Preparation method for synthesizing high aluminum-silica gel

A technology of silica gel and high alumina, which is applied in chemical instruments and methods, organic chemistry, physical/chemical process catalysts, etc., can solve the problems of increasing the input of raw material aluminum sulfate, low catalytic activity and strength, and high price, and achieve excellent catalytic activity , easy to promote, and reduce the effect of equipment corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

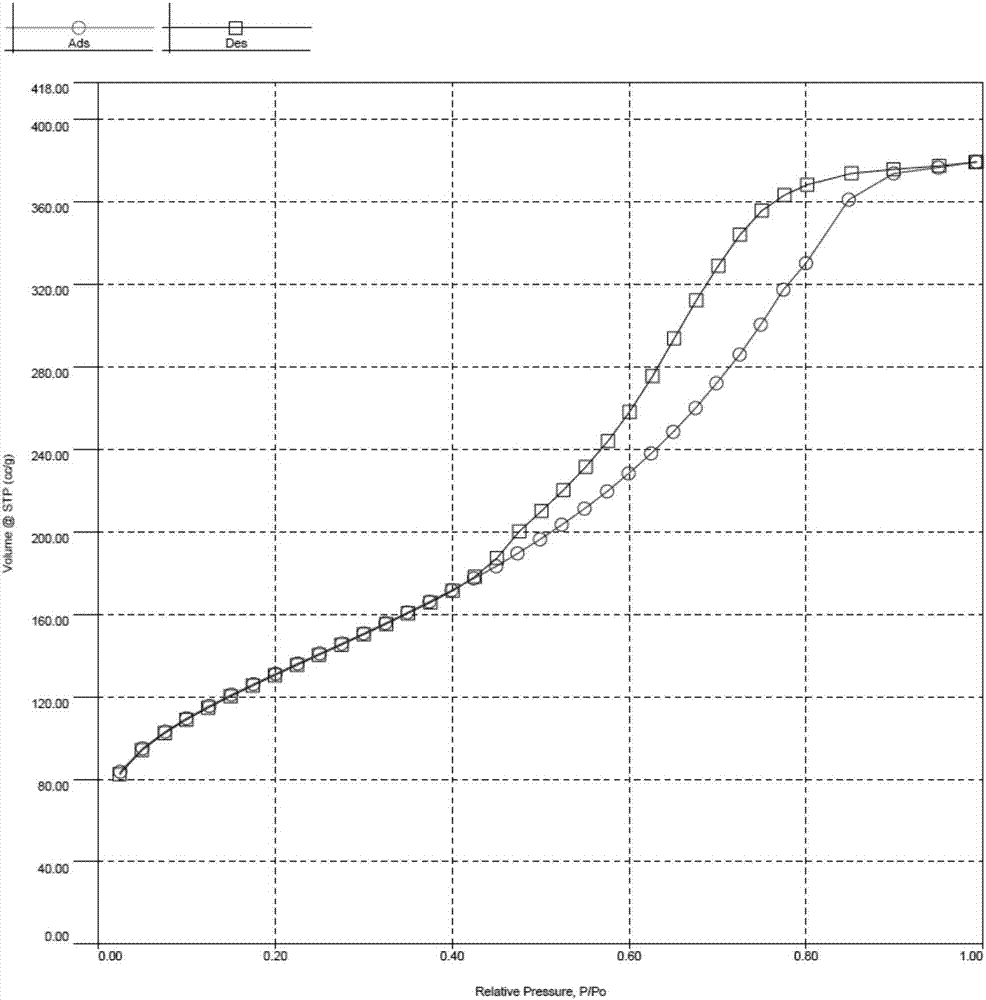

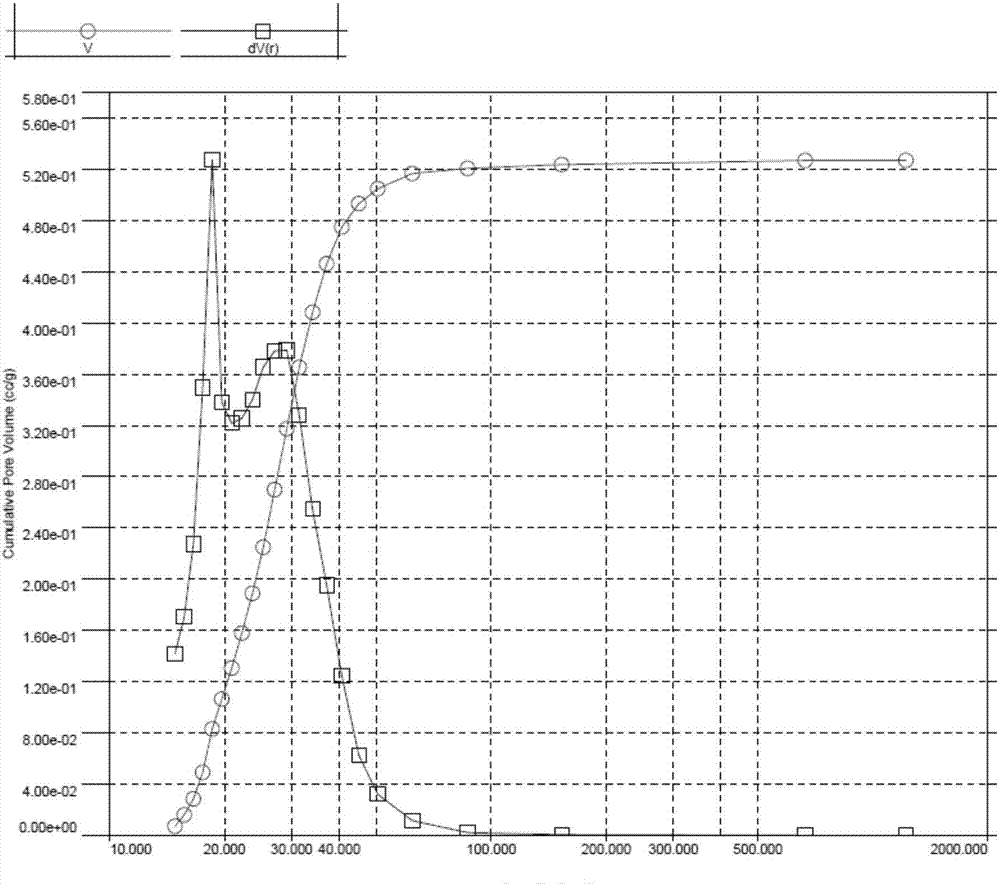

Embodiment 1

[0038] Using sodium silicate and sulfuric acid as raw materials, the air-forming process is used to make granular silica gel balls, and the particle size of the silica gel balls is 1-3mm. The molded silica gel particles are aged at 30-70°C