Harmful gas treatment system for metal material hot working

A technology of harmful gases and metal materials, applied in indirect heat exchangers, heat exchanger types, lighting and heating equipment, etc., can solve the problems of inhomogeneous catalyst addition, high temperature of harmful gases, inconvenient direct treatment and discharge, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

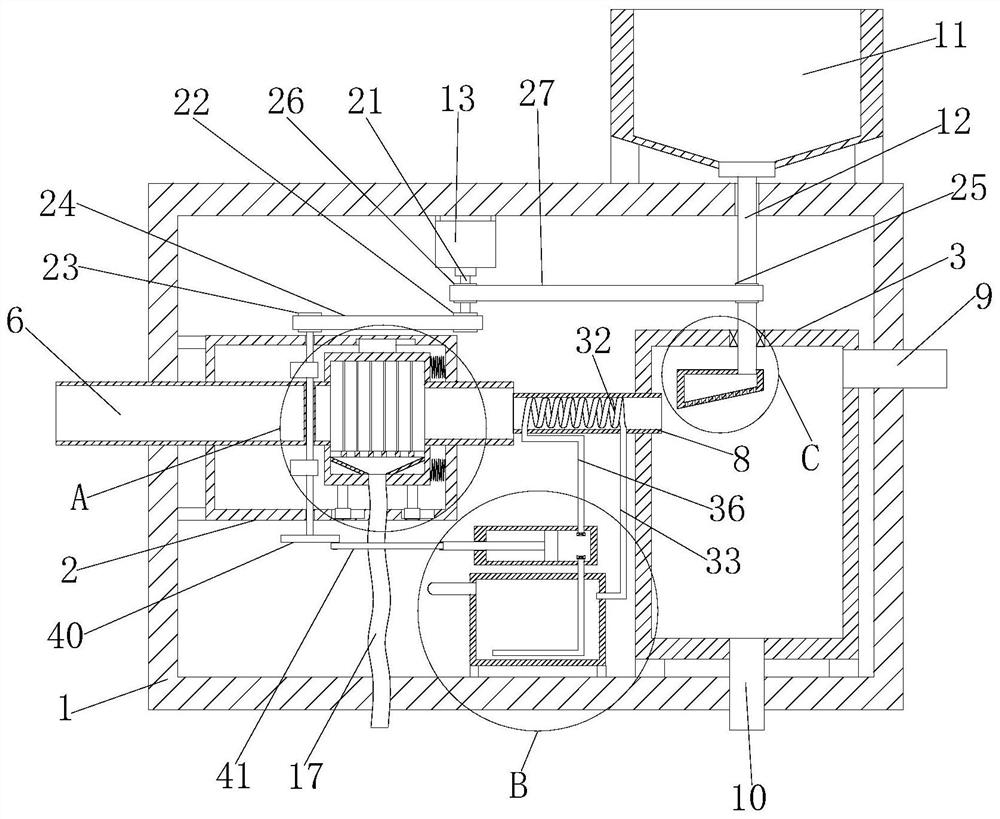

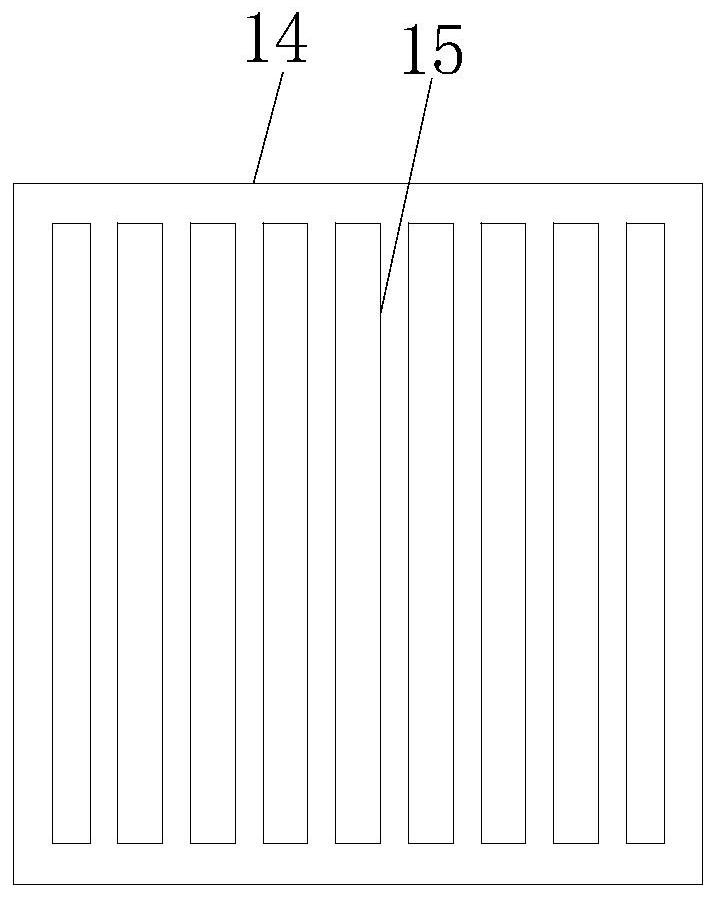

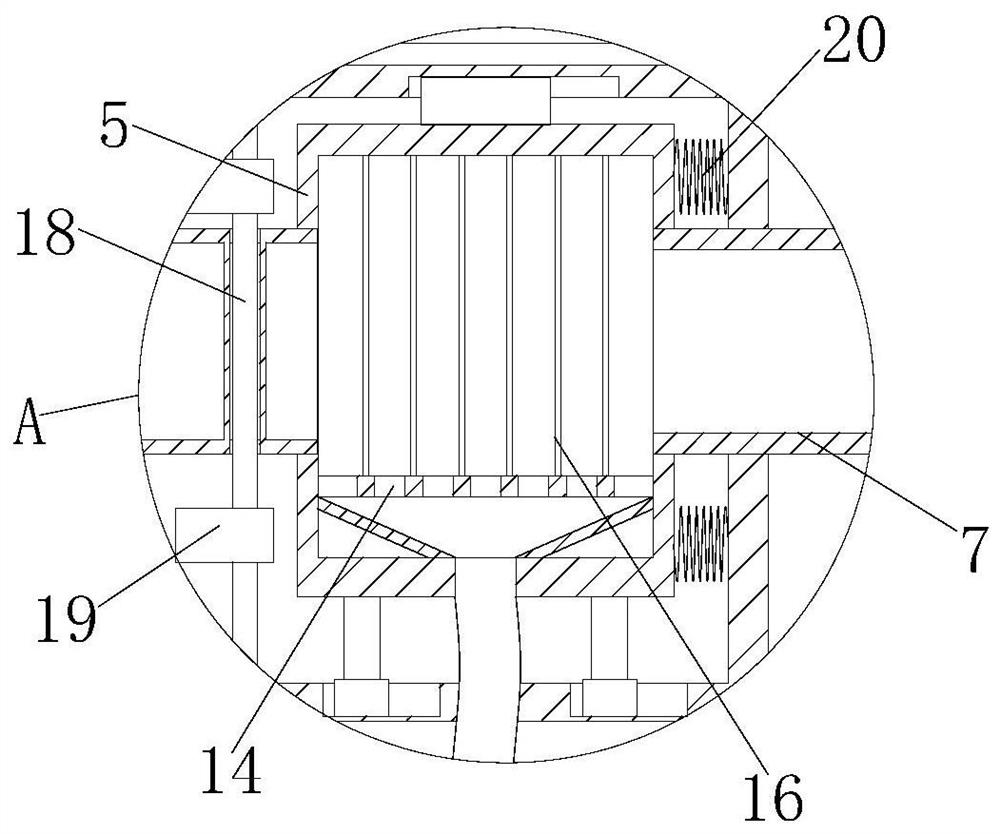

[0029] Reference Figure 1-5 , A harmful gas treatment system for thermal processing of metal materials, comprising a housing 1, a first dust removal housing 2 and a purification housing 3 and a water tank 4 are fixedly installed in the housing 1, and the first dust removal housing 2 is slidably installed The second dust removal housing 5, one side of the second dust removal housing 5 is connected with one end of the air inlet pipe 6, the other end of the air inlet pipe 6 penetrates the first dust removal housing 2 and the housing 1, and the second dust removal housing 5 One end of the first air outlet pipe 7 is connected to the other side, and the other end of the first air outlet pipe 7 extends through the first dust removal housing 2 into the housing 1 and is connected to one end of the second air outlet pipe 8. The other end of the air pipe 8 is connected to one side of the purification housing 3, and the other side of the purification housing 3 is connected to one end of a...

Embodiment 2

[0040] Refer to Figure 1-5 , A hazardous gas treatment system for thermal processing of metal materials, comprising a housing 1, in which a first dust removal housing 2 and a purification housing 3 and a water tank 4 are fixedly installed by bolts, and the first dust removal housing 2 slides A second dust removal housing 5 is installed, one side of the second dust removal housing 5 is connected to one end of the air inlet pipe 6, and the other end of the air inlet pipe 6 penetrates the first dust removal housing 2 and the housing 1, and the second dust removal housing One end of the first air outlet pipe 7 is connected to the other side of 5, and the other end of the first air outlet pipe 7 extends through the first dust removal housing 2 into the housing 1 and is connected to one end of the second air outlet pipe 8. The other end of the two air outlet pipes 8 is connected to one side of the purification housing 3, the other side of the purification housing 3 is connected to o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com