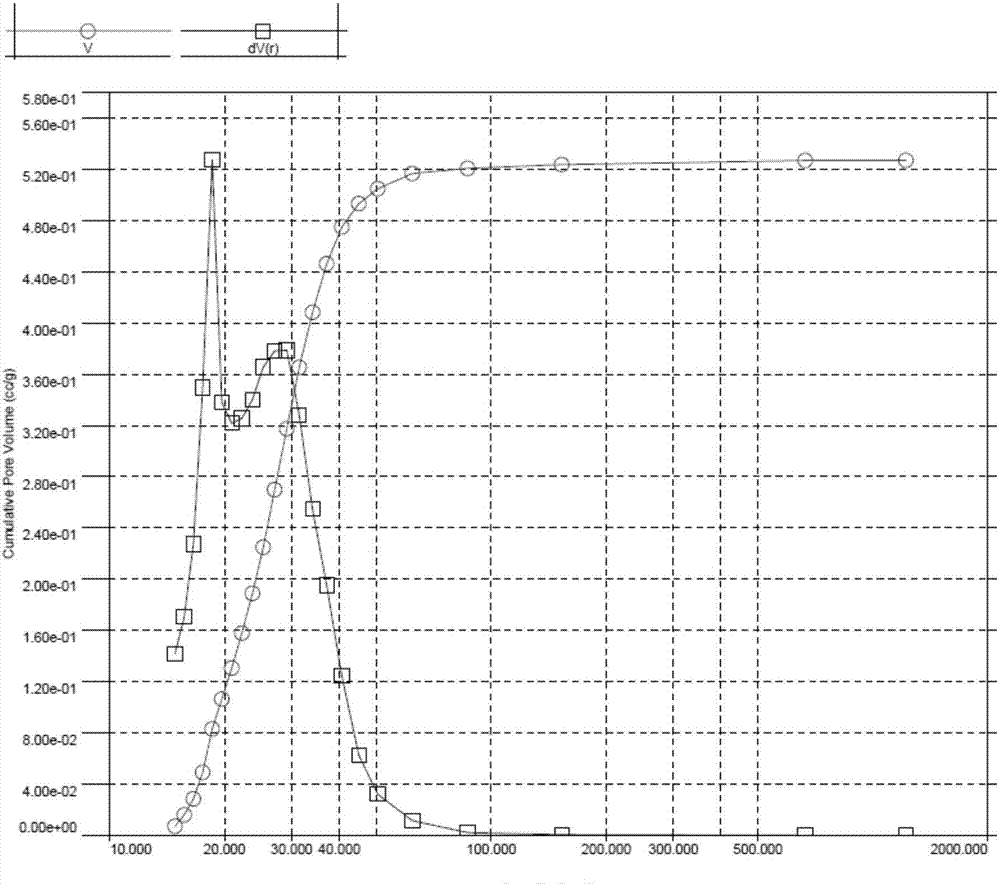

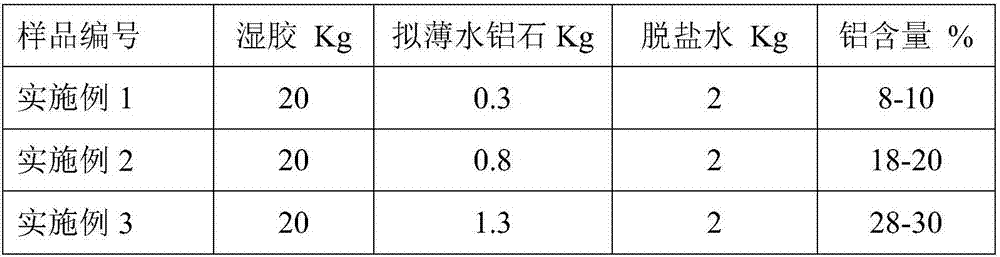

Preparation method for synthesizing high aluminum-silica gel

ActiveCN106902799ALarge apertureIncrease the areaOrganic chemistryPhysical/chemical process catalystsSodium metasilicateSlurry

The invention provides a preparation method for synthesizing a melamine high aluminum catalyst, and particularly relates to a preparation method of high aluminum-silica gel with the advantages of higher specific surface area, larger pore volume, higher strength and low wear rate. According to the preparation method disclosed by the invention, sodium metasilicate, sulfuric acid and pseudo boehmite are used as main production raw materials, wherein the sodium metasilicate and the sulfuric acid are gelatinized and then need to be subjected to aging and reaming, acid soaking and water washing, so that higher specific surface area, larger pore volume and larger pore diameter of the catalyst are guaranteed, and the activity of the catalyst is effectively improved; high-quality pseudo boehmite is added in beaten silica gel slurry, so that the content of activated aluminum oxide in the catalyst and the strength of the catalyst are effectively improved. By adopting the preparation method provided by the invention, the high-quality silica gel required by industry can be produced: the specific surface area is greater than or equal to 300 m<2> / g, the pore volume is 0.4 to 0.7 cm<3> / g, and the wear rate is smaller than or equal to 1.5 percent; the key problem of producing alumino silica gel with the high specific surface area, the high pore volume, the high strength and the low wear rate is solved; the preparation method has the advantages of simple steps, convenience in operation and high practicality.

