Engineering bacterium for whole-cell catalytic production of 5-aminopentanoic acid and preparation method of 5-aminopentanoic acid

A technology of engineering bacteria and lysine, applied in the biological field, can solve the problems of the gap in yield level and the low catalytic performance of engineering bacteria cells

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0062] The detection method of embodiment 1 5AVA

[0063] Take 10 μL of the diluted sample and add it to 990 μL of water, and take 1 μL for injection after filtering with an organic filter membrane.

[0064] Mobile phase A is 10mM Na 2 HPO 4 and 10mM Na 2 B 4 o 7 , pH8.2. To prepare 1L of mobile phase, weigh 1.4g of anhydrous Na 2 HPO 4 and 3.8gNa 2 B 4 o 7 10H 2 O, dissolve it in 1L of water. Adjust the pH to about 8.4 with 1.2 mL of concentrated hydrochloric acid, then add a few drops of acid and adjust the final pH to 8.2. Stir well before adjusting the pH to completely dissolve the borate crystals. Filtration was performed with a 0.45 m regenerated cellulose membrane (p / n 3150-0576). Mobile phase B is acetonitrile:methanol:water (45:45:10, v:v:v). All mobile phase solvents were HPLC grade. The injection diluent was 100mL mobile phase A and 0.4mL concentrated H 3 PO 4 . The solution was made up in 100 mL bottles and stored at 4°C. Derivatization reagents...

Embodiment 2

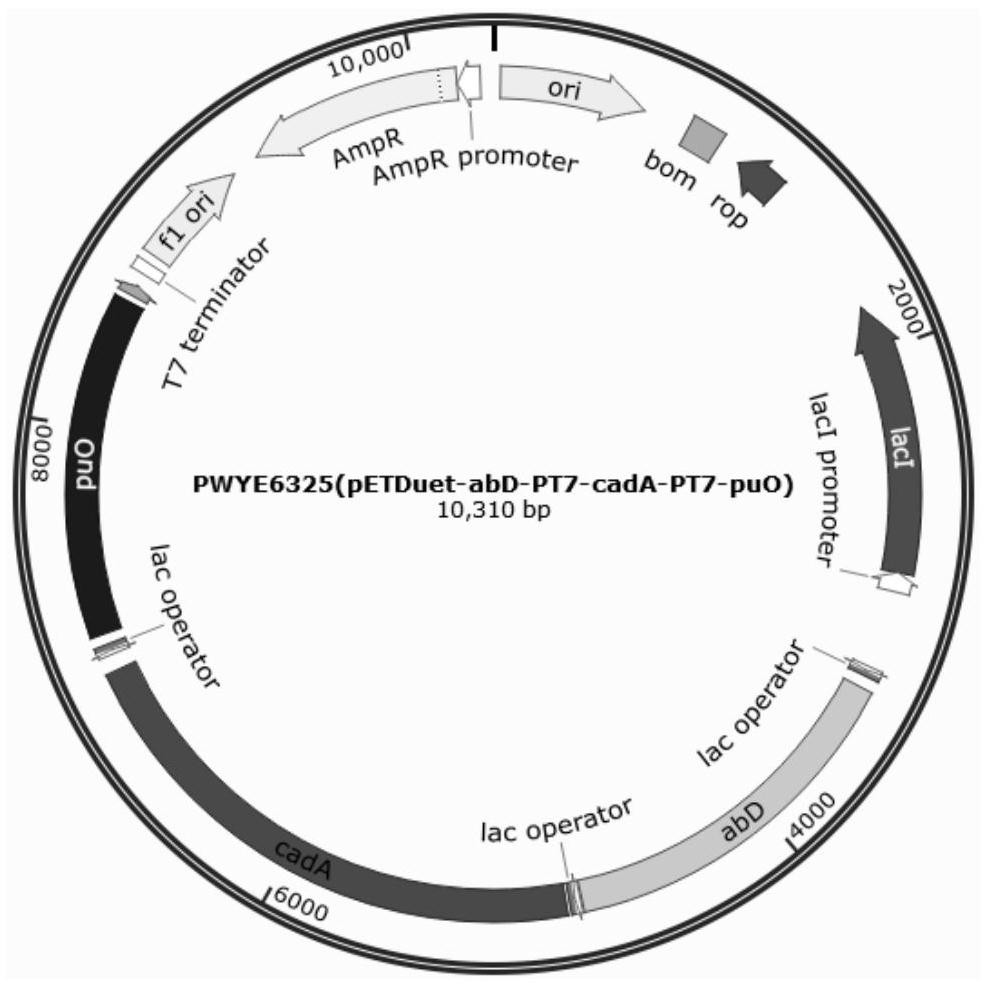

[0065] Example 2 Construction of γ-aminobutyraldehyde dehydrogenase abD, lysine dehydrogenase cadA, butanediamine oxidase puO expression vector and engineering bacteria

