Preparation method of nanoparticles of amphoteric ionized dendrimer inclusion gold

A dendrimer and amine dendrimer technology, applied in the field of catalyst preparation, can solve the problems of reducing the long-term stability of nanoparticles, reducing the catalytic efficiency of gold nanoparticles, etc., achieving excellent stability, good reproducibility, The effect of mild reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

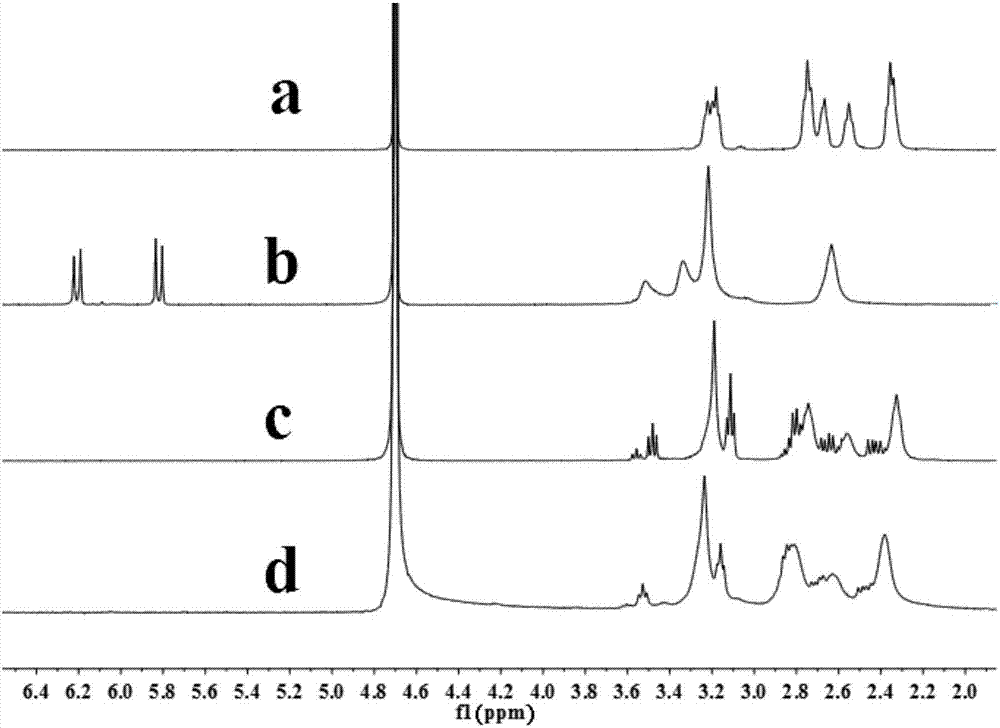

[0026] (1) Dissolve 16mg of fifth-generation polyamidoamine dendrimers (G5PAMAM) in 4mL of dimethyl sulfoxide, then add 13.8mg of maleic anhydride to dimethyl sulfoxide, react for 24 hours, select molecular weight cut-off ( MWCO)=14000 cellulose dialysis bag dialysis reaction mixture, to remove impurity, obtain G5M;

[0027] (2) Dissolve 2.87mg of G5M in 1mL of water, and then add 13.5mg of mercaptoethylamine to the water. After 24 hours of reaction, the mixture is dialyzed against water with a cellulose dialysis membrane (MWCO=14000) to remove impurities to obtain G5MC;