Owner:LUXI CATALYST

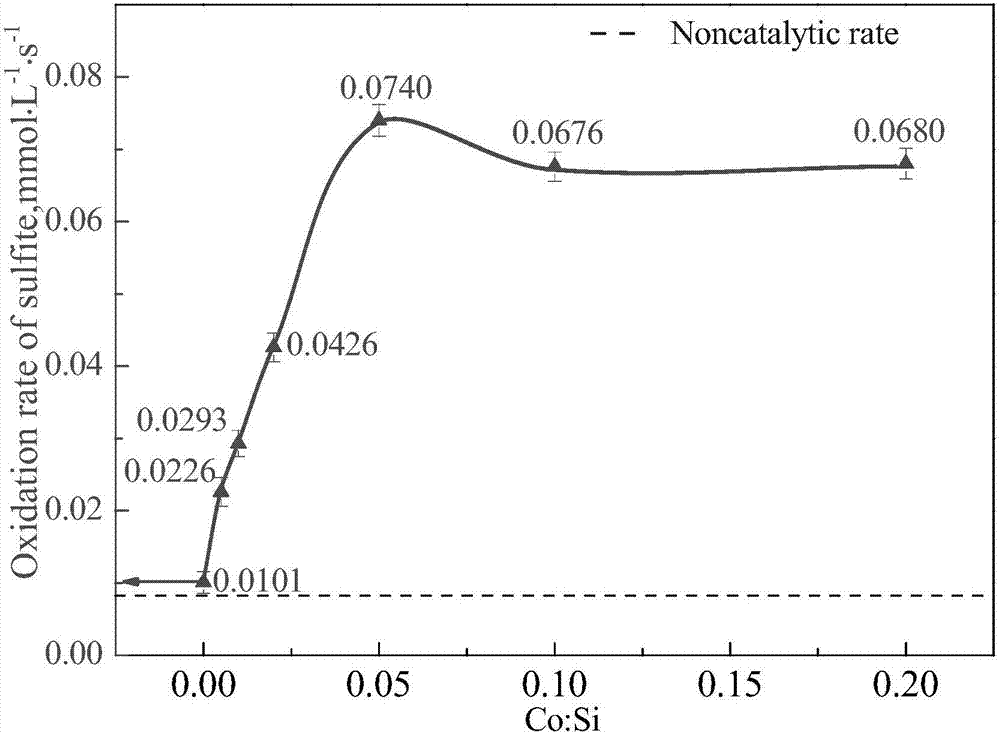

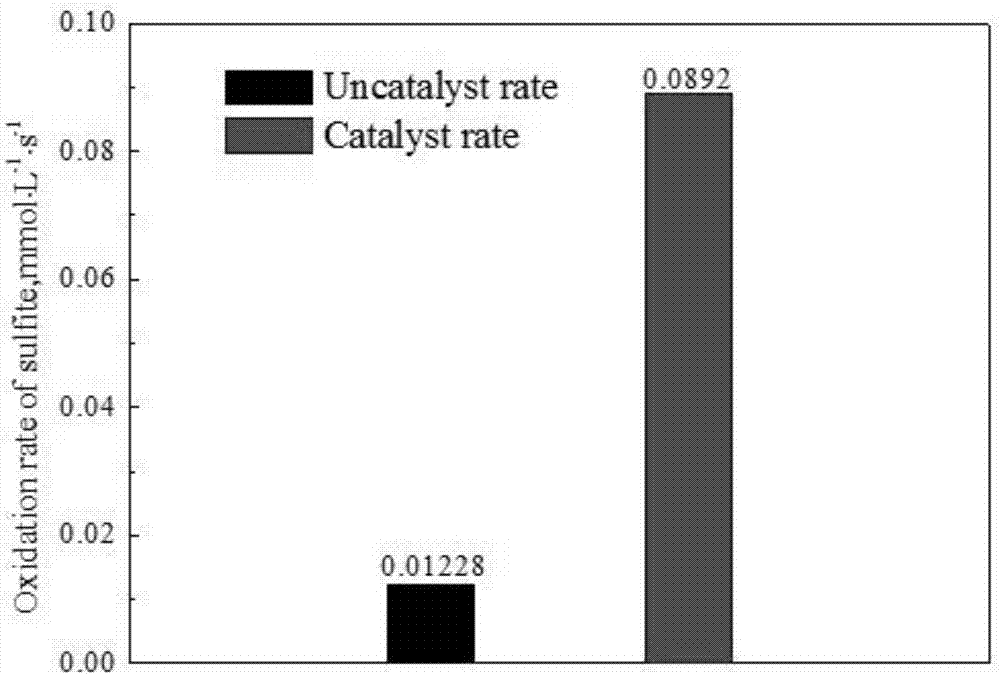

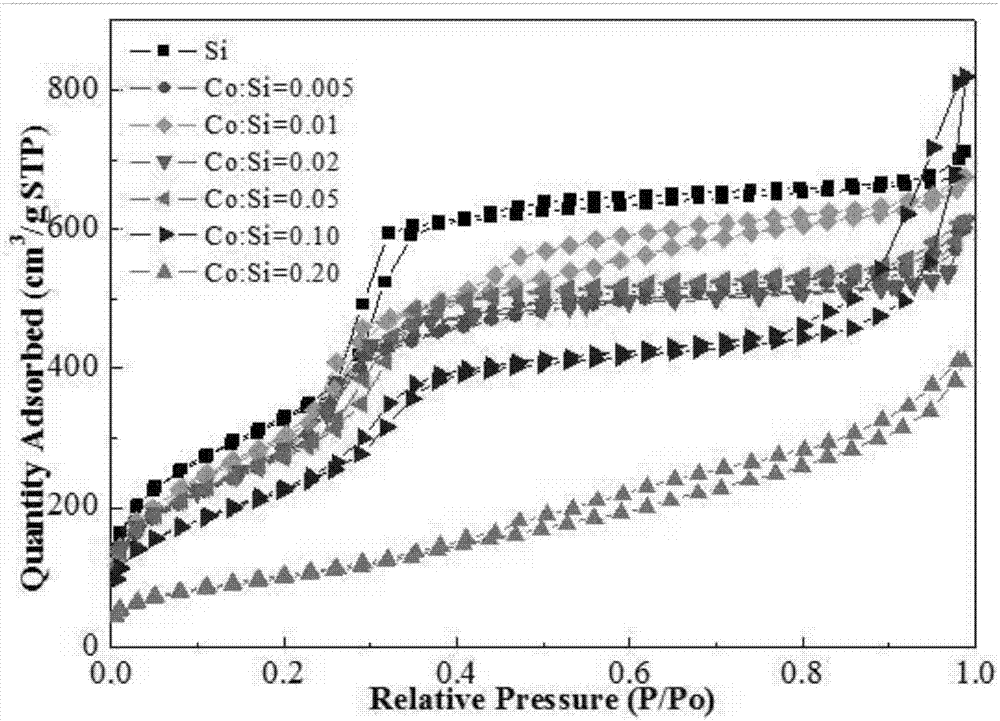

Cobalt-doped MCM-48 catalyst

InactiveCN107442158AReduce manufacturing costFirmly connectedMolecular sieve catalystsMagnesium sulfiteCobalt

The invention discloses a cobalt-doped MCM-48 catalyst which is a solid phase catalyst. The transition metal cobalt is fused in the framework of MCM-48, wherein the ratio of cobalt to silicon is (0.025-0.075):(0.9-1). The invention also discloses a preparation method for the catalyst. In the cobalt-doped MCM-48 catalyst disclosed by the invention, the transition metal cobalt is introduced into the framework of MCM-48 in the manner of fusion. The cobalt-doped MCM-48 catalyst is applied to the magnesium sulfite oxidization in magnesium desulphurization and the ammonium sulfite oxidization in ammonium desulphurization.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

Harmful gas treatment system for metal material hot working

InactiveCN111804077AAdd evenlyEasy dischargeDispersed particle filtrationSteam/vapor condensersPtru catalystDust control

The invention belongs to the technical field of harmful gas treatment, and especially relates to a harmful gas treatment system for metal material hot working. The harmful gas treatment system is provided to solve the problems that when existing harmful gas treatment devices are used, a large amount of dust in harmful gas is inconvenient to filter in advance, harmful gas which is just generated istoo high in temperature and is inconvenient to directly treat and discharge. The system comprises a shell, a first dust removal shell, a purification shell and a water tank are installed in the shell, a second dust removal shell is installed in the first dust removal shell, one side of the second dust removal shell is communicated with one end of a gas inlet pipe, the other end of the gas inlet pipe penetrates through the first dust removal shell and the shell, and the other side of the second dust removal shell is communicated with one end of a first gas outlet pipe. When the system is used,a large amount of dust in harmful gas can be filtered in advance, the harmful gas with over-high temperature is cooled, catalytic reaction and low-temperature gas emission are facilitated, and a catalyst can be uniformly added.

Owner:罗峰

Spiroketal frame bidentate phosphoramidite ligand as well as preparation method and application thereof

ActiveCN102746338BHigh mole percentageIncrease catalytic rateGroup 5/15 element organic compoundsOrganic-compounds/hydrides/coordination-complexes catalystsIsomerizationDiastereomer

The invention discloses a spiroketal frame bidentate phosphoramidite ligand as well as a preparation method and an application thereof. The ligand is the compound shown in a formula I or II or the enantiomer, racemate or diastereoisomer of the compound; and the ligand is prepared by condensation reaction of the compound in the formula I or II, and phosphorus-chlorine compounds. The spiroketal frame bidentate phosphoramidite ligand disclosed by the invention and transition metal salt form a complex, and the complex can be used for terminal olefine hydroformylation or isomerization-hydroformylation of internal olefins; and moreover, the spiroketal frame bidentate phosphoramidite ligand has high catalytic rate, good selectivity and practical value.