[0066] Using the vector carrying the abD gene sequence synthesized by codon optimization as a template, and using P1 and P2 as primers, PCR amplification was carried out as follows: denaturation at 98°C for 30 seconds, annealing at 65°C for 15 seconds, and extension at 72°C for 150 seconds, 26 cycle, amplify the abD-1 gene to obtain a 1431bp PCR product (SEQ ID NO.1); similarly use the E.coli MG1655 genome as a template, and use P3 and P4 as primers to amplify the cadA-1 gene to obtain a 2148bp The PCR product (SEQ ID NO.2); using the vector carrying the optimized and synthesized puO gene sequence as a template, and using P5 and P6 as primers to amplify the puO gene, a 1362bp PCR product (SEQ ID NO.3) was obtained.

[0067] The above three PCR products were purified.

[0068] Plasmid pETDuet-1 (purchased fro...

Embodiment 3

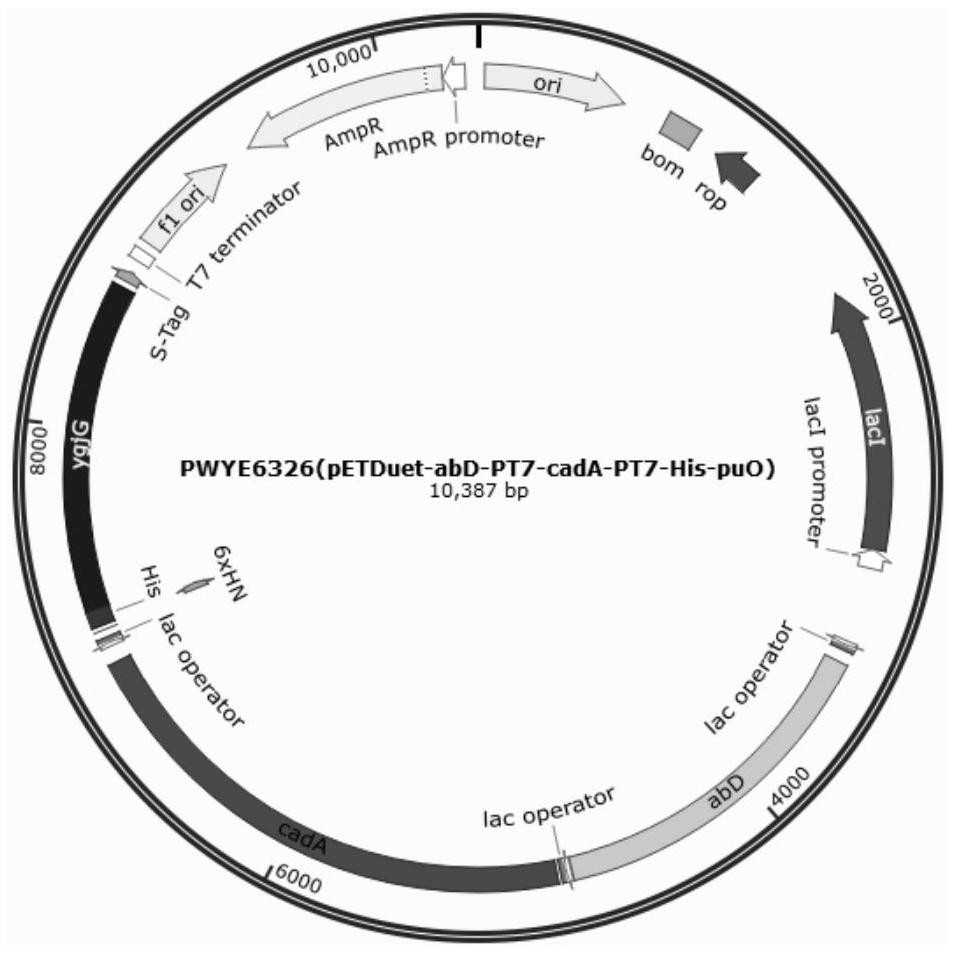

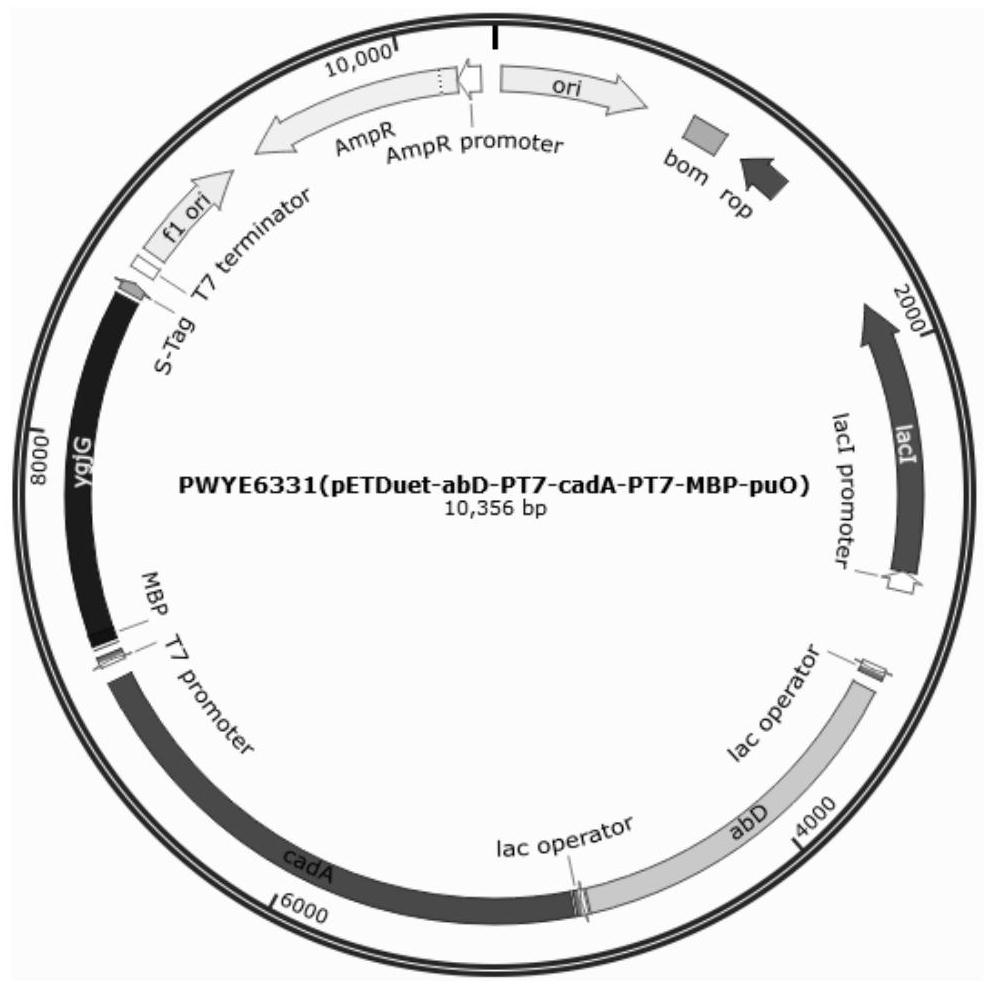

[0105] Example 3 Induced expression of AbD, CadA, and PuO proteins of engineering strains

[0106] The engineering bacteria EC7009(E.coli BL21(DE3) / pETDuet-PT7-abD-PT7-cadA-PT7-puO( Figure 5 abbreviated as pD T7 A T7 C T7 P)), EC7010 (E.coli BL21(DE3) / pETDuet-PT7-abD-PT7-cadA-PT7-His-puO)( Figure 5 Chinese abbreviation is pD T7 A T7 C T7 HIS P)), EC7011(E.coli BL21(DE3) / pETDuet-PT7-abD-PT7-cadA-PT7-MBP-puO( Figure 5 abbreviated as pD T7 A T7 C T7 MBP P)) and EC7012(E.coliBL21(DE3) / pETDuet-PT7-abD-PT7-cadA-PT7-BCD2-puO( Figure 5 abbreviated as pD T7 A T7 C T7 BCD2 P)), respectively streaked and inoculated on LB medium plates containing 100mg / L ampicillin, cultured in a 37°C incubator for 12 hours, scraped the cultured bacteria lawns on the plates and transferred them into 5mL liquid LB (containing 100mg / L L ampicillin) in a 50 mL shaker flask, placed on a shaker at 37°C at 200 rpm for 10 h. Take the cultured bacterial solution and transfer it into a 500mL...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com