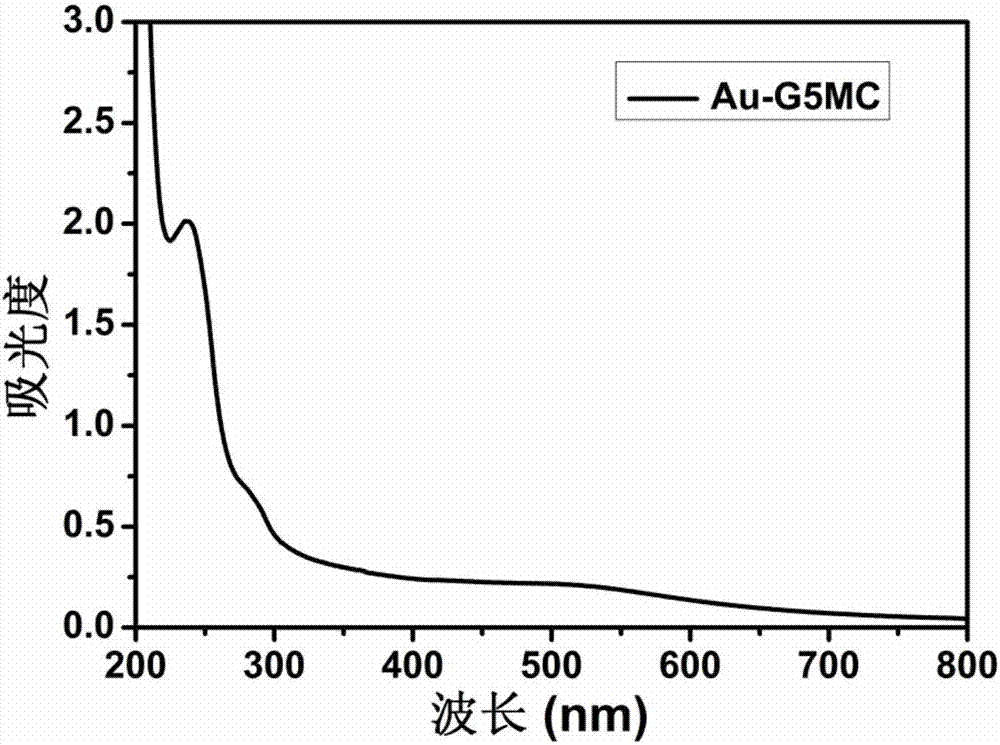

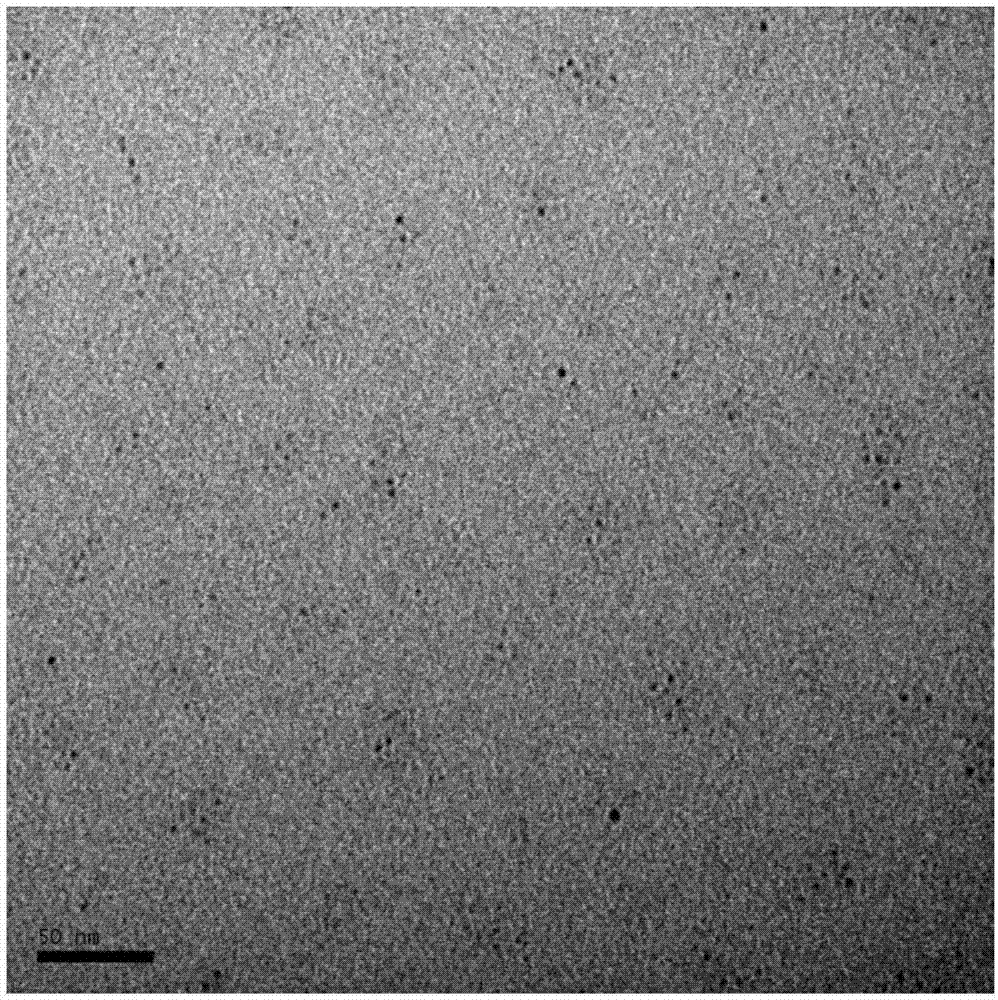

[0028] (3) Dissolve 0.533mg of G5MC in 1mL of water, then add 286mg of chloroauric acid aqueous solution with a concentration of 2mM to the water, after stirring for 20 minutes, add 126.5mg of sodium borohydride solution to the above solution, the sodium borohydride solution It is a mixed solution in which 1 mg of sodium borohydride is added to 1 mL of 0.3 M sodium hydroxide solution, and the pH of the mixed...

Embodiment 2

[0042] (1) Dissolve 1.6mg of fifth-generation polyamidoamine dendrimers (G5PAMAM) in 1mL of dimethyl sulfoxide, then add 0.754mg of maleic anhydride to dimethyl sulfoxide, react for 8 hours, select the molecular weight cut-off (MWCO)=14000 cellulose dialysis bag dialysis reaction mixture, to remove impurity, obtain G5M;

[0043] (2) Dissolve 0.52 mg of G5M in 1 mL of water, then add 0.136 mg of mercaptoethylamine to the water, react for 8 hours, and dialyze the mixture against water with a cellulose dialysis membrane (MWCO=14000) to remove impurities to obtain G5MC;

[0044] (3) 0.154mg of G5MC was dissolved in 1mL water, and then adding 61mg concentration of 1mM chloroauric acid aqueous solution in water, after stirring for 10 minutes, 4.5mg of sodium borohydride