Owner:SHANGHAI INST OF ORGANIC CHEM CHINESE ACAD OF SCI

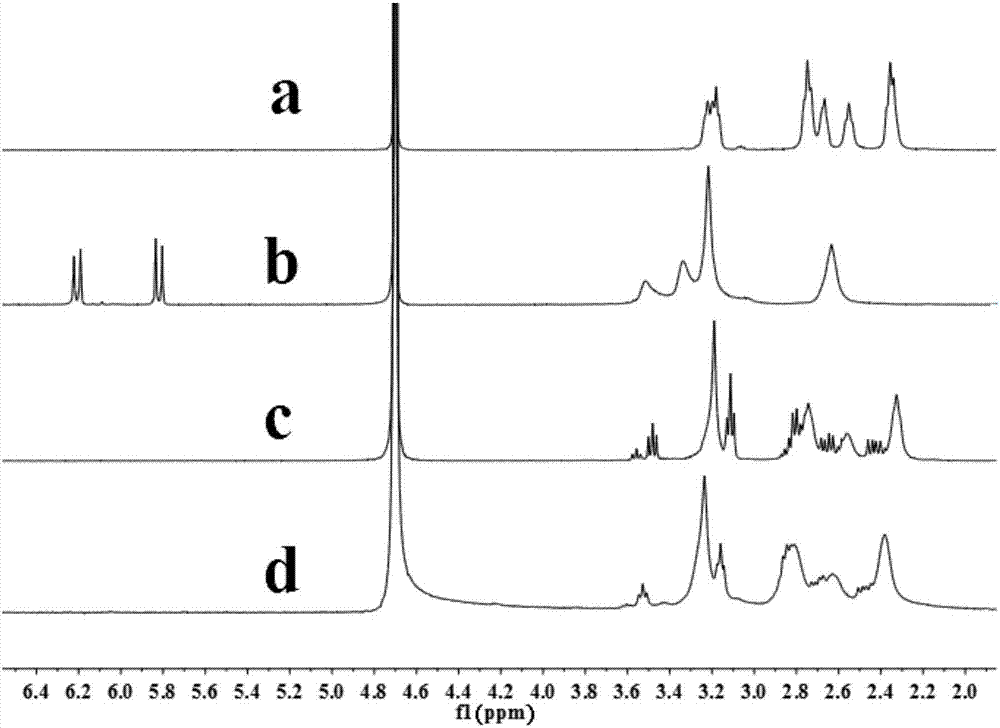

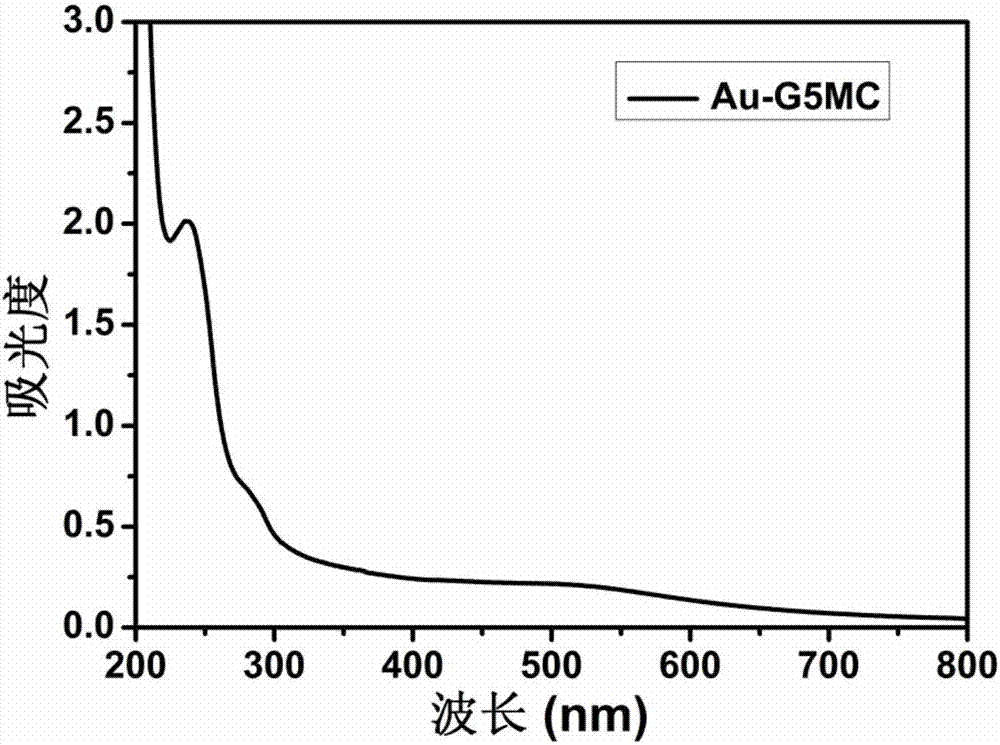

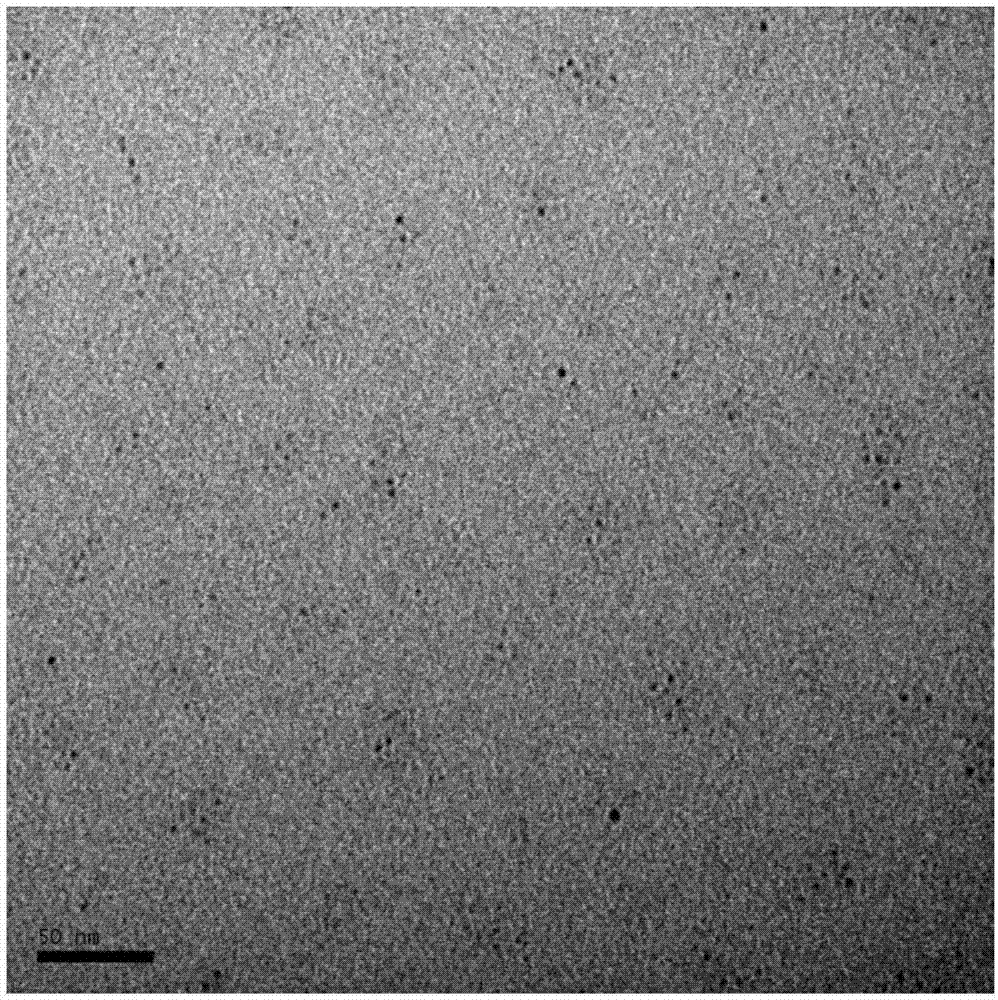

Preparation method of nanoparticles of amphoteric ionized dendrimer inclusion gold

ActiveCN107081171ASimple preparation processMild reaction conditionsOrganic-compounds/hydrides/coordination-complexes catalystsMetal/metal-oxides/metal-hydroxide catalystsMercaptoethylaminesMaleic anhydride

The invention provides a preparation method of nanoparticles of amphoteric ionized dendrimer inclusion gold. The preparation method mainly comprises the following steps: adding dimethyl sulfoxide into a fifth generation polyamide-amine dendrimer (G5 PAMAM); adding maleic anhydride to obtain fifth generation polyamide-amine dendrimer-maleic anhydride (G5M); then, adding mercaptoethylamine into a G5M water solution to obtain fifth generation polyamide-amine dendrimer-maleic anhydride-mercaptoethylamine (G5MC); adding a chloroauric acid water solution into a G5MC water solution; after stirring for 10min to 70min, adding sodium borohydride and adjusting the pH (Potential of Hydrogen) of a mixed solution to be neutral by utilizing 1M hydrochloric acid, so as to obtain the nanoparticles of the amphoteric ionized dendrimer inclusion gold (Au-G5MC). The preparation method has moderate preparation conditions and is simple to operate; a reaction process is easy to control and the stability of the nanoparticles is effectively protected.

Owner:YANSHAN UNIV

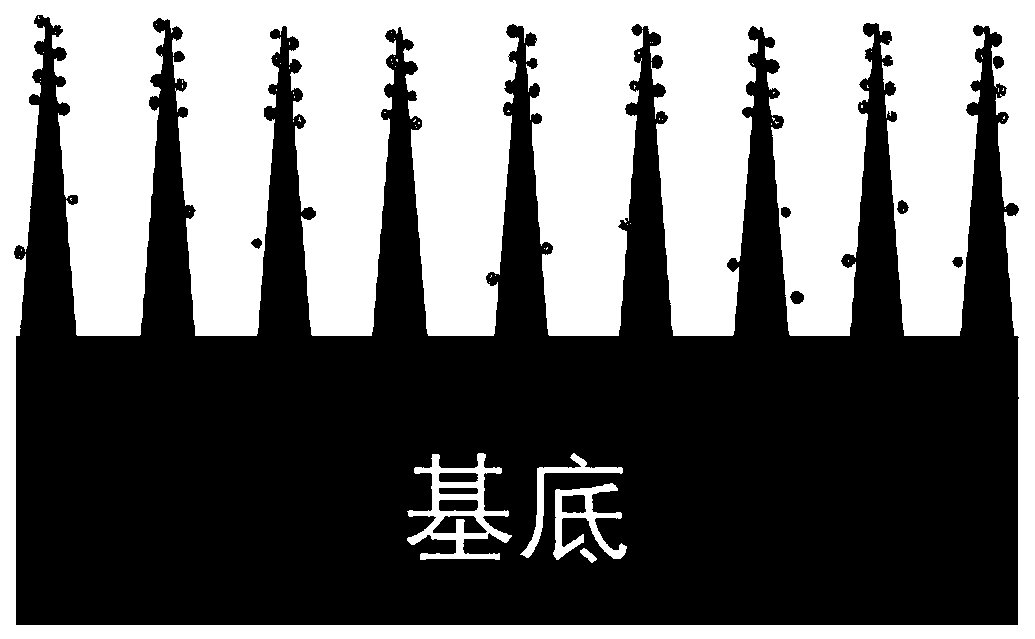

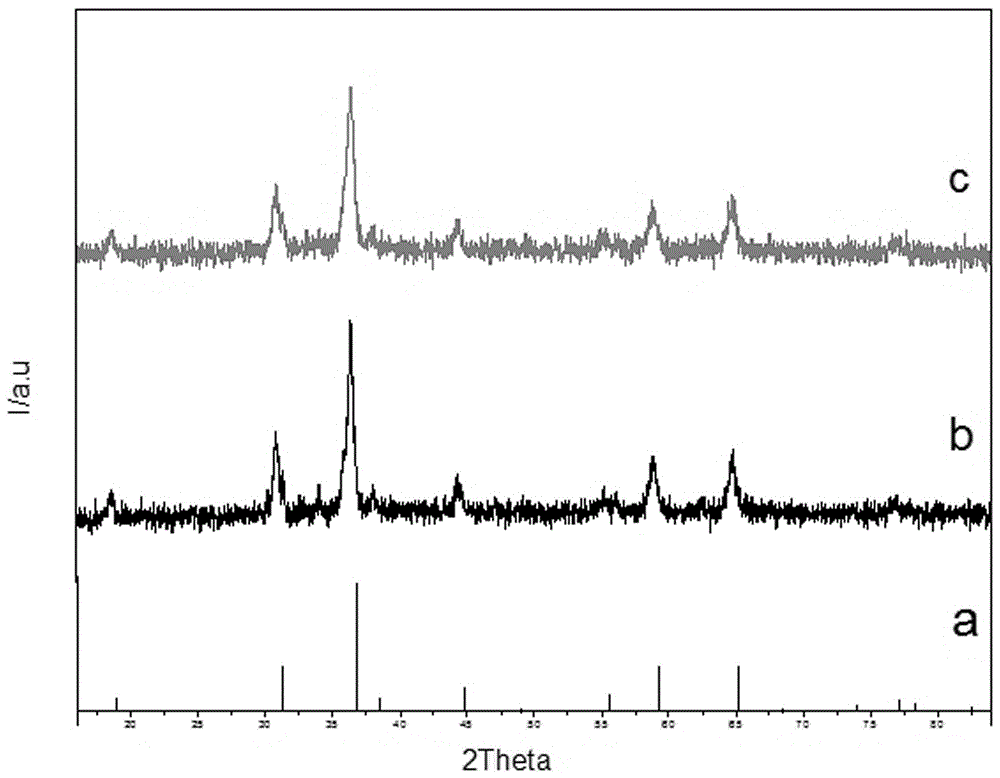

Photoelectrocatalytic metal-supported boron-doped diamond, and preparation method and application thereof

ActiveCN110496616AImprove stabilityHigh selectivityVacuum evaporation coatingSputtering coatingBoronNanometre

The invention provides a photoelectrocatalytic metal-supported boron-doped diamond. The metal-supported boron-doped diamond comprises a substrate and a boron-doped diamond layer arranged on any side of the substrate, and the boron-doped diamond layer comprises a flat bottom layer, a conical structure layer perpendicular to the flat bottom layer, and a metal nanoparticle catalyst uniformly loaded at the tip of the conical structure layer. The photoelectrocatalytic metal-supported boron-doped diamond has the advantages of high catalytic activity, high stability, high selectivity in a chemical process, and great increase of the selectivity and efficiency of the catalytic process.