for 1-3 hours to expand the pores. After the expanded silica gel particles are soaked in acid and washed with water until the conductivity is less than 1000μs / cm, they enter the beater for pulping, and the slurry is filtered to obtain SiO 2 Wet glue with a content of 8-15% is ready for use.

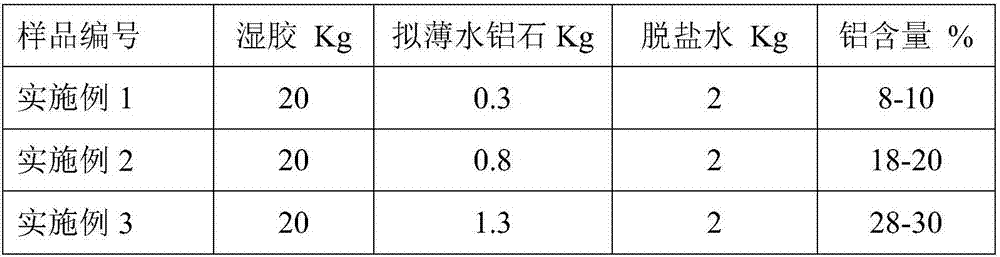

[0039] Weigh a certain weight of pseudo-boehmite (see the table below) and mix it with 2Kg desalted water. Under high-speed stirring, add 5% nitric acid until the mixed solution is gelatinous (gelled) and the pH is 2-4, then filter. Then take 20Kg of wet glue and mix it with aluminum glue, and adjust the pH of the mixture to 6-6.5 with 5% nitric acid. The mixed solution is poured into the spray dryer by the plunger pump to be spray-dried and shaped, a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com