was added to the above solution, and the sodium borohydride was prepared according to Add a mixed solution of 1 mg sodium borohydride to 1 mL of 0.1 M sodium hydroxide solution, adjust the pH of the mixed solution to...

Embodiment 3

[0046] (1) Dissolve 41.2mg of the fifth-generation polyamidoamine dendrimer (G5PAMAM) in 1mL of dimethyl sulfoxide, then add 58.937mg of maleic anhydride to the dimethyl sulfoxide, react for 24 hours, select the molecular weight cut-off (MWCO)=14000 cellulose dialysis bag dialysis reaction mixture, to remove impurity, obtain G5M;

[0047] (2) Dissolve 1.83mg of G5M in 1mL of water, and then add 5.802mg of mercaptoethylamine to the water. After 24 hours of reaction, the mixture is dialyzed against water with a cellulose dialysis membrane (MWCO=14000) to remove impurities to obtain G5MC;

[0048] (3) 1.077 mg of G5MC was dissolved in 1 mL of water, and then 495 mg of chloroauric acid aqueous solution of 6 mM was added to the water. After stirring for 25 minutes, 1335.2 mg of sodium borohydride was added to the solution, and the sodium borohydride was prepared according to Add a mixed solution of 1 mg of sodium borohydride to 1 mL of 0.2 M sodium hydroxide solution, adjust the pH...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com