Owner:SHENZHEN INST OF ADVANCED TECH

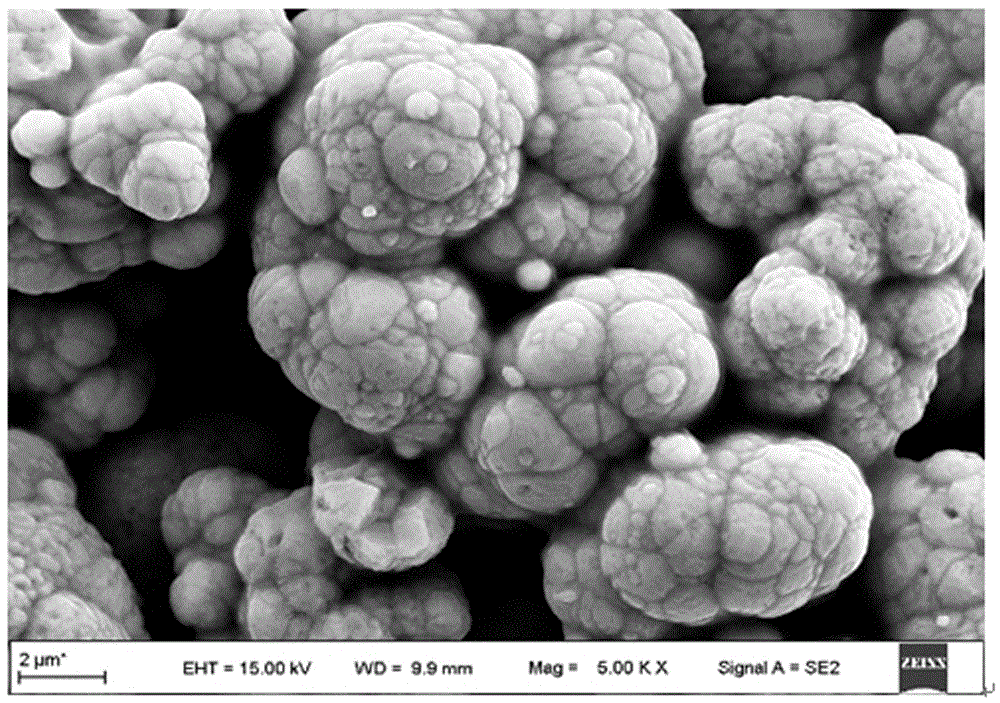

Preparation method and application of erbium-doped zinc cobaltate photocatalyst powder

ActiveCN106423178AImprove photocatalytic performanceImprove stabilityWater/sewage treatment by irradiationWater treatment compoundsErbium dopingPhotocatalytic degradation

The invention belongs to the technical field of photocatalysis, and particularly relates to a preparation method and application of erbium-doped zinc cobaltate photocatalyst powder. The general formula of the photocatalyst is ZnEr2xCo2 (1-X) O4 where x is equal to 0.02 to 0.06. The preparation method is to use zinc cobaltate as a matrix which is doped with an erbium element, and the crystalline form of the doped matrix is not affected. The photocatalyst powder obtained is high in purity, and the photocatalysis performance is greatly improved. The preparation process realized by adopting direct sintering is simple and easy to operate, the calcination temperature is low, and the conditions are mild and easy to control. The sample prepared has the advantages of high purity, high yield and no need of adding precipitant and low cost, and is suitable for industrial production. The erbium-doped zinc cobaltate photocatalyst powder disclosed by the invention can be applied to increasing the photocatalytic degradation rate of Congo red.

