Preparation method of iron-based MOFs oxygen evolution electrocatalyst with high-activity crystal face proportion, and catalyst

An electrocatalyst, high-activity technology, applied in the direction of electrodes, electrolysis process, electrolysis components, etc., can solve the problems of decreased stability, difficulty in meeting environmental friendliness, cost saving, affecting material uniformity and crystallinity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-2

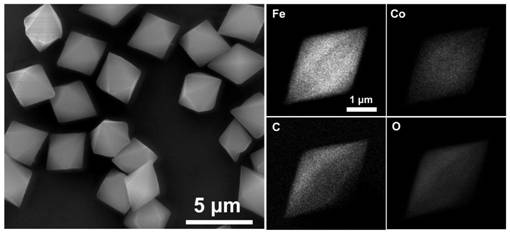

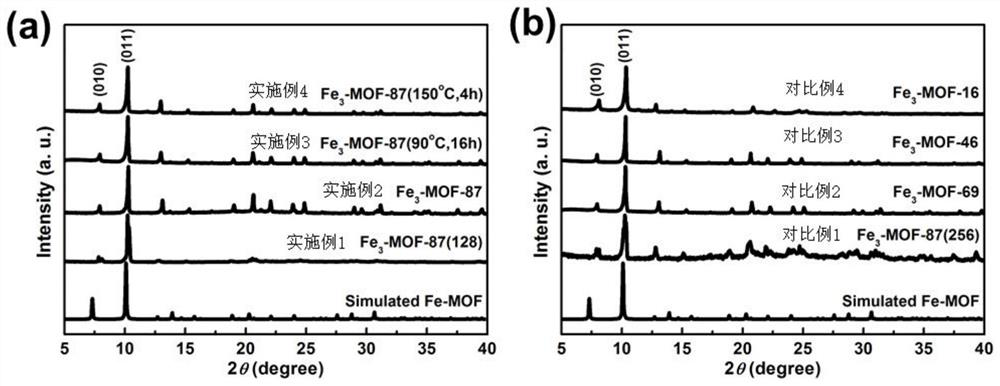

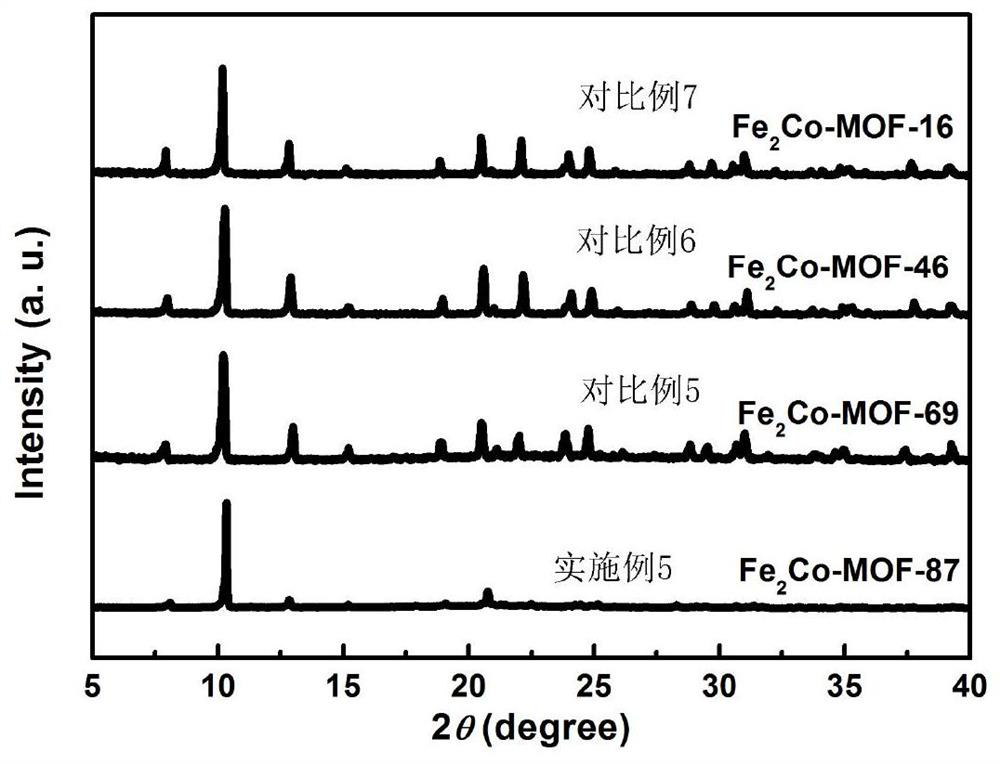

[0039] A method for preparing an iron-based MOFs oxygen evolution electrocatalyst with a high active crystal facet ratio, comprising the following steps:

[0040] (1) Weigh ferric nitrate nonahydrate and organic ligand fumaric acid according to the dosage and ratio in Table 1, and dissolve ferric nitrate nonahydrate and fumaric acid in 10ml of N,N-2 In methylformamide solvent, stir evenly to obtain a mixed solution;

[0041] (2) Transfer the mixed solution obtained in step (1) to the reactor lining of 25ml polytetrafluoroethylene; solvothermal reaction at 120°C for 8 hours, and naturally cool to room temperature; Centrifugal cleaning was carried out for 3 times, and then collected after vacuum drying at 30°C for a period of time. The obtained product was an iron-based MOFs oxygen evolution electrocatalyst with a high active crystal facet ratio.

[0042] The mol ratio of table 1 iron ion and organic ligand fumaric acid

[0043]

Embodiment 3

[0045] A method for preparing an iron-based MOFs oxygen evolution electrocatalyst with a high active crystal facet ratio, comprising the following steps:

[0046] (1) Dissolve 0.125 mmol of ferric chloride hexahydrate and 8 mmol of organic ligand fumaric acid in 10 ml of N,N-dimethylformamide solvent under ultrasound, and stir evenly to obtain a mixed solution; In the mixed solution of the present embodiment, the mol ratio of iron ion and organic ligand fumaric acid is 1:64;

[0047] (2) Transfer the mixed solution obtained in step (1) to the reaction kettle lining of 25ml polytetrafluoroethylene; solvothermal reaction at 90°C for 16 hours, and naturally cool to room temperature; Centrifugal cleaning was carried out for 3 times, and then collected after vacuum drying at 30°C for a period of time. The obtained product was an iron-based MOFs oxygen evolution electrocatalyst with a high active crystal facet ratio.

Embodiment 4

[0049] A method for preparing an iron-based MOFs oxygen evolution electrocatalyst with a high active crystal facet ratio, comprising the following steps:

[0050] (1) Dissolve 0.125mmol of ferric nitrate nonahydrate and 8mmol of organic ligand fumaric acid in 10ml of N,N-dimethylformamide solvent under ultrasound, and stir evenly to obtain a mixed solution; In the mixed solution of embodiment, the mol ratio of iron ion and organic ligand fumaric acid is 1:64;

[0051] (2) Transfer the mixed solution obtained in step (1) to the reactor lining of 25ml polytetrafluoroethylene; solvothermal reaction at 150°C for 4 hours, and naturally cool to room temperature; Centrifugal cleaning was carried out for 3 times, and then collected after vacuum drying at 30°C for a period of time. The obtained product was an iron-based MOFs oxygen evolution electrocatalyst with a high active crystal facet ratio.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com