Graphene oxide and graphite-phase carbon nitride composite modified membrane material and preparation method thereof

A modification and membrane flux technology, applied in chemical instruments and methods, special compound water treatment, physical/chemical process catalysts, etc., can solve the problems of low visible light catalytic efficiency, high photogenerated charge recombination rate, insufficient photocatalyst activity, etc. , to achieve the effects of low cost, improved anti-pollution performance, visible light catalytic ability and enhanced hydrophilic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

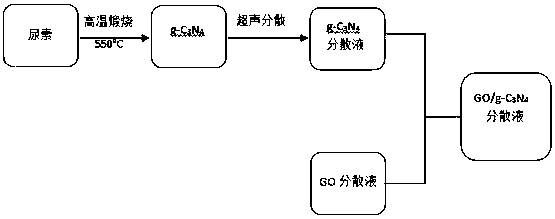

[0068] Embodiment 1 graphene oxide (GO) and graphite phase carbon nitride (g-C 3 N 4 ) Preparation of blended dispersion

[0069] GO and g-C 3 N 4 The preparation process of blended dispersion liquid is as follows: figure 1 As shown, g-C was first prepared by high temperature calcination 3 N 4 . Take 1g of prepared g-C 3 N 4 Add 200mL of pure water, ultrasonic 20min (power 300W). to g-C 3 N 4 Become a uniform dispersion, and dilute to 1L as a stock solution. Then take a certain amount of 100mg·L -1 GO dispersion and g-C 3 N 4 Mix the dispersion, add pure water to 200mL, and ultrasonically disperse for 20min to prepare GO and g-C 3 N 4 mixed dispersion.

Embodiment 2

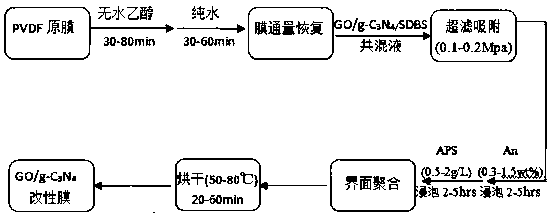

[0070] Example 2 GO / g-C 3 N 4 Preparation of modified membrane

[0071] 1. Preparation method

[0072] GO / g-C 3 N 4 The preparation process of the modified membrane is as follows: figure 2 shown. First, immerse the original PVDF membrane in absolute ethanol solution for 30 minutes. After the original membrane is fully wetted, then immerse it in pure water for 30 minutes to restore the flux of the original membrane. In GO / g-C 3 N 4 Add 5g of surfactant SDBS to the blend solution and set the volume to 1L, put the original membrane into the ultrafiltration cup, under the action of ultrafiltration pressure (0.15Mpa), make the original membrane to GO / g-C 3 N 4 / SDBS blend was subjected to ultrafiltration adsorption. After the ultrafiltration adsorption is completed, the membrane is soaked in the hydrochloric acid (PH=1) solution of aniline (An). Immediately after soaking, soak it in the hydrochloric acid solution (PH=1) of ammonium persulfate (APS) to make it undergo in...

Embodiment 3

[0087] Example 3 GO / g-C 3 N 4 Preparation of modified membrane

[0088] 1. Preparation method

PUM

| Property | Measurement | Unit |

|---|---|---|

| decolorization rate | aaaaa | aaaaa |

| decolorization rate | aaaaa | aaaaa |

| recovery rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com