Owner:东北大学秦皇岛分校

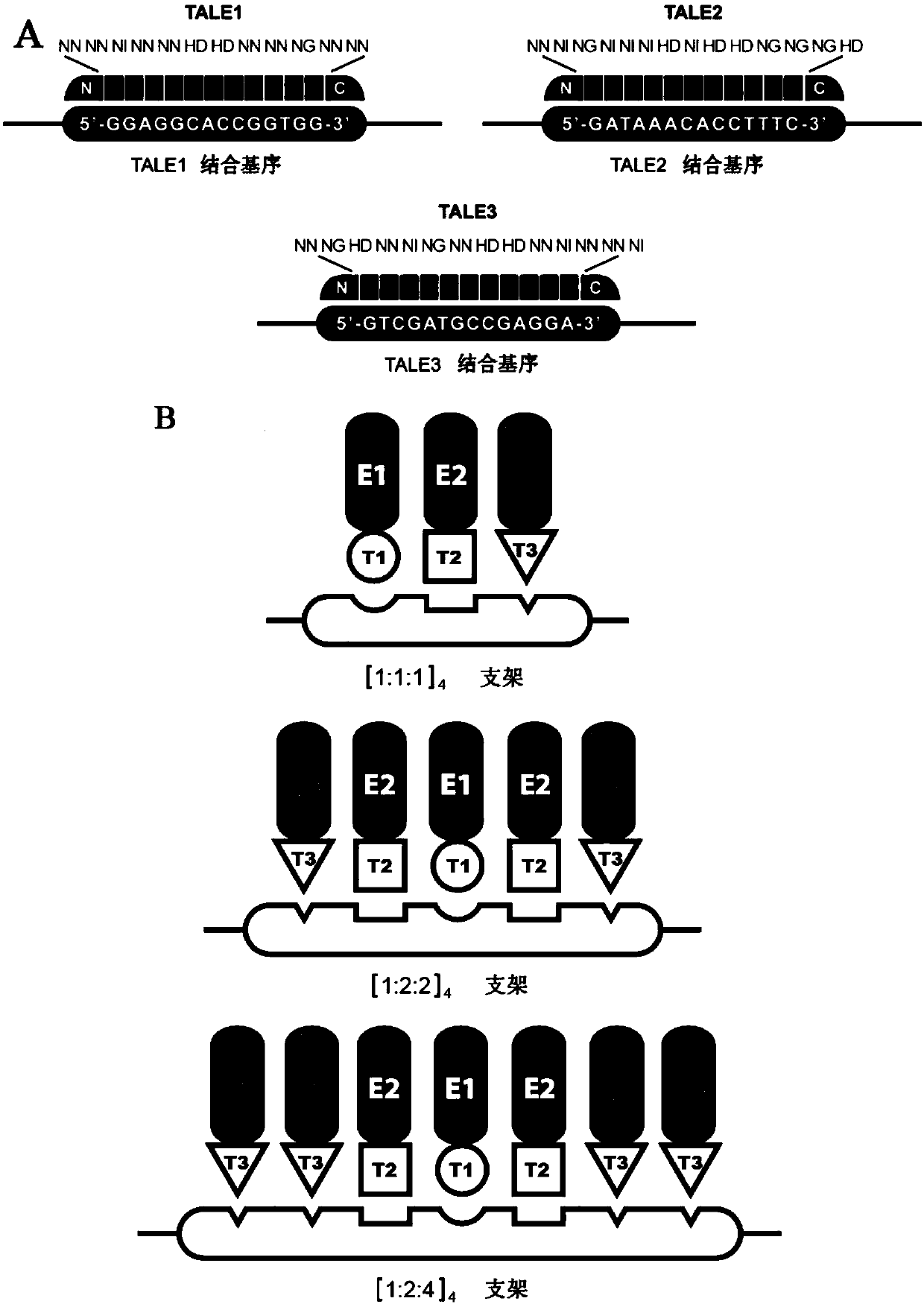

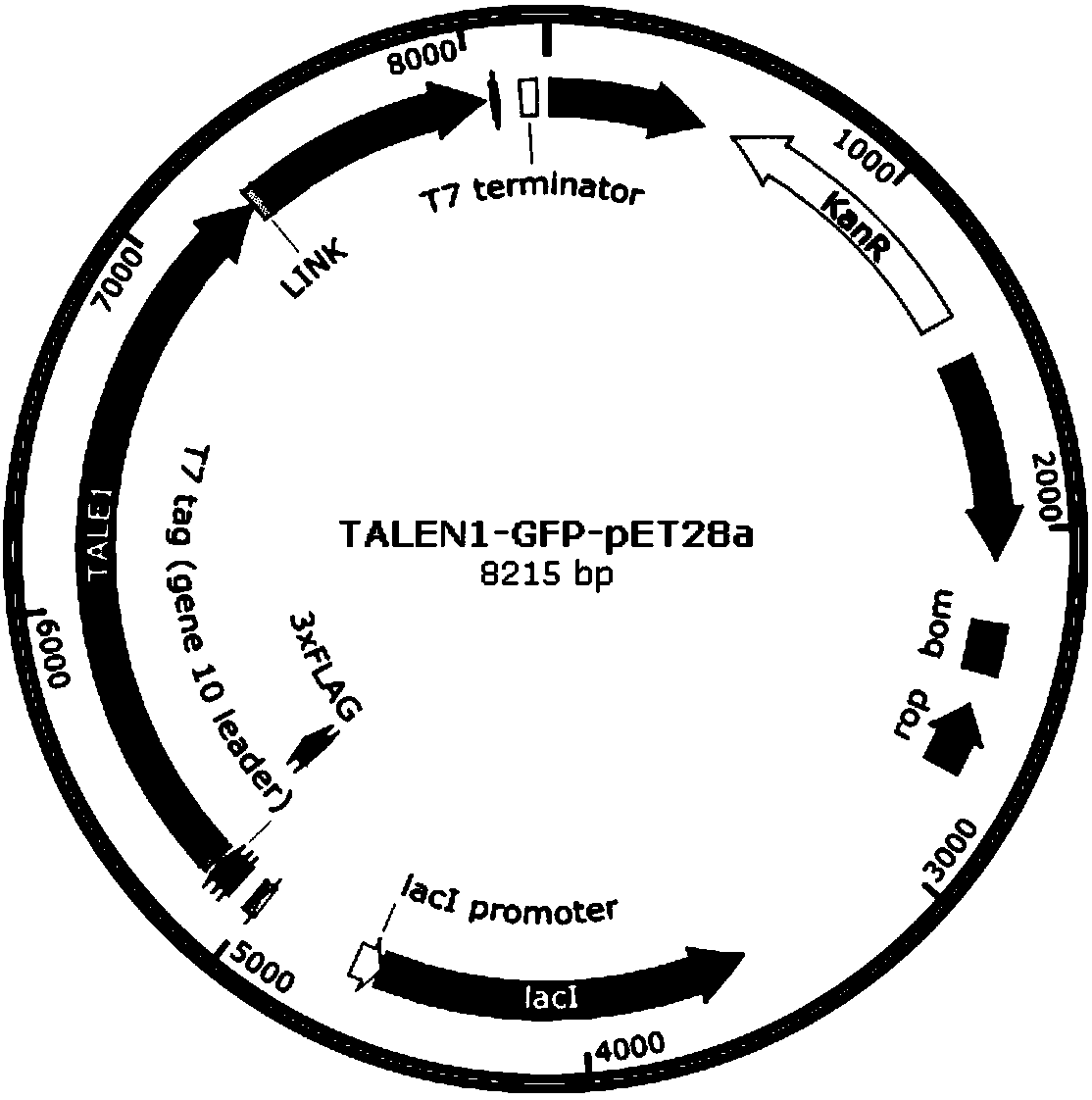

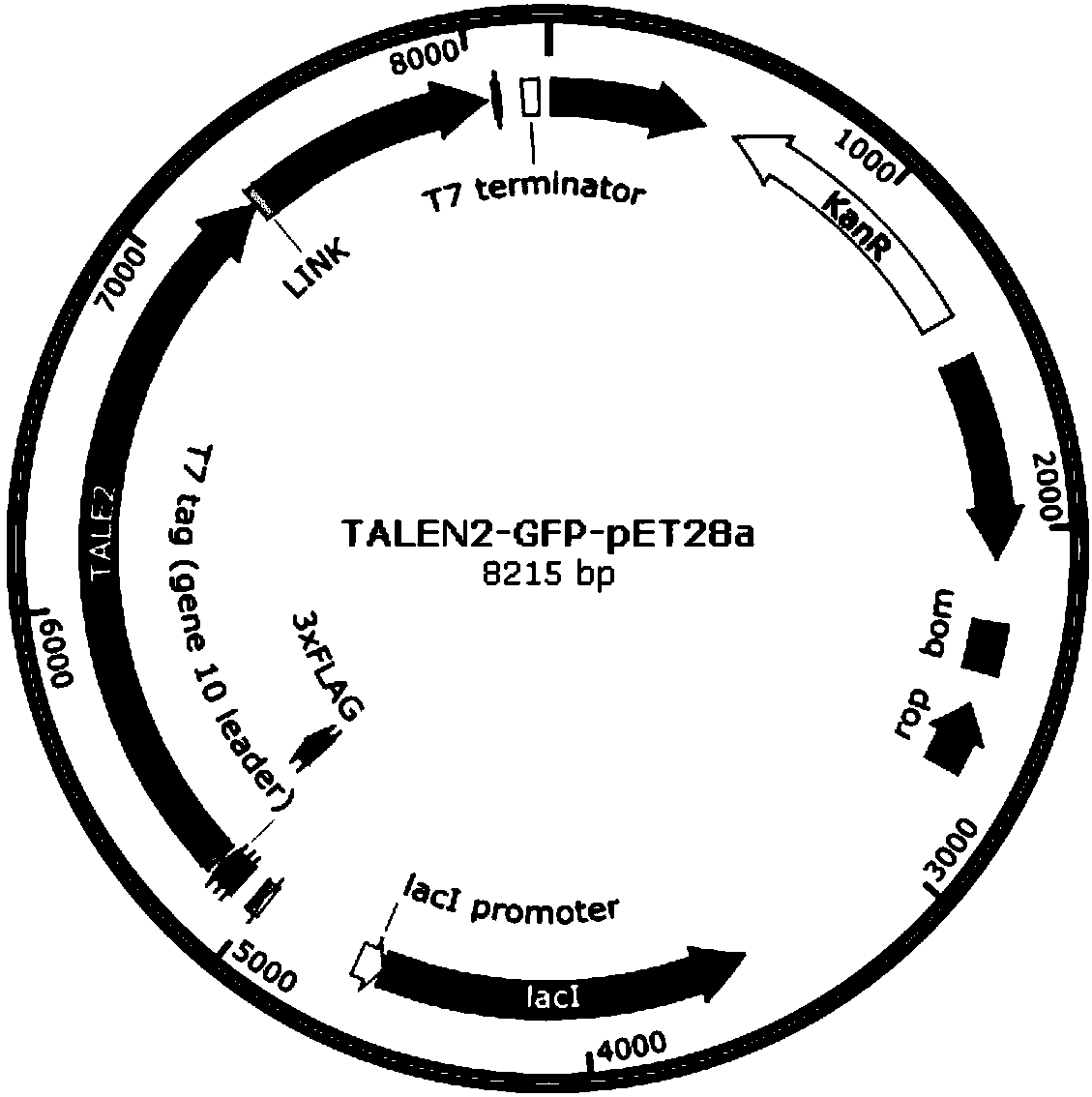

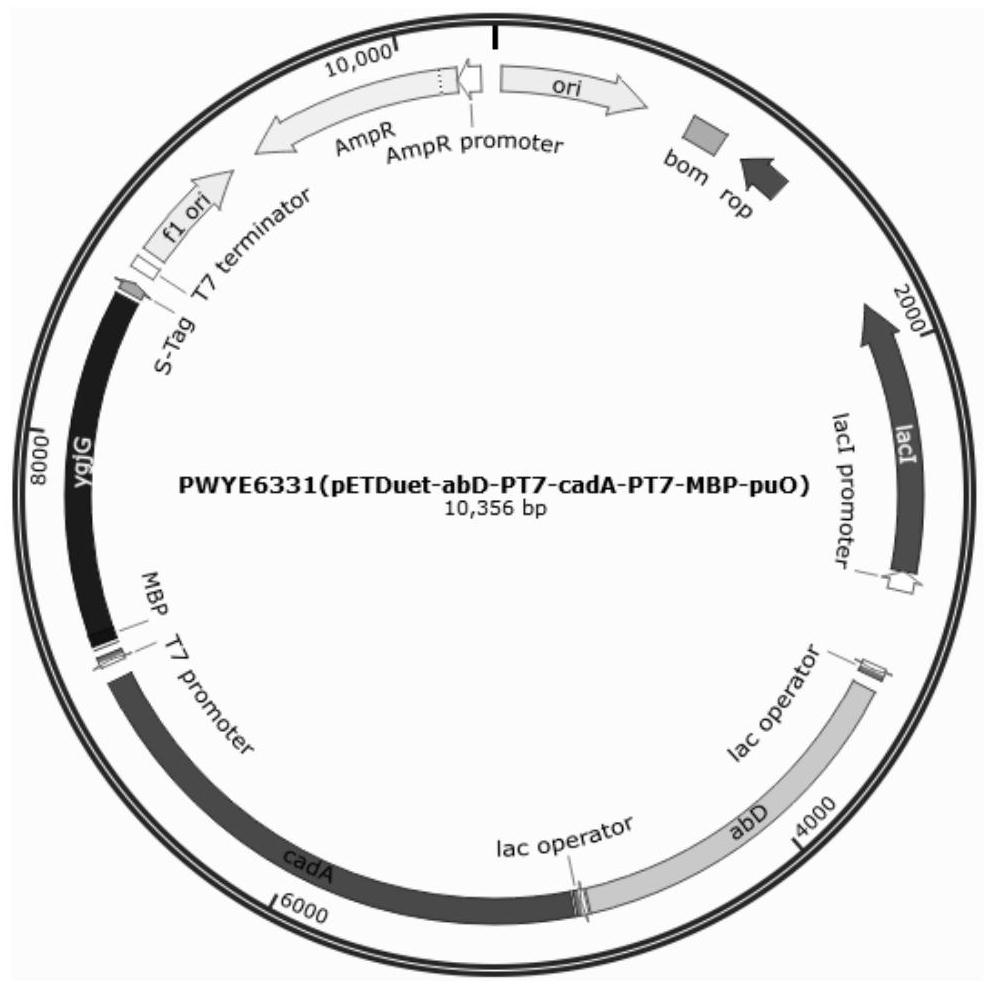

Intracellular scaffold, plasmids constructed by intracellular scaffold and application of plasmids

ActiveCN109536520AStrong copolymerizationFacilitates protein aggregationAntibody mimetics/scaffoldsMicroorganism based processesMevalonic acidIntracellular

The invention discloses an intracellular scaffold, plasmids constructed by the intracellular scaffold and an application of the plasmids. The intracellular scaffold consists of a DNA scaffold sequenceand a TALE-target molecule fusion protein; the DNA scaffold sequence includes a binding sequence BM1, a binding sequence BM2 and a binding sequence BM3; the TALE-target molecule fusion protein includes a TALE1-target molecule fusion protein, a TALE2-target molecule fusion protein and a TALE3-target molecule fusion protein; the TALE1-target molecule fusion protein is bound to the binding sequenceBM1, the TALE2-target molecule fusion protein is bound to the binding sequence BM2, and the TALE3-target molecule fusion protein is bound to the binding sequence BM3. The DNA scaffold sequence is constructed on pSB1C3, BBa-J63009 or pSB4A5 plasmids, the TALE-target molecule fusion protein is constructed on pET28a (+) plasmids, and the obtained transformed plasmids are co-transformed into escherichia coli, IPTG-induced expression is performed, and the obtained plasmids can be used for improving the yield of mevalonic acid in mevalonic acid synthesis reaction.

Owner:NAT UNIV OF DEFENSE TECH

Nanometer porphyrin catalyst and method for catalyzing TMB color development by using nanometer porphyrin catalyst

ActiveCN109682804AIncreased peroxidase-like activityExcellent peroxidase-like activityMaterial analysis by observing effect on chemical indicatorColor/spectral properties measurementsWater bathsPorphyrin

The invention discloses a nanometer porphyrin catalyst. The nanometer porphyrin catalyst takes a cationic surface active agent and ZnTPyP as main raw materials, and is formed through water bath self-assembly; the nanometer porphyrin catalyst has better peroxidase activity and can be effectively utilized to catalyze and oxidize 3,3',5,5'-tetramethylbenzidine (TMB) to generate a colorless-to-blue color development reaction. The nanometer porphyrin catalyst has the advantages that rapid color development is achieved, the catalytic efficiency is high, the synthetic cost is low, and the catalytic effect of DTAB self-assembled ZnTPyP is higher than that of a pure surface active agent DTAB and much higher than that of the ZnTPyP, and the nanometer porphyrin catalyst has an important application prospect.

Owner:SOUTH CENTRAL UNIVERSITY FOR NATIONALITIES

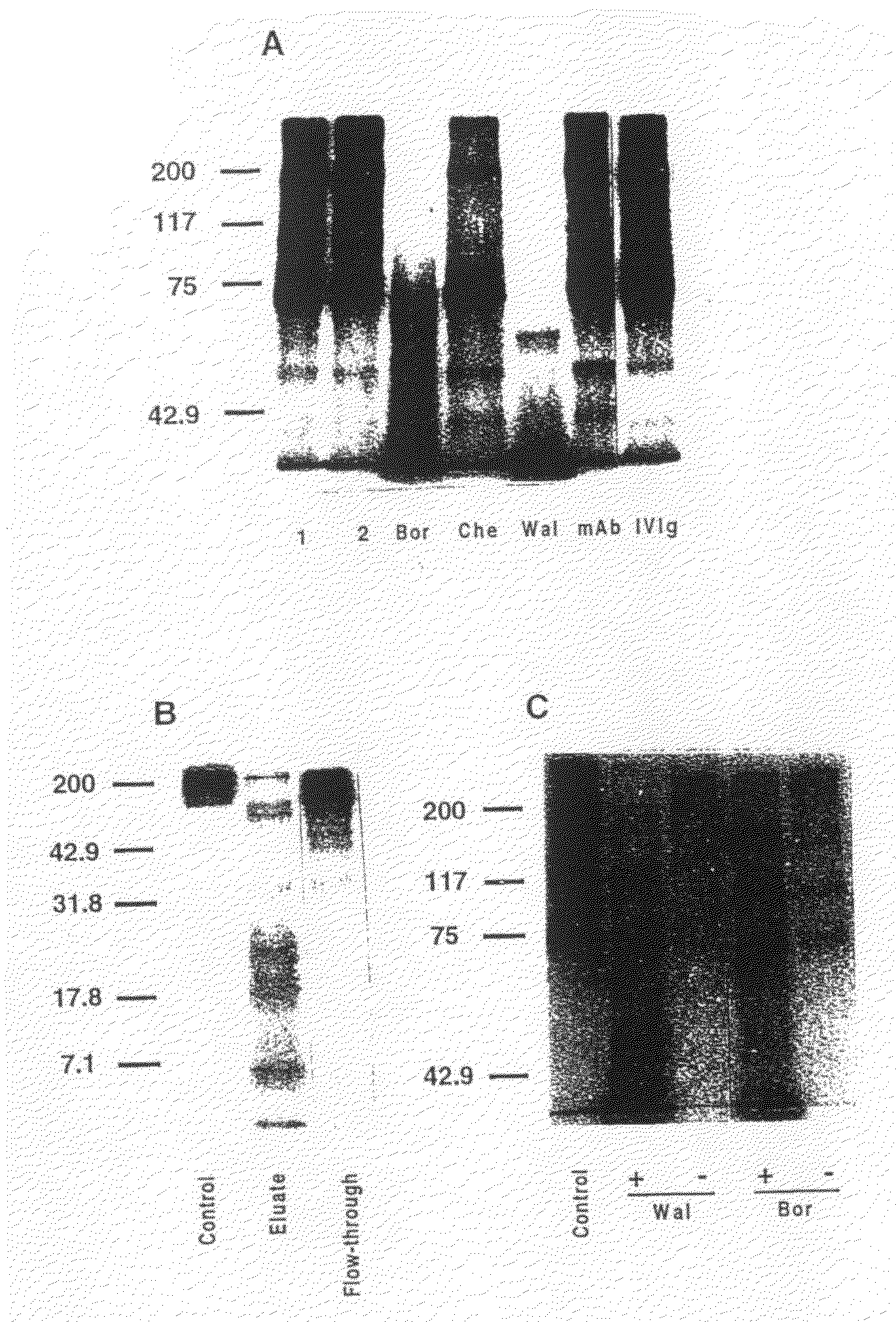

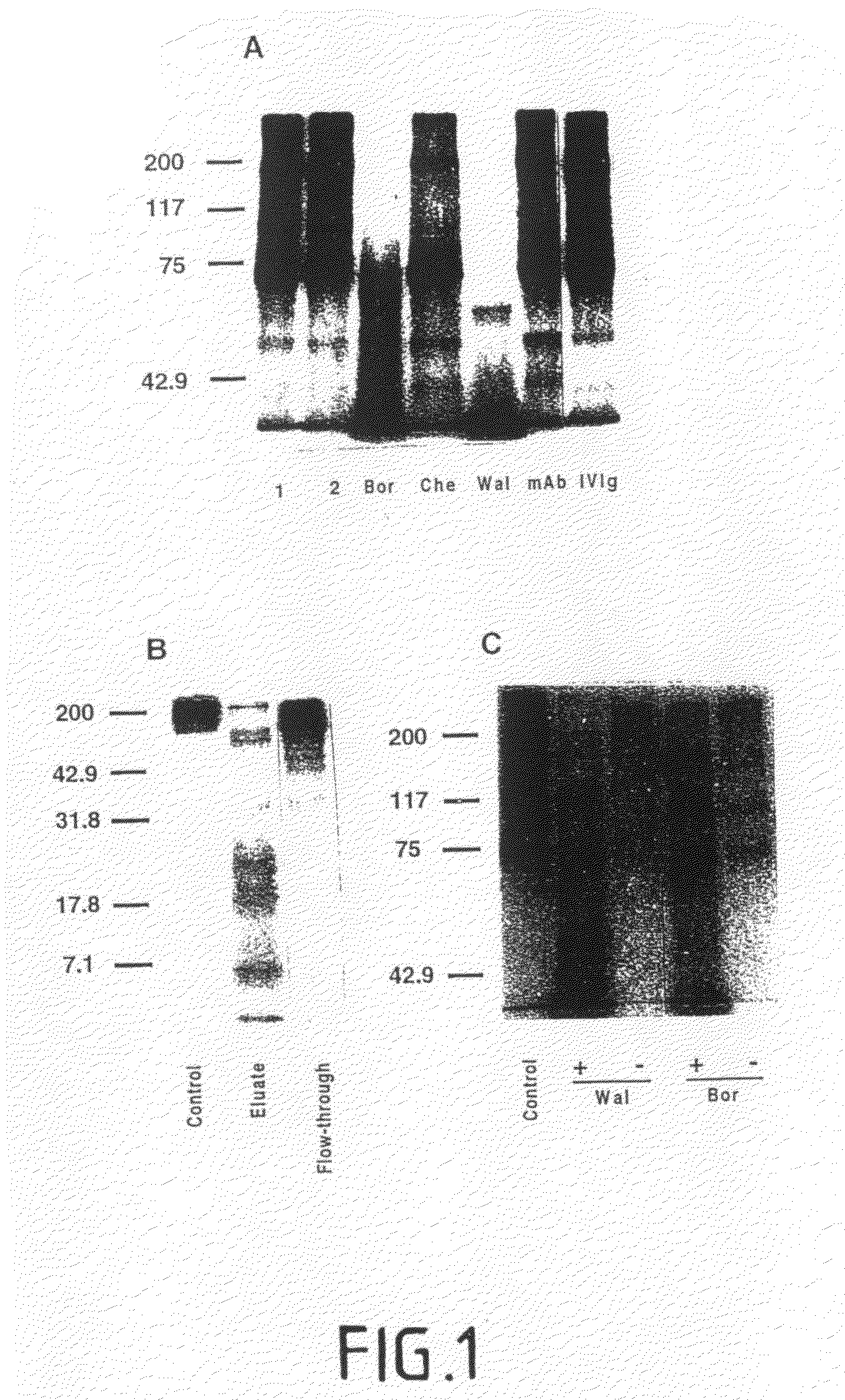

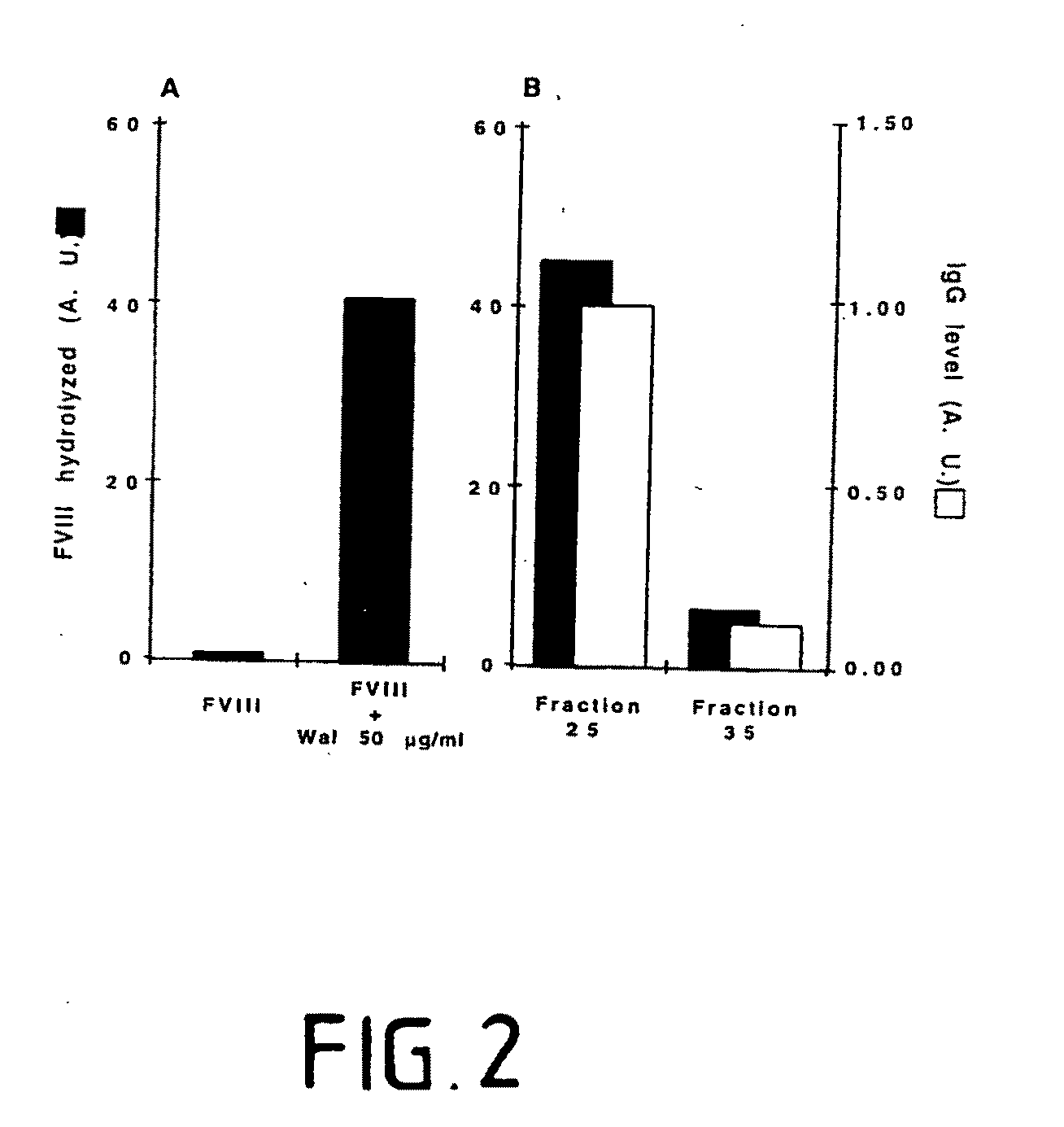

Catalytic anti-factor VIII allo-antibodies

InactiveUS20090208512A1Convenient treatmentIncrease catalytic rateImmunoglobulins against blood coagulation factorsFactor VIIFactor iiCombinatorial chemistry

The present invention relates to a method of determining the presence of catalytic anti-Factor VIII allo-antibodies capable of degrading Factor VIII in a mammal, and of characterising the cleavage sites in said Factor VIII molecule by said catalytic anti-Factor VIII allo-antibodies. It also relates to an anti-Factor VIII allo-antibody-catalysed Factor VIII degradation inhibitor; and to a pharmaceutical composition comprising said catalytic anti-Factor VIII allo-antibodies which are capable of degrading Factor VIII and which originate from said method of determination; and further to a pharmaceutical composition comprising said anti-Factor VIII allo-antibody-catalysed Factor VIII degradation inhibitor. Finally, the present invention relates to the application in therapeutics of said anti-Factor VIII allo-antibody-catalysed Factor VIII degradation inhibitor, of a pharmaceutical composition comprising said catalytic anti-Factor VIII allo-antibodies which are capable of degrading Factor VIII and which originate from said method of determination, and of a pharmaceutical composition comprising said anti-Factor VIII allo-antibody-catalysed Factor VIII degradation inhibitor.

Owner:KAVERI SRINIVAS +2

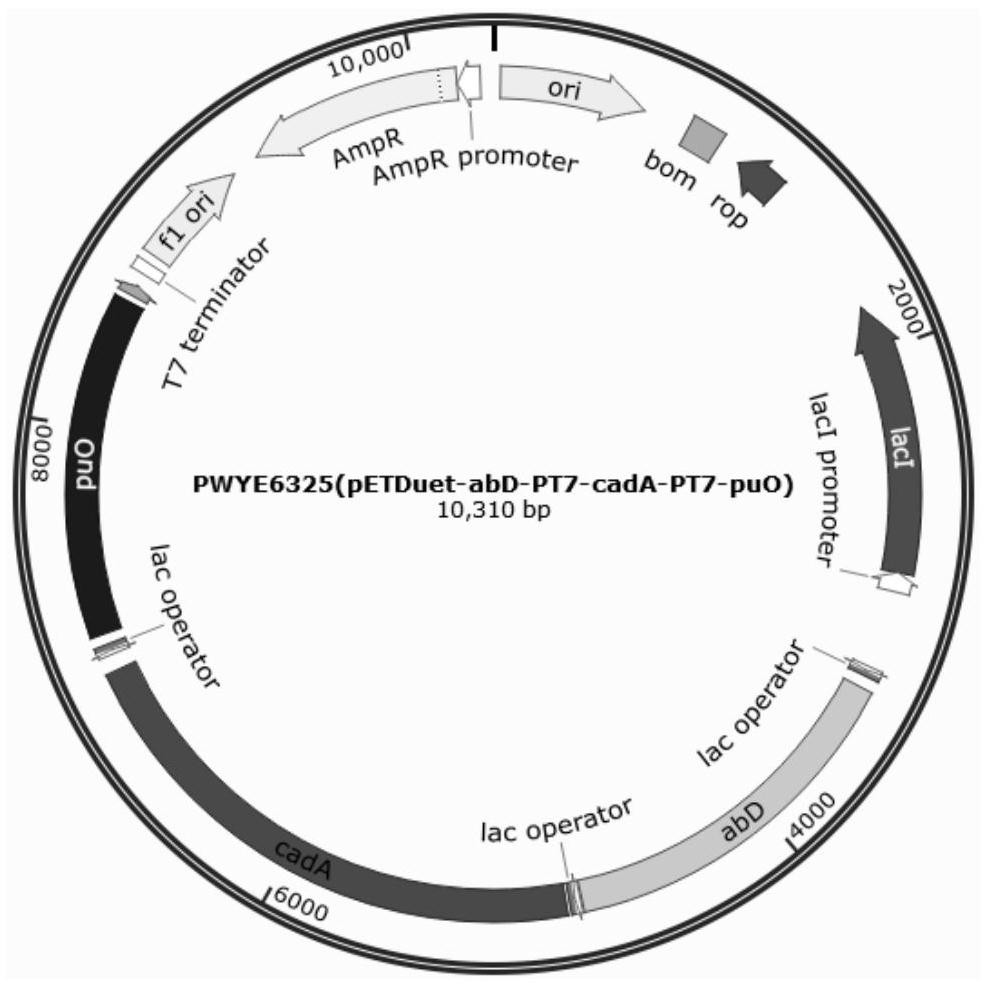

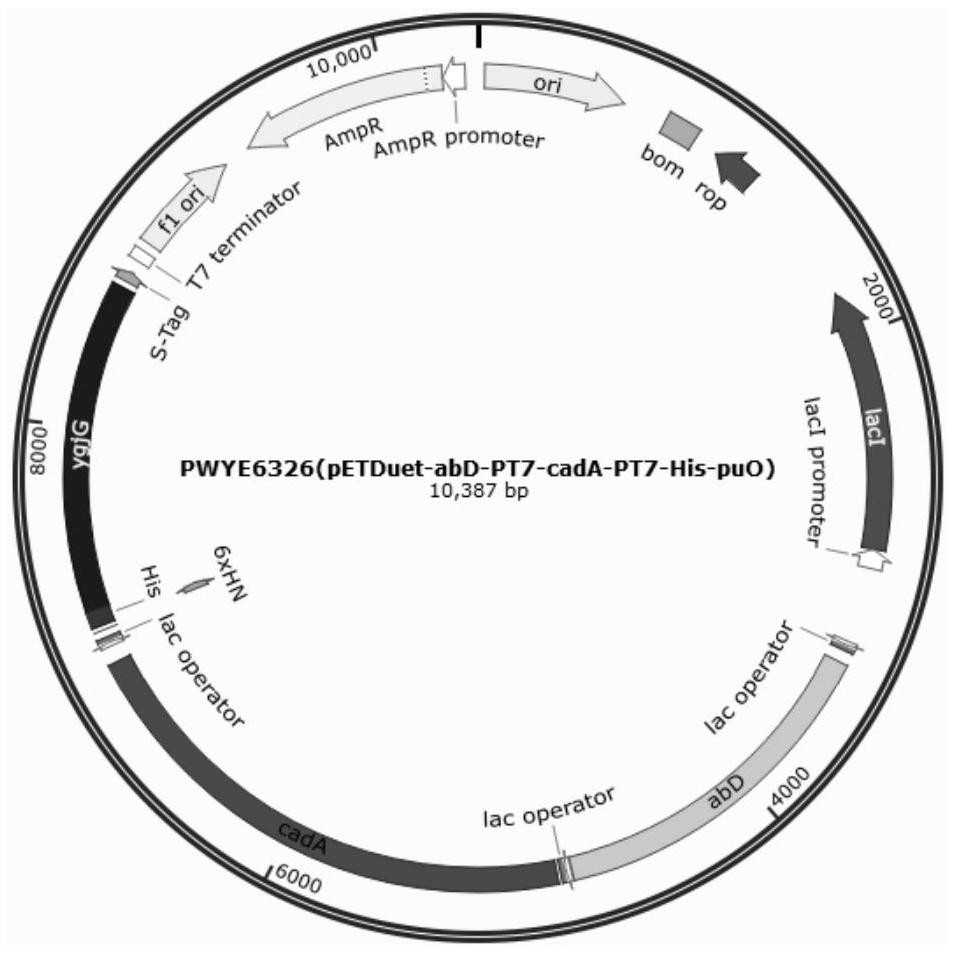

Engineering bacterium for whole-cell catalytic production of 5-aminopentanoic acid and preparation method of 5-aminopentanoic acid

PendingCN111849845AIncrease catalytic rateHigh catalytic concentrationBacteriaMicroorganism based processesLysine dehydrogenaseOxidative enzyme

The invention relates to an engineering bacterium for whole-cell catalytic production of 5-aminopentanoic acid and a preparation method of the 5-aminopentanoic acid. Compared with a starting strain, the engineering strain has the same expression as a gamma-aminobutyraldehyde dehydrogenase abD gene, a lysine dehydrogenase cadA gene and a butanediamine oxidase puO gene. The 5-aminopentanoic acid whole-cell catalytic engineering bacterium with high catalytic rate and high catalytic concentration is constructed through combination optimization of the expression of the gamma-aminobutyraldehyde dehydrogenase abD, the lysine dehydrogenase cadA and the butanediamine oxidase puO and selection of an optimal host bacterium.

Owner:INST OF MICROBIOLOGY - CHINESE ACAD OF SCI

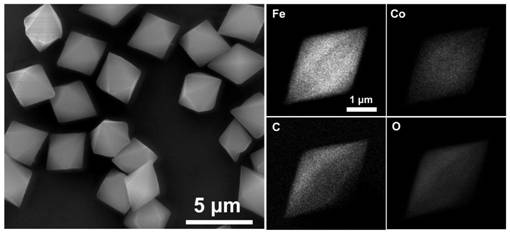

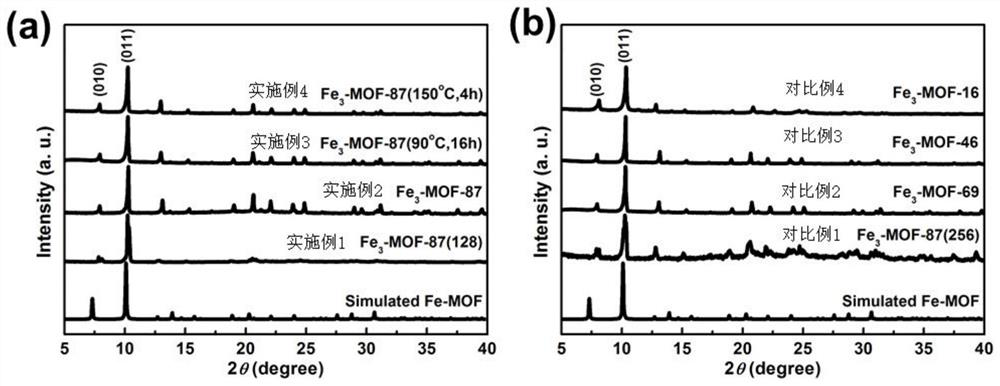

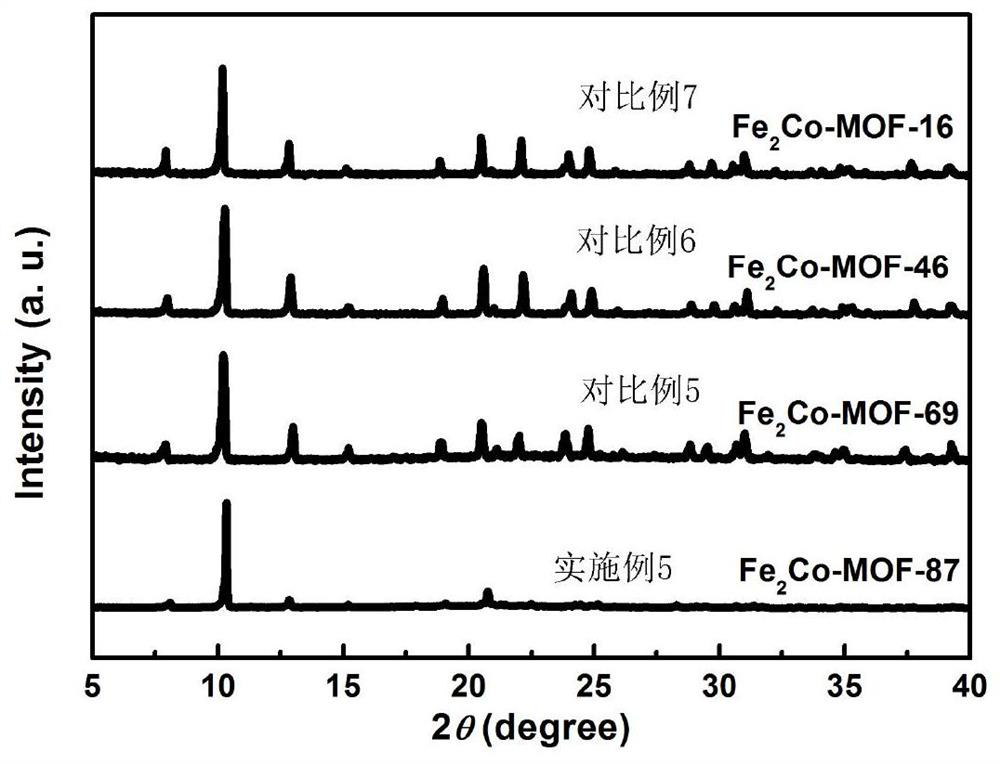

Preparation method of iron-based MOFs oxygen evolution electrocatalyst with high-activity crystal face proportion, and catalyst

ActiveCN113073350AExposure can be regulatedHigh exposure ratio of active crystal facetsElectrodesPtru catalystActive agent

The invention provides a preparation method of an iron-based MOFs oxygen evolution electrocatalyst with a high-activity crystal face proportion, and the catalyst, and belongs to the technical field of oxygen evolution electrocatalysts. The method comprises the following steps: weighing ferric salt and an organic ligand fumaric acid according to the molar ratio of iron ions to fumaric acid of 1: (64-128), dissolving the ferric salt and the organic ligand fumaric acid in an N, N-dimethylformamide solvent, and uniformly stirring to obtain a mixed solution; carrying out solvothermal reaction on the obtained mixed solution at a certain reaction temperature for a period of time, and naturally cooling to room temperature; and washing the obtained product with absolute ethyl alcohol, and then drying and collecting to obtain the product which is the iron-based MOFs oxygen evolution electrocatalyst. The iron-based MOFs electrocatalyst with the high active crystal face exposure proportion can be synthesized in situ by regulating and controlling the proportion of the metal Fe ions and the organic ligand fumaric acid and using a mild solvothermal method, the preparation method is mild, simple and easy to operate, and the purpose of regulating and controlling the crystal face can be achieved without additionally introducing a surfactant.

Owner:GUANGXI NORMAL UNIV

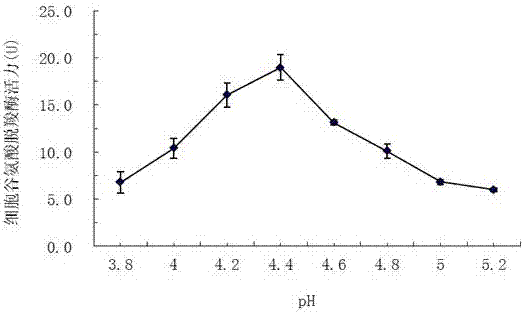

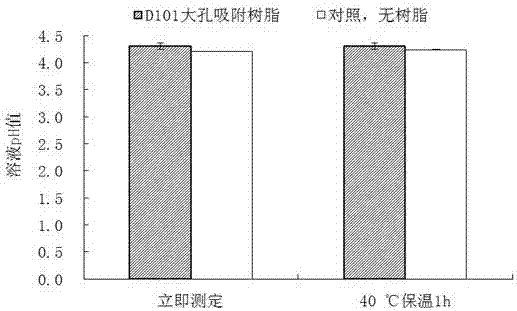

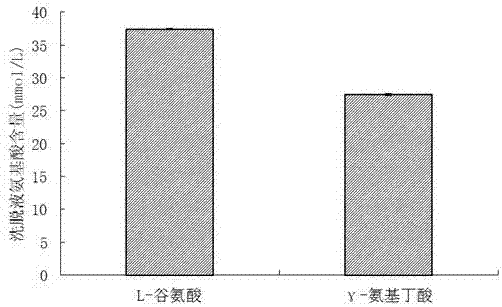

Method for increasing activity of GAD (Glutamate Decarboxylase) by using D101 macroporous adsorption resin

ActiveCN107326052AAvoid inactivationAccelerate the speed of leaving the active center of glutamic acid decarboxylaseMicroorganism based processesFermentationWater bathsGlutamate decarboxylase

The invention relates to a method for increasing the activity of enterococcus faecium Glutamate Decarboxylase by using D101 macroporous adsorption resin, and belongs to the technical field of biology. According to the method disclosed by the invention, the D101 microporous adsorption resin is used as an enzyme activity accelerator of enterococcus faecium GAD, and a D101 microporous adsorption resin-GAD composite catalytic system is constructed according to a proportion that the mass of the D101 macroporous adsorption resin to the volume of a substrate solution to the volume of an enterococcus faecium bacterial suspension solution or a GAD free enzyme solution is 1 to 1 to 1; when the D101 microporous adsorption resin-GAD composite catalytic system is subjected to reaction in a water bath oscillator of which the temperature is 37 to 43 DEG C at 80r / min or stirring reaction in a stirring tank at a low speed for 24 to 36 hours, the yield of GABA (Gamma-Aminobutyric Acid) can be increased by 18.54 to 149.11 percent; the D101 macroporous adsorption resin is capable of remarkably increasing the activity of the GAD, an exchange adsorption function of the D101 microporous adsorption resin on the GABA is also a purifying process of the GABA, a downstream extracting and purifying technology is simplified, and the production cost is reduced; the method is simple, green and environment-friendly.

Owner:LINGNAN NORMAL UNIV

Systems And Methods For Altering Rates Of Enzymatic Processes

InactiveUS20110300585A1Increase catalytic rateBioreactor/fermenter combinationsBiological substance pretreatmentsCelluloseEnzymatic hydrolysis

The various embodiments of the present invention relate generally to compositions, systems, and methods for altering rates of catalysis. More particularly, the various embodiments of the present invention are directed toward compositions, systems, and methods for enzymatic hydrolysis of polysaccharides, such as cellulose and starch. An aspect of the present invention comprises a method for altering the rate of conversion of a substrate into a product comprising: providing a substrate in a carrier; mixing a reactant and a co-factor with the carrier to form a substantially homogeneous mixture of the reactant, the co-factor, and the substrate in the carrier; and reacting the reactant with the substrate in the presence of the co- factor to convert at least a portion of the substrate into the product, wherein the reaction rate of the reactant with the substrate in the presence of the co-factor is different than the reaction rate of the reactant with the substrate in the absence of the co-factor.

Owner:GEORGIA TECH RES CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com